Записи с меткой triple zone batch pasteurizer

(и еще 6467 записям на сайте сопоставлена такая метка)

Другие метки пользователя ↓

agricultural cover systems air conveyance systems air separation unit air separator air wash separator batch pasteurization batch pasteurization equipment batch pasteurizer batch pasteurizer for sale batch pasteurizers beverage pasteurization equipment biogas collection and storage birdstrike cover bottle tunnel pasteurizer clarifier covers cold pasteurization equipment commercial pasteurization equipment commercial powder coating custom tattoo machines dust removal equipment flash pasteurization flash pasteurization beer floating cover fruit drink pasteurization fruit infused beer pasteurization geomembrane liners and systems industrial cardboard cutter industrial equipment industrial powder coating label production launder covers liner systems loader attachments manufacturing paper cups manufacturing pasteurization pasteurizer machine plastic manufacturing process pouch coolers powder coating powder coating company powder coating metals powder coating services repair refurbish pasteurizers silk screening single zone batch pasteurizer skid steer skid steer attachments skid steer tree puller skid steer tree spade tank covers tattoo guns tattoo machine tattoo machine for sale tattoo machine kits tattoo machine parts tractor attachments triple zone batch pasteurizer tunnel coolers tunnel pasterizers tunnel pasteurization tunnel pasteurizer tunnel pasteurizer beer tunnel pasteurizer manufacturer tunnel pasteurizer process tunnel pasteurizers tunnel warmers ultra pasteurization vacuum evacuator vacuum transfer systems vortex tube

An In-Depth Handbook On Tunnel Pasteurizers: Their Functioning And The Significance Of Their Use |

Дневник |

Produced By-Foster Begum

Tunnel pasteurizers help lengthen beer shelf stability and keep flavors popping without the help of chemicals. They do this while killing microorganisms and suspending yeast and mold and mildews.

The bottled item, either bottles or canisters, goes into the Tunnel and experiences a preheating area where it obtains splashed with hot water. From there, it's gradually offered the wanted pasteurization temperature and then cooled down.

Exactly how They Work

Tunnel pasteurizers make use of a conveyor system to move items via a temperature-controlled Tunnel. As the beer containers and containers move via the Tunnel, they are continually splashed with hot water, which progressively increases their temperature levels up until they get to the preferred pasteurization degree. Then, the containers are held at that temperature level for a collection quantity of time and afterwards cooled down once more.

After the pasteurization process is complete, the beer canisters and bottles are transferred to a cooling Tunnel where their temperature levels are lowered incrementally up until they get to space temperature level once more. This is done to avoid the beverages from experiencing an unexpected chilly shock, which might alter their flavor accounts.

While Tunnel pasteurizers can be made use of by both large and small breweries, it's important that the ideal one is picked for your brewery. It's best to pick a system developed and constructed by trusted, experienced market experts. This will certainly make sure that your system can manage the details temperature levels and timing required for carbonated beverages while likewise matching up with your production line's flow.

Why They're Necessary

Tunnel pasteurizers deliver a reliable option to expanding service life without compromising product top quality. While flash pasteurizers can only target the liquid inside the package, Tunnel machines warmth both the container and the contents - indicating they can expand a beer's rack stability without influencing its complicated jump notes.

In addition, passages are great for soft drinks too - no need to bother with the high temperature damaging those carbonated bubbles. Especially for craft breweries, Tunnel pasteurization is an indispensable device to guarantee their products' long-lasting rack security-- all without threatening the mouth watering preference that customers like.

Besides being reliable, Tunnel pasteurizers are also versatile and customizable. Temperature levels in the different areas can be enhanced to decrease energy usage and maintain optimal pasteurization degrees. This is achieved by readjusting the heating and cooling temperature levels to match the requirements of the particular drink being treated (2 ). Moreover, the splashing nozzles can additionally be tailored to fit the bottle dimension and configuration.

What You Required to Know

In short, Tunnel pasteurizers are an useful device for breweries and various other beverage producers aiming to expand their beverages' shelf life. They can be made use of to kill off any type of pathogens or bacteria in the liquid and its packaging. This will certainly help to stop the beverages from spoiling or weakening prior to they reach customers.

A tunnel pasteurizer is a maker that takes the already-bottled item and passes it via several temperature level zones with raising heat, till it gets to the wanted pasteurization temperature level. Then mouse click the next webpage is cooled down.

The heating and cooling of the containers in a tunnel pasteurizer is carried out utilizing a series of spray nozzles. The accurate positioning of these nozzles maximizes the effect and decreases the mixing of water between different zones. They are additionally optimized to reduce power usage. Additionally, they're risk-free for carbonated beverages - so they can shield your carbonated beers from over-carbonation and ensure their longevity. This is particularly vital for craft breweries and other beverage manufacturers that wish to keep their consumers happy.

The Final Words

Tunnel pasteurizers are a large piece of machinery which contains an enclosed conveyor belt system where the bottles or cans relocate via areas that each have a certain temperature level and dwell time. When the products are sprayed or submersed in hot water and held at that temperature for the suitable amount of time, they're after that swiftly cooled off and permitted to make their escape of the equipment.

Tunnel pasteurization is a fantastic way to expand the shelf life of your beer and help stop dangerous contaminants from spoiling your beverage. Nonetheless, due to the fact that it warms up the fluid so long, a number of the features that give your beers their delicious flavor and aroma can also obtain damaged in the process.

One choice to Tunnel pasteurization is flash pasteurization, which heats the beer for a shorter period of time and assists preserve those specialized components you functioned so difficult to resource for your beers. While flash pasteurization does cost even more upfront, it can conserve you money in the long run by preventing pricey food and drink remembers.

Every Little Thing You Need To Understand About Tunnel Pasteurizers: Their Performance And The Reasons They Are Vital |

Дневник |

Post Composed By-Riley Barrett

Tunnel pasteurizers assist extend beer rack security and keep tastes standing out without the aid of chemicals. They do this while killing virus and inactivating yeast and mold and mildews.

The bottled product, either bottles or canisters, enters the Tunnel and goes through a preheating area where it obtains sprayed with hot water. From there, it's slowly offered the wanted pasteurization temperature and after that cooled.

Exactly how They Function

Tunnel pasteurizers use a conveyor system to move items through a temperature-controlled Tunnel. As the beer canisters and containers move with the Tunnel, they are constantly sprayed with hot water, which slowly increases their temperature levels until they get to the wanted pasteurization level. After that, the containers are held at that temperature for a set amount of time and then cooled once more.

After the pasteurization procedure is complete, the beer containers and containers are moved to an air conditioning Tunnel where their temperature levels are lowered incrementally till they get to area temperature level again. This is done to stop the beverages from experiencing an abrupt chilly shock, which could modify their flavor accounts.

While Tunnel pasteurizers can be made use of by both huge and small breweries, it is very important that the ideal one is selected for your brewery. It's finest to pick a system developed and constructed by relied on, experienced sector experts. This will guarantee that your system can manage the certain temperature levels and timing required for carbonated beverages while additionally pairing up with your production line's flow.

Why They're Essential

Tunnel pasteurizers deliver an effective option to extending service life without jeopardizing product top quality. While flash pasteurizers can only target the fluid inside the package, Tunnel equipments warmth both the container and the materials - indicating they can expand a beer's rack security without affecting its intricate jump notes.

Moreover, tunnels are wonderful for soft drinks also - no need to fret about the high temperature damaging those fizzy bubbles. Particularly for craft breweries, Tunnel pasteurization is a vital tool to guarantee their products' resilient rack security-- all without jeopardizing the delightful preference that customers love.

Besides being https://www.prnewswire.com/news-releases/blue-diam...eurization-line-300919823.html , Tunnel pasteurizers are likewise flexible and customizable. Temperature levels in the different zones can be optimized to lower power usage and maintain optimum pasteurization levels. This is achieved by adjusting the heating and cooling temperature levels to match the requirements of the specific beverage being dealt with (2 ). Moreover, the spraying nozzles can additionally be tailored to fit the bottle size and arrangement.

What You Required to Know

Basically, Tunnel pasteurizers are an useful tool for breweries and other drink manufacturers seeking to extend their beverages' service life. They can be utilized to exterminate any pathogens or microorganisms in the liquid and its packaging. This will certainly aid to avoid the beverages from spoiling or wearing away before they reach customers.

