Записи с меткой pasteurization

(и еще 9573 записям на сайте сопоставлена такая метка)

Другие метки пользователя ↓

agricultural cover systems air conveyance systems air separation unit air separator air wash separator batch pasteurization batch pasteurization equipment batch pasteurizer batch pasteurizer for sale batch pasteurizers beverage pasteurization equipment biogas collection and storage birdstrike cover bottle tunnel pasteurizer clarifier covers cold pasteurization equipment commercial pasteurization equipment commercial powder coating custom tattoo machines dust removal equipment flash pasteurization flash pasteurization beer floating cover fruit drink pasteurization fruit infused beer pasteurization geomembrane liners and systems industrial cardboard cutter industrial equipment industrial powder coating label production launder covers liner systems loader attachments manufacturing paper cups manufacturing pasteurization pasteurizer machine plastic manufacturing process pouch coolers powder coating powder coating company powder coating metals powder coating services repair refurbish pasteurizers silk screening single zone batch pasteurizer skid steer skid steer attachments skid steer tree puller skid steer tree spade tank covers tattoo guns tattoo machine tattoo machine for sale tattoo machine kits tattoo machine parts tractor attachments triple zone batch pasteurizer tunnel coolers tunnel pasterizers tunnel pasteurization tunnel pasteurizer tunnel pasteurizer beer tunnel pasteurizer manufacturer tunnel pasteurizer process tunnel pasteurizers tunnel warmers ultra pasteurization vacuum evacuator vacuum transfer systems vortex tube

Tunnel Pasteurizers Are Highly-Effective Pasteurization Services For Foods And Also Beverages |

Дневник |

Content writer-Herring Contreras

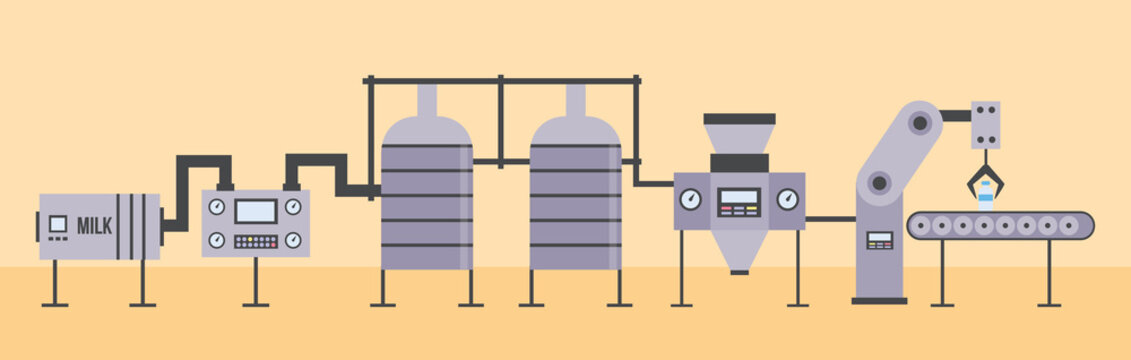

They are ergonomic as well as lasting, as well as they make use of a special control software to maximize efficiency and also reduce water use. This makes sure a high level of sanitary performance. The small layout offers easy access to the parts, permitting very easy cleaning and also substitute of inlet displays. Tunnel Pasteurizers can also be made use of in mix with hot loading methods, consisting of warm loading technology.

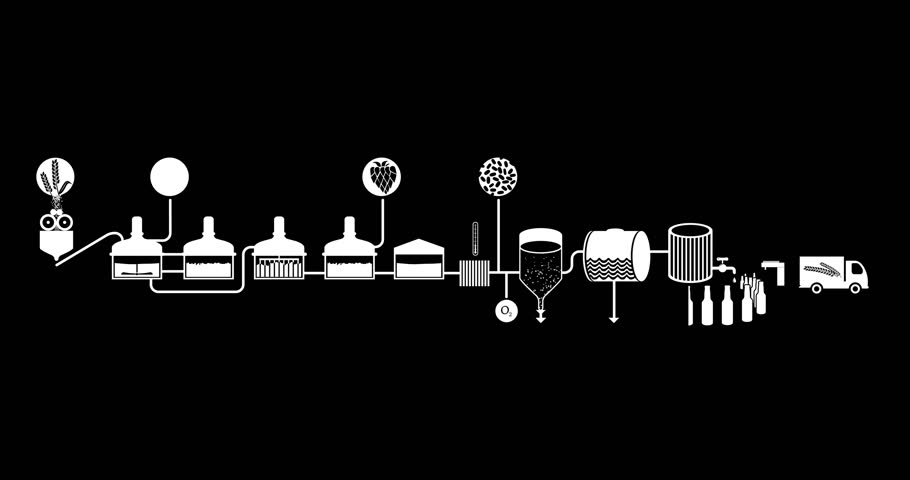

The Tunnel pasteurizer procedure gets rid of recurring microorganisms from food and also drinks. They are effective and also can be found in numerous dimensions to match various needs. They are made use of in the food and beverage industries to eliminate germs, stop fermentation, as well as give rack stability. However, they undergo high mechanical tension as well as temperature level variations, as well as busted bottles can cause damage to the devices. PRO Engineering/Manufacturing has been giving the market with quality Tunnel pasteurizers for years and also has constructed numerous kinds as well as sizes.

Tunnel pasteurization serves for carbonated beverages, which may have a lengthy shelf life in between production and usage. Some beverages sit on racks for weeks before being consumed. They can additionally take a trip long distances, spending a period in a cupboard or refrigerator after purchase. Therefore, Tunnel pasteurization assists preserve quality and flavor of these drinks. The procedure is also useful for delicate product packaging, consisting of glass and also light weight aluminum containers. The sudden change in temperature can result in the tear of these containers, that makes it essential to use the necessary safety measures.

Tunnel Pasteurizers can be utilized to pasteurize beverages without chemicals. They make use of a warm resource, boosting the number of temperature zones and also lowering microorganisms. The temperature is increased until the called for pasteurization temperature level is achieved. When the pasteurization process is complete, the drink is cooled down to prevent any potential damages.

