-Рубрики

- шиття печворк (7)

- обкладинки (4)

- вироби з паперу (4)

- орігамі (1)

- вінки (14)

- вінки весняні (1)

- вінки осінні (4)

- вінки різдвяні (7)

- декор (46)

- декор гудзиками (5)

- декор з гілок (7)

- декор з камінців (7)

- декор з металевих банок (5)

- декор осінній (30)

- гарбузи декорування (12)

- декор різдвяний (3)

- дитячі ідеї (88)

- дитячі свята - декор (11)

- дитячі свята - ідеї (12)

- дитячі святкові костюми (5)

- зберігання іграшок (7)

- матеріали для творчості (6)

- саморобки для дітей (47)

- іграшки до різдва (6)

- ангели (1)

- сніжинки (1)

- іграшки до свят (60)

- будиночки лялькові (7)

- іграшки до паски (22)

- іграшки на хелловін (8)

- розвиваючі іграшки, календарі (2)

- сердечка (22)

- іграшки тварини (450)

- ведмеді (13)

- вівці, кози (17)

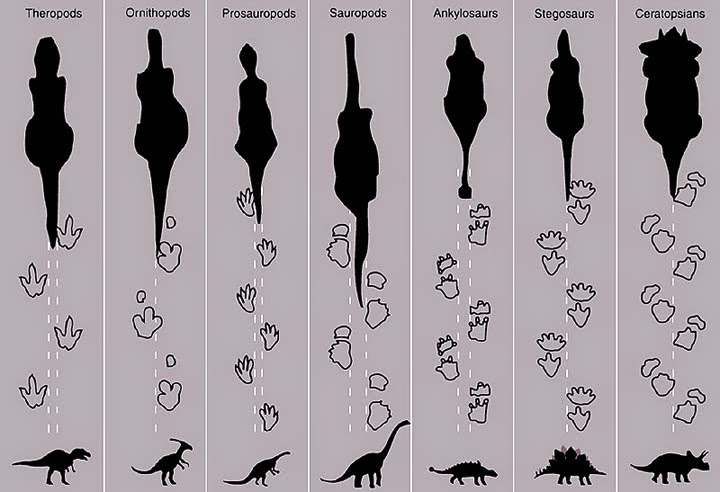

- динозаври (9)

- жабки (8)

- жирафи (9)

- зайці (30)

- змії, ящірки (10)

- іграшки з шкарпеток (17)

- іграшки ідеї (8)

- іграшки на руку, палець (1)

- інші (39)

- їжаки (8)

- кажани (5)

- комахи, равлики (23)

- коні, корови (15)

- коти (36)

- крокодили (4)

- лисиці (8)

- маленькі тварини (27)

- миші (15)

- олені, лосі (14)

- птахи (46)

- птахи домашні (24)

- риби, морські тварини (36)

- свинки (8)

- слони (14)

- собаки (9)

- сови (22)

- ящірки (4)

- інтер'єри (8)

- інтер'єр вітальні (1)

- інтер'єр кухні (3)

- інтер'єр санвузла (1)

- коробки (183)

- коробки великі з тканини (53)

- коробки фотоальбоми-скриньки (13)

- коробки-холдери (7)

- коробки з відділеннями (26)

- коробки з картону (38)

- коробки круглі (20)

- коробки маленькі (23)

- коробки пластикові (1)

- кошики (25)

- листівки (2)

- меблі (94)

- використання старих дверей (2)

- вішаки (5)

- гамак (4)

- дитяча кімната (6)

- дитяче ліжко (1)

- для кухні (10)

- зберігання речей (22)

- меблі-органайзери, газетниці (12)

- освітлення (9)

- полиці (2)

- полиці вертикальні (5)

- полиці, стелажі (3)

- робимо двері (1)

- робимо меблі (14)

- шафа-гардеробна (2)

- мило, освіжувач (1)

- мішковина (20)

- наплічники (3)

- органайзери (135)

- аптечки (2)

- інші варіанти органайзерів (22)

- органайзер корзинка (9)

- органайзер сумочка (21)

- органайзер торбинка (24)

- органайзери для дітей (32)

- органайзери для журналів (3)

- органайзери для канцтоварів (5)

- органайзери для олівців, фломастерів (3)

- органайзери кишеньки (31)

- органайзери-вкладки в шухляди (3)

- торбинки для піжами (8)

- пакування (97)

- інші форми упаковок (25)

- коробка упаковка (42)

- пакування до дня валентина (5)

- пакування різдвяні (12)

- прикрашання упаковок (33)

- пенали (2)

- подушки (63)

- подушки мк (55)

- подушки ідеї (16)

- подушки валики (3)

- подушки-іграшки (69)

- автоподушки (4)

- прикраси (70)

- бантики (11)

- намисто (10)

- квіти (34)

- ремонт (20)

- наливні підлоги (2)

- фарба під крейду (4)

- рецепти (58)

- страви до дитячих свят (23)

- торти (7)

- вівсяне печиво (4)

- пісочне печиво (4)

- рецепти на хелловін (5)

- свічки (6)

- сервірування, святкового столу (19)

- кільця для серветок (5)

- складання серветок (4)

- стиль вінтаж & шеббі-шик (27)

- стиль скандинавський (5)

- сумки & гаманці (154)

- вкладки в сумки (13)

- гаманці (24)

- інструкції для шиття сумок (16)

- сумки (61)

- таємниці шиття (36)

- тільда (380)

- тільда декор (41)

- тільда журнали (65)

- тільда ляльки (133)

- тільда тварини (144)

- фетр (66)

- хамелеон (4)

- цукеркові букети (7)

- чохли та ін.аксесуари для гаджетів (18)

- шиття аплікації (14)

- шиття для дому (93)

- будиночки (23)

- ковдри, покривала (11)

- коврики (16)

- постіль (11)

- чохли на стільці (8)

- штори (14)

- шиття для кухні (42)

- вишивки та аплікації для кухні (4)

- пакетниці (3)

- серветки, скатертини (15)

- шиття для тварин (66)

- одяг для тварин (41)

- шиття для шиття (38)

- голочниці (8)

- кишеньки під машинку (3)

- чохли для швейних машин (8)

- швейні органайзери (21)

- шиття одягу, взуття (29)

- взуття (10)

- одяг (11)

-Поиск по дневнику

-Подписка по e-mail

-Статистика

динозаври робимо з усього |

відбитки слідів

з паперових тарілок

з рулонів від туалетного паперу

з картону

маски

Printable Pterodactyl Mask Printable Styracosaurus Mask

Printable Raptor Mask Printable Spinosaurus MaskSpino

Printable Raptor Mask Printable Spinosaurus MaskSpino

Printable Brontosaurus Mask Printable Diplodocus MasksaPrintable Brontosaurus M

Printable Anklyosaurus Mask Printable Stegosaurus Mask

з мозаїки

/www.zujava.com/users/gonnafly:" target="_blank">http://www.zujava.com/users/gonnafly: " src="https://s-media-cache-ak0.pinimg.com/736x/64/35/d7/6435d754e7210659de75483e77303cce.jpg" style="height: 331px; width: 330px;" />

з кульок

з пластикових банок

відбитки динозаврів

льодяні яйця динозаврів

з макаронів

диноїжа

|

Процитировано 1 раз

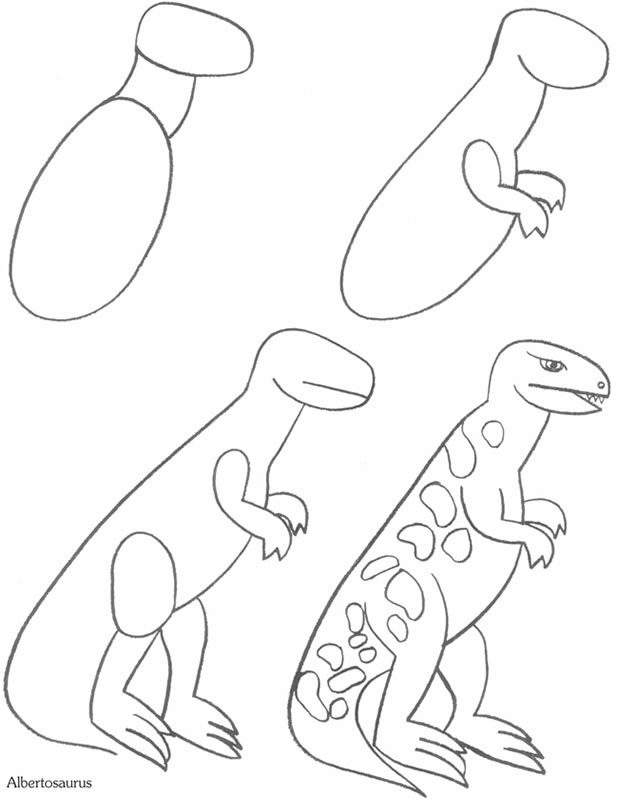

динозаври малюємо |

|

хамелеони |

шиємо

/www.etsy.com/listing/88260897/paintball-chameleon-stuffed-toy:" target="_blank">http://www.etsy.com/listing/88260897/paintball-chameleon-stuffed-toy: " src="https://s-media-cache-ak0.pinimg.com/736x/8e/7c/00/8e7c00bd450a8faf4b1beb02fcfe8506.jpg" style="height: 400px; width: 500px;" />

валяємо

/www.livemaster.ru/item/1229615-kukly-igrushki-kompozitsiya-iz-shersti-hello:" target="_blank">http://www.livemaster.ru/item/1229615-kukly-igrushki-kompozitsiya-iz-shersti-hello: " src="https://s-media-cache-ak0.pinimg.com/736x/bd/ca/b3/bdcab39335c1f0d8d1973c0ff17e9a2d.jpg" style="height: 305px; width: 500px;" />

в'яжемо

/www.lovecrafts.co.uk/projects/chameleon-free-bonus-pattern-from-knit-your-own-zoo/:" target="_blank">http://www.lovecrafts.co.uk/projects/chameleon-fre...ttern-from-knit-your-own-zoo/: " src="https://s-media-cache-ak0.pinimg.com/736x/99/74/d5/9974d5736da7b87c7519956e6209744e.jpg" style="height: 300px; width: 300px;" />

/hative.com/pipe-cleaner-animals-for-kids/,:" target="_blank">http://hative.com/pipe-cleaner-animals-for-kids/,: " src="https://s-media-cache-ak0.pinimg.com/736x/e0/16/45/e01645544d922455c1d120c94040d713.jpg" style="height: 375px; width: 300px;" />

/hative.com/pipe-cleaner-animals-for-kids/,:" target="_blank">http://hative.com/pipe-cleaner-animals-for-kids/,: " src="https://s-media-cache-ak0.pinimg.com/736x/00/35/de/0035de6216a34f4f75c49ea6aaba5397.jpg" style="height: 255px; width: 340px;" />

малюємо і робимо з паперу

/hartiatoys.com/:" target="_blank">http://hartiatoys.com/: " src="https://s-media-cache-ak0.pinimg.com/736x/f5/27/db/f527db37534afd53fc10d6fce24e7a25.jpg" style="height: 302px; width: 500px;" />