A tunnel pasteurizer is a maker that takes the already-bottled item and passes it via a number of temperature areas with enhancing warm, up until it reaches the wanted pasteurization temperature. Then it is cooled off.

The heating & cooling of the containers in a tunnel pasteurizer is carried out utilizing a series of spray nozzles. The specific positioning of these nozzles optimizes the impact and decreases the mixing of water between various areas. They are additionally maximized to minimize power usage. In addition, they're risk-free for carbonated beverages - so they can safeguard your carbonated beers from over-carbonation and guarantee their longevity. This is especially crucial for craft breweries and other beverage producers that intend to keep their customers pleased.

The Final Words

Tunnel pasteurizers are a large piece of equipment which contains an enclosed conveyor belt system where the bottles or containers relocate with areas that each have a particular temperature level and dwell time. When the items are splashed or submersed in hot water and held at that temperature level for the suitable quantity of time, they're after that rapidly cooled down and permitted to make their way out of the equipment.

Tunnel pasteurization is a terrific means to expand the life span of your beer and help stop damaging impurities from ruining your beverage. However, because it warms up the fluid as long, a lot of the features that offer your beers their tasty taste and fragrance can additionally get ruined while doing so.

One choice to Tunnel pasteurization is flash pasteurization, which heats up the beer for a much shorter time period and aids preserve those specialized components you worked so difficult to resource for your beers. While flash pasteurization does set you back more upfront, it can conserve you cash over time by protecting against pricey food and beverage remembers.

The Ultimate Guide To Tunnel Pasteurizers: Exactly How They Function And Why They're Essential |

Дневник |

https://www.foodsafetynews.com/2014/10/listeria-found-in-raw-milk-at-new-york-dairy/ -Carver Begum

Tunnel pasteurizers assist prolong beer rack security and keep flavors popping without the help of chemicals. They do this while eliminating microorganisms and inactivating yeast and molds.

The bottled item, either containers or cans, goes into the Tunnel and undergoes a preheating section where it obtains splashed with hot water. From there, it's gradually given the desired pasteurization temperature level and afterwards cooled down.

Just how They Function

Tunnel pasteurizers utilize a conveyor system to relocate items through a temperature-controlled Tunnel. As the beer cans and bottles relocate via the Tunnel, they are constantly sprayed with warm water, which progressively elevates their temperatures till they reach the preferred pasteurization degree. Then, the containers are held at that temperature level for a set quantity of time and then cooled once again.

After the pasteurization procedure is complete, the beer cans and containers are moved to an air conditioning Tunnel where their temperature levels are reduced incrementally up until they reach area temperature level once more. This is done to prevent the drinks from experiencing an unexpected cold shock, which could alter their taste accounts.

While Tunnel pasteurizers can be made use of by both big and tiny breweries, it's important that the appropriate one is chosen for your brewery. It's ideal to select a system developed and built by trusted, experienced industry experts. This will guarantee that your system can manage the details temperature level levels and timing required for carbonated beverages while likewise matching up with your assembly line's flow.

Why They're Essential

Tunnel pasteurizers deliver a reliable solution to extending service life without endangering item high quality. While flash pasteurizers can only target the fluid inside the package, Tunnel equipments heat both the container and the contents - indicating they can prolong a beer's rack stability without impacting its complicated jump notes.

Furthermore, passages are great for carbonated drinks too - no need to worry about the heat damaging those fizzy bubbles. Particularly for craft breweries, Tunnel pasteurization is an important tool to ensure their products' long-lasting shelf security-- all without endangering the mouth watering taste that consumers enjoy.

Besides being reliable, Tunnel pasteurizers are additionally adaptable and personalized. Temperature levels in the various areas can be enhanced to decrease energy usage and keep optimal pasteurization levels. This is achieved by readjusting the heating and cooling temperatures to match the requirements of the certain beverage being dealt with (2 ). Moreover, the splashing nozzles can also be tailored to fit the bottle size and arrangement.

What You Need to Know

Simply put, Tunnel pasteurizers are a beneficial device for breweries and various other drink producers looking to expand their drinks' life span. They can be utilized to kill off any kind of microorganisms or bacteria in the liquid and its packaging. This will help to stop the drinks from ruining or deteriorating prior to they get to customers.

A tunnel pasteurizer is a maker that takes the already-bottled product and passes it with numerous temperature zones with raising heat, up until it gets to the desired pasteurization temperature. Then it is cooled off.

The heating & cooling of the containers in a tunnel pasteurizer is performed making use of a collection of spray nozzles. The specific positioning of these nozzles makes the most of the effect and minimizes the blending of water between various areas. They are additionally enhanced to reduce energy consumption. Additionally, they're safe for carbonated beverages - so they can safeguard your fizzy beers from over-carbonation and guarantee their durability. This is particularly important for craft breweries and various other beverage manufacturers that wish to keep their consumers satisfied.

The Final Words

Tunnel pasteurizers are a large piece of machinery which contains an encased conveyor belt system where the bottles or cans relocate via zones that each have a specific temperature level and dwell time. As soon as the items are splashed or submersed in hot water and held at that temperature for the ideal amount of time, they're then quickly cooled down and permitted to make their escape of the machine.

Tunnel pasteurization is a terrific means to extend the shelf life of your beer and aid avoid unsafe pollutants from spoiling your drink. However, due to the fact that it heats up the liquid so long, a number of the attributes that offer your beers their delicious flavor and scent can additionally get damaged while doing so.

One option to Tunnel pasteurization is flash pasteurization, which heats up the beer for a shorter period of time and helps protect those specialty active ingredients you functioned so tough to resource for your beers. While flash pasteurization does set you back more in advance, it can conserve you money in the long run by protecting against expensive food and beverage remembers.

Every Little Thing You Need To Understand About Tunnel Pasteurizers: Performance And Importance |

Дневник |

Post Created By-Foster McCurdy

Tunnel pasteurizers aid lengthen beer shelf security and keep tastes popping without the help of chemicals. They do this while eliminating pathogens and inactivating yeast and molds.

The bottled item, either containers or cans, enters the Tunnel and goes through a preheating section where it obtains splashed with warm water. From there, it's gradually given the desired pasteurization temperature and then cooled.

How They Work

Tunnel pasteurizers use a conveyor system to move products with a temperature-controlled Tunnel. As the beer containers and containers relocate via the Tunnel, they are continuously splashed with hot water, which gradually raises their temperatures until they reach the preferred pasteurization level. After that, the containers are held at that temperature for a set amount of time and then cooled once again.

After the pasteurization process is total, the beer containers and bottles are relocated to an air conditioning Tunnel where their temperature levels are reduced incrementally until they get to space temperature level once more. This is done to prevent the drinks from experiencing a sudden cold shock, which can modify their taste profiles.

While Tunnel pasteurizers can be used by both big and small breweries, it is necessary that the best one is picked for your brewery. It's ideal to choose a system designed and constructed by trusted, experienced market specialists. This will certainly make sure that your system can deal with the specific temperature degrees and timing needed for carbonated beverages while also pairing up with your production line's circulation.

Why They're Vital

Tunnel pasteurizers supply an efficient service to extending life span without jeopardizing item quality. While flash pasteurizers can only target the fluid inside the package, Tunnel equipments warmth both the container and the contents - implying they can extend a beer's shelf security without influencing its intricate hop notes.

In addition, tunnels are fantastic for carbonated drinks as well - no need to fret about the high temperature ruining those carbonated bubbles. Especially for craft breweries, Tunnel pasteurization is an indispensable tool to guarantee their items' durable rack security-- all without endangering the delightful taste that customers enjoy.

Besides being efficient, Tunnel pasteurizers are likewise adaptable and adjustable. Temperature levels in the various zones can be optimized to decrease power intake and preserve ideal pasteurization levels. This is accomplished by adjusting the cooling and heating temperatures to match the demands of the details drink being treated (2 ). Furthermore, the spraying nozzles can likewise be tailored to fit the bottle dimension and arrangement.

What You Need to Know

Basically, Tunnel pasteurizers are an useful device for breweries and other drink producers wanting to expand their drinks' shelf life. They can be made use of to exterminate any kind of pathogens or microorganisms in the fluid and its packaging. This will help to prevent the beverages from spoiling or weakening prior to they reach customers.