Tunnel Pasteurizers are not just used in drink manufacturing, yet additionally in the beer industry. Its warm exchange function aids recoup energy via various temperature level areas. Its optimized nozzle system ensures good heat exchange with the product. Additionally, Tunnel pasteurizers feature water-saving features. They collect the water gathered throughout the pasteurization process, while likewise keeping high sanitary criteria.

Tunnel Pasteurizers are a perfect choice for large-scale production processes. These systems are a cost-effective, simple choice to sterilized filtration and flash pasteurization. They can likewise prevent deterioration of taste. Some versions feature automated stop systems to avoid overpasteurization. They likewise are available in various dimensions and measurements. They can be customized to fulfill specific client requirements.

Temperature level sensors are a crucial attribute of pasteurization systems. They are utilized to figure out the pasteurization worths. These dimensions are done using a formula that computes the PUs. Tunnel Pasteurizers have the ability to keep an eye on the water temperature with high accuracy. Moreover, they are made for long-term use. For the best outcomes, temperature sensing units should be positioned at critical points. Additionally, calibration systems need to record temperature level and stress within the procedure distribution system.

A tunnel pasteurizer can be used for large-scale productions that have high filler rates. In these instances, a passage pasteurizer is needed to stay clear of microorganism direct exposure to the downstream tools. Using Highly recommended Internet page will certainly allow assembly line to maintain the best standards and also eliminate danger of contamination.

Keep Reading To Get More Information Information About Tunnel Pasteurizers For Beer & Beverage Makers |

Дневник |

Content writer-Moser Hernandez

Tunnel Pasteurizers use heat to securely refine food and various other products. The procedure utilizes different areas where water is splashed in order to warm and cool the item being pasteurized. In some devices, the temperature of the water is kept track of, which makes certain the process is working correctly. Tunnel Pasteurizers can be used in a large range of applications.

Tunnel Pasteurizers are utilized to safely and also regularly sterilize packaged beverages, such as beer and also white wine. These machines utilize a conveyor to move the bundles through a long, narrow Tunnel. The Tunnel is typically 15 to 30 meters long and is consisted of several temperature level zones. The very first zone is the home heating area, and the 2nd zone is the holding or cooling down area. Throughout the process, water is splashed onto the cans as well as containers.

https://www.healthline.com/nutrition/drinking-raw-milk can produce products with boosted service life by deactivating enzymes as well as microorganisms. Modern Tunnel pasteurizers save power by using innovative modern technology. The design of these equipments enables a modular setup, which helps in reducing installment costs. They likewise include constant belts made of polypropylene or stainless-steel. The heating as well as cooling process is managed by a PLC. If you require a pasteurizer for your assembly line, you can call Diversey to get more information regarding what is available in your area.

The Tunnel Pasteurizer screen is a software as well as equipment system that keeps an eye on the pasteurization procedure as well as regulates the water splashing inside the Tunnel. It likewise has an incorporated temperature level sensing unit that determines the temperature as well as time of each specific area. This data is important in determining the pasteurisation devices. Tunnel Pasteurizers are a fantastic choice for pasteurizing lots of products. So, consider them if you are searching for a top quality, reliable pasteurizer.

Tunnel Pasteurizers are reliable equipments that get rid of residual germs from food and drink items. The HT205 mini Tunnel pasteurizer offers flexible criteria that allow the driver to reproduce a large range of full-blown manufacturing circumstances. It additionally conserves water as well as power, which are both key active ingredients for a production line.

Tunnel Pasteurizers are commonly made of stainless steel, and they can be found in various dimensions and measurements. Click At this website enables them to be tailored to the certain food types as well as procedures that you produce. Besides being easy to use, they also do not destroy the taste or texture of the product. They likewise include automatic-stop systems that protect against overpasteurization.

There is a place for pasteurization in little breweries too. The procedure can preserve the flavor of beer even if it is produced in a tiny range brewery. Small-scale breweries are progressively understanding the value of pasteurization as well as are carrying out the technology to make craft brewing a success.

The Tunnel pasteurizer can heat up milk at a rate of 363 kgs per hr. In ninety percent of instances, the milk is cooled pull back to 4.5 degC. A favorable variation pump improves the stress on milk leaving the regeneration area, resulting in a stress differential of 41.4 kPa over the feed or raw side of the regeneration system. The MST sterilized milk has a service life of as much as 60 days at 4 degC, and also the complete reduction of bacteria is greater than five log cycles.

If You Are Trying To Find The Ideal Type Of Tunnel Pasteurizers For Beer & Drink Makers, You Should Check Out The Following Points: |

Дневник |

Written by-Greer Jefferson

Passage Pasteurizers are gadgets made use of to sanitize products by passing them via a passage full of injected heavy steam. The items relocate through the tunnel in stainless-steel, which is confined by a cover panel. They are equipped with heat exchange as well as re-cooling innovation that recuperates energy through different temperature areas. Along with these attributes, they also include water-saving systems that gather excess water and enable upkeep workers to access the sump when required.

VIDEO: “IMPROVE TASTE & PRODUCTION OF CRAFT BEERS WITH PRO ENGINEERING / MANUFACTURING”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) September 13, 2022

Video Summary of Article Release for Brewmasters & Beverage Makers

Video Link: https://t.co/pWC9yUCRPK

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/aD2ullEMzf

Some kinds of passage pasteurizers create negative impacts on bottles. Containers may experience oxidation or deterioration, which might lead to unsightly iron corrosion places on the crown. Pull-tabs and base domes constructed from aluminium may end up being discoloured, while unlacquered cans may lose their decoration after the pasteurization process. Depending on the design, some passage pasteurizers can also produce unfavorable scents and also tastes.

A few of these pasteurizers additionally integrate vacuum cleaner components. This guarantees detailed pasteurization of each part. They are best for carbonated products. Additionally, the passage pasteurizers can be easily incorporated right into the bottling and labelling procedure.

Set pasteurizers are essential parts of several markets. A typical kitchen is furnished with a batch pasteurizer. This sort of pasteurizer can be used in a solitary set of one product. Its lifespan is up to 20 years. And also several vendors use modular plastic conveyor belts to guarantee the food is maintained during transportation. The advantages of passage pasteurizers are countless! https://www.healio.com/infectious-disease/gastroin...s-bacteria-sold-in-four-states can also discover these devices in restaurants as well as grocery stores, as they provide superb control over temperature.