ліпимо

одяг та взуття

прикраси

/www.facebook.com/pages/Liz-Potter-Art/168895573220619:" target="_blank">https://www.facebook.com/pages/Liz-Potter-Art/168895573220619: " src="https://s-media-cache-ak0.pinimg.com/736x/95/8f/64/958f64997cff3a9b3c7117f1992d8383.jpg" style="height: 375px; width: 500px;" />

вишиваємо

/www.facebook.com/SilviaMan...:" target="_blank">https://www.facebook.com/SilviaMan...: " src="https://s-media-cache-ak0.pinimg.com/736x/e6/92/e6/e692e61358a7c066042f87842b0db086.jpg" style="height: 583px; width: 640px;" />

|

великодні курочки ідеї |

Это цитата сообщения Elnik14 [Прочитать целиком + В свой цитатник или сообщество!]

|

журнал з домашнім декором Hand-Stitched Home |

Это цитата сообщения Ayfa [Прочитать целиком + В свой цитатник или сообщество!]

|

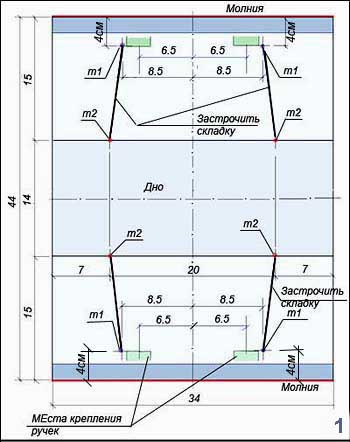

сумка мк |

| Для начала скажу, что идея сшить эту сумочку появилась у меня после увиденной на просторах интернета сумки, которая была сшита так же, как косметичка из «Дорожного набора», показанного тут на сайте. |

|

|

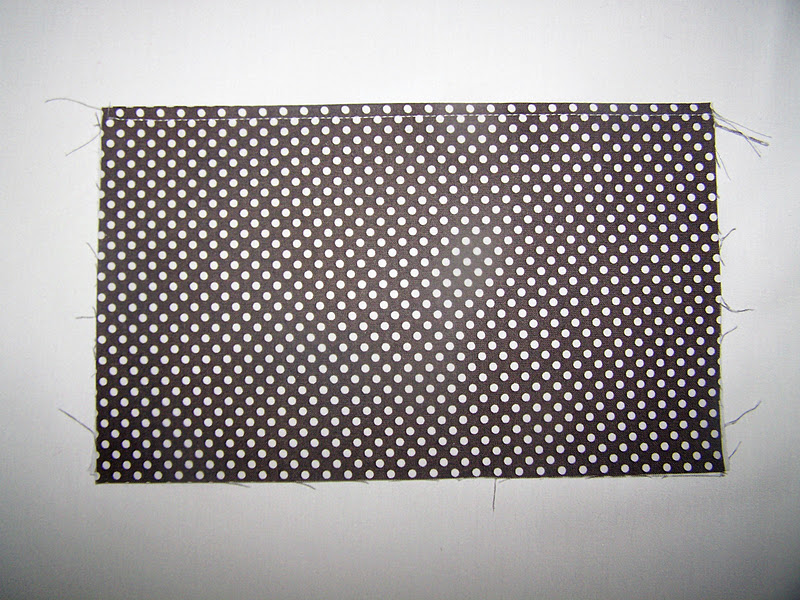

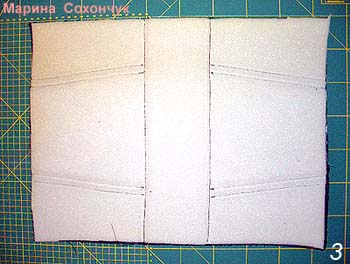

Моя новая сумка получилась после небольшого изменения технологии изготовления такой косметички. Каким образом? А все просто: у них общая выкройка - простой прямоугольник. И несложные преобразования дают возможность изменять внешний вид сумки по вашему желанию. Начну с описания своей сумки. А о вариантах превращения прямоугольника в другие сумки и сумочки вы прочитаете дальше. Марина СОХОНЧУК, Волгоград |

|

|

|

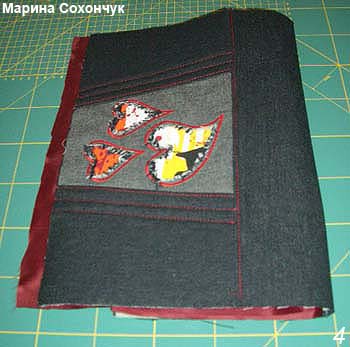

Не буду описывать подробно процесс сборки полотнища, потому что каждый выберет свой дизайн. Декоративным элементом для моей сумки стала вставка, выполненная в технике «обратной аппликации». А все необходимые для пошива точки и размеры нанесены на выкройке. Припуски на швы по длинным сторонам учтены в выкройке и равны 1 см. |

|

2. Сначала надо заготовить прямоугольник, из которого и должна получиться сумка. В качестве материала я взяла джинсовую ткань и яркую контрастную ткань для аппликации сердечек. Разный цвет джинсы – это лицо и изнанка одной и той же ткани. |

|

В качестве уплотнителя использовала клеящийся поролон. Этот материал я обнаружила недавно и пока экспериментирую с его использованием в разных лоскутных изделиях. |

|

3. После приклейки поролона проложила несколько декоративных строчек, заодно и поролон дополнительно прикрепился к основному полотну. |

|

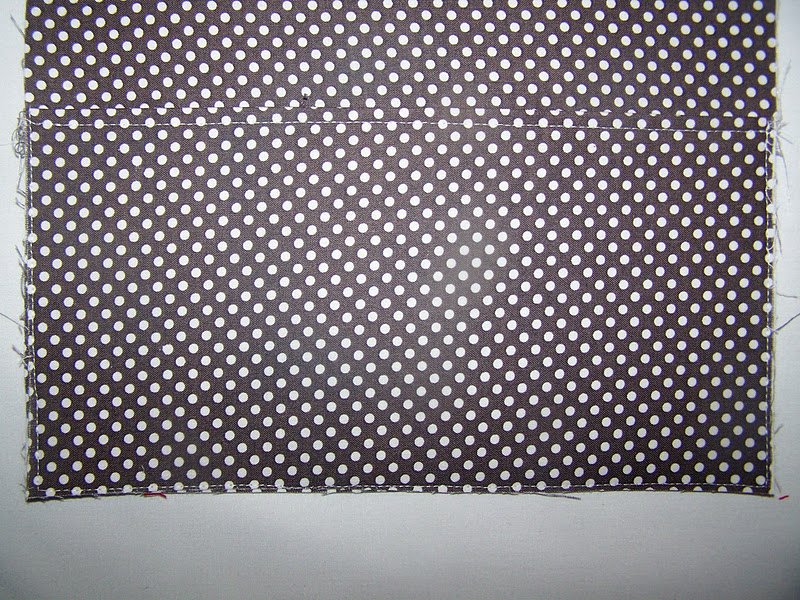

4. В сумку я планировала поставить яркую красную подкладку. Для этого выкроила из подкладочной ткани прямоугольник размером с основную деталь (34х44 см). Чтобы определить излишек подкладки по длине, надо ее приколоть сметочными булавками (или приметать) по одной стороне и затем перегнуть пополам вместе с подготовленным верхом. У меня излишек составил 1,5 см. Отрезаем излишек подкладки. |

|

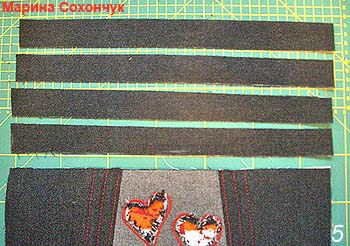

5. Выкраиваем 4 обтачки шириной 3 см для пришивания молнии. Длина обтачки – по ширине сумки. 2 обтачки – для верха сумки, 2 – для пришивания подкладки. |

|

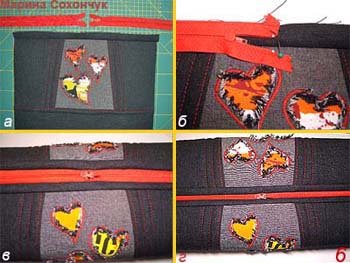

6. Переходим к вшиванию молнии. а. По обеим коротким сторонам прямоугольной заготовки пришиваем обтачки. Я выбрала для застежки две короткие «молнии», которые сходятся к середине. Но можно использовать и одну длинную. б. Совмещаем начало молнии с центром, кончик тесьмы подгибаем. Сначала прострачиваем с помощью обычной лапки по краю тесьмы, прихватывая обтачку. В этом случае ткань меньше припосаживается. в. Так выглядит застежка после того, как пришили обе молнии. г. Теперь меняем лапку на специальную для притачивания застежек-молний, и прострачиваем еще раз ближе к зубчикам. Вторую пару обтачек (для притачивания подкладки) пришиваем к тесьме молнии. |

|

7. Подготовим и подкладку – пришьем карманы для мелочей. |

|

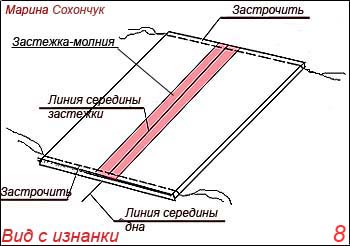

8. Застегнув застежку-молнию, совмещаем ее середину с линией середины дна (это линия сгиба нашей заготовки-прямоугольника), плоско складываем лицом вовнутрь и застрачиваем по боковым швам. Заодно закрепится в шве и «хвостик» молнии, а излишек длины можно срезать. Внимание! Перед тем, как застрочить боковые швы не забудьте чуть-чуть расстегнуть молнию, иначе потом трудно будет вывернуть изделие налицо. |

|

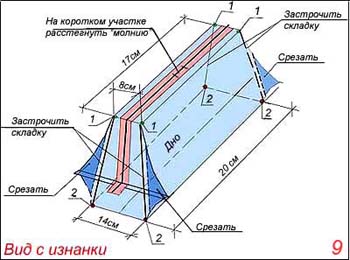

9. А сейчас начинаем формировать из заготовки будущую форму нашей сумки. Поскольку на фото плохо видно (сумка сшита из темного материала), я даю объемную схему, как это сделать. Для начала перенесем с выкройки нужные нам сейчас точки 1 и 2 (соответственно, по четыре точки на верхней и нижней стороне нашего сложенного «полуфабриката»). Плоскую деталь расправляем руками (молнию – вверх, дно – вниз), между точками 1 и 2 закладываем складки, закалываем их булавками и застрачиваем. Образующиеся при этом излишки (на схеме – темные треугольники) срезаем, оставляя припуск около 1 см. Расстегиваем застежку, выворачиваем, и это уже не полуфабрикат, а почти что сумка. Подкладку сошьем, проделав с ней все операции, описанные выше. Вложим ее в сумку и притачаем по открытым краям к внутренней обтачке застежки. Осталось только пришить ручки. |