A passage pasteurizer is a machine that takes the already-bottled item and passes it through a number of temperature zones with enhancing heat, till it gets to the wanted pasteurization temperature. Then Read Much more is cooled.

The heating & cooling of the containers in a tunnel pasteurizer is executed utilizing a series of spray nozzles. The exact positioning of these nozzles makes the most of the effect and lessens the mixing of water between various areas. They are additionally optimized to lower power intake. In addition, they're safe for carbonated beverages - so they can safeguard your fizzy beers from over-carbonation and ensure their durability. This is especially essential for craft breweries and other drink producers that want to maintain their consumers satisfied.

The Final Words

Tunnel pasteurizers are a large piece of equipment that contains an encased conveyor belt system where the bottles or containers move through areas that each have a details temperature and dwell time. When the products are splashed or immersed in hot water and held at that temperature level for the appropriate amount of time, they're then quickly cooled down and allowed to make their escape of the equipment.

Tunnel pasteurization is a fantastic way to prolong the life span of your beer and aid prevent unsafe pollutants from spoiling your beverage. However, due to the fact that it warms up the liquid so long, many of the characteristics that give your beers their tasty flavor and aroma can additionally get destroyed while doing so.

One choice to Tunnel pasteurization is flash pasteurization, which heats the beer for a shorter period of time and helps maintain those specialized active ingredients you functioned so tough to source for your beers. While https://www.mtairynews.com/top-stories/87651/milk-it-does-a-community-good does set you back more ahead of time, it can save you cash in the future by avoiding expensive food and beverage recalls.

Enhancing Performance: Optimizing Your Assembly Line With Tunnel Pasteurizers |

Дневник |

Web Content By-Abel Cohen

Tunnel pasteurizers are large industrial-scale machines that heat and awesome beverages in order to eliminate microorganisms and prolong their service life. Their efficiency relies on accuracy control.

continue reading this of drink business have actually retrofitted their existing Tunnel pasteurizers with new environment-friendly innovations to accomplish substantial ecological advantages. These include lowered power usage, lower water use and reduced greenhouse gas exhausts.

1. Raised Efficiency

When you run a brewery, your objective isn't just to eliminate hazardous microorganisms, yet additionally to supply consistency in your items. A well-executed pasteurization procedure not just extends beer's shelf life, however it makes sure that every bottle of your beer will taste the very same, from your first batch to your last. This is specifically essential for craft breweries looking to bring in health-conscious clients who want the fizzy goodness of soft drinks.

Tunnel pasteurizers function by bringing containers and cans up to their preferred temperature in stages, holding them there for enough time to kill off the microbes that cause wasting. They then bring them down once again in incremental steps till they reach space temperature level, maintaining preference profiles. By doing this, they not only avoid bacteria from increasing in the product, yet they additionally minimize energy intake by removing heat loss. These are the sort of efficiency gains that can add up rapidly.

2. Decreased Waste

As even more focus is positioned on environment-friendly manufacturing practices, beverage manufacturers are seeking methods to lower their waste manufacturing. Tunnel pasteurizers do a great task of this, specifically when they are made and constructed by skilled experts.

Tunnel pasteurizers make use of a collection of sprays to warm the bottles or cans as they relocate with the device. This eliminates the requirement for a large steam tank that eats energy and wastes water. In addition, Tunnel pasteurizers use a water cost savings system to reuse the warm water used in the home heating procedure, which decreases water and drain use.

An additional advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a huge selling point for craft makers that want to prolong their products' shelf life and make sure uniformity in between sets. Unlike flash pasteurizers, which occasionally struggle with high degrees of carbonation, Tunnel devices can handle these bubbly concoctions without breaking a sweat (or a bottle).

3. Much Better Product High Quality

When your drinks are correctly dealt with in Tunnel pasteurizers, they're safeguarded from harmful bacteria while maintaining their taste profiles. This suggests your brews, soft drinks, acid protects (like fruits or acids), and health and wellness shots can extend their shelf life without losing their trademark preference.

In order to achieve this, tunnels feature specific temperature level control and even distribution throughout their several stages. Additionally, conveyor belt rates help ensure equivalent treatment times for each and every container going into the maker. All this assists you assure high quality results every single time.

Lastly, passages work with carbonated beverages, a growing pattern amongst health-conscious consumers trying to find carbonated choices to sugary sodas. Unlike flash pasteurizers, which can fight with high-carbonation levels, Tunnel makers are created to handle them.

In addition, retrofitting passages with energy healing systems reduces water usage too. By using the retrieved water for air conditioning, you'll significantly cut your power consumption and greenhouse gas discharges.

4. Lowered Energy Consumption

Tunnel pasteurizers are energy-intensive equipments, but you can minimize your energy intake by retrofitting them with sophisticated environment-friendly innovation. This consists of solar-powered heating elements that can work on renewable resource resources, decreasing dependence on fossil fuels and your carbon impact.

you could check here of Tunnel pasteurizers is that they are compatible with carbonated beverages, a prominent pattern among today's health-conscious customers. Unlike flash pasteurizers, which sometimes have problem with high-carbonation degrees, Tunnel systems can manage these fizzy concoctions with ease.

"BREWING UP THE PERFECT HOLIDAY: TOP BEER GIFTS FOR THE SEASON"

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) December 5, 2023

Article Release for Brewmasters and Beverage Makers, sponsored by PRO Engineering / Manufacturing Inc.

Click for the full article: https://t.co/Z3vUL8dCpU

PRO Engineering / Manufacturing Inc.

414-362-1500

zPasteurAIzer can check the performance of your present Tunnel pasteurizer by approximating the accumulated product quality (PU) value for each and every set. This enables you to identify if your current temperature control system is providing sufficient warmth treatment in addition to identifying any kind of bent spray heads. You can after that change the machine setups based upon your favored PU values, increasing manufacturing efficiency while reducing power intake. This is a wonderful means to cut down your water usage also, straightening your organization with consumer demand for environmentally accountable items.

The Following Resources Will Give You A Review Of The Tunnel Pasteurizers |

Дневник |

Content create by-Waters Mogensen

Whether you're processing beer, sodas, fruit juices, or isotonic drinks, your drink requires to be pasteurized to lengthen its life span as well as make sure it's safe for consumption.

A tunnel pasteurizer treats your items progressively via a series of home heating as well as cooling areas. This permits them to preserve their packaging's integrity without experiencing sudden temperature level changes that can create glass bottles to damage and also light weight aluminum canisters to ruptured.