The majority of tunnel pasteurizers include digital recording gadgets as well as have distinct as well as aesthetic alarm systems. These devices have the ability to tape-record the temperature as well as bed rate. These functions are crucial for computing the pasteurisation system. Tunnel pasteurisers are different from plate, tubular, mass, as well as flowing-stream pasteurisers. With this, it is possible to check every aspect of the procedure thoroughly. There are numerous sorts of tunnel pasteurizers, as well as selecting the right one depends upon the type of item you prepare.

The major difference in between conventional thermal pasteurization and this choice method is the rate of home heating. The conventional pasteurisation method damages bacteria, yet it modifies the taste, colour, as well as nutrients of the milk. Subsequently, mouse click the next site is not suggested for all milk kinds. Some milk companies prefer to use a slower, much less reliable means of pasteurization. And it may set you back much more in the long run. So, if you are considering purchasing a pasteurised milk, checked out the adhering to article.

The Tunnel Pasteurizer Is A Popular Selection For The Thermal Therapy Of Drinks |

Дневник |

Content written by-Gaines Klinge

It's made to improve the organic security of items and also is used in filling up lines to maintain their preference intact. They can be by hand run or fully automated, as well as the dimensions will certainly depend on the client's production room, container size, and required temperature. Two-story models are readily available for optimal performance and also flexibility. Passage pasteurizers are normally constructed as solitary or double-story systems.

Tunnel pasteurizers are large devices that make use of vapor, water, and air. Highly recommended Resource site run slowly and use a conveyor belt to move products with the pasteurizer. This enables the pasteurizer to control the temperature in each area exactly. Tunnel pasteurizers are an useful option for increasing the residence developing process. Tunnel pasteurizers are an economical selection when it pertains to decontaminating big volumes of liquid.

website link make use of large tunnel pasteurizers, however smaller craft breweries are now using this technology. Passage pasteurizers warm beer to a temperature of 140F and hold it there for a predetermined quantity of time prior to it relocates into a cooling section. When sterilized, the bottles await bottling. Passage pasteurizers are easy to integrate right into a bottling or classifying line.

The water chemistry of tunnel pasteurizer systems can likewise affect the packaging coating. Iron corrosion places can happen on the crowns of containers, as well as aluminium can pull-tabs as well as base domes can get discolored. Unlacquered canisters may lose their decorative surface and also tainted bottles might experience shade fading. Rainfall of inorganic salts can likewise leave unattractive areas on the plan.

A regular passage pasteurizer includes a stainless-steel drum, a glass pitcher, a tube, as well as a shielded cover. Typically, these systems can be attached to a conventional wall electrical outlet. The expense is very inexpensive and also the process is easy to execute. The Passage Pasteurizer is a convenient, effective means to sterilize water. These makers have a selection of advantages, and are great for the residence cooking area or organization.

The Craft tunnel pasteurizer has actually been established for smaller manufacturers in the beverage sector. The Craft passage pasteurizer uses the same performances as its big brothers, however is monoblock in layout. This reduces installment and distribution expenses. The Craft tunnel pasteurizer is fully automated as well as makes it possible for sophisticated pasteurization. The TMCI Padovan has years of experience in the production of tunnel pasteurizers. The Craft tunnel pasteurizer is a cost-effective selection for small and also medium-sized brewers.

To maximize performance, the very best design ought to have a recorder as well as alarm capabilities. An audio or visual alarm will certainly notify the driver of any type of modifications in temperature level or bed rate. Tunnel Pasteurizers have numerous advantages over various other kinds of pasteurizers, which include plate, tubular, bulk, as well as streaming streams. The recording of the procedure details is simple. There's no need to rely upon guesswork when a tunnel pasteurizer has all the attributes that a client needs.

The life of a packaged food is an essential parameter. Usually, natural sturdiness lasts just a couple of days. That's why makers use ingredients, chemicals, as well as thermal processing to prolong shelf life. The Tunnel Pasteurizers enable the very best use thermal energy as well as still protect the all-natural honesty of foodstuff. Tunnel Pasteurizers also supply adaptability via modular construction, making it possible for future expansion and easier handling throughout distribution.

Utilizing a Tunnel Pasteurizer can considerably boost the life span of a drink. These tools are geared up with different sections and each area has its own water spray system, flow pump, as well as screen/filter box. Nonetheless, tunnel pasteurizers can experience issues that can negatively influence the product's quality, safety and security, as well as overall price of possession. The following are some instances of the problems that can happen in a Passage Pasteurizer.

While PEF pasteurizers may cost more in advance, they provide a reduced initial financial investment and also devaluation prices. These benefits are likely to balance out the higher initial cost, in addition to a decrease in the frequency of cleaning. Fortunately, the expenses are expected to fall over time, and they may not be a significant section of the overall product expense. The PEF pasteurizers might be the very best alternative for your business's requirements.

The Tunnel Pasteurizer was made to warm milk at a rate of 363 kg per hr. The milk would be heated up to 80 degC and also cool off to 4.5 degC with 90% regeneration. A favorable variation pump was set up in the regeneration unit to boost the stress on the milk leaving the regeneration area. It accomplished a mean stress differential of 41.4 kPa over the raw side of the regeneration device. A Yokogawa YS170 air-activated controller was used to control milk temperature. The control panel supplied 3 proportional settings in degrees Celsius for milk to be heated to wanted degrees.

If You Are Looking For The Right Kind Of Tunnel Pasteurizers For Beer & Beverage Makers, You Must Look Into The Adhering To Points: |

Дневник |

Content writer-Asmussen McClanahan

Tunnel Pasteurizers are tools utilized to sterilize items by passing them via a passage loaded with infused heavy steam. The items move with the passage in stainless steel, which is confined by a cover panel. They are furnished with warm exchange and re-cooling innovation that recoups energy through different temperature areas. Along with these features, they also feature water-saving systems that gather excess water and also enable maintenance workers to access the sump when needed.