|

10. Опытным путем определяем длину ручек. У меня получилось 58 см (с учетом по 1 см на подгибку с каждого конца). а. Сумка не очень большая, поэтому я взяла корсажную ленту в тон молнии шириной 2 см ( для более объемной сумки ручки можно сделать пошире). б. С помощью утюга и металлической линейки (спасибо Насте Дорожкиной! - в курсе про японское плетение подсказалаудобный способ изготовления бейки) заутюживаем припуски так, чтоб получилась бейка, равная по ширине корсажной ленте. в. Осталось только красиво соединить бейку с корсажной лентой. Чтобы строчка выглядела более декоративной, выбрала режим "тройной стежок". Отстрочка выглядит рельефнее, когда длина стежка - максимальная. Накладываем бейку на корсажную ленту как можно ровнее и пристрачиваем их друг к другу декоративным «тройным» стежком. г. Ручки пришиваем так: сначала прикладываем изнаночной стороной вверх (место прикрепления ручек показано на выкройке), прикрепляем обычной прямой строчкой, затем отгибаем, прикрывая припуск. Окончательно прошиваем плотным «зиг-загом». |

|

Вот и все, сумка готова! Если вы хотите поэкспериментировать – попробуйте смещать на выкройке точки 1 и 2, и вы увидите, как изменение положения этих точек трансформирует нашу прямоугольную заготовку в разные по форме и пропорциям сумки. А дальше мы покажем несколько примеров такой трансформации. |

|

|

Как меняется форма той сумки, которую сшила Марина Сохончук, можно наглядно увидеть на примере этих двух сумок (фото взяты из интернета). Сумка справа – сшита по такому же принципу, как и у Марины, и имеет с боковой стороны форму трапеции. Сумка слева – сшита по той же выкройке, однако имеет форму кирпичика. Рассмотрим, в чем разница в крое этих сумок. |

|

|

Мы показали два положения складок, но как вы теперь поняли, вариантов может быть больше. Возьмите другой наклон складки – и у вас получится новая форма сумки. Так что пробуйте, моделируйте и подберите ту форму, которая вам понравится больше всего.

|

||||||

|

гаманець мк |

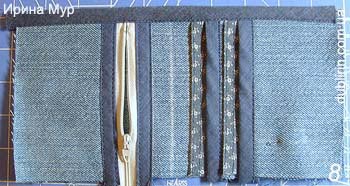

| Первый такой кошелек в нежно-розовую клеточку я сшила в подарок девочке. Потом повторила его для себя в джинсовом варианте, с «разрезалками». А новый кошелек по многочисленным просьбам моих подруг по рукоделию |

|

шила специально, чтобы показать весь процесс его изготовления. Размер кошелька в готовом (разложенном) виде - 5х8,5 дюйма (примерно 12,5 x 21 см). Такой размер взят с учетом того, чтобы в него можно было положить бумажные купюры, мелочь и всевозможные карточки, которые становятся все более популярными. Ирина Мур Все размеры даны в дюймах. Для справки: 1 дюйм = 2,5 см. |

|

|

||

|

1. Выкраиваем с учетом припусков на швы из джинсовой ткани: * 2 детали А 5,5 х 9,0 дюйм. – основа кошелька, его обложка; * 1 деталь Б 5,0 х 9,0 дюйм. – отделение для бумажных купюр; * 1 деталь В 5,0 х 3,0 дюйм. – кармашек для мелочи; * 1 деталь Г 5,0 х 3,5 дюйм. – кармашек для карточек; * 1 деталь Д 5,0 х 2,5 дюйм. – кармашек для карточек. Для карточек я предусмотрела 4 кармана. Но, в связи с тем, что джинсовая ткань достаточно плотная, два из них я сделала из обычной х/б ткани, чтобы уменьшить толщину кошелька и избежать трудностей при сборке. Таким образом, еще два кармашка для карточек выкраиваем из х/б ткани: *1 деталь Е 5,0 х 8,0 дюйм. *1 деталь Ж 5,0 х 6,0 дюйм. |

|

2. Начинаем работу с обложки. Для ее укрепления я использовала 808 Сraft Fuse фирмы PELLON. Этот материал хорош тем, что он тонкий, как бумага, но очень хорошо держит форму, не теряя при этом эластичности. Если же его нет, то обе детали нужно укрепить плотным клеевым односторонним флизелином или жестким дублирином. Укрепляем одну из деталей А (верхнюю), декорируем по своему усмотрению. Отступив 1,25 - 1,5 дюйма от короткого края, посередине устанавливаем на этой детали магнитную застежку. Отложим эти заготовки пока в сторону. |

|

3. Обрабатываем бейкой все джинсовые детали кармашков и одну сторону застежки-молнии. При обработке молнии начинайте пришивать бейку выше ограничителя застежки-молнии приблизительно на ширину окантовки. Потом этот запас скроется под бейкой-окантовкой, которую будете пришивать с другой стороны. |

|

4. Обе детали карманчиков из х/б ткани (детали Е и Ж) складываем пополам, прокладываем внутри "паутинкой" соответствующего размера, и проглаживаем. Отступив от сгиба, прокладываем одну или две параллельные декоративные строчки. Таким «двойным» кармашком удобнее пользоваться при доставании карточки. |

|

5. Теперь окантованную деталь кармана для мелочи (деталь В) пристрачиваем ко второй стороне застежки-молнии так, чтобы припуски от верхнего ограничителя на обеих сторонах были одинаковыми. |

|

6. Окантованную сторону тесьмы молнии накладываем сверху на короткую сторону детали Б и притачиваем ее по краю бейки. Закрепляем затежку-молнию по верху поперечной строчкой как можно ближе к краю, чтобы потом эта строчка не выглядывала из-под окантовки. На детали Б намечаем линию центра готового кошелька, мысленно разделив получившуюся заготовку пополам по вертикали. |

|

7. На получившуюся заготовку накладываем окантованные заготовки для кармашков (слева направо детали Е, Г, Ж, Д, от большего к меньшему), как показано на фото. Выравниваем размеры всех сложеных деталей. |

|

8. Окантовываем бейкой верхний срез заготовки для отделения для бумажных купюр. |

|

9. Для обложки у нас было заготовлено две детали А – наружная (с застежкой) и внутренняя. Складываем их изнанкой к изнанке и выравниваем по размеру готового кошелька (5 х 8,5 дюйм.). Наружная деталь с застежкой – внизу! На внутренней детали разметим линию середины. |

|

10. Накладываем сверху подготовленную заготовку кармана для бумажных купюр, совместив линию середины и нижние срезы деталей. Скрепляем все булавками. |

|

11. Соединяем строчкой по краю все детали кошелька, чтобы они не сдвигались относительно друг друга. Уголки надо скруглить. Чтобы они были одинаковыми, удобно это делать по какому-нибудь шаблону. |

|

12. Ну вот, сам кошелек практически уже готов… Пора приступать к застежке. Выкраиваем из джинсовой ткани 2 детали 4,0 х 1,5 дюйм. С одной стороны скругляем уголки на обеих заготовках (как на фото). Обратите внимание! Длина хлястика для застежки может меняться в зависимости от ширины окантовки и толщины получившегося изделия. Поэтому уточните его длину по вашему варианту. |

|

13. Детали клапана застежки следует укрепить флизелином. На одной детальке поставьте вторую часть магнитного замочка. Сложите детали друг с другом изнаночными сторонами и соедините их (обшейте) плотным швом «зиг-заг» по краю, как бы обметывая. Я сделала это декоративными нитками, такими же, как декорировала лицевую сторону обложки. |

|

14. Пристрочите клапан застежки, как показано на фото. Осталось совсем немного - и мы у цели! |

|

15. И заключительный аккорд: окантовка почти готового изделия. Выкраиваем полоску ткани по косой и складываем ее по длине пополам. Заглаживаем, предварительно подвернув косой срез на внутреннюю сторону на 0,5 дюйма. Начинаем работу от точки сгиба кошелька. Стык бейки здесь будет наименее заметен. Обходим бейкой по всему периметру кошелька. |

|

16. Чтобы замкнуть окантовку, настрачиваем конец бейки на ее начало до короткой стороны поперечного среза, зайдя за него приблизительно на 0,5 дюйма (см. фото!). Теперь излишек бейки можно отрезать. |

|

17. Перегибаем бейку на внутреннюю сторону изделия и пришиваем ее внутренний край вручную потайными стежками. Стык бейки можно тоже прихватить несколькими потайными стежками, а можно этого и не делать. (Я не делаю, бейка лежит плотно и вывернуться никак не может). |

|

18. Теперь прогладьте швы, проверьте, надежно ли держит застежка и… кошелечек готов! |

|

Если вы шьете его кому-то в подарок (или даже в подарок себе, любимой!), не забудьте положить в него мелкую монетку! Говорят, так принято дарить кошельки, чтобы в них всегда водились денежки! Удачи вам! Пусть в новом кошелечке у вас всегда водятся… сами знаете что…! И не забудьте показать, что у вас получилось! |

|

|

|

|

|

|

|

|

як пришити блискавку |

|

Такой способ вшивания застежки-молнии в сумку один из самых распространенных. Он пригоден для сумок разной формы: прямоугольных, круглых, косметичек и рюкзачков на молнии. Этот способ действительно универсален, но особенно хорош для сумок, в которых планка для молнии сшивается с боковыми стенками. Еще одно его преимущество в том, что внутренняя часть планки играет одновременно роль подкладки для боковин. А дело все в том, что планка, в которую вшивается молния, двойная. Итак, начнем... Ирина Лукашенко |

|

|

|

||

|

1. Выкраиваем из ткани 4 полоски-обтачки: две для верхней (лицевой) и две для внутренней (я бы сказала подкладочной) стороны. Размеры полосок зависят от того, какой размер планки (вместе с вшитой молнией) необходимо получить в результате. Ширину рассчитываем так: нужная ширина этой планки в готовом виде делится пополам + 1 см на подворот + 1-1,5 см припуск. Предположим, ширина планки в выбранной модели сумки была 6 см. Отсюда ширина каждой полоски из ткани 6 : 2 = 3 + 1 + 1,5 = 5,5 см. Вообще-то обычно я делаю ширину немного шире. Лучше один раз потом все подровнять, чем сто раз делать вычисления или – еще хуже – окажется, что вы ошиблись с размером в меньшую сторону. Длина обтачки зависит от длины молнии. Для удобства в работе я стала часто пользоваться клеевыми флизелиновыми вставками для поясов. Их ширина известна, и можно не делать разметку по ткани, а просто наклеить полоски нужной длины и вырезать с необходимыми припусками по ширине. |

|

2. Сначала обрабатываем нижнюю сторону застежки-молнии. Прикладываем обтачку лицевой стороной к нижней стороне тесьмы молнии, совмещаем края и стачиваем на расстоянии приблизительно 0,5 см от края тесьмы молнии. Отворачиваем обтачку и прокладываем строчку близко к сгибу. На фото видно ту сторону планки, которая смотрит как бы «внутрь» сумки. |