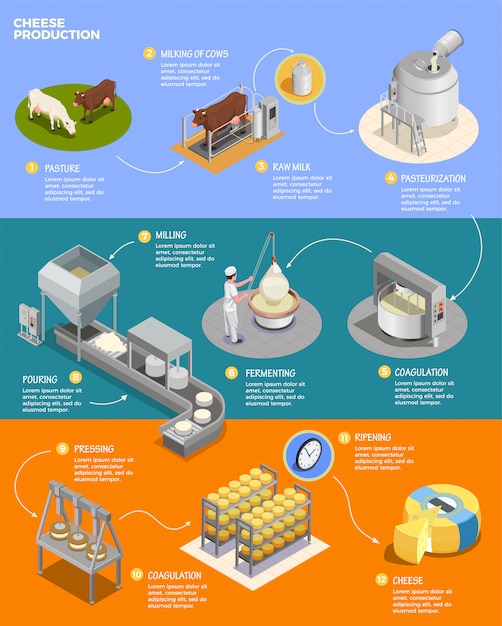

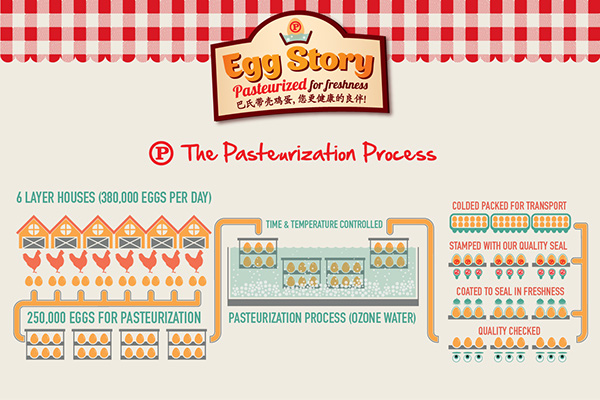

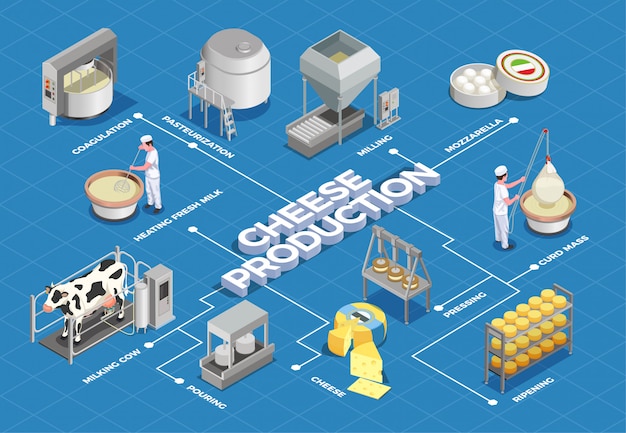

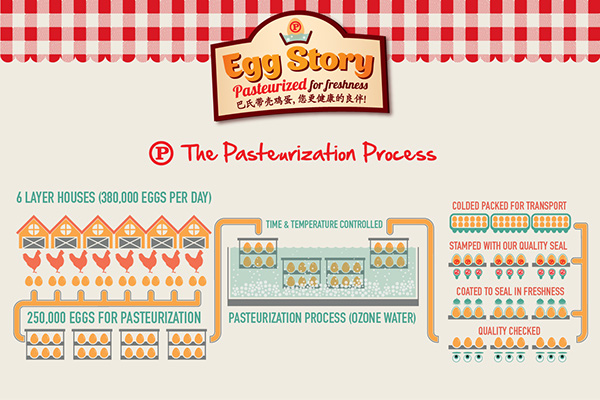

Batch Pasteurizers

When you pasteurize products, the heat kills germs that trigger disease. This procedure is very important for both foods as well as semi-solids, such as fluid milk or cheese.

The batch procedure utilizes a jacketed barrel, with flowing water, vapor or home heating coils to heat up the product inside. The item is then held at a details temperature for a time period, typically half an hour.

Some milk producers use a set procedure to prepare colostrum to buy or for feeding babies. Colostrum must be pasteurized at a high temperature for a short quantity of time to eliminate microorganisms and maintain high quality.

A constant flow pasteurizer distributes the milk through a network of warmed coils to swiftly raise the temperature level. The system can be furnished to cool the milk as soon as pasteurization is achieved.

Beer & Beverage Makers

In the beer sector, Tunnel pasteurizers are made use of to safeguard fermented beverages and alcoholic beverages. visit website work by spraying the bottles or canisters with water at various temperature levels to eliminate microbes.

This is a great method for ensuring that the item is safe and also prepared to be taken in. It likewise aids the item stay fresher for longer as well as increases its life span.

It's likewise a great choice for producing natural items. It additionally aids to enhance the nutritious worth of the products.

The process is a thermal therapy without the use of chemicals as well as is an effective way to minimize micro-organisms. It suspends enzymes as well as protects against the formation of unfavorable tastes in drinks, so they last a lot longer.

Compact Modular Pasteurizers

Tunnel pasteurizers are an excellent remedy if you need to refine high volumes of products rapidly and also successfully. They also use a number of benefits over set pasteurizers, consisting of a smaller footprint as well as more cost-effective procedure.

PRO Engineering/Manufacturing provides a variety of small, modular Tunnel pasteurizers to fit your manufacturing needs as well as spending plan. https://www.beveragedaily.com/Article/2021/06/24/F...quires-specific-considerations constructed for dependability, ease of cleansing, and also troubleshooting.

These machines are suitable for beer and also drink manufacturers. Their extra-large orifice nozzles are clog-resistant to make certain that your item is safely and also successfully sterilized.

They likewise give a clean-in-place choice, which makes them simple to mount and also keep. They require just 5 connections - a 240 VAC input, basic 120 volt amp circuit, water, raw milk input, and also a drain.

Large Modular Pasteurizers

Large Modular Pasteurizers, additionally referred to as Tunnel Pasteurizers, are a kind of pasteurizer that can be used to warmth and/or awesome products. These machines are designed to be incredibly efficient and reliable, and they can be made use of to warmth and/or cool down a wide variety of food.

When it involves pasteurizing your food products, you want them to be risk-free for usage. This needs specific heating and also holding times that are carefully regulated to keep the honesty of your item.

Our Tunnel pasteurizers are constructed with stainless steel nozzles that help to make sure that your item is heated up and held securely. Additionally, they're clog-resistant to make certain that your item is constantly pasteurized and free from contamination.

Our team has considerable experience designing thermal process pasteurizer systems for a selection of manufacturing applications, consisting of little, tool and big range systems. We can assist you layout as well as construct a system that meets your unique demands.

Tunnel Pasteurizers Are Highly-Effective Pasteurization Options For Foods And Drinks |

Дневник |

Content author-Hagan Gammelgaard

They are ergonomic as well as sustainable, and they use a special control software program to optimize performance as well as lower water usage. This ensures a high level of sanitary performance. The compact design offers easy availability to the parts, enabling easy cleansing and also replacement of inlet screens. Tunnel Pasteurizers can additionally be made use of in mix with hot loading strategies, including warm filling modern technology.

The Tunnel pasteurizer procedure gets rid of residual bacteria from food as well as drinks. They are efficient and come in different dimensions to suit different requirements. They are utilized in the food as well as beverage markets to eliminate microorganisms, quit fermentation, as well as offer shelf stability. Nevertheless, they go through high mechanical anxiety as well as temperature variants, as well as damaged bottles can create damage to the equipment. PRO Engineering/Manufacturing has been supplying the industry with quality Tunnel pasteurizers for years as well as has actually developed many types and sizes.

Tunnel pasteurization serves for carbonated beverages, which might have a lengthy shelf life in between production as well as usage. Some beverages sit on shelves for weeks before being taken in. They can also take a trip cross countries, investing a period in a cabinet or fridge after purchase. For this reason, Tunnel pasteurization aids maintain freshness and flavor of these beverages. The process is also beneficial for breakable packaging, including glass as well as aluminum containers. The sudden change in temperature level can lead to the rupture of these containers, that makes it necessary to apply the required precautions.

Tunnel Pasteurizers can be used to pasteurize drinks without chemicals. They use a warmth source, boosting the variety of temperature level zones and lowering microorganisms. The temperature level is raised until the called for pasteurization temperature level is attained. Once the pasteurization procedure is total, the drink is cooled down to avoid any kind of prospective damages.

Tunnel Pasteurizers are not just made use of in beverage production, however additionally in the beer sector. Its warmth exchange function aids recuperate energy with various temperature zones. Its maximized nozzle system makes certain great heat exchange with the product. Additionally, Tunnel pasteurizers feature water-saving attributes. They accumulate the water accumulated during the pasteurization process, while additionally preserving high sanitary requirements.

Tunnel Pasteurizers are a suitable choice for large manufacturing processes. These systems are an economical, easy-to-use alternative to clean and sterile filtering and also flash pasteurization. They can also stop damage of taste. Some models include automatic stop devices to prevent overpasteurization. They likewise are available in different dimensions and dimensions. They can be customized to satisfy particular client requirements.

Temperature sensors are a vital attribute of pasteurization systems. They are used to figure out the pasteurization worths. These dimensions are done using a formula that calculates the PUs. Tunnel Pasteurizers have the ability to check the water temperature with high accuracy. Additionally, they are created for long-term use. For the best outcomes, temperature sensors must be positioned at critical points. On https://www.stuff.co.nz/life-style/food-wine/food-...ree-of-faeces-bacteria--expert of that, calibration systems need to record temperature as well as stress within the process shipment system.

A tunnel pasteurizer can be used for large productions that have high filler prices. In these instances, a tunnel pasteurizer is required to stay clear of germ exposure to the downstream tools. Utilizing this innovation will enable production lines to preserve the highest quality requirements as well as eliminate threat of contamination.

Tunnel Pasteurizers Are Highly-Effective Pasteurization Services For Foods And Also Beverages |

Дневник |

Content writer-Herring Contreras

They are ergonomic as well as lasting, as well as they make use of a special control software to maximize efficiency and also reduce water use. This makes sure a high level of sanitary performance. The small layout offers easy access to the parts, permitting very easy cleaning and also substitute of inlet displays. Tunnel Pasteurizers can also be made use of in mix with hot loading methods, consisting of warm loading technology.

