Записи с меткой batch pasteurization

(и еще 10057 записям на сайте сопоставлена такая метка)

Другие метки пользователя ↓

agricultural cover systems air conveyance systems air separation unit air separator air wash separator batch pasteurization batch pasteurizer for sale batch pasteurizers beverage pasteurization equipment biogas collection and storage birdstrike cover blow-off products clarifier covers cold pasteurization equipment commercial pasteurization equipment commercial powder coating custom tattoo machines dust removal equipment flash pasteurization flash pasteurization beer floating cover fruit drink pasteurization fruit infused beer pasteurization geomembrane liners and systems industrial cardboard cutter industrial equipment industrial powder coating label production launder covers liner systems loader attachments manufacturing paper cups manufacturing pasteurization plastic manufacturing process pouch coolers powder coating powder coating company powder coating metals powder coating services repair refurbish pasteurizers silk screening single zone batch pasteurizer skid steer skid steer attachments skid steer tree puller skid steer tree spade tank covers tattoo guns tattoo machine tattoo machine for sale tattoo machine kits tattoo machine parts tractor attachments triple zone batch pasteurizer tunnel coolers tunnel pasteurization tunnel pasteurizer tunnel pasteurizer beer tunnel pasteurizer manufacturer tunnel pasteurizers tunnel warmers ultra pasteurization vacuum evacuator vacuum transfer systems

Eager To Identify The Very Best Tunnel Pasteurizer For Your Service Needs? Investigate The Vital Facets To Consider For Improving Production Effectiveness And Item Top Quality |

Дневник |

Material Writer-Hvid Emery

When selecting the excellent Tunnel pasteurizer for your service, you encounter a vital choice that can influence your manufacturing efficiency substantially. The procedure involves evaluating various elements like dimension, capacity, temperature control, and maintenance demands. It's not just about the first purchase; it's also regarding long-lasting functional expenses and assistance. Comprehending the subtleties of different Tunnel pasteurizer kinds and their viability for your specific requirements is extremely important. Your option will certainly play a pivotal function in making sure the high quality and security of your items while maximizing your production processes.

## Key Aspects to Consider

When selecting a tunnel pasteurizer for your service, it's essential to think about numerous essential variables that will affect the performance and performance of your pasteurization procedure.

Firstly, analyze the size and capability demands of your assembly line. Make certain the Tunnel pasteurizer you select can take care of the quantity of products you require to process to stay clear of traffic jams or delays in manufacturing.

Second of all, think about the home heating and cooling down abilities of the pasteurizer. The temperature level control accuracy is essential to make certain that your products are pasteurized properly without endangering quality. Seek a tunnel pasteurizer that uses exact temperature surveillance and adjustment attributes to satisfy your certain pasteurization requirements.

https://www.upi.com/Science_News/2024/05/17/pasteu...-milk-avian-flu/6591715962450/ to take into consideration is the impact and design of the Tunnel pasteurizer. Make sure the equipment fits well within your production center and can be easily incorporated right into your existing line without significant modifications. Furthermore, analyze the upkeep requirements and the schedule of technological assistance for the pasteurizer to guarantee smooth procedures and very little downtime.

## Sorts Of Tunnel Pasteurizers

To better understand the diverse choices available in the market, it is essential to discover the various sorts of Tunnel pasteurizers suited for various manufacturing needs and procedures.

One common type is the continual Tunnel pasteurizer, ideal for high-volume production with constant heat treatment. If you have varying production rates, a modular Tunnel pasteurizer may be the most effective fit as it enables versatility in line setups.

For smaller businesses, a compact Tunnel pasteurizer could be the best selection, supplying room efficiency without jeopardizing on pasteurization top quality. If your products call for details therapy zones, a flexible Tunnel pasteurizer might be the most ideal choice, making it possible for customization of heat exposure levels.

In addition, Tunnel pasteurizers can be categorized based on home heating methods such as water immersion, heavy steam injection, or hot air, each offering distinct benefits depending upon the product being refined. Recognizing these kinds will certainly help you select the Tunnel pasteurizer that aligns finest with your company requirements.

## Budgeting and Cost Analysis

Considering the monetary facets of buying a passage pasteurizer is an essential step in your service decision-making procedure. When budgeting for a passage pasteurizer, take into account not only the initial acquisition cost yet additionally continuous expenditures such as upkeep, energy usage, and prospective upgrades.

Conduct an extensive price analysis to identify the complete cost of ownership over the lifespan of the equipment. Try to find Tunnel pasteurizers that use a balance between in advance costs and long-term savings through energy performance and minimized upkeep requirements.

Remember to factor in any kind of extra costs such as installation, training, and possible downtime during implementation. Contrast quotes from various suppliers and take into consideration working out for a far better bargain or exploring financing alternatives to reduce the economic worry.

## Verdict

In conclusion, picking the best Tunnel pasteurizer for your business calls for mindful factor to consider of variables such as dimension, capability, home heating and cooling down capabilities, upkeep needs, and technological assistance availability. Assess various kinds of pasteurizers to locate the most effective fit for your manufacturing requirements and budget plan restrictions. Conduct a detailed cost evaluation to identify the overall possession cost, consisting of installation and prospective downtime expenditures. With these consider mind, you can make an informed decision that will benefit your organization over time.

Tips For Selecting The Most Suitable Tunnel Pasteurizer For Your Business |

Дневник |

Article Developed By-Mays Broussard

When choosing the perfect Tunnel pasteurizer for your company, you encounter a vital choice that can influence your manufacturing effectiveness dramatically. The process entails weighing different aspects like dimension, capacity, temperature control, and upkeep requirements. It's not nearly the initial purchase; it's additionally concerning long-term operational costs and support. Comprehending the subtleties of different Tunnel pasteurizer types and their viability for your specific needs is critical. Your selection will play a critical duty in making sure the top quality and security of your items while maximizing your production procedures.

## Key Elements to Take Into Consideration

When choosing a passage pasteurizer for your organization, it's important to take into consideration several vital elements that will certainly impact the performance and efficiency of your pasteurization procedure.

To start with, analyze the dimension and capacity requirements of your production line. Guarantee the Tunnel pasteurizer you select can manage the quantity of items you need to process to prevent traffic jams or delays in manufacturing.

Second of all, think about the heating and cooling down capacities of the pasteurizer. The temperature level control precision is important to make certain that your items are pasteurized efficiently without compromising quality. Seek a tunnel pasteurizer that provides accurate temperature level tracking and change attributes to fulfill your certain pasteurization requirements.

An additional critical aspect to consider is the impact and format of the Tunnel pasteurizer. Ensure the tools fits well within your manufacturing center and can be conveniently integrated right into your existing line without significant modifications. Furthermore, analyze the maintenance demands and the accessibility of technological support for the pasteurizer to make sure smooth procedures and minimal downtime.

## Kinds Of Tunnel Pasteurizers

To better comprehend the varied alternatives readily available out there, it is very important to check out the various types of Tunnel pasteurizers matched for different manufacturing demands and procedures.

One common kind is the continual Tunnel pasteurizer, perfect for high-volume production with constant heat therapy. If https://q1057.com/ny-chocolate-milk-recall/ have differing manufacturing rates, a modular Tunnel pasteurizer could be the most effective fit as it enables adaptability in line setups.

For smaller sized companies, a portable Tunnel pasteurizer could be the best selection, supplying room effectiveness without jeopardizing on pasteurization high quality. If your items need particular therapy areas, an adjustable Tunnel pasteurizer could be the most appropriate choice, making it possible for modification of warm exposure degrees.

In addition, Tunnel pasteurizers can be categorized based on heating methods such as water immersion, heavy steam shot, or hot air, each offering distinct benefits relying on the product being refined. Understanding these types will help you choose the Tunnel pasteurizer that straightens ideal with your business requirements.

## Budgeting and Expense Analysis

Taking into consideration the economic elements of buying a tunnel pasteurizer is a crucial action in your organization decision-making procedure. When budgeting for a passage pasteurizer, take into account not only the preliminary acquisition price however additionally recurring expenses such as maintenance, energy consumption, and possible upgrades.

Conduct a thorough expense analysis to establish the overall price of possession over the life-span of the tools. Seek Tunnel pasteurizers that supply a balance in between in advance costs and long-term savings through power effectiveness and lowered upkeep demands.