|

3. Полоски ткани для верхней обтачки подгибаем на 1 см и заметываем. Если вы будете пользоваться клеевыми вставками для поясов, то это делается еще проще – заглаживаете по перфорации – и все! Заготовку с молнией выкладываете застежкой наверх, как показано на фото. |

|

4. Заглаженной стороной накладываем обтачку на верхнюю сторону тесьмы молнии близко к зубчикам. Наложить нужно как можно ближе, но так, чтобы обтачка не мешала при застегивании. Зафиксируем обтачку булавками (или наметкой). |

|

5. С помощью лапки для притачивания молнии пристрачиваем обтачку к тесьме молнии близко к краю. |

|

6. Убираем все булавки, наметки, планку хорошо отглаживаем ивыравниваем в соответствии с нужными вам размерами. Я использовала молнию, купленную «на метраж». В этом случае внимательно следите, чтобы не слетел «бегунок» или предусмотрительно зашейте края застежки-молнии. Торчащий край молнии потом обрежется. |

|

7. Переходим к боковым стенкам. Для того, чтобы пришить к готовой планке боковые стенки, необходимо выкроить 4 заготовки из ткани – по две на каждую боковую часть. Ширина их равна ширине планки с молнией, а длина – зависит от модели сумки. На фото показана обработка только одного края планки с молнией. Складываем заготовки для боковушек лицом к лицу, между ними «подсовываем» торцевой край планки с молнией. |

|

8. Совмещаем все три открытых среза, фиксируем булавками. Стачиваем все три слоя. |

|

9. Отворачиваем верхнюю и нижнюю боковушки в сторону от планки и отстрачиваем в край место перегиба. Это место часто самое «слабое» в застежке, поэтому лишние строчки тут не помешают. |

|

10. Очень часто именно туда, где планка молнии сходится с боковыми стенками, вшивается ручка сумки (или лямки, или шлевка для карабина, или декоративная петелька). Тогда ручку нужно подсунуть ровно посередине и все хорошо застрочить, возможно даже несколькими строчками для крепости. |

|

11. Вот так будет выглядеть соединение планки с застежкой с боковыми стенками и вшитой ручкой. Вот, собственно, и вся сложность. С противоположной стороны планки-застежки боковая часть пришивается аналогично п.9. Я знаю, что часто в пошиве сумок вы побаиваетесь именно вшивания молнии. Но вшив молнию таким образом хотя бы один раз, вы и в дальнейшем будете довольны своим результатом! Как говорится, глаза страшатся, а руки делают! |

|

сумочка з квадратиків мк |

Это цитата сообщения Марриэтта [Прочитать целиком + В свой цитатник или сообщество!]

|

сумка-клатч мк |

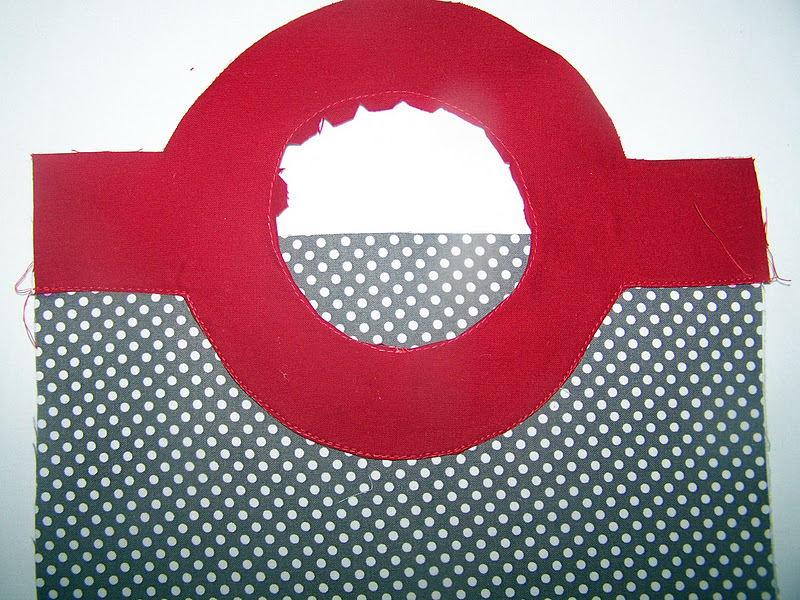

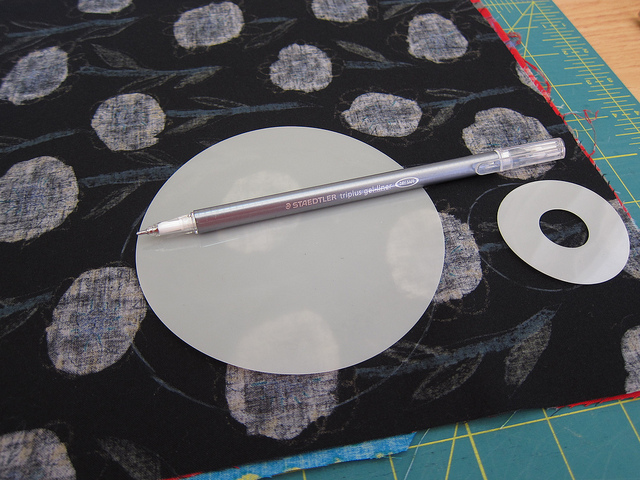

I’m excited to bring you this clutch pattern! It converts from a tote into a clutch, with beautiful circle handles. I wrote this pattern for Pellon Projects; it uses 3 different kinds of interfacing, which will give you a chance to get familiar with each. This pattern is appropriate for intermediate level sewing. It features inner pockets, a magnetic closure, and a metal buckle. You will also be required to make one buttonhole.

This pattern is appropriate for intermediate level sewing. It features inner pockets, a magnetic closure, and a metal buckle. You will also be required to make one buttonhole. ALL SEAM ALLOWANCES ARE 1/2″ UNLESS OTHERWISE NOTED. PLEASE READ ALL INSTRUCTIONS BEFORE BEGINNING. Printable Instructions and Pattern Pieces

ALL SEAM ALLOWANCES ARE 1/2″ UNLESS OTHERWISE NOTED. PLEASE READ ALL INSTRUCTIONS BEFORE BEGINNING. Printable Instructions and Pattern Pieces

SUPPLIES

– 1/4 yard (or a fat quarter) exterior fabric

– 2/3 yard interior fabric

– 1/2 yard side accent/handle fabric

– 2 yards Pellon SF-101 fusible woven interfacing

– 1/2 yard Pellon Fusible Fleece

– 1/2 yard Pellon Decor-Bond

– magnetic snap

– metal buckle with tongue (I used the Dritz 1-5/8″ fashion buckle)

– coordinating thread

– hand sewing needle

STEP 1 ~ CUT OUT YOUR FABRIC

From the Exterior Fabric

1a. Cut 2 pieces, each measuring 8″ x 11″. These will be your Exterior Main Panels.

From the Interior Fabric

1b. Cut 2 pieces, each measuring 11″ x 11″. These will be your Interior Main Panels.

1c. Cut 4 pieces, each measuring 11″ x 6″. These will be the Pockets.

From the Accent Fabric

1d. Cut 4 pieces, each measuring 2″ x 11″. These will be the Side Panels.

1e. Cut 2 pieces, each measuring 2″ x 3″. These will be the Bottom Strap pieces.

1f. Using the Top Strap piece that you printed out, cut 2 pieces from the Accent Fabric.

1g. Using the Handle pattern piece that you printed out, cut 4 pieces from the Accent Fabric.

From the Pellon SF-101 Fusible Woven Interfacing

1h. Repeat Step 1a. through Step 1g.

From the Pellon Fusible Fleece

1i. Repeat Step 1a. and Step 1b. Also cut two 2″ x 2″ squares from the fleece.

From the Pellon Decor-Bond

1j. Cut 8 pieces from the Handle pattern piece. Trim the Handle by approximately 1/4″ on all edges (except trim by 1/2″ in the inner circle) in order to reduce bulk in the seam allowance.

1k. Cut 8 pieces, each measuring 2″ x 11″.

STEP 2 ~ FUSE YOUR FABRICS

2a. Take 1 Exterior Main Panel and one of the corresponding fusible woven interfacing pieces. Fuse the woven interfacing to the wrong side of the Exterior Main Panel using manufacturer instructions. Then, fuse the fusible fleece to the interfaced side of the Exterior Main Panel. Repeat for the other Exterior Main Panel.

2b. Repeat Step 2a. for both Interior Main Panels.

2c. Take one Bottom Strap Piece and one of the corresponding fusible woven interfacing pieces. Fuse. Repeat for the remaining Bottom Strap Piece, both of the Top Strap Pieces, and each of the Pockets.

2d. Take one Handle Piece and one of the corresponding fusible woven interfacing pieces. Fuse. Then, fuse a Decor Bond Handle piece to the interfaced side of the Handle. Repeat so that you have fused a total of 2 pieces of Decor Bond to the Handle. Repeat this step for the remaining Handle pieces, and also for all of the Side Panels.

STEP 3 ~ ASSEMBLE THE INTERIOR

3a. Take 2 of the Pocket pieces and place them, right sides together. Sew along one 11″ edge. Press seam open.

3b. Turn the Pocket so it is wrong sides together. Press again along the sewn edge so that it lies flat. Topstitch 1/4″ from the edge.

3c. Repeat Step 3a. and Step 3b. for the 2 remaining Pocket pieces.

3d. Take one of the Interior Main Panels, right side facing you. Lay one Pocket with the raw edge even with the bottom of the Interior Main Panel. Pin, then baste along the raw edges of the Pocket (you will not baste the sewn edge of the Pocket). Repeat for the remaining Interior Main Panel and Pocket.

3e. Take one of the Handle Pieces. Sew along 1 long edge, pivoting through the curve, approximately 1/4″ from the raw edge of the fabric. Also sew 1/2″ along the inside circle of the Handle. Clip the ‘valley’ of the fabric with slits, and notch the ‘peak’ of the fabric with small v’s, approximately every 1/2″. Be sure not to cut in to your stitching.

3f. Turn your iron on. Using your fingers, turn the fabric to the wrong side at your stitches, then slowly ease along your fabric with your iron. It is especially important to press the inside circle very well.

3g. Repeat Step 3e. and Step 3f. for all 4 Handle pieces (set 2 of the Handles aside for the exterior).

3h. Take one Interior Main Panel and measure down 3/4″ from the top (the pocket will be at the bottom). Make a mark on the top left and top right corners. Align the bottom straight edges of the Handle along the marks that you made, and pin to the Interior Main Panel. Edgestitch on the Handle along the long pressed edge, 1/8″ from the edge. You will not stitch the inside circle of the Handle at this time.

3i. Trim inside the inner circle of the Handle where the Interior Main Panel is sticking out. You’ll want to flip it over to the wrong side and trim an additional 1/2″ away.

3j. Repeat Step 3h. and Step 3i. for the other Interior Main Panel and Handle.