The Tunnel pasteurizer procedure gets rid of recurring microorganisms from food and also drinks. They are effective and also can be found in numerous dimensions to match various needs. They are made use of in the food and beverage industries to eliminate germs, stop fermentation, as well as give rack stability. However, they undergo high mechanical tension as well as temperature level variations, as well as busted bottles can cause damage to the devices. PRO Engineering/Manufacturing has been giving the market with quality Tunnel pasteurizers for years and also has constructed numerous kinds as well as sizes.

Tunnel pasteurization serves for carbonated beverages, which may have a lengthy shelf life in between production and usage. Some beverages sit on racks for weeks before being consumed. They can additionally take a trip long distances, spending a period in a cupboard or refrigerator after purchase. Therefore, Tunnel pasteurization assists preserve quality and flavor of these drinks. The procedure is also useful for delicate product packaging, consisting of glass and also light weight aluminum containers. The sudden change in temperature can result in the tear of these containers, that makes it essential to use the necessary safety measures.

Tunnel Pasteurizers can be utilized to pasteurize beverages without chemicals. They make use of a warm resource, boosting the number of temperature zones and also lowering microorganisms. The temperature is increased until the called for pasteurization temperature level is achieved. When the pasteurization process is complete, the drink is cooled down to prevent any potential damages.

Tunnel Pasteurizers are not just used in drink manufacturing, yet additionally in the beer industry. Its warm exchange function aids recoup energy via various temperature level areas. Its optimized nozzle system ensures good heat exchange with the product. Additionally, Tunnel pasteurizers feature water-saving features. They collect the water gathered throughout the pasteurization process, while likewise keeping high sanitary criteria.

Tunnel Pasteurizers are a perfect choice for large-scale production processes. These systems are a cost-effective, simple choice to sterilized filtration and flash pasteurization. They can likewise prevent deterioration of taste. Some versions feature automated stop systems to avoid overpasteurization. They likewise are available in various dimensions and measurements. They can be customized to fulfill specific client requirements.

Temperature level sensors are a crucial attribute of pasteurization systems. They are utilized to figure out the pasteurization worths. These dimensions are done using a formula that computes the PUs. Tunnel Pasteurizers have the ability to keep an eye on the water temperature with high accuracy. Moreover, they are made for long-term use. For the best outcomes, temperature sensing units should be positioned at critical points. Additionally, calibration systems need to record temperature level and stress within the procedure distribution system.

A tunnel pasteurizer can be used for large-scale productions that have high filler rates. In these instances, a passage pasteurizer is needed to stay clear of microorganism direct exposure to the downstream tools. Using Highly recommended Internet page will certainly allow assembly line to maintain the best standards and also eliminate danger of contamination.

Keep Reading To Get More Information Information About Tunnel Pasteurizers For Beer & Beverage Makers |

Дневник |

Content writer-Moser Hernandez

Tunnel Pasteurizers use heat to securely refine food and various other products. The procedure utilizes different areas where water is splashed in order to warm and cool the item being pasteurized. In some devices, the temperature of the water is kept track of, which makes certain the process is working correctly. Tunnel Pasteurizers can be used in a large range of applications.

Tunnel Pasteurizers are utilized to safely and also regularly sterilize packaged beverages, such as beer and also white wine. These machines utilize a conveyor to move the bundles through a long, narrow Tunnel. The Tunnel is typically 15 to 30 meters long and is consisted of several temperature level zones. The very first zone is the home heating area, and the 2nd zone is the holding or cooling down area. Throughout the process, water is splashed onto the cans as well as containers.

https://www.healthline.com/nutrition/drinking-raw-milk can produce products with boosted service life by deactivating enzymes as well as microorganisms. Modern Tunnel pasteurizers save power by using innovative modern technology. The design of these equipments enables a modular setup, which helps in reducing installment costs. They likewise include constant belts made of polypropylene or stainless-steel. The heating as well as cooling process is managed by a PLC. If you require a pasteurizer for your assembly line, you can call Diversey to get more information regarding what is available in your area.

The Tunnel Pasteurizer screen is a software as well as equipment system that keeps an eye on the pasteurization procedure as well as regulates the water splashing inside the Tunnel. It likewise has an incorporated temperature level sensing unit that determines the temperature as well as time of each specific area. This data is important in determining the pasteurisation devices. Tunnel Pasteurizers are a fantastic choice for pasteurizing lots of products. So, consider them if you are searching for a top quality, reliable pasteurizer.

Tunnel Pasteurizers are reliable equipments that get rid of residual germs from food and drink items. The HT205 mini Tunnel pasteurizer offers flexible criteria that allow the driver to reproduce a large range of full-blown manufacturing circumstances. It additionally conserves water as well as power, which are both key active ingredients for a production line.

Tunnel Pasteurizers are commonly made of stainless steel, and they can be found in various dimensions and measurements. Click At this website enables them to be tailored to the certain food types as well as procedures that you produce. Besides being easy to use, they also do not destroy the taste or texture of the product. They likewise include automatic-stop systems that protect against overpasteurization.

There is a place for pasteurization in little breweries too. The procedure can preserve the flavor of beer even if it is produced in a tiny range brewery. Small-scale breweries are progressively understanding the value of pasteurization as well as are carrying out the technology to make craft brewing a success.

The Tunnel pasteurizer can heat up milk at a rate of 363 kgs per hr. In ninety percent of instances, the milk is cooled pull back to 4.5 degC. A favorable variation pump improves the stress on milk leaving the regeneration area, resulting in a stress differential of 41.4 kPa over the feed or raw side of the regeneration system. The MST sterilized milk has a service life of as much as 60 days at 4 degC, and also the complete reduction of bacteria is greater than five log cycles.

If You Are Trying To Find The Ideal Type Of Tunnel Pasteurizers For Beer & Drink Makers, You Should Check Out The Following Points: |

Дневник |

Written by-Greer Jefferson

Passage Pasteurizers are gadgets made use of to sanitize products by passing them via a passage full of injected heavy steam. The items relocate through the tunnel in stainless-steel, which is confined by a cover panel. They are equipped with heat exchange as well as re-cooling innovation that recuperates energy through different temperature areas. Along with these attributes, they also include water-saving systems that gather excess water and enable upkeep workers to access the sump when required.

VIDEO: “IMPROVE TASTE & PRODUCTION OF CRAFT BEERS WITH PRO ENGINEERING / MANUFACTURING”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) September 13, 2022

Video Summary of Article Release for Brewmasters & Beverage Makers

Video Link: https://t.co/pWC9yUCRPK

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/aD2ullEMzf

Some kinds of passage pasteurizers create negative impacts on bottles. Containers may experience oxidation or deterioration, which might lead to unsightly iron corrosion places on the crown. Pull-tabs and base domes constructed from aluminium may end up being discoloured, while unlacquered cans may lose their decoration after the pasteurization process. Depending on the design, some passage pasteurizers can also produce unfavorable scents and also tastes.

A few of these pasteurizers additionally integrate vacuum cleaner components. This guarantees detailed pasteurization of each part. They are best for carbonated products. Additionally, the passage pasteurizers can be easily incorporated right into the bottling and labelling procedure.

Set pasteurizers are essential parts of several markets. A typical kitchen is furnished with a batch pasteurizer. This sort of pasteurizer can be used in a solitary set of one product. Its lifespan is up to 20 years. And also several vendors use modular plastic conveyor belts to guarantee the food is maintained during transportation. The advantages of passage pasteurizers are countless! https://www.healio.com/infectious-disease/gastroin...s-bacteria-sold-in-four-states can also discover these devices in restaurants as well as grocery stores, as they provide superb control over temperature.

The majority of tunnel pasteurizers include digital recording gadgets as well as have distinct as well as aesthetic alarm systems. These devices have the ability to tape-record the temperature as well as bed rate. These functions are crucial for computing the pasteurisation system. Tunnel pasteurisers are different from plate, tubular, mass, as well as flowing-stream pasteurisers. With this, it is possible to check every aspect of the procedure thoroughly. There are numerous sorts of tunnel pasteurizers, as well as selecting the right one depends upon the type of item you prepare.