Some sorts of tunnel pasteurizers create adverse effects on bottles. Bottles may experience oxidation or rust, which might result in unattractive iron corrosion areas on the crown. Pull-tabs and also base domes made of aluminium might come to be discoloured, while unlacquered canisters might shed their design after the pasteurization procedure. Depending upon the version, some tunnel pasteurizers can also create unfavorable scents as well as flavors.

A few of these pasteurizers additionally integrate vacuum components. find out this here makes certain comprehensive pasteurization of each component. They are best for carbonated products. Additionally, the tunnel pasteurizers can be easily integrated right into the bottling and labelling procedure.

Batch pasteurizers are crucial parts of numerous industries. A regular cooking area is outfitted with a batch pasteurizer. This sort of pasteurizer can be utilized in a single set of one product. Its life expectancy is up to two decades. As well as many distributors use modular plastic conveyor belts to make certain the food is maintained throughout transport. The advantages of tunnel pasteurizers are countless! You can also locate these makers in restaurants and also supermarkets, as they supply excellent control over temperature level.

Many tunnel pasteurizers feature electronic recording devices and also have audible and visual alarm systems. These gadgets are able to record the temperature level as well as bed speed. These attributes are essential for computing the pasteurisation unit. Passage pasteurisers are different from plate, tubular, bulk, and also flowing-stream pasteurisers. With this, it is possible to keep an eye on every element of the process thoroughly. There are numerous types of passage pasteurizers, as well as choosing the appropriate one depends on the kind of product you prepare.

The primary difference in between traditional thermal pasteurization as well as this choice approach is the speed of heating. The traditional pasteurisation approach ruins microbes, but it changes the taste, colour, as well as nutrients of the milk. Subsequently, it is not suggested for all milk kinds. Some milk companies like to make use of a slower, much less effective way of pasteurization. As well as it might set you back a lot more in the long run. So, if you are thinking about acquiring a pasteurised milk, checked out the following write-up.

What Are The Differences Between Tunnelpasteurizers Vs Batch Pasteurizers |

Дневник |

Article created by-Blankenship Villarreal

TunnelPasteurizers are utilized to disinfect the components of tiny bottles, such as red wine, spirits, and also beer. These pasteurizers warm the elements in a container filled with hot water and permit them to relax for some time prior to relocating to a conveyor belt. During the pasteurization process, the water is pumped from the discharge end to the infeed end. This process makes certain that all of the elements are completely sterilized. A vacuum cleaner system is likewise mounted on a lot of conveyor belts to capture broken bottles.

When pasteurizing fluid in containers or containers, Tunnelpasteurizers provide both re-cooling as well as warm exchange. This heat exchange system combines pasteurization and also re-cooling, and its maximized nozzle system is made to supply a high degree of warmth exchange with the item. Water cost savings systems are additionally consisted of, which accumulate water as well as various other waste and reuse the water in the Tunnelpasteurizer. As long as the process is done according to the guidelines as well as security guidelines, a passage pasteurizer is an economical option.

Modern Tunnelpasteurizers have a water conserving system that enhances water consumption. Tunnelpasteurizers are available in a range of dimensions and also capacities, so you can select one that best meets your requirements. Additionally, a compact Tunnelpasteurizer is smaller sized in size, making it ideal for small processes. Regardless of its little size, the portable version allows you to save space in your manufacturing area, which is very important in the manufacturing procedure.

A tunnel pasteurizer is an efficient machine that gets rid of all recurring germs in food and also beverage items. They are offered in a variety of dimensions and are utilized in the food and beverage markets to eliminate germs, avoid fermentation, as well as offer shelf stability. Since Tunnelpasteurizers experience huge temperature variants, caustic cleaning chemicals, and massive mechanical anxiety, they are extremely long lasting and trustworthy. A busted bottle can seriously damage a passage pasteurizer. PRO Engineering layouts as well as develops Tunnelpasteurizers and also has over four years of experience.

On the other hand, batch pasteurizer systems have been made for home installments. They include a stainless-steel drum, a pre-heated glass pitcher, a condenser, as well as auxiliary devices. A lot of set pasteurizers are designed to be connected to a wall surface outlet and also feature customer manuals. During the pasteurization procedure, the item travels through stainless steel tunnels filled with injected steam. The temperature surge is sluggish and also non-uniform.

Unlike typical sanitation techniques, set pasteurizers have actually a managed temperature level. Unlike various other sanitation strategies, which entail trial-and-error, the temperature levels of Tunnelpasteurizers are meticulously adjusted prior to the process starts. This makes certain that the final product keeps its flavor and also top quality while safeguarding against contamination. If you're intending on brewing your very own beer, it's a great idea to start with a batch pasteurizer.

To determine the temperature in a tunnel pasteuriser, look for a gadget that can tape-record measurements. Generally, the gadget will certainly have distinct or aesthetic alarm systems to inform the driver of a modification in temperature. A fixed surveillance device is likewise valuable for measuring temperature. Tunnelpasteurizers can be quickly checked and made use of to keep an eye on temperatures. So, pick the most effective choice for your demands. And also, don't forget to inspect your product for any kind of leakages!

Depending on the chemistry of the water in the Tunnelpasteuriser system, containers might experience high quality issues. Some containers might experience rust places on the crown of the bottle. Aluminium cans might also struggle with staining. On top of that, unlacquered cans might experience fading in decor. These troubles may also influence the overall expense of possession of the product. And, the water chemistry in the pasteuriser can likewise negatively influence the product packaging quality.

Tunnelpasteurizers are becoming much more preferred, and professional brewers are discovering them to be an effective way to sterilize beer for mass usage. Along with industrial developing centers, more mid-tier craft breweries are going with Tunnelpasteurizers to make certain the safety and security and also quality of their item. Tunnelpasteurizers warm the beer to a temperature level of 140 levels Fahrenheit, after that cool it down.

The control system of a Tunnel Pasteurizer includes hardware and software. visit the following post takes a trip with the item throughout pasteurization. It downloads the measurements to a laptop and computes the PU. Usually, the control systems are PLC-based. The programs made use of in these devices manage the temperature and time within the passage. If the temperature is higher than the needed degree, the vapor shutoff opens up and also shuts according to the error.