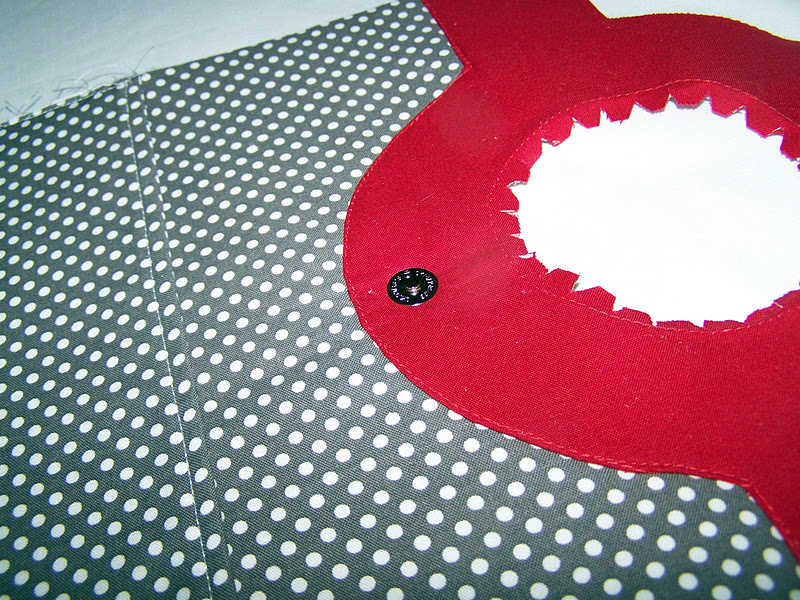

STEP 4 ~ INSTALL THE MAGNETIC SNAP

4a. Take 1 Interior Main Panel piece and 1 of the fleece squares that you cut in Step 1i. Take the washer from one of the prongs and mark the prong placement with a fabric marker or chalk, approximately in the center of the Thermolam. Cut small slits at the marks. The reason that you are using the fleece is that it will help to reinforce your fabric against the pull from the magnetic snap every time you open and shut the clutch.

Helpful Hint: I like to put a dab of Fray Check on the slits that were cut. I feel this helps the fabric hold up a bit better under the stress of the magnetic snap.

4d. Slide the prongs of the snap through the right side of the Interior Main Panel. Place the fleece square, then the washer, over the prongs. Close the prongs outward (use pliers with a piece of scrap fabric over the metal, if you need to), making sure they lie flat.

4e. Repeat Steps 4a. through 4d. to attach the other half of the snap to the other Interior Main Panel.

STEP 5 ~ ASSEMBLE THE EXTERIOR

5a. Take one of your Exterior Main Panels and one Side Panel. With right sides facing, place the Side Panel along the 11″ edge on the left-hand side of the Exterior Main Panel. Sew along the 11″ edge. Press seam toward the Side Panel. Repeat this step for another Side Panel and the right-hand side of the Exterior Main Panel.

5b. Edgestitch on the Side Panel 1/8″ from the seam on the left side of the Exterior. Then edgestitch 1/4″ from the stitches that you just made. Sew slowly, and make sure that the seam allowance is underneath your stitching; this will ensure that it gets tacked down securely. Now your Side Panel will have a nice finished look. Repeat for the right side of the Exterior.

5c. Repeat Step 3h. to attach each remaining Handle to each Exterior Main Panel.

STEP 6 ~ ASSEMBLE THE STRAPS/BUCKLE

6a. Take both of your Bottom Strap pieces. Place them right sides together, and stitch along each 3″ edge. Turn Bottom Strap right side out and press.

6b. Make a mark on the bottom of one Exterior Main Panel, over 4-7/8″ from the left hand edge.

6c. Place your Bottom Strap piece to the right of the mark that you made in Step 6b. One raw edge of the Bottom Strap should be even with the raw edge of the Exterior Main Panel. Slide the metal buckle over the Bottom Strap, then fold the Bottom Strap down so that now both of the raw edges of the Bottom Strap are even with the bottom of the Exterior Main Panel. Pin in place.

6d. Take both of the Top Strap pieces and place them, right sides together. Sew along 3 edges but do not sew the short straight edge.

6e. Trim the seam allowance to 1/4″, and clip the corner off, which will help it lie more flat. Turn the Top Strap right sides out and press.

6f. Edgestitch the Top Strap 1/8″ from the sewn edges (again, do not sew the straight short edge), being sure to pivot at the corners; then edgestitch the Top Strap 1/4″ from what you just sewed.

6g. On the Top Strap piece, make a buttonhole 1-1/2″ down from the pointed top corner.

6h. Remove the pin from under the Bottom Strap. Slide the Top Strap piece under the Bottom Strap piece, making sure to re-adjust the buckle. The raw edges of all Strap pieces should be even with the bottom edge of the Exterior Main Panel. Re-pin.

6i. Baste across the bottom of the Exterior Main Panel, attaching the Strap pieces. Sew horizontally right under the metal buckle, as close to the buckle as you are able to (you might want to pop your zipper foot on for this).

STEP 7 ~ ASSEMBLE THE CLUTCH

7a. Take both Interior Main Panels, and place right sides together. Pin along the 3 straight edges. Sew along those 3 straight edges only, with a 5/8″ seam. This will help the interior fit more snuggly inside your exterior. Trim the seam allowance to 1/4″. Clip the 2 bottom corners, being careful not to cut into your stitching. Leave the Interior wrong side out.

7b. Take both Exterior Main Panels, and place right sides together (you might want to buckle the strap so that it does not get caught in the stitching). Pin along the 3 straight edges. Sew along those 3 straight edges only, with a 1/2″ seam. When you get to the part where the straps are, sew slowly or hand crank your needle, and backstitch again (to give the strap added strength). Clip the 2 bottom corners. Press seams open, and turn the Exterior right side out.

7c. Place the Exterior inside of the Interior. Make sure the Handles and the side seams are aligned, then pin in place. Make sure you pin an exterior handle to an interior handle (otherwise you might be sewing the bag shut!).

7d. Sew the top of the Handles, all along the top of the clutch, with a 1/4″ seam allowance. Do not stitch the inside circles. Clip the ‘valley’ of the fabric with slits, and notch the ‘peak’ of the fabric with small v’s, approximately every 1/2″. Be sure not to cut in to your stitching.

7e. Turn the clutch right side out through one of the openings. Edgestitch the tops of the handles, 1/4″ from the edge, all the way around.

7f. Match the insides of the handles. You should have a nice pressed edge to work with from earlier. Pin the inside circles. Edgestitch the inside circles, 1/4″ from the edge. Note: Depending on your machine, you may not be able to sew around the entire inside circle of the handles. I was able to sew half by machine and half by hand. This is the trickiest (and last!) step of the pattern, so take your time…the results will be worth your patience!

CONGRATULATIONS! You’re finished!

Give your bag a good pressing for a professional-looking finish. Now you have a tote that collapses into a clutch, held in place with the metal buckle!

If you have any questions about this pattern, feel free to e-mail me directly at sara@sewsweetness.com, or check out my Flickr Group! I would love to see your completed project posted there!

|

сумка-портфель з вишивкою мк |

Even if you are new to embroidery, you will have lots of fun with this beautiful design!

Even if you are new to embroidery, you will have lots of fun with this beautiful design!I was also able to use Cosmo embroidery floss for the first time. The threads look so much more smooth than either DMC or Iris flosses, and they are also glossier. Pink Castle Fabrics carries some nice Cosmo floss starter kits, if you are interested in taking a peek!

Embroidery Pattern and Printable Instructions

ALL SEAM ALLOWANCES ARE 1/2″ UNLESS OTHERWISE NOTED.

Finished size: 9.5″ long x 7″ high x 1.75 deep

SUPPLIES

– 1/2 yard exterior fabric

– 1/2 yard interior fabric

– 9″ x 7″ piece of fabric for the embroidery (we used Kona white)

– 1/3 yard Pellon Thermolam fusible interfacing

– 1 yard Pellon SF-101 fusible woven interfacing

– 1/3 yard Pellon Decor Bond fusible interfacing

– 28″ zipper (trim to 28″ including the tape)

– fabric marker or chalk

– ruler

– hand sewing needle

– zipper foot

– seam ripper

– turning tool

STEP 1 ~ CUT YOUR FABRICS

From the Exterior Fabric

1a. Cut 1 piece measuring 10.5″ long x 8″ high, for 1 of the Exterior Main Panels (the other Exterior Main Panel will be assembled using your embroidery).

1b. Cut 1 piece measuring 3.75″ x 30″ for your Exterior Zipper Panel.

1c. Cut 1 piece measuring 2.5″ x 5.5″ for the Exterior Top Panel.

1d. Cut 2 pieces, each measuring 10.5″ x 7″ for the Pocket.

1e. Cut 2 pieces, each measuring 2″ x 6.5″, for the Handles.

1f. Cut 2 strips, each measuring 1″ x 7″.

1g. Cut 2 strips, each measuring 7/8″ x 11.5″

From the Interior Fabric

1h. Repeat Steps 2a. through 2c. for the Interior pieces.

1i. Cut 5 pieces, each measuring 4″ x 18-1/2″ for the Dividers.

From the Pellon Thermolam

1j. Cut 4 pieces, each measuring 8″ x 10.5″

1k. Cut 2 pieces, each measuring 3.75″ x 30″.

1l. Cut 2 pieces, each measuring 2.5″ x 5.5″.

1m. Cut 1 piece measuring 1″ x 5.25″ for the Handle Insert.

From the Pellon SF-101

1n. Cut 2 pieces, each measuring 2″ x 6.5″.

1o. Cut 5 pieces, each measuring 4″ x 18-1/2″ (dividers)

1p. Cut 2 pieces, each measuring 10.5″ x 7″.

From the Pellon Decor Bond

1q. Cut 10 pieces, each measuring 1-1/4″ x 17″ (dividers)

STEP 2 ~ EMBROIDER THE DESIGN

2a. Using your 9″ x 7″ piece of fabric, embroider the design using the attached template and instructions.

2b. Take one of your 1″ x 7″ strips cut from the exterior fabric. The long edge of the strip should be even with the right-hand edge of your embroidered piece. Sew, right sides together, using a 1/4″ seam allowance. Repeat with the remaining 1″ x 7″ strip and the left-hand edge of the embroidery. Press seams open.

2c. Take one of your 7/8″ x 11.5″ strips cut from the exterior fabric. The long edge of the strip should be even with the top edge of your embroidered piece. Sew, right sides together, using a 1/4″ seam allowance. Repeat with the remaining 7/8″ x 11.5″ strip and the bottom edge of the embroidery. Press seams open. This assembled embroidered piece will now serve as one of your Exterior Main Panels.

STEP 3 ~ FUSE YOUR FABRICS

3a. Take 1 Exterior Main Panel and one of the corresponding pieces of Pellon Thermolam. Fuse the interfacing to the wrong side of the Exterior Main Panel according to manufacturer instructions. Repeat for the remaining Exterior Main Panel, the Exterior Zipper Panel, Exterior Top Panel, both Interior Main Panels, Interior Zipper Panel, and the Interior Top Panel.