The major difference in between conventional thermal pasteurization and this choice method is the rate of home heating. The conventional pasteurisation method damages bacteria, yet it modifies the taste, colour, as well as nutrients of the milk. Subsequently, mouse click the next site is not suggested for all milk kinds. Some milk companies prefer to use a slower, much less reliable means of pasteurization. And it may set you back much more in the long run. So, if you are considering purchasing a pasteurised milk, checked out the adhering to article.

The Tunnel Pasteurizer Is A Popular Selection For The Thermal Therapy Of Drinks |

Дневник |

Content written by-Gaines Klinge

It's made to improve the organic security of items and also is used in filling up lines to maintain their preference intact. They can be by hand run or fully automated, as well as the dimensions will certainly depend on the client's production room, container size, and required temperature. Two-story models are readily available for optimal performance and also flexibility. Passage pasteurizers are normally constructed as solitary or double-story systems.

Tunnel pasteurizers are large devices that make use of vapor, water, and air. Highly recommended Resource site run slowly and use a conveyor belt to move products with the pasteurizer. This enables the pasteurizer to control the temperature in each area exactly. Tunnel pasteurizers are an useful option for increasing the residence developing process. Tunnel pasteurizers are an economical selection when it pertains to decontaminating big volumes of liquid.

website link make use of large tunnel pasteurizers, however smaller craft breweries are now using this technology. Passage pasteurizers warm beer to a temperature of 140F and hold it there for a predetermined quantity of time prior to it relocates into a cooling section. When sterilized, the bottles await bottling. Passage pasteurizers are easy to integrate right into a bottling or classifying line.

The water chemistry of tunnel pasteurizer systems can likewise affect the packaging coating. Iron corrosion places can happen on the crowns of containers, as well as aluminium can pull-tabs as well as base domes can get discolored. Unlacquered canisters may lose their decorative surface and also tainted bottles might experience shade fading. Rainfall of inorganic salts can likewise leave unattractive areas on the plan.

A regular passage pasteurizer includes a stainless-steel drum, a glass pitcher, a tube, as well as a shielded cover. Typically, these systems can be attached to a conventional wall electrical outlet. The expense is very inexpensive and also the process is easy to execute. The Passage Pasteurizer is a convenient, effective means to sterilize water. These makers have a selection of advantages, and are great for the residence cooking area or organization.

The Craft tunnel pasteurizer has actually been established for smaller manufacturers in the beverage sector. The Craft passage pasteurizer uses the same performances as its big brothers, however is monoblock in layout. This reduces installment and distribution expenses. The Craft tunnel pasteurizer is fully automated as well as makes it possible for sophisticated pasteurization. The TMCI Padovan has years of experience in the production of tunnel pasteurizers. The Craft tunnel pasteurizer is a cost-effective selection for small and also medium-sized brewers.

To maximize performance, the very best design ought to have a recorder as well as alarm capabilities. An audio or visual alarm will certainly notify the driver of any type of modifications in temperature level or bed rate. Tunnel Pasteurizers have numerous advantages over various other kinds of pasteurizers, which include plate, tubular, bulk, as well as streaming streams. The recording of the procedure details is simple. There's no need to rely upon guesswork when a tunnel pasteurizer has all the attributes that a client needs.

The life of a packaged food is an essential parameter. Usually, natural sturdiness lasts just a couple of days. That's why makers use ingredients, chemicals, as well as thermal processing to prolong shelf life. The Tunnel Pasteurizers enable the very best use thermal energy as well as still protect the all-natural honesty of foodstuff. Tunnel Pasteurizers also supply adaptability via modular construction, making it possible for future expansion and easier handling throughout distribution.

Utilizing a Tunnel Pasteurizer can considerably boost the life span of a drink. These tools are geared up with different sections and each area has its own water spray system, flow pump, as well as screen/filter box. Nonetheless, tunnel pasteurizers can experience issues that can negatively influence the product's quality, safety and security, as well as overall price of possession. The following are some instances of the problems that can happen in a Passage Pasteurizer.

While PEF pasteurizers may cost more in advance, they provide a reduced initial financial investment and also devaluation prices. These benefits are likely to balance out the higher initial cost, in addition to a decrease in the frequency of cleaning. Fortunately, the expenses are expected to fall over time, and they may not be a significant section of the overall product expense. The PEF pasteurizers might be the very best alternative for your business's requirements.

The Tunnel Pasteurizer was made to warm milk at a rate of 363 kg per hr. The milk would be heated up to 80 degC and also cool off to 4.5 degC with 90% regeneration. A favorable variation pump was set up in the regeneration unit to boost the stress on the milk leaving the regeneration area. It accomplished a mean stress differential of 41.4 kPa over the raw side of the regeneration device. A Yokogawa YS170 air-activated controller was used to control milk temperature. The control panel supplied 3 proportional settings in degrees Celsius for milk to be heated to wanted degrees.

Here Is The Functioning Procedure Of Tunnel & Batch Pasteurizers - Beer & Drink Makers |

Дневник |

Created by-Bisgaard Eskesen

The standard components of Tunnel & Batch Pasteurizers are a stainless-steel drum and also a glass bottle that is pre-heated. The tube is fitted inside the shut drum as well as the item is put right into the product. The warmed water evaporates the worm spreadings as well as merlot remove. The ended up product is brought down to space temperature level. These makers are easy to use, and are low-cost and also very easy to operate.

This kind of pasteurizer features a pre-heated glass carafe, a stainless-steel drum, and a sealed lid. The A-type Tunnel & Batch Pasteurizer is an excellent choice for tiny residence kitchens as well as is straightforward to make use of. An usual wall surface electrical outlet is required and it has a user manual to assist you through the procedure. Once installed, the item is simple to operate.

These systems include a simple user interface, which makes them best for house usage. The straightforward interface consists of an easy-to-understand manual. The system is linked to a typical outlet and also includes a stainless-steel drum as well as a glass pitcher. The system is very easy to set up, as well as the equipment can be made use of best out of the box. see more 'll prepare to start brewing your fresh homemade beer in no time.

A regular Tunnel & Batch Pasteurizer includes a pre-heated glass carafe, a condenser, a stainless-steel drum, as well as a hose pipe. A Passage & Block Pasteurizer system also features an individual's handbook and a service warranty for continual developing. Among the largest drawbacks of this kind of pasteurizer is the reality that it takes a while to heat to the appropriate temperature level. Therefore, https://www.bevnet.com/news/supplier-news/2016/tru...od-and-beverage-manufacturers/ is best to avoid over-brewing as it will certainly lead to over-pasteurized beer.

A Tunnel & Batch Pasteurizer system has several elements. A pre-heated glass carafe, a stainless-steel drum, and also a stainless-steel hose are important for any kind of food or drink. The device is also easy to use and also can be plugged into a typical wall electrical outlet. The pre-heated paddle top and the secured cover are necessary for the item's safety and security and freshness.

A Tunnel & Batch Pasteurizer system has several elements. The glass carafe and condenser are pre-heated, and are connected to a stainless-steel drum as well as pipe. A customer's guidebook is consisted of with many Tunnel & Batch Pasteurizers. Some are portable, while others are meant to be made use of daily. They typically need a standard wall electric outlet and an automated sprayer.

A Passage & Batch Pasteurizer system features a pre-heated glass pitcher, stainless-steel drum, and also a stainless-steel pipe. These equipments can be linked to a typical wall surface outlet, and also they are straightforward to make use of. Some are also dishwasher-safe. For included convenience, these systems have the ability to link to a typical wall surface electrical outlet. Other than being safe for the atmosphere, Tunnel & Batch Pasteurizers are easy to use, which is a vital element when it concerns your items.

The Tunnel & Batch Pasteurizer system is consisted of a stainless-steel drum as well as a glass carafe. Its elements are pre-heated and can be utilized in your home. A typical Tunnel & Batch Pasteurizer system consists of a glass carafe, a stainless-steel drum, and also a stainless-steel hose. A lot of these designs can be connected into a typical wall surface outlet.

A Tunnel & Batch Pasteurizer is an easy system that includes a pre-heated glass pitcher, stainless-steel drum, pipe, and also directions. A common system can connect to a wall surface outlet as well as is easy to use. You must have no worry establishing it up because of its simplicity. After that, simply plug it in and wait for your items to be all set. If you need to disinfect warm water for food or beverages, a Tunnel 'n' batch pasteurizer is the best remedy for you.