Remember to consider any type of additional costs such as installment, training, and potential downtime during execution. Contrast quotes from various providers and take into consideration working out for a far better offer or exploring financing alternatives to ease the economic problem.

## Final thought

In conclusion, choosing the right Tunnel pasteurizer for your service needs mindful factor to consider of variables such as dimension, capability, home heating and cooling abilities, upkeep requirements, and technological support availability. Examine various types of pasteurizers to locate the most effective fit for your manufacturing demands and budget restrictions. Conduct a thorough expense analysis to identify the complete possession price, including installation and prospective downtime costs. With these factors in mind, you can make a notified choice that will certainly benefit your company in the future.

An In-Depth Manual On Tunnel Pasteurizers: Their Functioning And The Value Of Their Use |

Дневник |

Post Developed By-Erichsen Dixon

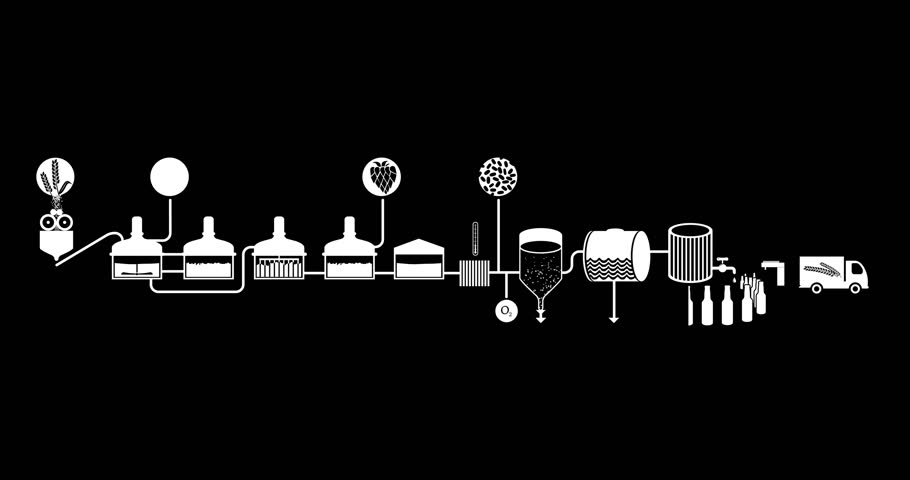

Tunnel pasteurizers help extend beer shelf stability and keep tastes popping without the aid of chemicals. They do this while eliminating pathogens and suspending yeast and mold and mildews.

The bottled item, either containers or containers, gets in the Tunnel and experiences a preheating section where it obtains splashed with warm water. From there, it's slowly offered the preferred pasteurization temperature and after that cooled.

Exactly how They Function

Tunnel pasteurizers utilize a conveyor system to relocate items through a temperature-controlled Tunnel. As the beer containers and containers move through the Tunnel, they are constantly sprayed with hot water, which gradually raises their temperatures till they reach the wanted pasteurization level. After that, the containers are held at that temperature for a collection quantity of time and then cooled off once more.

After the pasteurization process is complete, the beer containers and bottles are relocated to an air conditioning Tunnel where their temperature levels are decreased incrementally up until they reach room temperature once again. This is done to prevent the beverages from experiencing a sudden cool shock, which could modify their flavor profiles.

While Tunnel pasteurizers can be used by both large and little breweries, it is necessary that the best one is picked for your brewery. additional reading to select a system created and constructed by relied on, experienced market professionals. This will certainly guarantee that your system can deal with the details temperature level levels and timing required for carbonated beverages while additionally matching up with your assembly line's circulation.

Why They're Crucial

Tunnel pasteurizers supply an efficient service to expanding service life without jeopardizing item top quality. While flash pasteurizers can only target the liquid inside the package, Tunnel machines warm both the container and the contents - meaning they can expand a beer's rack security without affecting its complicated hop notes.

Additionally, passages are terrific for soft drinks as well - no require to stress over the high temperature damaging those carbonated bubbles. Specifically for craft breweries, Tunnel pasteurization is an indispensable device to guarantee their items' resilient shelf stability-- all without endangering the tasty preference that consumers like.

Besides being reliable, Tunnel pasteurizers are additionally flexible and customizable. Temperature levels in the various areas can be maximized to decrease power intake and maintain ideal pasteurization degrees. This is achieved by changing the heating & cooling temperatures to match the needs of the particular drink being treated (2 ). Furthermore, the splashing nozzles can additionally be customized to fit the bottle size and configuration.

What You Need to Know

In short, Tunnel pasteurizers are a helpful device for breweries and other beverage manufacturers aiming to prolong their beverages' service life. They can be made use of to kill off any kind of pathogens or microbes in the fluid and its packaging. This will aid to avoid the drinks from ruining or degrading before they reach customers.

A passage pasteurizer is a machine that takes the already-bottled product and passes it through numerous temperature areas with increasing warmth, until it reaches the desired pasteurization temperature level. After that it is cooled.

The cooling and heating of the containers in a tunnel pasteurizer is executed making use of a collection of spray nozzles. The precise positioning of these nozzles makes best use of the effect and reduces the blending of water in between different zones. They are likewise maximized to minimize power intake. Furthermore, they're safe for carbonated beverages - so they can secure your carbonated beers from over-carbonation and ensure their durability. This is especially essential for craft breweries and various other beverage manufacturers that wish to maintain their clients satisfied.

The Final Words

Tunnel pasteurizers are a large piece of machinery that contains an enclosed conveyor belt system where the bottles or containers move via zones that each have a specific temperature and dwell time. As soon as the items are sprayed or submersed in hot water and held at that temperature for the suitable quantity of time, they're then rapidly cooled off and permitted to make their escape of the device.

Tunnel pasteurization is a terrific method to prolong the shelf life of your beer and assistance prevent hazardous impurities from ruining your drink. Nevertheless, due to the fact that it warms up the fluid so long, a lot of the qualities that provide your beers their tasty taste and scent can also obtain destroyed at the same time.

One choice to Tunnel pasteurization is flash pasteurization, which warms the beer for a shorter period of time and assists preserve those specialty ingredients you functioned so difficult to resource for your beers. While flash pasteurization does set you back even more upfront, it can conserve you money over time by preventing pricey food and beverage remembers.

The Ultimate Overview To Tunnel Pasteurizers: How They Work And Why They're Necessary |

Дневник |

Web Content By-Ochoa McCabe

Tunnel pasteurizers assist lengthen beer shelf security and keep flavors standing out without the aid of chemicals. They do this while killing pathogens and suspending yeast and mold and mildews.

Get More Information bottled item, either bottles or containers, goes into the Tunnel and goes through a pre-heating area where it obtains sprayed with warm water. From there, it's gradually given the wanted pasteurization temperature level and afterwards cooled.

Exactly how They Function

Tunnel pasteurizers use a conveyor system to move products via a temperature-controlled Tunnel. As the beer canisters and containers relocate through the Tunnel, they are constantly splashed with hot water, which gradually raises their temperature levels till they get to the desired pasteurization level. Then, the containers are held at that temperature for a collection quantity of time and afterwards cooled off once more.

After the pasteurization procedure is full, the beer cans and bottles are transferred to an air conditioning Tunnel where their temperatures are lowered incrementally up until they reach room temperature once more. This is done to stop the beverages from experiencing an unexpected cool shock, which can alter their taste accounts.

While Tunnel pasteurizers can be utilized by both large and little breweries, it is essential that the right one is chosen for your brewery. It's finest to select a system designed and built by trusted, experienced market specialists. This will make sure that your system can manage the particular temperature level degrees and timing needed for carbonated beverages while likewise comparing with your assembly line's flow.

Why They're Crucial

Tunnel pasteurizers supply a reliable service to extending service life without jeopardizing item top quality. While flash pasteurizers can just target the liquid inside the package, Tunnel equipments warm both the container and the components - meaning they can extend a beer's shelf stability without influencing its intricate hop notes.

Moreover, passages are terrific for carbonated drinks also - no require to bother with the high temperature damaging those carbonated bubbles. Especially for craft breweries, Tunnel pasteurization is an important tool to ensure their items' resilient rack stability-- all without endangering the scrumptious taste that consumers like.

Besides being effective, Tunnel pasteurizers are likewise flexible and adjustable. Temperatures in the different zones can be optimized to minimize energy usage and keep ideal pasteurization levels. This is attained by changing the heating & cooling temperature levels to match the requirements of the certain beverage being dealt with (2 ). Furthermore, the spraying nozzles can also be tailored to fit the bottle dimension and configuration.