3b. Take 1 Pocket piece and one of the corresponding pieces of Pellon SF-101. Fuse the interfacing to the wrong side of the Pocket according to manufacturer instructions. Repeat for the remaining Pocket and both of the Handle pieces.

STEP 4 ~ ATTACH THE ZIPPER

4a. Take your Exterior Zipper Panel and cut it in half, lengthwise.

4b. Place the resulting 2 pieces right sides together. With your fabric marker, measure and make a mark that is 1″ in from that left-hand edge. Do the same for the right-hand edge. Sew from the mark to the corresponding edge (each line of stitching will be only 1″ long), using a 5/8″ seam allowance.

STEP 5 ~ MAKE THE HANDLE

5a. Take both of your Handle pieces, and place them right sides together. Sew along both of the long edges.

5b. Turn your Handle right side out through one of the openings. Press. Pass the Thermolam Handle Insert into the tube. Fuse according to manufacturer instructions.

Helpful Hint: Use a safety pin attached to one end of the Handle Insert to pass it through the tube more easily.

5c. Turn both of the unfinished edges in by approximately 1/2″. Topstitch 1/4″ from both of the finished edges.

5d. Take your Exterior Top Panel. Make a mark that is in 1″ from both of the short edges.

5e. Place 1 short edge of the Handle to the inside of one of the marks that you just made, and centered. Pin in place. Do the same thing for the remaining short edge of the Handle. Sew on top of the Handle, 1/8″ from both short edges. Then sew another line of stitches that is 1/8″ from the previous stitching.

STEP 6 ~ ASSEMBLE THE BAG

6a. Place both Pocket pieces right sides together. Sew along 1 long edge. Press the seam open.

6b. Turn the fabrics so that they are wrong sides together, press again, and topstitch the straight edge, 1/8″ from the edge.

6c. Take the Exterior Main Panel without the embroidery, and place the Pocket that you just sewed, with the bottom raw edges of both even. Baste the Pocket to the Exterior Main Panel using a 1/4″ seam allowance.

6d. Take the Exterior Zipper Panel and the Exterior Top Panel and place them, right sides together, along one short edge. Sew. Press seam open.

6h. Notch small v’s into the seam allowance of the corners of both Exterior Main Panels, being careful not to cut into the seam allowance.

6i. Repeat Steps 4a. and 4b. for the Interior Zipper Panel. Press the center of the panel in by 5/8″ on each side.

6j. USING A 5/8″ SEAM ALLOWANCE (this will help the interior sit snuggly in the exterior), repeat Steps 6d. through 6h. to assemble the Interior.

6k. Turn your exterior right side out and your interior wrong side out. Place the interior inside of the exterior (so that wrong sides will be touching). Pin in place along the pressed edges of the Interior Zipper Panel against the wrong side of your zipper.

6m. Please give your bag a good pressing for a nice, professional look.

STEP 7 ~ ASSEMBLE THE DIVIDERS

7a. Take 1 of your Divider pieces and fold it in half, right sides together, along the long edge. Sew along that long edge.

7b. Turn your Divider right side out using the turning tool. Press. Turn 1 raw edge in by approximately 1/2″. Press.

7c. Slip 2 pieces of your Decor Bond inside of the assembled Divider. Again, using a safety pin to guide the Decor Bond through the tube will be helpful. Fuse according to manufacturer instructions.

7d. Measuring in from the raw edge of the Divider, make the following marks:

– 1/2″

– 2-1/4″

– 9-1/4″

– 11″

7e. Stitch on top of the marks that you just drew.

7f. Slide the raw edge of the Divider into the pressed edge on the opposite end, by 1/4″. Topstitch 1/4″ from the pressed edge (this will create a ‘ring’ with the fabric).

7g. Press along the 4 stitched lines. This will create a rectangle.

7h. Repeat Steps 7a. through 7g. to assemble all 5 Dividers.

7i. Place one Divider on top of another, along the long edges. Topstitch along both long edges, approximately 1/8″ from the edge. Continue adding another Divider until all 5 are connected.

7j. Place the assembled Divider inside of your bag.

Optional: You may wish to adhere the Divider to the bottom half of your interior with fabric glue.

Congratulations, you’ve finished!!

If you have any questions about this pattern, feel free to e-mail me directly at sara@sewsweetness.com, or check out my Flickr Group! I would love to see your completed project posted there!

|

сумка-сафарі мк |

Can't you picture Harrison Ford slinging this amazing duffle over his shoulder as Indiana Jones?! We blended heavy canvas and faux leather with webbing and brass zipper accents for the dashing exterior. Inside is a tough rip-stop nylon lining. Even if you're not a world-renowned archeologist and adventurer, this bag is is great way to pack your stuff, whether you're heading across town to the gym or getting away for the weekend. Father's Day is coming up, and this would make a very nice gift for your personal action hero. The combination of fabrics, colors and textures has the perfect feel – a little bit retro and a whole lot cool (just like Dad).

Our finished bag looks like you could have grabbed it off the shelf at Eddie Bauer®, but don't let the professional finish scare you off. Achieving a polished end result is often easier than you might think. Read through the project a few times before you start, then if a particular part has you stumped, try doing it with scraps to get the hang of it before moving on to your final fabric. And of course, we offer our trademark S4H details and photos to help you through each step.

We do strongly recommend the heavy canvas and faux leather combo to insure your duffle has the stability and durability you want for active, on-the-go (safari style) use.

The bag finishes at approximately 22" wide x 11" high.

Sewing Tools You Need

- Any Sewing Machine (we recommend the Janome Horizon Memory Craft 8900 QCP)

- Walking foot - the MC8900 QCP has the built-in AcuFeed Flex™ system, which we used (with the optional narrow walking foot VD) - and love. If you do not have a built-in feeding system, we recommend a Walking foot or similar for working with the tricky and/or thick layers.

- Adjustable Zipper foot - again, we used the built-in AcuFeed Flex™ system on the MC8900 QCP (with the optional zipper foot ED). If you do not have a built-in feeding system, we recommend an Adjustable Narrow Base Zipper foot.

Fabric and Other Supplies

- 1 yard of 58"+ wide medium to heavy-weight cotton fabric for the bag top exterior; we used 60" wide medium-heavy weight 9 oz. Canvas in Khaki (#EL-239) from Fabric.com

- ½ yard of 45"+ wide heavy-weight faux leather for the bag bottom exterior; we used 54" wide upholstery weight Faux Leather in Boca Cocoa (item #CW-699) from Fabric.com

- 1 yard of 58"+ wide lightweight nylon fabric for the bag lining; we used 62" wide Rip Stop Nylon in Brown (item #DL-264) from Fabric.com

- 1¼ yards of 45" heavyweight fusible interfacing; we used Pellon's 809 Décor Bond® firm fusible

- 4¼ yards of 1½" poly webbing for the handles and carry strap; we used khaki

- TWO 1½" wide D-rings; we used black plastic

- TWO 1½" wide swivel hooks; we used black plastic

- ONE 1½" slide; we used black plastic

- ONE 22" metal separating zipper; we used brass

- ONE 9" metal zipper; we used brass

- ½ yard of thin leather for the two zipper pulls

- All-purpose sewing thread in colors to match fabric

- Scissors or rotary cutter and mat

- See-through ruler

- Straight pins

- Seam gauge

- Seam ripper

- Iron and ironing board

Getting Started

- Download and print FOUR copies of the Duffle Bag Side Pattern.

-

Download and print TWO copies of the Duffle Bag Side Pocket Pattern.

IMPORTANT: Each pattern consists of ONE 8½" x 11" sheet. You must print the PDF files at 100%. DO NOT SCALE to fit the page. - Cut out the pieces along the solid lines.

- Butt together (do not overlap) and tape the four Duffle Bag Side Pattern pieces to form a circle as shown on the diagram printed on the pattern.

- Butt together (do not overlap) and tape the two Duffle Bag Side Pocket Pattern pieces to form a half circle as shown on the diagram printed on the pattern.

-

From the top exterior fabric (Nutmeg Canvas in our sample), cut the following:

TWO 23" x 12" rectangles

ONE 10" x 15" rectangle

TWO 1¼" x 2" strips for the zipper tabs

Using the assembled Duffle Bag Side pattern, cut TWO side panel circles

Using the assembled Duffle Bag Side Pocket pattern, cut TWO side panel pockets - From the bottom exterior fabric (Boca Cocoa Faux Leather in our sample), cut ONE 14" x 23" rectangle.

-

From the lining fabric (Brown Rip Stop Nylon in our sample), cut the following:

ONE 23" x 36" rectangle

Using the assembled Duffle Bag Side pattern, cut TWO side panel circles

Using the assembled Duffle Bag Side Pocket pattern, cut TWO side panel pockets -

From the interfacing, cut the following:

TWO 23" x 12" rectangles

Using the assembled Duffle Bag Side pattern, cut TWO side panel circles

Using the assembled Duffle Bag Side Pocket pattern, cut TWO side panel pockets -

From the webbing cut the following:

TWO 36" lengths

ONE 60" length

TWO 7" lengths

At Your Sewing Machine & Ironing Board

NOTE: As mentioned above, we used the built-in AcuFeed Flex™ system on our Janome MC8900 QCP with the optional narrow foot VD throughout the entire project. If you don't have a built-in feeding system, attach a Walking foot or similar. It helps keep all the layers involved in this project feeding more smoothly.

Apply the interfacing

-

Following manufacturer's instructions, fuse the interfacing to the wrong side of the two 23" x 12" exterior panels, the two exterior side circles, and the two exterior side pockets.

Side pockets

- Find the two exterior pocket pieces (with interfacing) and the two pocket lining pieces.

-

Place one lining piece and one exterior piece right sides together, aligning all the raw edges. Pin in place along the top edge only.

-

Using a ½" seam allowance, stitch along the top edge only.

-

Press flat.

-

Fold the lining to the wrong side of the pocket. Press again.

- Edgestitch on the right side along the top edge only.

-

Run a second line of stitching ¼" from the first.

- Repeat to create the second pocket.

- Find the two exterior side circles (with interfacing).

-

Place a finished pocket on each side circle, matching the curved raw edges. Pin in place.

- Machine baste each pocket in place on its circle within the ½" seam allowance, an approximate ⅜" seam allowance is good.

- Set the side panels aside.

Front zippered pocket

- Find ONE of the two 23" x 12" exterior panels (with interfacing), the 10" x 15" exterior pocket panel, and the 9" zipper.

- Place the 23" x 12" panel wrong side up and flat on your work surface. Orient it properly: 23" wide x 12" high.

- Find the exact center of the panel (11½" from either side). Mark this point with a pin.

-

Using your fabric pencil and see-through ruler, measure 4½" to the left of the center point and mark, then measure 4½" to the right of the center point and mark. Measure 3½" down from the upper edge and make an intersecting mark. Draw a connecting 9" horizontal line.

-

Draw a second line ½" down from the first line and parallel. Join the lines at each end to create a box.