The Tunnel Pasteurizer Is A Popular Choice For The Thermal Treatment Of Beverages |

Дневник |

Content writer-Aguilar Alvarado

It's developed to boost the organic security of items and is utilized in filling lines to keep their preference intact. They can be manually run or totally automatic, and the measurements will depend on the client's manufacturing room, container size, as well as needed temperature. Two-story designs are offered for optimal effectiveness as well as adaptability. Passage pasteurizers are typically constructed as solitary or double-story devices.

Passage pasteurizers are large units that make use of steam, water, as well as air. The systems run slowly and also make use of a conveyor belt to move items via the pasteurizer. This permits the pasteurizer to control the temperature in each area specifically. Passage pasteurizers are a functional alternative for speeding up the home brewing procedure. Tunnel pasteurizers are a cost-effective choice when it comes to sterilizing big volumes of fluid.

The majority of commercial breweries make use of large passage pasteurizers, yet smaller craft breweries are currently using this technology. Tunnel pasteurizers heat beer to a temperature of 140F and also hold it there for a fixed amount of time before it relocates right into a cooling area. As soon as sterilized, the bottles await bottling. Passage pasteurizers are very easy to incorporate into a bottling or classifying line.

The water chemistry of tunnel pasteurizer systems can additionally impact the product packaging finish. Read More Here can happen on the crowns of containers, and also aluminium can pull-tabs as well as base domes can get discolored. Unlacquered cans might lose their decorative coating as well as tainted bottles may experience color fading. Precipitation of not natural salts can also leave unsightly places on the plan.

A typical tunnel pasteurizer consists of a stainless-steel drum, a glass carafe, a tube, and also an insulated cover. Normally, these systems can be affixed to a conventional wall outlet. The price is really cost effective as well as the process is simple to perform. The Passage Pasteurizer is a convenient, reliable way to decontaminate water. These devices have a range of benefits, and are fantastic for the home cooking area or organization.

The Craft passage pasteurizer has been created for smaller producers in the beverage sector. The Craft passage pasteurizer offers the very same capabilities as its big brothers, but is monoblock in layout. This minimizes installation and also distribution costs. The Craft passage pasteurizer is fully automated as well as makes it possible for advanced pasteurization. The TMCI Padovan has decades of experience in the manufacturing of tunnel pasteurizers. The Craft passage pasteurizer is an economical option for little and medium-sized makers.

To make best use of efficiency, the very best design ought to have a recorder as well as alarm system capabilities. An audio or aesthetic alarm system will certainly inform the driver of any type of changes in temperature level or bed rate. Passage Pasteurizers have a number of benefits over various other types of pasteurizers, which include plate, tubular, mass, and flowing streams. The recording of the procedure information is simple. There's no need to rely on guesswork when a tunnel pasteurizer has all the features that a consumer needs.

The life of a packaged food is a critical specification. Generally, all-natural resilience lasts just a couple of days. That's why manufacturers use ingredients, chemicals, as well as thermal processing to extend life span. The Passage Pasteurizers allow the most effective use thermal energy as well as still maintain the all-natural stability of food products. Tunnel Pasteurizers additionally use flexibility via modular building and construction, enabling future development as well as simpler handling throughout shipment.

Utilizing a Tunnel Pasteurizer can substantially raise the life span of a beverage. These tools are equipped with different areas as well as each area contains its very own water spray system, circulation pump, as well as screen/filter box. Nonetheless, passage pasteurizers can experience issues that can negatively impact the item's high quality, security, and general price of ownership. The complying with are some instances of the troubles that can happen in a Passage Pasteurizer.

While PEF pasteurizers may cost more up front, they provide a reduced initial financial investment and devaluation costs. These advantages are likely to counter the higher first cost, in addition to a decrease in the regularity of cleansing. Fortunately, the prices are expected to tip over time, and they may not be a considerable section of the total product price. The PEF pasteurizers might be the very best alternative for your company's requirements.

The Tunnel Pasteurizer was made to warmth milk at a rate of 363 kg per hour. The milk would certainly be heated up to 80 degC and cool to 4.5 degC with 90% regrowth. A favorable displacement pump was set up in the regrowth system to boost the pressure on the milk leaving the regeneration section. just click the following page attained a mean pressure differential of 41.4 kPa over the raw side of the regrowth system. A Yokogawa YS170 air-activated controller was made use of to manage milk temperature level. The control panel gave 3 proportional settings in levels Celsius for milk to be heated up to wanted levels.

If You Are Searching For The Ideal Kind Of Tunnel Pasteurizers For Beer & Beverage Makers, You Ought To Check Out The Complying With Factors: |

Дневник |

Article by-Valentine Ellington

Passage Pasteurizers are gadgets used to disinfect products by passing them with a passage filled with infused heavy steam. The products relocate through the tunnel in stainless steel, which is confined by a cover panel. They are geared up with warmth exchange and also re-cooling modern technology that recovers power with various temperature level zones. In addition to these features, they likewise feature water-saving systems that accumulate excess water and enable maintenance employees to access the sump when essential.

Some sorts of passage pasteurizers cause unfavorable effects on bottles. Containers might experience oxidation or corrosion, which might lead to undesirable iron corrosion places on the crown. Pull-tabs as well as base domes constructed from aluminium might come to be discoloured, while unlacquered containers might shed their decoration after the pasteurization process. Depending on the model, some tunnel pasteurizers can likewise produce unwanted smells and also flavors.

Continue Reading of these pasteurizers additionally include vacuum parts. This ensures complete pasteurization of each part. They are best for carbonated items. Additionally, the passage pasteurizers can be quickly integrated right into the bottling and also identifying procedure.

Set pasteurizers are vital parts of many sectors. A typical kitchen is geared up with a set pasteurizer. This kind of pasteurizer can be made use of in a single batch of one item. Its life expectancy is up to twenty years. As well as lots of suppliers utilize modular plastic conveyor belts to make sure the food is maintained during transportation. The advantages of tunnel pasteurizers are endless! You can also discover these makers in dining establishments as well as supermarkets, as they give exceptional control over temperature.