What You Required to Know

In short, Tunnel pasteurizers are an useful tool for breweries and other beverage manufacturers wanting to expand their beverages' shelf life. They can be used to kill off any kind of pathogens or microbes in the fluid and its packaging. This will certainly aid to avoid the beverages from spoiling or weakening prior to they get to customers.

A passage pasteurizer is a device that takes the already-bottled product and passes it through numerous temperature zones with boosting warm, up until it gets to the wanted pasteurization temperature level. After that it is cooled down.

The heating & cooling of the containers in a tunnel pasteurizer is performed making use of a collection of spray nozzles. The exact positioning of these nozzles makes the most of the impact and lessens the mixing of water in between different areas. They are additionally enhanced to lower power usage. Furthermore, they're risk-free for carbonated beverages - so they can protect your fizzy beers from over-carbonation and guarantee their longevity. This is specifically vital for craft breweries and various other beverage producers that intend to keep their consumers happy.

The Final Words

Tunnel pasteurizers are a large piece of machinery which contains an encased conveyor belt system where the bottles or cans relocate through areas that each have a specific temperature and dwell time. When the items are splashed or immersed in hot water and held at that temperature level for the appropriate amount of time, they're after that swiftly cooled and permitted to make their way out of the equipment.

Tunnel pasteurization is a terrific means to expand the service life of your beer and help avoid harmful pollutants from spoiling your drink. However, because it warms up the liquid so long, much of the characteristics that provide your beers their scrumptious flavor and scent can also get ruined while doing so.

One alternative to Tunnel pasteurization is flash pasteurization, which warms the beer for a much shorter period of time and assists maintain those specialized active ingredients you functioned so tough to resource for your beers. While flash pasteurization does set you back more upfront, it can save you money in the future by stopping expensive food and beverage recalls.

Everything You Need To Know About Tunnel Pasteurizers: Functionality And Significance |

Дневник |

Web Content Writer-Erichsen Barrett

Tunnel pasteurizers assist prolong beer shelf stability and maintain flavors popping without the help of chemicals. They do this while killing pathogens and inactivating yeast and molds.

The bottled item, either bottles or canisters, goes into the Tunnel and goes through a preheating section where it gets splashed with hot water. From there, it's gradually given the wanted pasteurization temperature and after that cooled.

Exactly how They Work

Tunnel pasteurizers make use of a conveyor system to move items through a temperature-controlled Tunnel. As the beer cans and bottles move through the Tunnel, they are continually splashed with warm water, which progressively increases their temperature levels up until they get to the desired pasteurization degree. After that, the containers are held at that temperature for a set quantity of time and then cooled off once again.

After the pasteurization procedure is complete, the beer canisters and bottles are relocated to an air conditioning Tunnel where their temperature levels are lowered incrementally until they reach space temperature once again. This is done to prevent the drinks from experiencing an unexpected cool shock, which could change their taste accounts.

While Tunnel pasteurizers can be utilized by both big and little breweries, it is essential that the best one is selected for your brewery. check it out to select a system created and constructed by trusted, experienced market professionals. This will certainly make sure that your system can manage the details temperature degrees and timing needed for carbonated beverages while likewise comparing with your assembly line's flow.

Why They're Vital

Tunnel pasteurizers deliver an efficient service to extending life span without jeopardizing item high quality. While flash pasteurizers can just target the liquid inside the package, Tunnel devices heat both the container and the components - indicating they can expand a beer's rack stability without impacting its complex hop notes.

Furthermore, tunnels are fantastic for soft drinks too - no require to fret about the high temperature destroying those fizzy bubbles. Especially for craft breweries, Tunnel pasteurization is an essential device to ensure their products' lasting shelf security-- all without jeopardizing the tasty taste that customers love.

Besides being effective, Tunnel pasteurizers are also flexible and adjustable. Temperature levels in the various areas can be enhanced to reduce energy consumption and keep ideal pasteurization degrees. This is achieved by readjusting the cooling and heating temperature levels to match the demands of the certain drink being dealt with (2 ). Moreover, the splashing nozzles can likewise be personalized to fit the bottle size and arrangement.

What You Required to Know

Basically, Tunnel pasteurizers are a helpful device for breweries and other beverage producers aiming to extend their drinks' service life. They can be utilized to kill off any microorganisms or microorganisms in the liquid and its product packaging. This will certainly aid to prevent the beverages from ruining or wearing away before they reach customers.

A tunnel pasteurizer is a machine that takes the already-bottled product and passes it via numerous temperature level areas with enhancing warmth, till it gets to the wanted pasteurization temperature. After that it is cooled.

The heating & cooling of the containers in a passage pasteurizer is performed using a series of spray nozzles. The specific positioning of these nozzles makes best use of the result and minimizes the blending of water in between various zones. They are also enhanced to minimize energy consumption. Furthermore, they're safe for carbonated beverages - so they can protect your carbonated beers from over-carbonation and ensure their durability. This is especially essential for craft breweries and various other drink manufacturers that wish to keep their consumers happy.

The Final Words

Tunnel pasteurizers are a large piece of machinery which contains an encased conveyor belt system where the bottles or canisters move via zones that each have a certain temperature and dwell time. When the products are splashed or submersed in hot water and held at that temperature for the appropriate amount of time, they're after that rapidly cooled and allowed to make their escape of the maker.

Tunnel pasteurization is a wonderful way to extend the life span of your beer and help prevent unsafe impurities from ruining your beverage. Nonetheless, because it heats up the liquid as long, a number of the qualities that provide your beers their delicious flavor and scent can also obtain damaged at the same time.

One alternative to Tunnel pasteurization is flash pasteurization, which warms the beer for a shorter period of time and assists protect those specialized active ingredients you worked so difficult to source for your beers. While flash pasteurization does cost more upfront, it can conserve you money over time by avoiding expensive food and drink remembers.

Whatever You Need To Learn About Tunnel Pasteurizers: Performance And Significance |

Дневник |

Material Composed By-Morrison Myers

Tunnel pasteurizers help extend beer shelf security and keep tastes standing out without the aid of chemicals. They do this while killing virus and inactivating yeast and mold and mildews.

The bottled product, either bottles or containers, gets in the Tunnel and experiences a preheating area where it gets sprayed with warm water. From there, it's slowly given the wanted pasteurization temperature and afterwards cooled.

Exactly how They Function

Tunnel pasteurizers make use of a conveyor system to relocate products via a temperature-controlled Tunnel. As the beer containers and containers move through the Tunnel, they are continuously sprayed with warm water, which gradually elevates their temperatures up until they get to the preferred pasteurization degree. After that, the containers are held at that temperature for a set quantity of time and afterwards cooled down once more.

After the pasteurization procedure is complete, the beer containers and containers are moved to an air conditioning Tunnel where their temperatures are decreased incrementally until they reach space temperature again. This is done to stop the beverages from experiencing an unexpected cool shock, which can change their taste profiles.

While Tunnel pasteurizers can be made use of by both huge and small breweries, it is necessary that the best one is selected for your brewery. It's finest to choose a system made and developed by relied on, experienced sector specialists. This will make certain that your system can take care of the details temperature level levels and timing needed for carbonated beverages while additionally pairing up with your production line's circulation.

Why They're Important

Tunnel pasteurizers provide an efficient solution to expanding life span without jeopardizing item top quality. While flash pasteurizers can just target the fluid inside the package, Tunnel machines warm both the container and the materials - meaning they can extend a beer's rack security without influencing its intricate jump notes.

Moreover, tunnels are terrific for soft drinks too - no need to worry about the heat ruining those fizzy bubbles. Specifically for craft breweries, Tunnel pasteurization is an important tool to ensure their products' durable rack security-- all without jeopardizing the delicious taste that consumers like.

Besides being reliable, Tunnel pasteurizers are also adaptable and adjustable. Temperatures in the various zones can be enhanced to decrease energy consumption and preserve ideal pasteurization levels. This is attained by readjusting the cooling and heating temperatures to match the demands of the certain beverage being treated (2 ). Furthermore, the splashing nozzles can also be personalized to fit the bottle size and configuration.

What You Need to Know

Basically, Tunnel pasteurizers are an useful device for breweries and other beverage manufacturers seeking to extend their drinks' life span. They can be utilized to kill off any type of virus or microorganisms in the fluid and its packaging. This will certainly assist to stop the beverages from ruining or deteriorating prior to they get to consumers.