- Place the 10" x 15" panel wrong side up and flat on your work surface. Orient it properly: 10" wide x 15" high.

-

Draw a matching box to what you just drew on the top 10" edge, positioning it ½" from the top raw edge and centered side to side.

-

Place the exterior panel and the pocket panel right sides together aligning the two drawn boxes. The easiest way to line up the boxes is to place a pin at each upper corner on the wrong side of the exterior panel.

-

Then, match up the pin points with the pocket on the other side.

-

With the wrong side of the exterior panel facing up, stitch around the marked box through both layers.

-

Cut through the center of the box, then clip into each corner.

-

Pull the pocket to the inside through the opening, smoothing the corners and edges of the box as best you can. Press.

-

Flip over and place the opening over the 9" zipper, centering the zipper's teeth. Pin in place.

-

Edgestitch in place around all four sides.

-

Run a second line of stitching ¼" from the first along the BOTTOM of the box opening only.

NOTE: Don't worry too much about keeping your corner pivots and end stitching super-duper perfect; the ends of the opening will be hidden by the webbing when complete. -

From the wrong side, fold just the pocket layer in half, bringing the lower edge of the pocket up so it aligns with the upper edge. Pin along the top.

-

Flip to the right side. Run a second row of topstitching ¼" from the TOP edgestitching along the TOP of the box opening (matching what you did previously along the bottom edge). You are stitching through all the layers, catching and securing that upper edge of the pocket you just folded up and pinned. Press well.

Side handles

- Find the two 36" lengths of webbing.

- Fold each length in half to find the exact center. Mark with a pin.

- Measure 3½" to the left of the center point and mark with a pin.

-

Measure 3½" to the right of the center point and mark with a pin.

- Remove the center pin.

- Fold the webbing in half, matching the long edges.

-

Edgestitch between the left and right pin points to create the handle.

- Find both exterior side panels, the one with the pocket and the plain panel.

- On the panel with the pocket, lay one handle length in place. The outer edge of the webbing should be positioned 5½" in from each side. The inner edge of the webbing should just cover either end of the zipper "box." The ends of the webbing should be flush with the lower raw edge of the panel. Be careful to insure the handle loop is not twisted.

-

Measure 2½" down from the top raw edge along each side of the webbing and mark with a pin, placing it horizontally across the webbing. This is where you will stop sewing and turn to go across and back down the webbing.

- Edgestitch each side of the handle in place, staying as close to the edge as you can. We also lengthened our stitch. Start at the bottom, stitch up one side, stop at the 2½" mark, pivot, stitch across, pivot, and stitch down the opposite edge to complete. This edgestitching will also finish the side seams of the inside pocket.

-

At each 2½" point, reinforce the strap with a 1½" "X Box."

-

Position the second webbing handle on the remaining plain panel, exactly matching the front, and repeat the steps to create the opposite side of the bag.

Attach the bottom exterior panel

- Find the 14" x 23" faux leather panel.

- Place one completed exterior panel on either side of faux leather panel, right sides together, aligning the the 23" raw edges. Pin in place.

- Using a ½" seam allowance stitch each seam. Finger press the seam allowance towards the faux leather. Do not press with an iron. Faux leather doesn't like the heat of an iron!

-

Flip the sewn panel over and run two lines of topstitching. One seam should be approximately ⅛" from the seam. Run a second seam ¼" from the first.

-

Stay stitch both long sides of the assembled exterior ½" from the edge.

NOTE: Stay stitching is a single line of stitching that simply helps stabilize the fabric to prevent stretching or distortion. In this project, it will also provide us with a seam line to follow later in the instructions.

Add the top zipper

- Find the 22" zipper and the two 1¼" x 2" end tabs.

-

Place one tab on each end of the zipper. The strip and the zipper are right sides together and the raw ends are flush. Pin in place.

NOTE: We based the width of these tabs on our zipper. Cut your tabs as needed to best fit your zipper; you want the tab to fit within the zipper tape. -

Using a ½" seam allowance, stitch the zipper tabs in place. You may need to "hand walk" the foot across the zipper to avoid breaking the needle.

-

Press the zipper tabs away from the zipper on each end.

- Lay the bag exterior right side up and flat on your work surface.

-

Place the zipper face down along the top on the side with the pocket, aligning the edge of the zipper tape with the raw edge of the strip. Pin in place along the top half of the zipper tape only.

-

Using an adjustable zipper foot or a built-in feeding system (we used our MC8900 AcuFlex™ ED Zipper foot), stitch along the zipper teeth. Your seam should be as close as possible to the teeth.

- Fold the fabric down and away from the zipper teeth. Lightly press. Pin if needed.

-

Edgestitch in place, approximately ⅛" from the fold.

-

Run a second seam ¼" from the first.

-

Repeat to attach the remaining raw edge of the panel to the opposite side of the zipper.

NOTE: This second side will be a little more challenging because your bag is now a tube rather than flat. However, both ends are open, giving you the flexibility to maneuver your fabric under the needle.

D-rings and tabs for side panels

- Find the two 7" lengths of webbing, the two D-rings and the side panels with the pockets basted in place.

- Slip each 7" strip through one of the D rings. Fold into place so one end extends 1½" below the other. Pin in place.

-

Fold up that extra 1½" on each tab, enclosing the upper end's raw edge.

- Find the two circular end units

-

Place one tab on each end unit, centering it above the pocket. The D-ring should be aligned with the curved top edge of the pocket as shown in the photo below. Stitch the tab in place with a 1¼" "X box" stitch.

Set in the side panels

- Find the bag "tube" and the two end panels.

-

Clip the raw edges of the two open ends of the tube. Clip approximately every ¾", taking care to not cut through the stay stitching.

- Place a pin at the exact center top, exact center bottom and top edge of each side pocket. Think of it like a clock, with pin points at 12:00, 3:00, 6:00 and 9:00.

- On the main tube, the corresponding 12:00 point will be the center of the zipper. Keeping the zipper in the exact center, flatten the tube to find the opposite 6:00 point. Then, flatten the tube in the opposite direction to find the 3:00 and 9:00 points. Place marking pins at all these points.

- Place the side panel right sides together with circular opening of the barrel, aligning all the pin points. Easing the fabric, fill in the rest of the circle with pins. If you've done garment sewing, this is very similar to putting in a sleeve. You can also clip around each of the side panels (again staying well within the the seam allowance) to help with the easing.

-

Stitch the layers together, following the original line of stay stitching.

- Turn the completed bag right side out.

Create and insert the lining

- Find the 23" x 36" lining panel and the two lining side circle panels. As you did with the exterior panel, stay stitch each 36" side of the lining.

- Clip to, but not through, the line of stay stitching every ¾" - again as you did with the exterior panel.

- With low heat, press under ½" along the each 23" edge.

- Following a similar method as you did for the exterior, pin the lining to the circles, leaving a ½" gap at what will be the top of the lining. When inserted into the bag, this gap will allow the lining to smoothly straddle the zipper.

- Sew the side circles in place, following along in the original line of stay stitching. This will be a bit easier than stitching the exterior since you are working with the lining panel as a flat piece.

-

With the completed lining still wrong side out, insert it into the exterior bag. Pin the lining in place along each side of the zipper, covering the lines of stitching.

-

Topstitch the lining in place, following along in the existing stitch line closest to the zipper.

-

The photo below shows how that opening in the lining sits over the zipper. It looks a little messy when you see everything close-up like this, but it's all actually hidden inside the bag and results in a professional finish. We thought it was important for you to see why that little space is left open in the lining end seams.

Create the shoulder strap

- Find the remaining 60" length of webbing, the slider and the two swivel clips.

-

Insert one raw end of the webbing through the center of the slider. Pull it through so it just clears the slider. Turn under the raw end approximately ½" and stitch in place as close to the slider as possible.

-

Place the slider end, with the webbing attached, wrong side up on your work surface. Thread the opposite raw end through one swivel clip, threading from the bottom and out the top.

-

Continue feeding the webbing through, pulling it across and over the portion laying flat, then threading it back through the slider.

-

Finally bring the opposite raw end through the remaining swivel clip, threading it from the top to the bottom. Pull it through as above, turn under the raw end, and stitch in place as close to the hook as possible

- Clip the strap in place on the D-ring tabs to complete.

|

сумка-торбинка з вишивкою та китичками мк |

Decorative stitching against a neutral canvas gives this slouchy bucket bag a great hipster style. We used the beautiful stitches available on the Janome Memory Craft 9900, which go up to 9mm in width. For a subtle boho flair, we then incorporated long, soft tassels at the sides and front. Read on to learn our unique steps for making these custom tassels: much less than buying, and in an exact color match!

There are decorative stitch accents along the top of the bag and the top of the exterior pocket, but the main feature is how we use them on the wide cross-body strap.

We added four lines of mirror-imaged decorative stiches down the length of the strap plus an embellished flat cord, which is stitched in place with a wide zig zag - a modern spin on a traditional heirloom technique.

Searching for innovative closures for our bag and tote designs is always fun. We've employed zippers, drawstrings, turn locks, and more. But, we hadn't yet used one of the best "cincher-upper" techniques: the belt! It does an amazing job holding up your pants, and works equally well as a functional, fashionable closure for this cute bag.

Our pretty custom tassels hang luxiously from the bag's side and sprout directly from the ends of twisted cord belt. If you've ever shopped for tassels, you know they can be hard to find in the color you want, and even if you do luck out and locate one to your liking, the price may surprise you. A single, small tassel can run $5.00 and up. Designer Alicia Thommas came up with an innovative way to unwrap twisted cording then sculpt it into perfectly-matched tassels.

This bag finishes at approximately 11" wide x 13½" high x 6" deep. The cross-body strap finishes at approximately 3" x 54½".

Sewing Tools You Need

- Any Sewing Machine (we recommend the Janome Memory Craft 9900)

- Satin Stitch foot for decorative stitching (optional)

Fabric and Other Supplies

-

¾ yard of 45-60" wide medium to heavy-weight cotton canvas or similar for the main bag exterior panels, the exterior pocket, the belt loops, and the strap; we used 60" 10oz Bull Denim in Natural from Jo-Ann Fabric

NOTE: If you use a fabric that is less than 60" wide, you should get a full yard as you will need to piece the strap, which is cut at 58". - ¼ yard of 45"+ wide medium to heavy-weight cotton canvas or similar for the base accent; we used 54" Baja Fret in Greystone an Outdoor Canvas by Robert Allen from Jo-Ann Fabric

- 1 yard of 44"+ wide standard weight cotton for the bag's lining, the exterior pocket's lining, and the lining pocket; we used a coordinating print purchased locally but not available online

-

2½ yards of ⅜ - ½" twisted cord; we used a soft gray metallic twisted cord, purchased locally

NOTE: This is a standard décor trim, but make sure you get the kind that is two twisted strands covered in a shiny rayon. Our unique tassel technique is created by pulling away the rayon covering to reveal the polyester core. It is a bit harder to source online, but is eadily available at sewing and craft stores, such as Jo-Ann (where we found ours), Michael's, etc. - TWO 1" D-rings; we used Dritz D-rings in Black, which is actually kind of a gunmetal tone

- ½ yard of 45" wide medium to heavyweight fusible interfacing; we used Pellon's Décor Bond

- All purpose thread to match fabrics

- Rayon thread for decorative stitch accents; we used sage green

- Small round or flat cording for optional corded accent on the bag's strap; we used Madeira Carat 2mm flat trim in Black Coral stitched in place with gray metallic thread

- Stabilizer as recommended by your machine's manual for the decorative stitching (a standard tear-away or a lightweight fusible should work if you have no recommendations to follow) – you need a piece approximately 3" x 58". You can also butt together pieces to create this length.