Many tunnel pasteurizers include electronic recording tools and have distinct as well as aesthetic alarm systems. These tools have the ability to record the temperature as well as bed rate. These functions are crucial for determining the pasteurisation unit. Passage pasteurisers are different from plate, tubular, bulk, and also flowing-stream pasteurisers. With this, it is possible to check every aspect of the process in detail. There are a number of kinds of passage pasteurizers, as well as picking the ideal one depends upon the sort of item you prepare.

The major distinction between standard thermal pasteurization and also this alternative approach is the rate of heating. The standard pasteurisation technique ruins microbes, yet it alters the preference, colour, as well as nutrients of the milk. Subsequently, it is not suggested for all milk kinds. Some milk companies favor to use a slower, much less reliable method of pasteurization. As well as it might cost extra in the future. So, if you are thinking of acquiring a pasteurised milk, reviewed the adhering to write-up.

What Are The Differences Between Tunnelpasteurizers Vs Set Pasteurizers |

Дневник |

Content create by-Workman Arildsen

TunnelPasteurizers are used to sanitize the contents of little bottles, such as white wine, spirits, and also beer. These pasteurizers warm the elements in a container loaded with hot water and enable them to relax for some time before transferring to a conveyor belt. Throughout the pasteurization process, the water is pumped from the discharge end to the infeed end. This process ensures that all of the parts are completely pasteurized. A vacuum system is additionally mounted on the majority of conveyor belts to catch damaged containers.

When pasteurizing liquid in bottles or containers, Tunnelpasteurizers offer both re-cooling and also warm exchange. This heat exchange system incorporates pasteurization as well as re-cooling, and its maximized nozzle system is developed to supply a high degree of heat exchange with the product. Water cost savings systems are also consisted of, which collect water and various other waste as well as reuse the water in the Tunnelpasteurizer. As long as the process is done according to the standards as well as security guidelines, a passage pasteurizer is a cost-efficient option.

Modern Tunnelpasteurizers have a water conserving system that enhances water intake. Tunnelpasteurizers are offered in a variety of dimensions and also capacities, so you can choose one that finest meets your needs. Additionally, a portable Tunnelpasteurizer is smaller sized in size, making it ideal for small procedures. Regardless of its tiny dimension, the compact design allows you to conserve space in your production area, which is essential in the production procedure.

A passage pasteurizer is a reliable equipment that eliminates all residual bacteria in food and drink items. They are readily available in a range of sizes as well as are used in the food and beverage markets to eliminate germs, stop fermentation, and also offer rack security. Since Tunnelpasteurizers experience huge temperature variations, caustic cleaning chemicals, and substantial mechanical anxiety, they are incredibly sturdy as well as reliable. A broken container can seriously harm a tunnel pasteurizer. PRO Design designs and also constructs Tunnelpasteurizers as well as has more than four years of experience.

On the other hand, batch pasteurizer systems have been designed for household setups. They consist of a stainless steel drum, a pre-heated glass pitcher, a condenser, and also complementary equipment. The majority of set pasteurizers are created to be attached to a wall surface electrical outlet and also feature customer manuals. Throughout the pasteurization procedure, the item passes through stainless-steel tunnels filled with injected vapor. The temperature surge is slow-moving and also non-uniform.

Unlike standard sanitation techniques, batch pasteurizers have actually a controlled temperature level. Unlike various other sanitation strategies, which involve trial-and-error, the temperature levels of Tunnelpasteurizers are carefully calibrated before the process starts. This ensures that the final product maintains its flavor as well as quality while securing against contamination. If https://www.rd.com/article/why-americans-refrigerate-milk-but-europeans-dont/ intending on brewing your very own beer, it's an excellent idea to start with a batch pasteurizer.

To measure the temperature in a passage pasteuriser, seek a device that can tape-record dimensions. Typically, the gadget will have distinct or visual alarms to signal the operator of a change in temperature level. A static tracking gadget is likewise valuable for gauging temperature. Tunnelpasteurizers can be quickly monitored and also made use of to keep track of temperature levels. So, choose the very best choice for your needs. And also, do not fail to remember to check your product for any type of leaks!

Depending on the chemistry of the water in the Tunnelpasteuriser system, containers might experience top quality problems. Some containers may experience corrosion places on the crown of the bottle. Aluminium cans may likewise experience discoloration. In addition, unlacquered containers might experience fading in design. These issues may also influence the overall expense of ownership of the item. And also, the water chemistry in the pasteuriser can additionally negatively influence the packaging top quality.

Tunnelpasteurizers are becoming extra preferred, and expert brewers are finding them to be an efficient method to pasteurize beer for mass intake. Along with business brewing centers, even more mid-tier craft breweries are selecting Tunnelpasteurizers to ensure the safety and high quality of their product. Tunnelpasteurizers heat the beer to a temperature level of 140 levels Fahrenheit, after that cool it down.

The control system of a Passage Pasteurizer includes software and hardware. The equipment takes a trip with the item throughout pasteurization. It downloads the dimensions to a notebook computer as well as determines the PU. Normally, the control systems are PLC-based. The programs used in these equipments manage the temperature as well as time within the tunnel. If the temperature is greater than the needed degree, the vapor shutoff opens up as well as shuts according to the mistake.

The Benefits Of Tunnel Pasteurizers |

Дневник |

Authored by-Mejer Mcclure

Batch Pasteurizers are home appliances made use of to quicken the blending as well as food preparation of foods. They are used in many food processing plants, food solution operations, as well as in the house. Batch Pasteurizers are usually embeded in central heating boilers or ovens to quicken the food preparation procedure and boost the shelf-life of many foodstuff. Food pasteurizers are available for various sorts of foods as well as for various sorts of food preparation procedures.

Batch pasteurizers are used in food handling plants because they permit an extra cost-effective use of energy when refining different type of foods. They are also more sanitary than the stand mixer method. Stand mixers have a tendency to infect food surface areas, therefore minimizing their quality. Additionally, with the stand mixer approach, it can be hard to identify when the components have actually been pasteurized. Batch pasteurizers do not have this issue since their process is slow-moving sufficient to guarantee the appropriate pasteurization of all products being processed.

tunnel pasteurization copacker are made use of in several sorts of food processing. They are usually made use of in meat and also fish processing plants. Meat as well as fish pasteurizers are particularly made use of in Europe as well as the United States. Food pasteurizers made use of in these food plants are particularly created to slow down the heating process and also to stop denaturation of flavors and also vegetables. Heat shock is a problem for lots of meat as well as fish procedures, as well as pasteurizers help reduce this risk.