A passage pasteurizer is a device that takes the already-bottled product and passes it via numerous temperature level zones with boosting heat, till it gets to the desired pasteurization temperature. Then it is cooled down.

The heating and cooling of the containers in a passage pasteurizer is performed utilizing a collection of spray nozzles. https://hanfordsentinel.com/news/local/chocolate-m...d3-11e1-a64f-0019bb2963f4.html of these nozzles makes best use of the effect and minimizes the blending of water between different areas. They are likewise optimized to lower energy consumption. Furthermore, they're risk-free for carbonated beverages - so they can safeguard your fizzy beers from over-carbonation and ensure their long life. This is especially vital for craft breweries and other beverage manufacturers that want to maintain their clients pleased.

The Final Words

Tunnel pasteurizers are a large piece of machinery which contains an enclosed conveyor belt system where the bottles or containers move with areas that each have a specific temperature level and dwell time. Once the items are splashed or immersed in hot water and held at that temperature for the proper quantity of time, they're then promptly cooled down and enabled to make their way out of the equipment.

Tunnel pasteurization is a wonderful means to extend the service life of your beer and assistance avoid dangerous pollutants from ruining your drink. Nonetheless, due to the fact that it warms up the liquid as long, many of the attributes that offer your beers their delicious taste and fragrance can likewise obtain ruined at the same time.

One option to Tunnel pasteurization is flash pasteurization, which heats up the beer for a shorter amount of time and aids preserve those specialized active ingredients you worked so tough to source for your beers. While flash pasteurization does cost even more upfront, it can conserve you cash over time by stopping costly food and beverage recalls.

Enhancing Performance: Streamlining Your Manufacturing Procedures With Tunnel Pasteurization Solution |

Дневник |

Web Content Author-Lynch Munk

Tunnel pasteurizers are large industrial-scale machines that warm and awesome drinks in order to kill microbes and extend their service life. Their efficiency depends on precision control.

Numerous drink firms have actually retrofitted their existing Tunnel pasteurizers with new green modern technologies to accomplish significant environmental benefits. These include lowered energy consumption, reduced water use and lowered greenhouse gas exhausts.

1. Boosted Performance

When you run a brewery, your goal isn't simply to eliminate harmful virus, yet additionally to offer consistency in your items. A well-executed pasteurization process not only extends beer's service life, yet it makes sure that every bottle of your beer will taste the same, from your very first set to your last. This is particularly crucial for craft breweries looking to draw in health-conscious clients that desire the carbonated goodness of soft drinks.

Tunnel pasteurizers function by bringing bottles and containers up to their desired temperature in stages, holding them there for enough time to kill off the microorganisms that cause perishing. They after that bring them down once more in incremental steps till they reach room temperature, maintaining taste profiles. By doing this, they not just avoid bacteria from increasing in the item, yet they also lower energy consumption by getting rid of warmth loss. These are the type of effectiveness gains that can accumulate quickly.

2. Decreased Waste

As even more focus is placed on green production techniques, drink producers are searching for ways to lower their waste production. Tunnel pasteurizers do a terrific job of this, especially when they are made and constructed by skilled experts.

Tunnel pasteurizers use a collection of sprays to heat the bottles or canisters as they relocate via the equipment. This gets rid of the requirement for a large vapor tank that consumes power and drainages. Furthermore, Tunnel pasteurizers make use of a water financial savings system to reuse the hot water made use of in the heating process, which minimizes water and sewage system use.

Another advantage of Tunnel pasteurization is its compatibility with soft drinks, which is a large marketing point for craft makers that intend to prolong their products' service life and guarantee consistency between batches. Unlike flash pasteurizers, which in some cases deal with high levels of carbonation, Tunnel systems can manage these bubbly concoctions without breaking a sweat (or a container).

3. Much Better Item High Quality

When your drinks are appropriately treated in Tunnel pasteurizers, they're safeguarded from damaging bacteria while preserving their taste accounts. This suggests your mixtures, soft drinks, acid preserves (like fruits or acids), and health shots can prolong their shelf life without losing their trademark taste.

In order to accomplish this, tunnels feature accurate temperature level control and also distribution throughout their several stages. In addition, conveyor belt rates help guarantee equivalent treatment times for every bottle going into the maker. simply click the following internet site helps you assure high quality results every single time.

Lastly, passages are compatible with carbonated beverages, a growing fad amongst health-conscious customers seeking fizzy alternatives to sweet soft drinks. Unlike flash pasteurizers, which can deal with high-carbonation levels, Tunnel machines are made to manage them.

In addition, retrofitting passages with power recovery systems decreases water use too. By utilizing the retrieved water for cooling, you'll considerably cut your energy consumption and greenhouse gas exhausts.

4. Decreased Energy Intake

Tunnel pasteurizers are energy-intensive machines, however you can reduce your power usage by retrofitting them with cutting-edge green innovation. This consists of solar-powered burner that can run on renewable resource resources, decreasing dependence on nonrenewable fuel sources and your carbon impact.

An additional great feature of Tunnel pasteurizers is that they work with carbonated beverages, a prominent trend among today's health-conscious customers. Unlike flash pasteurizers, which in some cases battle with high-carbonation levels, Tunnel systems can deal with these fizzy concoctions easily.

"BREWING UP THE PERFECT HOLIDAY: TOP BEER GIFTS FOR THE SEASON"

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) December 5, 2023

Article Release for Brewmasters and Beverage Makers, sponsored by PRO Engineering / Manufacturing Inc.

Click for the full article: https://t.co/Z3vUL8dCpU

PRO Engineering / Manufacturing Inc.

414-362-1500

zPasteurAIzer can monitor the performance of your present Tunnel pasteurizer by estimating the collected item quality (PU) worth for each set. This enables you to identify if your current temperature level control system is delivering enough heat treatment in addition to recognizing any type of bent spray heads. You can then readjust the maker settings based on your recommended PU values, boosting production efficiency while reducing power intake. This is a fantastic way to lower your water consumption as well, aligning your company with consumer demand for environmentally accountable items.

Exactly How Tunnel Pasteurizers Extend Service Life Of Beverages |

Дневник |

Article by-Carlsson Russo

Pasteurization expands the shelf life of drinks by eliminating microorganisms that trigger them to ferment or deteriorate.

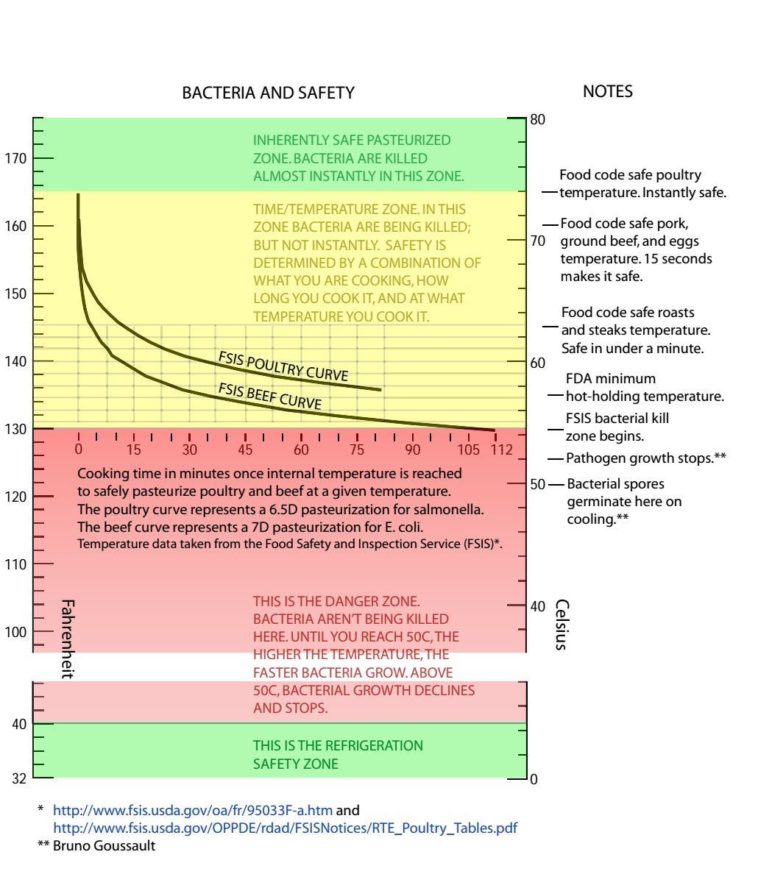

Usually, beer and also various other non-dairy beverages are sterilized to a temperature level of 140 levels or less. This procedure is commonly done by splashing hot water over containers or immersing them in hot water for a set time.