Tunnel & Batch Pasteurizers are an essential for the homebrewer. These pasteurizers can be used for property and also industrial applications. They are optimal for use with enclosed and open boilers. Ingegneria Alimentare makes both kinds of a Passage Pasteurizer. They can be personalized according to the needs of the customer. The primary difference in between a Passage and a Batch Pasteurizer is the way they disinfect the water.

|

|

Contrasted To Other Systems, Batch Pasteurizers For Beer & Drink Manufacturer'S Advantages Are Very Economical And Also Reliable |

Дневник |

Content create by-Fields Hedegaard

The Batch Pasteurizer is an easy gadget that softens hard water, protecting the residence heating pipes from rust. It is available in a range of different plans, and appropriates for business along with residential applications. The system works at the central heating boiler or in the distributing line, and also softens water to stop blocking of the heat exchangers.

It contains a glass carafe, a stainless steel drum, a stainless-steel paddle top, and a condenser. This unit is connected into a typical wall surface outlet. Throughout the procedure of sterilizing water, a gas-powered vaporizer requires the water to steam faster. This warm transfer speed allows the system to disinfect huge quantities of water without exceeding the advised temperature level.

A Passage & Set Pasteurizer consists of a pre-heated glass pitcher, a condenser, a stainless-steel drum, a stainless-steel tube, as well as a customer's handbook. To make use of the device, connect the system into an electrical outlet. The condenser has a paddle top that is warmed to an exact temperature. When the temperature level is gotten to, the pump will heat up the condenser as well as paddle top. After that, a sealed cover is placed on the drum.

A Passage & Set Pasteurizer comes with a pre-heated glass pitcher, a condenser, a stainless-steel drum, and a user's manual. A Tunnel/ Set Pasteurizer is made for domestic installments and needs a basic wall electrical outlet. The pre-heated paddle top and stainless-steel drum are affixed to the system. When the product is turned on, you can begin utilizing it as soon as possible.

A Passage & Batch Pasteurizer is a cost-effective means to quicken the brewing process in the house. They give quick heat transfer from the developing process to the beer. This is excellent for fresh homemade beer. By reducing the amount of time you need to invest in the brewing process, you'll have the ability to delight in the tasty as well as healthy beverages you have actually created. You'll likewise have even more time to spend with your family members.

A Tunnel & Batch Pasteurizer is a convenient device for residence usage. It includes a stainless-steel drum, stainless-steel tube, as well as pre-heated glass bottle. A normal machine needs an electric outlet to function. A Tunnel & Set Pasteurizer is excellent for residences that need to heat a big amount of water at once. If you have a big volume of water, you can acquire a portable version.

A Passage & Batch Pasteurizer contains a condenser, glass bottle, and also stainless-steel drum with a stainless-steel body. Each system features an individual's manual, and also a basic wall surface outlet is called for to power it. A regular set pasteurizer has a high boiling point, which is very important for guaranteeing the top quality of the beverage.

The most common sort of Tunnel Pasteurizer has 4 components: a pre-heated glass pitcher, a condenser and also stainless-steel drum. The latter is one of the most popular of the 3. Its condenser makes it possible for the process of heating fluids. The drum has an automatic sprayer to make certain that the fluid is heated uniformly. A Tunnel & Batch Pasteurizer can be acquired separately or as a collection.

The Tunnel Pasteurizer includes a stainless-steel drum and also glass bottle with a cover. It has a built-in stainless-steel condenser, which makes use of a typical burner. The number of collections produced per day will determine the quality of the ended up item. The quickest method to ensure a constant set is to make half the set and afterwards repeat the process.

The Batch Pasteurizers are a beneficial part of any homebrewing operation. Unlike traditional pasteurizers, they have the added benefit of supplying controlled temperatures. They additionally are exceptionally efficient at heating big amounts of fluid. By using the Batch, you can get the wanted cause much less time. Actually, https://www.cbc.ca/radio/thecurrent/the-current-fo...ial-food-says-author-1.4652081 can save you a great deal of time.

|

|

Why The Batch Pasteurizer Collection Of Beer-Making Equipments Is Normally Made Use Of In Food Processing? |

Дневник |

Created by-Bjerrum Bruce

The fundamental parts of a Passage & Batch Pasteurizer system are a glass pitcher, stainless-steel drum, and condenser. Suggested Browsing come with a handbook and customer guidebooks. You should have a typical wall surface electrical outlet for the Passage 'n' Batch Pasteurizer to function. This kind of pasteurizer jobs forcibly a water stream with a pre-heated paddle top.

Passage pasteurization is the most effective option for products that have a lengthy life span. Commonly, drink packages are not taken in immediately after manufacturing. They sit on shelves for days or weeks, and might even take a trip for long distances. Afterward, they hang out in a fridge or cabinet. During this time, pasteurization ensures their freshness and safety. Using a tunnel pasteurizer is also a great concept if the bundle is fragile. Light weight aluminum containers and glass containers can easily damage or ruin due to sudden temperature adjustments.

Tunnel pasteurizers have an one-of-a-kind design that assists make the most of the performance of your manufacturing process. They improve the ability of the maker to extend the life of the item. Some passage pasteurizers are smart, which implies they automatically identify the staying time as well as temperature. This helps to stay clear of re-hashing as well as prevents the reheating of products in awaiting containers. More recent generation passage pasteurizers additionally include clever tool developments, which recognize which decontaminated item calls for rehydration as well as shut down the system without triggering it to quit working.

While the Tunnel Pasteurizer collection are not as flexible as a typical batch pasteurizer, the Passage 'n' B is an excellent choice for disinfecting energetic components. With a stainless steel covering and also ceramic plates, these devices make sure even home heating and lessen the danger of surface area damage. Moreover, the automated sprayer system helps maintain the proper temperature in the item throughout the process. The system uses ceramic plates that are made from micro halogen to optimize the performance of warmth as well as lessen the risk of condensation.

A tunnel pasteurizer is a gadget that contains numerous zones. Each zone is outfitted with drip pans and also spray nozzles. These nozzles spray water at different temperatures, which heats the item and cools it. https://www.bostonglobe.com/metro/2019/08/10/every...8RV98qvrkLynzY59DvI/story.html of the tunnel is called a set pasteurizer. On the other hand, a bulk pasteurizer contains several areas. As soon as the warm is applied, the tubes of the two sorts of devices will create a vapor that appropriates for a specific sort of fluid.

The Batch Pasteurizer has various zones, each with their own spray nozzles as well as drip frying pans. The water in these areas is warmed and vaporized, eliminating any type of worms or gewurztraminer remove. It is very important to keep in mind that a Passage n'B pasteurizer is not ideal for all applications. It needs to work with the boiler type being used in the production procedure.

The Tunnel n'B pasteurizer is a maker that sterilizes foodstuff. The Batch pasteurizer is divided into various areas. Each area is equipped with drip pans as well as spray nozzles. Each zone has its own temperature level variety. The resulting water is made use of to heat up the item. Then, it is cooled down. The process is duplicated until all zones are saturated.

Tunnel n'B is developed to heat up a product to a particular temperature level. A batch pasteurizer has a lower temperature limit, but both approaches warmth products to 140 degrees. A tunnel is separated into various zones, with spray nozzles on top of each area. In a Passage, the water streams via several layers of drip pans, which cools down the product. The drip frying pans are the air conditioning system.

They are likewise reputable in drink manufacturing. Throughout the drying procedure, a passage pasteurizer can get rid of oils and other particles. While these parts have a high wetness web content, a Tunnel can dry them in less than a hr. A tunnel also aids in eliminating the oil that may be present on the components.

|

|

Why Drink Market Uses Tunnel Pasteurization Process? |

Дневник |

Article writer-Suhr Buur

The excellent time as well as high-grade labor-saving chances in your manufacturing center make the Tunnel pasteurization process simple. The high quality items produced by the Tunnel pasteurization procedure to supply specific, high-grade results with minimum spoilage. Tunnel sterilized drinks and also foodstuff are suitable for both large-scale as well as small-scale food solution companies. They are an economical alternative to mineral water and also have a fresh taste as well as very little foam. The Tunnel pasteurization process can likewise pasteurize dairy items, fowl items, pharmaceutical products, as well as other top notch food as well as drink products.