Batch pasteurizers are also made use of in several industrial food processing plants. In these plants, they are used to speed up the drying out and grinding of grains before they are used in the food product line. This allows the preparation of dry and all set to cook foods. Pasteurizers are also made use of in the drying out procedure of fruits, which typically are not refined at the handling plant before being shipped to shops.

The meat and also fish processing plant is not the only place you will locate Tunnel pasteurizers. You will likewise generally locate them in drugs as well as cosmetics plants. They are made use of to accelerate the drying out and also grinding of natural herbs and also oils. These products are then utilized in skin care, hair treatment as well as individual treatment items. Because they are used so frequently, Tunnel pasteurizers are normally of a higher quality than other similar products.

When you compare meat as well as fish pasteurizers to Batch pasteurizers, you will rapidly see just how one functions a lot more efficiently. A batch pasteurizer will certainly take numerous mins to complete processing while a set pasteurizer will certainly begin working nearly quickly. Actually, Tunnel pasteurizers give the specific pH as well as temperature level needed to eliminate microorganisms in the food as it is refined.

Tunnel pasteurizers likewise aid extend the shelf life of food by protecting against bacterial development. The microorganisms are eliminated even prior to food is packed right into boxes or saved on shelves for long periods of time. simply click the following internet page as well as fish prior to food manufacturing is commonly used to protect them for a longer amount of time. Several raw meat providers, fowl vendors, and fish as well as fish and shellfish cpus currently make use of Tunnel pasteurizers each day. Actually, some farmers who grow food utilizing pets feed additionally make use of the procedure as an avoidance for food putridity and also contamination.

Batch pasteurizers also ensure that meat and also seafood remain fresh and are secure to consume for a longer period of time. It is likewise important that meat as well as fish and shellfish are refined at the correct temperature. Meat ought to not be refined at reduced temperature levels, as well as seafood needs to be cooked at just the right temperature to eliminate microorganisms and also clean away excess oil. There are a variety of various designs of pasteurizers offered in the marketplace today. You can pick from the numerous sorts of basket models that have stainless-steel bases and also include a temperature level probe, or you can opt for the table leading sort of pasteurizers that has a basket and an integrated thermometer.

|

|

Batch Pasteurizers Is A Great Enhancement To Any Type Of Food Procedure |

Дневник |

Content by-Barnes Barker

Tunnel Pasteurizers are used to promote the growth of microbes and to enhance the top quality and pureness of fermented foods. They have been around because the earliest techniques of pasteurization were developed, and also they have actually evolved together with the various methods of fermenting foods. Batch Pasteurizers and Repair Service Refurbish Pasteurizers are normally utilized together to speed up the Fermentation process as well as to shield the product from contamination as it is moved from basic materials to the finished goods.

Fermentation, in some cases called procedure of maceration, is the conversion of raw food product to a product where the procedure causes modifications that advertise growth of microorganisms as well as urge development of flavor. The end result is an item that is thought about to be pure, although not always. In the starting the objective is to develop something that has the greatest feasible dietary worth. Later on the goal is to produce foods that are both yummy and fascinating. There are four steps associated with the whole procedure.

Initially, the food is put in a container with a faucet put for air. Second, the food is heated up to concerning 160 degrees Fahrenheit or even more utilizing a heater or range. The heater or cooktop is typically geared up with an air flow system to compel great air into the container. This second procedure seals in the taste as well as prolongs the service life of the product.

Tunnel Pasteurizers are used as main fermentation ingredients, but they can likewise be utilized as additional fermentation components. The difference in between primary and also additional fermentation is the approach of including the culture. Recommended Internet site with the alternative of main or second fermentation are an excellent financial investment for anyone curious about making their own home pasteurizers. When utilizing Tunnel pasteurizers to promote second fermentation, you make use of an active component like S. cerevisiae, which is frequently utilized in the pet food industry.

Batch pasteurizers utilized in this way are called "Tunnel cellars". Batch cellars are created to ferment food in large sets. They make use of the natural process of food batchning by sluggish and gentle conditioning of grains and also various other active ingredients in secondary fermentation vessels. These vessels are usually referred to as "fermenters". They can be made of metal or timber, depending upon the fermenting requirements of business.

Tip 3 involves the heating of the raw materials to the preferred temperature level. This ensures that the item goes to the proper fermentation temperature level prior to it is packaged. This step is important because it ensures that microorganisms do not expand after the food is packaged. A lot of the very best pasteurizers on the market today use a direct-pasteurization procedure.

find out here now of the process is the conditioning of the item. There are 2 key ways to condition foodstuff utilizing these kinds of pasteurizers. Straight pasteurizing needs no additional conditioning of the product. Indirect pasteurizers require a container to be loaded with the fermented product.

Batch pasteurizers will certainly make your fermentation items even more delicious as well as have a longer life span. They likewise will certainly keep foods fresher longer. Food can be conditioned for any type of variety of months, relying on the product as well as the maker's recipe. Pasteurizing is an easy as well as efficient procedure for optimizing the taste of fermented food.

To make use of Tunnel pasteurizers successfully, you should have a reliable container for keeping and afterwards making use of the completed product. These items need to be identified with the Batch number, the name of the company (if different from the brand made use of to make the pasteurizer), and also the temperature at which the item was pasteurized. Be sure that there are no fumes or condensation marks from the original manufacture procedure. You should be able to pour the materials of the Tunnel into the container without concern of the food becoming contaminated. Food ought to be prepared right before serving.

Batch pasteurizers are offered in many shapes and sizes, relying on how much food is being created at one time. Some Tunnel makers are dual-purpose as well as will certainly sterilize and chill different foods at the same time. Various other Batch machines have extra capacity for constant production while still keeping a smaller impact. It's up to you to pick the ideal Tunnel device for your procedure.