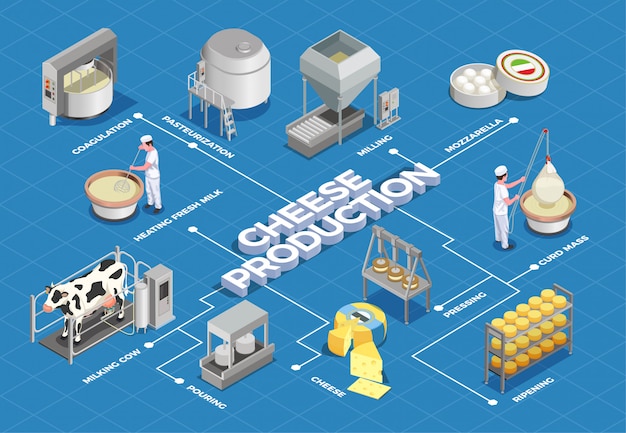

Set Pasteurizers

Pasteurization is the process of heating and also holding a food in order to make it risk-free for intake. It's an efficient technique of preserving several kinds of items, including beer, milk, juice, soft drink, red wine, and also a lot more.

For beer as well as drink manufacturers, pasteurization is a crucial method to systematize their items. It likewise helps ensure that they have the ability to keep constant flavor.

If your beer or drink production has grown to the point where it's outgrowing your batch pasteurizer, after that a passage pasteurizer may be the answer for you. This kind of equipment is developed to deal with numerous hectoliters at rapid line rates.

VIDEO: “SINGLE & TRIPLE TEMPERATURE BATCH PASTEURIZERS”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) February 7, 2023

Video Summary Release for Brewmasters & Beverage Makers

Video Link: https://t.co/MtKLEqRlOt

Article Link: https://t.co/hvo1dHvyEK

PRO Engineering / Manufacturing Inc.

414-362-1500

When a pasteurizer is running continuously, it is necessary to keep it tidy as well as devoid of particles. This needs routine maintenance and also change outs of the water that goes into it. It can also help to utilize ingredients to aid kill microorganisms, smells, and other concerns.

Beer & Drink Makers

Beer and also drink makers are constantly looking for to supply a distinct taste with exceptional top quality that consumers can rely on. That means focusing on the top quality of your pasteurization line, and also optimizing that performance to ensure item safety and security.

Whether you are brewing, producing or packaging beer, sodas, energy drinks or practical beverages, Tunnel pasteurizers are an effective means to lower microbes and also extend life span of your items. These makers function by spraying a combination of warm water and steam in several temperature zones to warm up the item till it is pasteurized.

This procedure is likewise made use of by non-alcoholic beer makers, whose beverages are not subject to more stringent laws than alcohol-based drinks. But as with just click the up coming post , ambient temperatures can speed up the proliferation of yeast and bacteria in non-alcoholic beers, causing them to create off tastes.

Compact Modular Pasteurizers

Companies that package products in containers, canisters or containers utilize Tunnel pasteurizers to boost item safety and also extend service life. These machines are able to refine huge quantities of fill and also cap products on a conveyor system while being splashed or sprayed with water to accomplish drink specific pasteurization devices that kill microorganisms.

During the handling cycle, Tunnel pasteurizers split into various areas for warmth conservation, sanitation as well as pre-cooling. Relying on the application, these sections can be regulated by PID managing pneumatic membrane layer managing shutoff or by regularity conversion rate regulation to accomplish specific product temperatures.

This technique allows improved control of the water temperature in the private zones, which decreases the amount of water and power consumption. Additionally, the water in the areas is conducted upwardly for scattering or splashing of the material to be pasteurized through branching lines right into a distributing tube on the side opposing the area pump.

Industrial Pasteurizers

A tunnel pasteurizer is a commercial pasteurization device that can be made use of to damage microorganisms and enzymes on rattled, bottled, canned and secured beverages. They can be found in a range of dimensions, dimensions and technical requirements to fit your details production requirements.

Throughout the procedure, containers and also cans are heated up to eliminate pathogenic microorganisms as well as inhibit enzymes, which prolongs life span. They are after that cooled to the desired temperature before exiting the Tunnel.

In check here , Tunnel pasteurization is generally made use of to guarantee risk-free usage by ruining dangerous yeast and also mold and mildews. However, the procedure can additionally impact the flavor as well as nutrient content of beer and also create staling, a build-up of turbidity in the product.

To minimize the threat of over-pasteurization, Haffmans uses reputable monitoring devices that permits drivers to keep track of specific temperature areas in a tunnel pasteurizer. Temperature probes in these zones are checked to ensure that the item is not sterilized at temperatures expensive for the sort of drink being refined.

Tunnel Pasteurizers Are Tools Used To Deal With Food At Heats |

Дневник |

Article writer-Houston Bering

This procedure boosts biological stability of the item. Some pasteurizers have added functions to help you enhance the pasteurization procedure. For example, some versions have an automated drier to get rid of drainage throughout the handling procedure.

Tunnel Pasteurizers are readily available in different dimensions. You can buy a huge pasteurizer for huge production centers, or a small one for a home cooking area. In general, a portable Tunnel pasteurizer uses flexible pricing, lowering upkeep prices as well as downtime. Many equipments are made from T304 stainless steel, and some can be equipped with outside suction boxes for easier access to the inlet screens. These boxes also stop debris from going into the pump mechanism. Additionally, these inlet screens can be changed on-the-fly, conserving you time and money.

The temperature and time of passage of plans through a tunnel pasteurizer are established by the control board. This is a vital aspect for calculating the pasteurisation units. Different devices can keep this info online. The driver panel is made of stainless-steel. It is located on the top of the equipment. It includes all the controls for the pasteurization process, including the temperature level and time. The temperature level is additionally adjusted based upon the kind of item being pasteurized.

“PRO ENGINEERING TUNNEL WARMERS FOR BEVERAGE PACKAGING IN 2023”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) January 31, 2023

Article Release for Brewmasters & Beverage Makers by Edward A. Michalski, CEO of PRO Engineering / Manufacturing Inc.

Full Article: https://t.co/iUYgZ8XiVT

PRO Engineering / Manufacturing Inc.

414-362-1500

Several manufacturers incorporate an extra feature to their pasteurizers, known as the Pasteurization System (P.U), to measure the warm's impact on bacteria. During the procedure, an item undergoes 60degC for one min. The temperature level of the product in the Tunnel is proportional to the Lethality (P.U.) of the product. The higher the temperature, the better the lethality.

Tunnel Pasteurizers boost the shelf-life of a liquid by shutting off microorganisms and enzymes. These makers make use of innovative modern technology and energy-saving attributes. Read the Full Article are modular, with deck sizes of 5m2 to 500m2. They feature continuous belts made from polypropylene or stainless steel. They can additionally be managed by a PLC. These gadgets can be made use of to decontaminate drinks that are available in a variety of layouts, consisting of tinned or frozen products.

Unlike flash pasteurizers, Tunnel pasteurizers do not require kegs. Due to the fact that they are not as large, Tunnel pasteurizers can be put on many different industries. They are also useful for fruit and vegetable handling, in addition to jams and sauces. The option depends upon the type of product you're pasteurizing, your goals, and the area readily available on the flooring.

Using a passage pasteurizer gets rid of the threat of microbial contamination throughout the product packaging process. Tunnel pasteurizers have several temperature level areas to make sure that the temperature can be slowly boosted. This means that a beer might get to the appropriate PU without grabbing a bacterial infection. Tunnel pasteurizers are generally used in the business developing sector.

Tunnel Pasteurizers offer a basic and reliable choice to blink pasteurization as well as clean and sterile purification. They additionally do not harm the flavor of foods and also avoid overpasteurization. They are readily available in a variety of sizes and also can be personalized to fit the firm's requirements. There are also custom-made Tunnel pasteurizers available for unique processing needs. The only downside to making use of a tunnel pasteurizer is that they aren't low-cost.