- See-through ruler

- Fabric pen or pencil

- Seam gauge

- Seam ripper

- Scissors or rotary cutter and mat

- Iron and ironing board

- Straight pins

- Large-eye upholstery needle

Getting Started

-

Download and print out the Strap End Template.

IMPORTANT: This template is ONE 8½" x 11" sheet. You must print the PDF file at 100%. DO NOT SCALE to fit the page. There is a guide rule on the page so you can confirm your final printout is to scale. - Cut out the template along the solid line. Set it aside.

-

From the fabric for the main bag exterior panels, the exterior pocket, the belt loops, and the strap, cut the following:

FOUR 10" wide x 13½" high rectangles for the main panels

ONE 11" wide x 8" high rectangle for the exterior pocket

FOUR 2½" x 4" strips for the belt loops

ONE 7½" x 58" strip for the cross-body strap

NOTE: Remember, if your fabric is less than 60" wide, you'll need to cut two pieces and seam the together to get a 58" finished length. - From the fabric for the base accent, fussy cut TWO 19" wide x 6" high rectangles.

-

From the fabric for the bag's lining, the exterior pocket's lining, and the lining pocket, cut the following:

TWO 19" x 16" rectangles for the lining

ONE 11" wide x 8" high rectangle for the exterior pocket lining

ONE 11" wide x 16" high rectangle for the lining pocket -

From the interfacing, cut the following:

TWO 10" x 7½" rectangles for the pockets

TWO 18" x 5" rectangles for the base of the bag (optional).

NOTE: Interfacing the base accent panels provides a bit more stability but is not mandatory since the bag is designed to be slouchy.

At Your Sewing Machine & Ironing Board

Create the exterior pocket

- Find the 11" x 8" exterior pocket panel, the 11" x 8 lining panel and one 10" x 7½" interfacing panel.

-

Place the interfacing on the wrong side of the exterior pocket panel. The interfacing should be flush with the bottom of the fabric panel and centered side to side. This leaves a ½" reveal of fabric along the top and both sides. Following manufacturer's instructions, fuse the interfacing to the wrong side of the exterior pocket panel.

- Place the fused exterior panel and the lining panel right sides together; the raw edges should be flush all around. Pin in place across the top and along both sides.

- Using a ½" seam allowance, stitch across the top and along both sides, remembering to pivot at the corners. The bottom remains open.

- Trim the corners diagonally and turn the pocket right side out. Push out the corners so they are nice and sharp. A long, blunt end tool, like a knitting needle or chopstick, works well for this. Press flat.

-

Using a fabric pen or pencil, measure ½" down from the top seamed edge and draw a horizontal line. This will be the decorative stitching guide line.

NOTE: We are working on the right side of the fabric with our marking throughout this project. Make sure your fabric pen or pencil will easily wash or wipe away or will vanish with exposure to the air. The FriXion Penwe used vanishes with heat.

-

Set up your machine for decorative stitching. Thread it with your chosen rayon thread in the top (we used a pale sage green) and a quality bobbin thread in the bobbin. Select a simple decorative stitch. We chose a triangle (Statin Stitch 09 on our Janome MC9900). We adjusted the width to 6.0 and the length to 2.5.

NOTE: You can use our embellishment pattern or design your own. If you choose your own, measure and test your stitch width and length to insure you will get the result you want. -

Following the drawn line on the pocket, stitch across the pocket.

- Set the finished pocket aside.

Create the belt loops

- Find the four 2½" x 4" strips.

- Press back the ends of each strip ½".

- Re-thread the machine with thread to match the exterior fabric in the top and bobbin, and edgestitch all these folds in place.

-

Press down the sides of each strip ½". Do not stitch these sides, simply leave them pressed.

Assemble the exterior panels and place the loops and pocket

- Find the four 10" x 13½" upper panels. Split the four pieces into two pairs and place them right sides together. Pin each pair together along one 13½" edge. If you using any type of directional fabric, make sure you are pinning and stitching what will become the center edge.

- Using a ½" seam allowance, stitch this center seam for each pair. Press the seam allowance together and to the right.

-

Flip over each seamed panel and topstitch ¼" to the right of the seam.

- Press each panel flat and place them both right side up on your work surface.

- Collect the exterior pocket and the four belt loops.

- Place the pocket right side up on one exterior panel. The pocket should be centered side to side (4½" in from each raw side edge of the exterior panel) and the raw bottom each edge of the pocket should be flush with the raw bottom edge of the exterior panel. Pin the pocket in place along both sides.

-

Place two belt loops above the pocket. The outer ends of the loops should be in line with the side edges of the pocket. The top edges of the loops should be 3" down from the top raw edge of the exterior panel. This position will leave 1½" between the bottom edges of the loops and the top of the pocket. Pin the loops in place.

NOTE: We drew in a horizontal line at 3" down from the top raw edge of the exterior panel to insure our loops would be perfectly parallel.

- Edgestitch the loops in place along the top and bottom (remember, these were the sides you just pressed in when forming the loops).

- Edgestitch the pocket in place along both sides.

- Place the remaining two loops in the exact same position on the remaining exterior panel.

- Find the two 19" x 6" accent base panels. If you wish, fuse the interfacing pieces to the wrong side of each panel, center the interfacing side-to-side and top-to-bottom.

-

Place a base panel right sides together with each exterior panel. Pin in place along the bottom edge of each exterior panel.

- Using a ½" seam allowance stitch each base panel seam. Press the seam allowance together and down towards the base panel.

-

Flip each panel to the right side and topstitch ¼" from the seam within the base panel.

- Place the front and back exterior panels right sides together. Pin along both sides.

- Using a ½" seam allowance, stitch both sides. Press the seam allowance together and toward the back panel.

- Turn the exterior (which is now a tube) right side out. As you did above with the center seams and accent panel seams, topstitch ¼" from each side seam within the back panel.

-

Create 6" box corners, which means your cut box will be half that size or 3".

- Stitch across the bottom, using a ½" seam allowance, and finish boxing the corners.

- If you are new to this technique, check out our tutorial: How To Box Corners.

-

Turn the main bag right side out, push out the corners and press.

Create the embellished strap

-

Find the 7½" x 58" strip.

NOTE: If you used a narrower-width fabric that required piecing, make sure your finished strip is 7½" x 58". - Place the strip right side up and flat on your work surface.

- Find the Strap End Template.

-

Center the template on one end. You want at least ½" of fabric showing along the top and sides of the template.

-

Using a fabric pen or pencil, trace around the template at both ends of the strap. And, using the template as a guide, draw in the center line. In the photo below, we slid down the template to show our tracing lines.

- Grab your longest clear ruler and fabric pen to draw in the final guidelines.

- Continue the solid outer lines from top to bottom; these are the strap cut lines.

- Continue the center line from top to bottom as a dashed line.

- On the right half of the strap, at both the top and bottom ends, draw in the ¼" seam lines – also as dashed lines, just like they're shown on the template.

- Finally, draw in all the embellishment guide lines as solid lines. Starting from the center dashed line, measure ¼" to the right and draw a vertical line the length of the strap. This is embellishment line #6.

- From this first line, measure ½" to the right and draw an another vertical line parallel with the first. This is embellishment line #5.

-

Repeat to draw and additional FOUR parallel vertical lines with the same ½" spacing. These are embellishment lines #4, #3, #2 and #1.

-

Embellishment line #1 should end up ¼" from the opposite dashed seam line.

- With all your embellishment guidelines in place, set up your machine for decorative stitching as you did above for the pocket stitching.

-

Re-thread the machine with your chosen rayon thread in the top (we used a pale sage green) and a quality bobbin thread. Select the same simple decorative stitch used on the pocket. We chose a triangle (Statin Stitch 09 on our Janome MC9900). We adjusted the width to 6.0 and the length to 2.5.

NOTE: As mentioned above, our steps and guideline measurements are based on our embellishment pattern. If you choose your own, re-measure and test your stitches on a scrap of fabric to confirm the spacing as well as the stitch length and width are to your liking. - Layer stabilizer under the fabric strip.

- We started with embellishment line #3, orienting the stitch so the point of the triangle is aiming toward the center of the strap. Following the drawn line, stitch from top to bottom.

-

Begin and end all your stitching beyond the drawn lines of the Strap End Template.

- Next, stitch embellishment line #6, which has the triangles pointing in the same direction as line #3. Following the drawn line, stitch from top to bottom.

-

If possible, use the Mirror Image function on your machine to flip the direction of the triangles. Stitch embellishment lines #4 and #1 with this new orientation.

NOTE: The Mirror Image function is a standard decorative stitching feature on many of the Janome models and we LOVE it! It allows you to create some very intricate patterns. If you do not have this function, you can flip the entire strap and stitch in the opposite direction. - For the final two embellishment lines, we stitched flat cording in place with a wide zig zag.

- Cut two 58" lengths of decorative cord.

- Re-thread the machine to coordinate with the cord. We used a metallic silver in the top and quality bobbin thread in the bobbin. We set our zig zig at a width of 6.0 and a length of 2.5. Test on a scrap to insure your width and length with work with your chosen cord. The swing of the zig zig should hit just outside the cord.

-

We started on embellishment line #5.

- You don't need to pin the cording in place; you can simply hold it with your finger, centering it over the drawn line. Just go slowly and stop (with the needle in the down position) to re-adjust as necessary. Stitch down the cording from top to bottom.

- Repeat to stitch cording in place down the length of embellishment line #2.

-

Here's a look at our finished embellishment. We folded the fabric so you could see both ends.

- Remove the stabilizer if you'd like; we left ours in place as it will be hidden between the layers and offers a bit of extra stability to the fabric. However, if you use a heavy fabric, such as the canvas we chose, it is not necessary.

-

Trim both ends of the strap along the drawn cut lines (the solid lines, not the dashed lines. Don't trim down the sides.

- Fold the strap in half along the center dashed fold line, right sides together, sandwiching the stitching between the layers.

- Using your long clear ruler and fabric pen, draw a final guideline. This will be your stitching line.

-

Measure ¼" to the right of the last line of decorative stitching. The line should run from top to bottom.

- Re-thread the machine with thread to match the fabric in the top and bobbin.

-

Using a ¼" seam allowance, stitch along the angled ends. Pivot and stitch down the long side, following your guideline. Pivot at the angles of the ends, stitching with the same ¼" seam allowance across this end. Leave a 2-3" opening along the long side seam for turning.