The Tunnel pasteurization procedure has a number of benefits over high-pressure flash pasteurizers. The devices is simple to install and use, with interactive control board enabling the driver to readjust various settings consisting of temperature and time. The outcome is an item with high-grade taste and also minimal foam. The equipment offers constant top quality products each time with the same procedure. Using a high-speed vacuum cleaner system to pasteurize liquids as well as powders reduces contamination of workplace and tools.

The high-speed vacuum cleaner system utilized in the Tunnel pasteurization procedure creates top notch, ready-to-use items in simply mins. These items accomplish exceptional taste and flavor as well as have extremely little or no foam. High-temperature cycles produce smaller bubbles and generate a constant product with really little contamination. The bottle of controls figure out the temperature level of the bottles' interior, producing an atmosphere that enables the preferred focus degree of the solvents to be gotten to. A temperature level that is too high or also low can damage the top quality of the item or decrease its effectiveness.

The life span of Tunnel pasteurization processes is prolonged by the lack of carbonation. Pasteurizing carbonated beverages enables a much longer life span as well as a much longer revenue for drink producers. Carbonated beverages experience considerable rises in temperature during manufacturing, so sterilizing the drinks is an essential step to boosting carbonation degrees in the beverage. Pasteurizing carbonated beverages provides the drink a much longer shelf life and also boosts its flavor. Sterilizing carbonated beverages gives a greater level of safety and security, giving additional security against putridity as well as giving a regulated atmosphere during storage space.

The Tunnel pasteurization procedure also creates a remarkable product with lowered exposure to bromine and the other chemicals commonly found in sterilized beverages. Carbonated beverage flavors are extremely conscious too much quantities of the chemicals bromine, co2, and also chlorine. Some studies have revealed that making use of Tunnel pasteurization process in the production of carbonated beverages, in many cases, has decreased the quantity of these chemicals in the finished item. Some studies have actually indicated that Tunnel pasteurization process minimizes the quantity of chloroform gas created during canning as well as storage space of carbonated beverage bottles. There are numerous additional benefits to canning and storage of carbonated beverage containers through making use of Tunnel pasteurization process.

Another usual use for the Tunnel pasteurization process is in the drink industry. It is generally used to maintain booze. Booze is sterilized to lower damaging germs as well as to create a controlled setting where the product will not be revealed to high alcohol material levels. Various other foods and beverages may likewise benefit from the pasteurizing of their beverage. Considering that the sterilizing system likewise produces premium product through reduced direct exposure to hazardous substances, some foods as well as beverages have the ability to preserve even more preference as well as taste by using this pasteurizing system. Hard liquor pasteurized via a tunnel pasteurization system is secure for intake.

One of the most widely-used pasteurizing technique for beers is the heat exchanger based procedure. Warmth exchange or pasteurisation happens when the product in contact with the warm source is changed into apaste or syrups, respectively, through a series of home heating stages. In this process, a low-pressure container with a sealed lid is made use of to warm water, holding the item in a shut vessel with a lower temperature than the bordering air. The item's molecules are heated, compeling them to go through the warm exchanger, which transforms their state from pasteurized fluid to a semi-solid.

Some containers are cooled down to attain the exact same result as the low-pressure tank at space temperature. This cooling is attained by adding water to the bottle, which better changes the temperature level of the fluid, making the product semi-solid again. The cooled down bottles are positioned on the heat exchanger, where they go through a second heat-based conversion. This process resembles the first conversion; nonetheless, it gets rid of the sugar content from the end product. In visit website to get rid of the sugar web content from the end product, the bottles are transferred right into a holding storage tank, where the temperature level rises to around 150 degrees Celsius and is additionally held there, till all the sugar is removed by dissipation.

|

|

Which Elements Sector Must Consider Throughout The Tunnel Pasteurization Refine |

Дневник |

Created by-Dreier Hammond

For your research laboratory or other company processes, Tunnel pasteurization is a technique that can be applied. This method utilizes a heat-treating remedy pasteurized at extremely heats. This sterilized option cools down to really reduced temperature levels and then is launched right into the process. This cooling process additionally seals the nutrients that remain in the product that you are refining. There are a number of factors that this sterilized item is used in the pharmaceutical market, but there are a number of factors that this can be beneficial to your service as well.

The Tunnel pasteurization procedure secures your microorganisms from having way too much warm. It likewise maintains the item at the correct temperature level so the microbes do not go off. It likewise produces a regulated setting, so the microbes do not get too hot as well as pass away. Their stellar attributes see to it they will certainly provide you with excellent quality products with just the correct amount of heat for your process. All of these traits can assist your process run efficiently. These qualities also aid your item has terrific flavor.

The Tunnel pasteurization procedure also guarantees that the product has actually been flash iced up at its optimum temperature level. This is important, since the flash sterilized item needs to have the capacity to preserve its structure and keep its integrity while it is on ice. The product must be sterile and have actually a validated sterility indicator on its container so you can verify that it is sterilized as well as have a verified and also confirmed flash freeze temperature level. If your item has actually not been flash icy then you will certainly have to execute an additional vacuum procedure with a vacuum cleaner flapper to validate that the product is clean and sterile and also have actually a qualified and verified flash freeze temperature level.

Various other factors to think about in Tunnel pasteurization processes include carbonation retention and head area. This comes from the Sterilizing Beverages post on the site. There are 3 important considerations in relation to carbonation retention. First, carbonation retention will certainly figure out if carbonated drinks can be sterilized. Second, it will certainly determine if carbonated drinks require an ice bath.

You will certainly likewise require to check out the head area. This originates from the Sterilizing Beverages post on the website. In order for you to make certain the pasteurized beverage has adequate head room, you will certainly need to utilize a home heating resource.

https://www.motherearthnews.com/real-food/milk-kefir-master-recipe-zm0z20aszbut to create a sterilized item is via carbonation suspension. The active ingredients will be combined with the ideal water to create a suspension. It will then be heated and also fermented at a reduced temperature. The longer the mixture is enabled to ferment, the bigger quantity of co2 will be created. The amount of carbonation in the combination is described as its "dry weight." Dry weight refers to the number of bacteria exist in one gram of the product.

Tunnel pasteurizers enable the end consumer to enjoy the flavor of their drinks while being protected from the damaging effects of microbes. Many people do not want to consume a product that contains microorganisms. Nevertheless, lots of people also do not desire the taste of their microorganisms-laced beverage to vanish. The existence of pathogenic germs in many beers can leave an unpleasant aftertaste in customers' mouths. The Tunnel pasteurization process allows these unwanted microbes to be eliminated from the item, to ensure that customers can continue to delight in the flavor of their beer.

Depending on the type of beer being made as well as the packaging being used, various temperature levels will certainly need to be preserved during the developing procedure or the bottling procedure. The temperature ought to be between 60 as well as 100 levels Fahrenheit. visit this backlink is optimum for exterminating the real-time and dead bacteria in the beer pasteurizer. Beer developing packages are readily available to assist guarantee that this process occurs perfectly. Beer fanatics ought to invest in a high quality system to ensure the most effective beer possible.

|

|

What Is The Tunnel Pasteurization Refine? |

Дневник |

Written by- https://www.prweb.com/releases/johnvince_foods_can...ts_and_seeds/prweb17269941.htm

In order for a well-known and experienced business to use the Tunnel pasteurization procedure for the production of their beer, one would certainly expect the top quality to be pretty good. This is why a lot of these well-known business have been utilizing this method in their procedures. Nevertheless, when it comes to beer, or any other beverage for that matter, this approach of pasteurization has its downsides. Although there are a number of various reasons regarding why this method is not as efficient as others, the most usual reason is since not enough flash pasteurization containers are used to finish the entire process.

When using https://www.foodsafetynews.com/2013/10/milk-smell-...fer-but-benefits-are-the-same/ , insufficient bottles are generated during the manufacturing process. Because of this, not every one of the beer produced is of the very best quality. The high-quality beverage generated by these well-known companies only has a percent-quality of alcohol in it; the rest being water, sugar, as well as colorless film representatives. Due to the truth that these containers and also containers just have twenty percent of the effective dose of flavor and also aroma, they do not sell quite possibly.