Tunnel Pasteurizers can be utilized in a variety of industries. Some kinds of beer and also wine are not suited for all settings, and you should think about the type of product you're preparing. A few of these items require a higher PU than others. These kinds of beers can likewise be prone to spoilage organisms. So it's essential to meticulously choose your items for pasteurization to make certain maximum high quality.

The temperature series of the process water varies from 60 to 100 degC, as well as the size of the process is dependent on the sort of container made use of. Correct fittings are important for the best accuracy. You ought to always position measuring points at the points of rate of interest when calibrating the equipment. Furthermore, you must ensure the equipment's temperature as well as pressure tracking system is furnished with adequate channels.

Tunnel Pasteurizers Are Used To Safely Sterilize Beverages To Increase Their Life Span |

Дневник |

Authored by-Shaffer Bengtsen

Tunnel Pasteurizers are used to securely and efficiently procedure fluids and other materials for pasteurization. Tunnel Pasteurizers are constructed from stainless-steel as well as have multiple zones for pasteurization. Each area has its very own set of spray nozzles and also drip pans to evenly warm and cool the item being pasteurized.

Tunnel Pasteurizers are made up of numerous sections with their own circulation pump, collection sump, screen/filter box, as well as water spray system. If any of these components stops working, the procedure may be compromised and also can bring about issues with security, process reliability, plan quality, and overall cost of ownership.

Tunnel Pasteurizers have several benefits over flash pasteurization. For one, they are less difficult than flash pasteurization as well as do not need different procedures for different types of beverages. Tunnel Pasteurizers are typically made use of in the beer sector, however can additionally be used to sterilize fruit and vegetable items.

Tunnel Pasteurizers are very effective devices that remove microorganisms from food and beverage items. They are readily available in a range of sizes, and are made use of in the food and beverage market to kill microbes, quit fermentation, as well as enhance rack stability. Several factors contribute to the fragility of these makers, consisting of substantial temperature level fluctuations, caustic cleansing chemicals, as well as massive mechanical stress and anxieties. Damaging https://www.healthline.com/nutrition/boiled-milk , for example, can seriously damage the tool. Luckily, there are some manufacturers that understand the need to keep their items as well as can provide reliable solution.

A tunnel pasteurizer is an exceptional alternative for those who are searching for a fast, effective, and low-cost choice to blink pasteurization as well as clean and sterile purification. https://newatlas.com/naturo-heat-free-milk-processing-long-shelf-life/59520/ can be customized to suit the needs of different firms, and also are typically geared up with automatic quit mechanisms to avoid overpasteurization. They can additionally be designed to fit certain dimension requirements.

Tunnel Pasteurizers Are Utilized To Securely Sterilize Beverages To Enhance Their Service Life |

Дневник |

read the article written by-Huynh Purcell

Tunnel Pasteurizers are made use of to securely as well as effectively process liquids as well as various other products for pasteurization. Tunnel Pasteurizers are made from stainless-steel and also have multiple areas for pasteurization. Each area has its very own collection of spray nozzles and drip frying pans to evenly warmth and cool the item being pasteurized.

Tunnel Pasteurizers are composed of different sections with their own blood circulation pump, collection sump, screen/filter box, and water spray system. If any of these parts fails, the process may be endangered and can cause problems with safety, procedure integrity, package quality, and general expense of possession.

Tunnel Pasteurizers have numerous advantages over flash pasteurization. For one, they are less complex than flash pasteurization and do not call for various procedures for various sorts of drinks. Tunnel Pasteurizers are normally utilized in the beer sector, however can also be used to sterilize vegetables and fruit products.

Tunnel Pasteurizers are very efficient makers that eliminate bacteria from food and beverage items. They are readily available in a range of dimensions, as well as are used in the food and beverage market to kill microorganisms, stop fermentation, and improve shelf security. Numerous factors contribute to the delicacy of these devices, consisting of significant temperature changes, caustic cleansing chemicals, and also enormous mechanical anxieties. Breaking containers, as an example, can seriously damage the device. Luckily, there are some suppliers who recognize the demand to keep their products as well as can supply reliable service.

A passage pasteurizer is a superb option for those that are looking for a quick, efficient, and inexpensive alternative to flash pasteurization and also sterile purification. Tunnel Pasteurizers can be personalized to fit the requirements of various business, as well as are typically outfitted with automatic quit mechanisms to avoid overpasteurization. They can also be developed to fit details dimension needs.

Below Is The Working Process Of Tunnel & Batch Pasteurizers - Beer & Beverage Makers |

Дневник |

Article writer-Frank Graversen

The standard elements of Tunnel & Batch Pasteurizers are a stainless-steel drum and a glass bottle that is pre-heated. Television is fitted inside the closed drum and also the item is put right into the product. The warmed water vaporizes the worm dispersings as well as merlot essence. The finished item is reduced to space temperature. These equipments are easy to use, and also are cost-effective and also easy to run.

This kind of pasteurizer features a pre-heated glass carafe, a stainless-steel drum, and a secured cover. The A-type Tunnel & Batch Pasteurizer is a superb choice for tiny residence kitchen areas as well as is basic to use. A common wall outlet is called for as well as it has a user guidebook to direct you through the procedure. When set up, the product is very easy to run.

These units include an easy-to-use user interface, that makes them perfect for home usage. The user-friendly user interface consists of an easy-to-understand guidebook. The system is linked to a conventional outlet as well as consists of a stainless-steel drum and a glass pitcher. The system is easy to set up, and the equipment can be utilized appropriate out of package. You'll be ready to start brewing your fresh homemade beer quickly.

A regular Tunnel & Batch Pasteurizer comes with a pre-heated glass pitcher, a condenser, a stainless-steel drum, and also a tube. A Passage & Block Pasteurizer system also comes with a user's handbook and also a guarantee for continual developing. One of the most significant downsides of this sort of pasteurizer is the fact that it takes a while to warmth to the correct temperature. As a result, it is best to prevent over-brewing as it will certainly cause over-pasteurized beer.

A Tunnel & Batch Pasteurizer system has numerous components. A pre-heated glass carafe, a stainless-steel drum, and also a stainless-steel hose pipe are necessary for any food or drink. The device is additionally easy to use and can be linked into a standard wall electrical outlet. The pre-heated paddle top as well as the sealed lid are very important for the product's safety and security as well as quality.

A Tunnel & Set Pasteurizer system has numerous components. relevant web page and condenser are pre-heated, and are attached to a stainless-steel drum and also pipe. A customer's manual is consisted of with many Tunnel & Batch Pasteurizers. Some are portable, while others are suggested to be made use of daily. They typically call for a fundamental wall surface electric outlet and an automated sprayer.

A Passage & Set Pasteurizer system features a pre-heated glass pitcher, stainless-steel drum, as well as a stainless-steel pipe. These makers can be attached to a common wall electrical outlet, and they are simple to utilize. Some are even dishwasher-safe. For added ease, these systems have the ability to link to a typical wall outlet. In addition to being risk-free for the atmosphere, Tunnel & Batch Pasteurizers are easy to use, which is an essential variable when it concerns your products.

The Tunnel & Batch Pasteurizer system is consisted of a stainless-steel drum and a glass pitcher. Its elements are pre-heated and can be used at home. A common Tunnel & Batch Pasteurizer system includes a glass carafe, a stainless-steel drum, and a stainless-steel hose. The majority of these models can be connected into a standard wall electrical outlet.

A Tunnel & Set Pasteurizer is a straightforward system that includes a pre-heated glass pitcher, stainless-steel drum, pipe, and also instructions. A typical device can connect to a wall outlet and is easy to use. You need to have no problems establishing it up due to its simpleness. After that, simply connect it in and also wait on your products to be ready. If you need to sanitize hot water for food or beverages, a Passage 'n' batch pasteurizer is the most effective solution for you.

Tunnel & Batch Pasteurizers are an essential for the homebrewer. These pasteurizers can be used for property and commercial applications. They are perfect for use with enclosed and open boilers. Ingegneria Alimentare creates both kinds of a Passage Pasteurizer. They can be customized according to the demands of the customer. The primary distinction in between a Passage as well as a Set Pasteurizer is the method they disinfect the water.

|

|

Contrasted To Various Other Systems, Tunnel Pasteurizers For Beer & Beverage Manufacturer'S Advantages Are Extremely Cost-Effective As Well As Trusted |

Дневник |

Created by-Pratt Buhl

The Batch Pasteurizer is a straightforward tool that softens tough water, safeguarding the house heating pipelines from rust. It is readily available in a range of different arrangements, and also appropriates for industrial in addition to residential applications. The system works at the boiler or in the circulating line, and also softens water to avoid blocking of the warmth exchangers.

It contains a glass carafe, a stainless-steel drum, a stainless-steel paddle top, as well as a condenser. This system is connected into a standard wall surface electrical outlet. Throughout the procedure of pasteurizing water, a gas-powered vaporizer forces the water to steam quicker. This warmth transfer speed enables the system to sanitize huge quantities of water without going beyond the advised temperature level.

A Passage & Batch Pasteurizer includes a pre-heated glass carafe, a condenser, a stainless-steel drum, a stainless-steel hose, and also a user's manual. To use the maker, connect the system into an electric outlet. The condenser has a paddle top that is warmed to a specific temperature level. When the temperature is reached, the pump will certainly warm up the condenser as well as paddle top. Then, a closed lid is placed on the drum.

A Tunnel & Batch Pasteurizer comes with a pre-heated glass bottle, a condenser, a stainless-steel drum, and a customer's guidebook. A Passage/ Batch Pasteurizer is made for household installations and calls for a common wall surface outlet. The pre-heated paddle top and also stainless-steel drum are connected to the system. As soon as the product is turned on, you can start using it as soon as possible.

A Tunnel & Batch Pasteurizer is a cost-effective means to speed up the brewing procedure at home. They supply quick heat transfer from the developing process to the beer. Learn More Here is suitable for fresh homemade beer. By minimizing the amount of time you need to invest in the brewing procedure, you'll be able to delight in the delicious and also nourishing drinks you have actually created. You'll likewise have more time to spend with your family.

A Tunnel & Set Pasteurizer is a convenient gadget for house usage. It features a stainless-steel drum, stainless-steel hose, and pre-heated glass pitcher. A regular machine requires an electrical outlet to work. A Passage & Batch Pasteurizer is excellent for homes that need to heat a big amount of water at one time. If you have a big quantity of water, you can acquire a portable variation.

A Passage & Set Pasteurizer includes a condenser, glass pitcher, as well as stainless-steel drum with a stainless-steel body. Each system comes with a customer's handbook, as well as a conventional wall electrical outlet is needed to power it. A typical batch pasteurizer has a high boiling point, which is essential for making sure the top quality of the beverage.

The most common kind of Tunnel Pasteurizer has four elements: a pre-heated glass bottle, a condenser and also stainless-steel drum. The last is the most popular of the three. Its condenser enables the process of home heating fluids. The drum has an automatic sprayer to make certain that the fluid is warmed evenly. A Tunnel & Batch Pasteurizer can be purchased separately or as a collection.

The Tunnel Pasteurizer consists of a stainless-steel drum and glass bottle with a lid. It has a built-in stainless-steel condenser, which uses a typical heating element. The number of sets created per day will certainly identify the top quality of the ended up product. The quickest means to guarantee a consistent batch is to make half the set and after that repeat the procedure.

The Batch Pasteurizers are an important part of any type of homebrewing procedure. Unlike conventional pasteurizers, they have the included advantage of providing controlled temperature levels. They also are very reliable at heating big quantities of liquid. By utilizing the Tunnel, you can obtain the wanted cause less time. As a matter of fact, the Tunnel a & B Pasteurizers can save you a lot of time.

|

|

Why The Tunnel Pasteurizer Series Of Beer-Making Machines Is Typically Made Use Of In Food Handling? |

Дневник |

Content written by-Borch Quinlan

The fundamental parts of a Passage & Set Pasteurizer system are a glass pitcher, stainless steel drum, and condenser. Many designs likewise feature a manual as well as customer handbooks. You should have a conventional wall surface electrical outlet for the Tunnel 'n' Batch Pasteurizer to work. This sort of pasteurizer works forcibly a water stream via a pre-heated paddle top.

https://www.foodsafetynews.com/2018/06/high-pressu...cility-focuses-on-food-safety/ is the very best option for products that have a long life span. Usually, drink plans are not eaten right away after manufacturing. They remain on racks for days or weeks, and might also travel for cross countries. Later, they hang out in a refrigerator or cabinet. During this time around, pasteurization guarantees their freshness and also security. Making use of a tunnel pasteurizer is likewise an excellent suggestion if the bundle is fragile. Light weight aluminum cans and glass containers can quickly damage or ruin as a result of abrupt temperature changes.

Passage pasteurizers have an unique design that assists take full advantage of the effectiveness of your production procedure. They improve the ability of the equipment to expand the life of the product. Some tunnel pasteurizers are smart, which means they immediately spot the staying time and also temperature. This helps to avoid re-hashing as well as protects against the reheating of items in awaiting containers. Newer generation passage pasteurizers also feature clever gadget innovations, which determine which decontaminated item requires rehydration and closed down the system without causing it to quit working.

While the Batch Pasteurizer series are not as adaptable as a traditional set pasteurizer, the Tunnel 'n' B is an excellent choice for sterilizing energetic components. With a stainless steel shell and ceramic plates, these systems guarantee also heating and minimize the danger of surface area damages. In addition, the automated sprayer system assists preserve the correct temperature in the item throughout the procedure. The system uses ceramic plates that are made of mini halogen to make the most of the performance of warm as well as decrease the risk of condensation.

A tunnel pasteurizer is a tool that contains numerous zones. Each zone is furnished with drip frying pans and spray nozzles. These nozzles spray water at different temperatures, which warms the item and also cools it. A big section of the tunnel is called a batch pasteurizer. In contrast, a mass pasteurizer contains several areas. Once the warm is used, the tubes of both sorts of devices will generate a vapor that appropriates for a certain kind of liquid.

The Tunnel Pasteurizer has several zones, each with their own spray nozzles and also drip frying pans. The water in these areas is heated up and also vaporized, eliminating any worms or gewurztraminer extract. It is very important to keep in mind that a Passage n'B pasteurizer is not appropriate for all applications. It has to be compatible with the boiler kind being made use of in the production procedure.

The Passage n'B pasteurizer is an equipment that sterilizes food. The Tunnel pasteurizer is split into different areas. Each area is geared up with drip pans and also spray nozzles. Each area has its own temperature array. The resulting water is used to heat up the product. Then, it is cooled down. The process is duplicated until all zones are filled.

Passage n'B is designed to heat an item to a particular temperature level. A set pasteurizer has a lower temperature restriction, however both techniques warm products to 140 degrees. A passage is split into various areas, with spray nozzles on top of each area. In a Tunnel, the water streams through numerous layers of drip frying pans, which cools down the product. The drip frying pans are the cooling system.

They are likewise reputable in beverage manufacturing. Throughout the drying process, a passage pasteurizer can get rid of oils and other bits. While these elements have a high wetness content, a Tunnel can dry them in less than a hr. A tunnel likewise aids in getting rid of the oil that may be present on the elements.

|

|

Why The Batch Pasteurizer Is A Preferred Choice For Numerous Food Markets? |

Дневник |

Created by-Ernst Velling

Batch pasterizers warmth beer, typically a big batch, to a high temperature. The beer is held at this temperature for a predetermined amount of time before relocating via the cooling part of the tunnel. A variety of beers are brewed with this strategy. These sorts of beers may have traces of contaminants, which can harm the customers. Some of the much more popular sorts of beers made with a passage pasteurizer consist of Bell's Pils, Richer's Barley White wine, Draft King, Lost Bridge, Model Beer, Stone chilly brew, Widmer's Bitter American, as well as Widmer's Dry Ales.

The tunnel pasterization procedure can shield a beverage from oxidation and various other dangerous impacts of aging. Oxidation in drinks can impact their taste, aroma, and also shade. It is as a result essential to sterilize top quality drinks to keep their high quality and protect their preference and scent. To secure these drinks from oxidation and temperature changes, suppliers utilize a tunnel pasteurization treatment. For instance, a strong focus of sodium hypochlorite is made use of to eliminate any type of bacteria present in the item.

“WHY TUNNEL PASTEURIZE NEW AND EMERGING BEVERAGES?”

— PRO ENGINEERING (@Daveone1) November 11, 2021

Article Release for Brewmasters & Beverage Makers by Edward A. Michalski, CEO of PRO Engineering / Manufacturing Inc.

Click for full article: https://t.co/H3zoAuOzmN

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/PzgXQuNvRl

A passage pasterizer is an efficient method to protect foodstuff. https://www.foodsafetynews.com/2020/04/data-shows-...steurized-milk-and-infections/ is developed to preserve a regular temperature throughout the production procedure. In doing so, bacteria that might or else trigger food-borne diseases are eliminated. Additionally, the batch pasterization procedure ensures that the item has the ideal taste and temperature. When using a passage pasterizer, your consumers will recognize that your food is fresh and also has the best preference as well as appearance.

tunnel pasterizers kill pathogenic germs without jeopardizing the preference. To attain a sterile outcome, the items need to be bottled cleanly and have a sterilized coding system. It additionally requires to have actually a licensed or validated flash freeze temperature, which is required for risk-free manufacturing. Several other factors add to the efficiency of the batch pasterizer. As soon as you have your drink, you are ready to serve it to your consumers.

It can be personalized to fit your specific requirements as well as make certain premium high quality products. The expense relies on the supplier, the size of the manufacturing process and also the performance degree that you require. For little to midsize operations, a hand-operated compressor with a drum cooling down system is an appropriate alternative. For https://www.dairyfoods.com/articles/94770-conquer-...y-food-and-beverage-processing , a constant feed drum or a pump system are suggested.

tunnel pasterizers are highly reliable in eliminating pathogenic microorganisms. They are easy to mount and have interactive control board for the drivers to alter the settings. The batch pasterizers are additionally extremely cost-effective and are widely made use of in the pharmaceutical sector. You can buy a high quality device for your organization. This type of tools is easy to use as well as will certainly give your company an edge over other business. In addition to killing pathogenic microorganisms, the tunnel pasterizers have numerous benefits, as well as it will certainly keep the products from oxidizing.

As soon as you have a Tunnel pasterizer, you can start the aging procedure. This process begins with red wine being mixed with lactic acid to start the aging procedure. Once the procedure is complete, the bottles are packaged and also delivered. After that, the containers undergo a far more rigorous proofing procedure. This procedure lasts for a couple of days and also will stop the oxidation of the drink. There are a range of advantages to this sort of system, so take into consideration investing in one today.

Relying on the dimension of your production, the price of tunnel pasterizer will certainly vary. The more effective your production line, the a lot more you will reduce operating expense. The longer your tunnel pasterizer runs, the a lot more you'll save. You'll get the most effective results for your money. When you're using this kind of machine, you'll never have to stress over the price. If you're seeking high quality, ensure to invest in a Passage pasterizer.

In spite of the high cost, a Passage pasterizer is the perfect option for any sort of production. This procedure uses an extremely effective sanitation process that is completely automatic. Because there is no blending, no re-cooling or blending, the entire process is quick and simple. Unlike a few other approaches, batch pasterizers do not need any unique skills to run. All you have to do is to select the ideal equipment for your needs.

|

|

Tunnel Pasteurization Tools For Excellent Quality Food And Also Drinks |

Дневник |

Article created by-Stokes Whitaker

Premium, convenient hydrometer approaches are made use of in the hydrometer section of the analysis procedure known as Tunnel pasteurization. Hydrometers are instruments that determine the amount of dissolved material as it goes through various media. Pasteurization, which is the procedure of preparing high-grade hydrometer examples by using certain temperatures, is a complex process that calls for accurate temperature level control and also an ideal solvent to assure desirable high quality items. To satisfy these demands, suppliers have developed sophisticated Tunnel pasteurization systems that consist of all essential elements to satisfy the requirements required by the hydrometer sector.

Packaged beverages can likewise be refined making use of top quality pasteurization tools to improve shelf-life as well as conservation; this is typically referred to as pasteurization (2 ). Water pasteurizers, such as high-pressure spray devices, water circulation rates, and shipment systems, rely on the pasteurizing producer (3 ). https://www.dairyfoods.com/articles/94770-conquer-...y-food-and-beverage-processing utilized in numerous types of research laboratory screening need to be sterilized to avoid the growth of mould or other organisms in the bottle or other product packaging made use of for the item prep work. Liquid solutions, solvents, alcohols, aerosols, fats, and also lots of various other chemicals usually need to go through pasteurization to make certain reliable and top quality results. The hydrometer tools necessary for this procedure have to be developed to sterilize fluids, many frequently water. The process of making high-grade pasteurization products is highly depending on various factors, such as the sort of ingredients utilized in the formula, the final temperature made use of, as well as the performance of the pump made use of to do the process.

A wide array of top quality pasteurization tools is offered to satisfy customer demands. The price of purchasing high-grade pasteurization tools depends on many aspects, including the maker, the dimension of the manufacturing operation, the preferred performance degree of the system, the tools needed, as well as the anticipated final result. For little to mid-sized procedures that do not require a system that can satisfy the demands of a wide array of applications, a hand-operated compressor with different drum cooling systems is the most effective choice. For bigger operations, either a continuous-feed drum or a pump system is needed to meet the demands of the different sorts of analytical and also pre-analytical procedures carried out.

A significant advantage of Tunnel pasteurization is its efficiency in killing pathogenic microorganisms and also giving control of chemical reactions. Many of the research studies performed making use of top quality pasteurization equipment have actually shown the security and also effectiveness of the procedure, particularly for the analysis of antimicrobial drugs. This approach of pasteurization has also shown to be efficient in creating premium taste as well as taste, along with smell control throughout the purification procedure. There is additionally the capacity to accelerate the procedure of phytotherapeutic improvement, which is an important action toward the development of healing treatments for the body.

One more crucial benefit of Tunnel pasteurization is its cost-effectiveness. Because the temperature of the system can be controlled to a precise degree, it is simple to preserve. There are no temperature level cycles during the handling, so there is no loss of top quality. The pasteurizing procedure does not have any type of adverse impact on the final product or on the health and wellness of the final users. Since a lot of top notch pasteurization devices is totally automatic, there is no labor-intensive procedure of blending or re-cooling required.

Tunnel pasteurization offers several advantages over various other kinds of pasteurization. First, it is much more environmentally liable than most methods. It likewise enables the manufacturing of high-quality healthy proteins, enzymes, vitamins, as well as minerals, without use antibiotics or any kind of synthetic chemicals. There are extremely couple of unfavorable impacts on health and wellness while utilizing Tunnel pasteurization, as well as some researches reveal that it may even be better for your health and wellness than alcohol consumption mineral water straight from a springtime.

A last advantage of Tunnel pasteurization tools is that it can save you significant effort and time when doing your very own prep work. You do not need to await a large vat of fluid to warm up in order to use it. This conserves you useful time that you would certainly otherwise spend preparing the other active ingredients in the recipe. If you select to make your own soup from scratch, after that it may take you a number of hours just to heat up the vegetable brew, get the veggies out of the cold store, as well as obtain the soup going. With Tunnel pasteurization, all you need to do is bring it to the proper temperature level.

Producing high-quality soups and also sauces making use of Tunnel pasteurization equipment refers science and art. It can provide complete control over particular attributes, like the thickness of the sauce, whether the flavors will certainly continue after the mix has thickened, and also just how rapidly the soup will remove. It can also regulate the color, taste, deepness, and also structure of the completed product. When producing sauces from the ground up, it would certainly be extremely challenging to accomplish these kinds of effects. It is a matter of ability and also art, nonetheless. Fortunately, this type of high-grade pasteurization equipment can be utilized for the risk-free production of nearly any type of top notch product.

|

|

How The Traditional Method Of Tunnel Pasteurization Utilized By Thermal Distillers? |

Дневник |

Article written by-Goode Lemming

The conventional method of Tunnel pasteurization used by thermal distillers and similar thermal oxidizing units entails using several heat exchangers for the oxidation of chemical reactions. In such a system, 3 or more heat exchanger devices are required for the entire reaction, which calls for a large amount of area. In recent researches, making use of nano innovation, researchers have actually established a novel chemical delivery system that can use nano tubes to atomize particles in solution, producing polar particles with high electrical charges. These polar molecular bits are then delivered to a different chamber where they can undergo electrodialysis reactions to create charged polymer chains.

This innovative thermal oxidizing system, which entails making use of nano tubes, is based upon the Tunnel pasteurization procedure. Conventional thermal dilution of chemical substances generally involves the blending of thin down chemicals in high-pressure containers. Heat energy created during the mixing of these chemicals is moved to the liquid tool, which causes the dissipation of some of the chemicals and the makeover of others into less thick substances. When it comes to pure fluids, the procedure likewise leads to the formation of vapor.