A batch pasteurizer is a vital piece of equipment in any type of food handling procedure. These systems allow a secure and also regulated heat handling of foods throughout any type of phase of the production process. They offer an affordable and also secure means of processing food at heats in an effective and prompt fashion.

|

|

Tunnel Pasteurizers Is A Great Enhancement To Any Food Procedure |

Дневник |

Content create by-Blom McIntyre

Batch Pasteurizers are made use of to promote the development of bacteria and also to boost the high quality as well as pureness of fermented foods. They have actually been around given that the earliest methods of pasteurization were developed, and they have actually developed along with the various methods of fermenting foods. Batch Pasteurizers and also Repair Refurbish Pasteurizers are normally utilized with each other to speed up the Fermentation procedure and to shield the item from contamination as it is moved from raw materials to the finished items.

Fermentation, in some cases called process of maceration, is the conversion of raw food material to a product where the procedure creates adjustments that promote advancement of bacteria and also motivate growth of taste. The end outcome is an item that is considered to be pure, although not always. In the starting the goal is to produce something that has the highest feasible dietary worth. Later the goal is to produce foodstuffs that are both yummy and intriguing. There are four steps associated with the whole process.

First, the food is positioned in a container with a faucet inserted for air. Second, the food is warmed to about 160 degrees Fahrenheit or even more making use of a heater or cooktop. The heater or stove is often equipped with a ventilation system to force cool air into the container. This second procedure seals in the flavor as well as expands the life span of the product.

Tunnel Pasteurizers are made use of as key fermentation components, but they can also be made use of as secondary fermentation active ingredients. The difference between key and also second fermentation is the technique of including the culture. Tunnel pasteurizers with the option of primary or secondary fermentation are a wonderful financial investment for anybody thinking about making their very own house pasteurizers. When utilizing Tunnel pasteurizers to advertise additional fermentation, you utilize an active component like S. cerevisiae, which is generally made use of in the pet food market.

Tunnel pasteurizers utilized in this way are called "Tunnel storages". Batch storages are designed to ferment food in large batches. They make use of the natural process of food batchning by sluggish and also gentle conditioning of grains as well as other active ingredients in second fermentation vessels. Recommended Browsing are often referred to as "fermenters". They can be made of steel or wood, depending upon the fermenting needs of the business.

Step three includes the home heating of the raw products to the desired temperature level. This makes certain that the product goes to the appropriate fermentation temperature level before it is packaged. This action is very important because it makes sure that microorganisms do not grow after the food is packaged. Much of the very best pasteurizers on the marketplace today utilize a direct-pasteurization procedure.

The last step of the process is the conditioning of the product. There are 2 main means to problem food using these sorts of pasteurizers. Straight pasteurizing needs no additional conditioning of the item. Indirect pasteurizers call for a container to be filled with the fermented item.

Batch pasteurizers will certainly make your fermentation items much more delicious as well as have a longer shelf life. They likewise will certainly keep foods fresher much longer. Food can be conditioned for any number of months, relying on the item as well as the supplier's dish. Sterilizing is a simple and also efficient process for taking full advantage of the taste of fermented food.

To utilize Tunnel pasteurizers successfully, you must have a well-made container for saving and then using the finished product. These things must be labeled with the Batch number, the name of the firm (if different from the brand name made use of to make the pasteurizer), and the temperature at which the product was sterilized. Make sure that there are no fumes or condensation marks from the original manufacture process. You must have the ability to pour the contents of the Batch into the container without fear of the food ending up being contaminated. tunnel pasteurization beer ought to be cooked just before serving.

Batch pasteurizers are readily available in several sizes and shapes, depending on how much food is being generated at one time. Some Batch makers are dual-purpose as well as will certainly sterilize as well as chill numerous foods at the same time. Other Tunnel equipments have added capability for continual manufacturing while still retaining a smaller sized footprint. It's up to you to select the proper Tunnel device for your procedure.

A batch pasteurizer is a vital piece of equipment in any type of food processing operation. These devices enable a safe and regulated warm processing of foods during any phase of the manufacturing process. They provide an affordable and safe means of processing food at heats in a reliable and also prompt way.

|

|

Batch Pasteurizers Is A Terrific Addition To Any Food Operation |

Дневник |

Written by-Guldager Troelsen

Batch Pasteurizers are utilized to promote the growth of bacteria as well as to enhance the quality as well as pureness of fermented foods. They have actually been around because the earliest techniques of pasteurization were produced, and also they have actually developed in addition to the numerous techniques of fermenting foods. Tunnel Pasteurizers and also Repair Work Refurbish Pasteurizers are commonly made use of with each other to quicken the Fermentation procedure and also to secure the item from contamination as it is moved from raw materials to the ended up goods.

Fermentation, often called process of maceration, is the conversion of raw food product to an item where the process causes adjustments that advertise growth of microbes and urge development of taste. The end result is a product that is thought about to be pure, although not constantly. In the beginning the goal is to produce something that has the greatest possible nutritional value. Later on the objective is to create foods items that are both delicious and interesting. There are 4 steps involved in the entire procedure.

Initially, the food is put in a container with a faucet put for air. Second, the food is warmed to concerning 160 levels Fahrenheit or even more making use of a heater or range. The heater or cooktop is usually outfitted with a ventilation system to compel great air right into the container. This 2nd procedure seals in the taste as well as expands the service life of the product.

Tunnel Pasteurizers are used as key fermentation ingredients, however they can also be made use of as additional fermentation components. The distinction between key and secondary fermentation is the method of adding the culture. Tunnel pasteurizers with the option of key or secondary fermentation are an excellent financial investment for any individual interested in making their own house pasteurizers. When making use of Tunnel pasteurizers to advertise additional fermentation, you make use of an energetic ingredient like S. cerevisiae, which is typically utilized in the pet food market.

Batch pasteurizers made use of in this way are called "Tunnel cellars". Tunnel storages are made to ferment food in huge batches. They make the most of the natural process of food batchning by slow and gentle conditioning of grains and various other components in secondary fermentation vessels. These vessels are typically described as "fermenters". They can be made of steel or timber, relying on the fermenting demands of business.

Tip 3 entails the heating of the raw products to the wanted temperature level. This guarantees that the item is at the appropriate fermentation temperature before it is packaged. This step is necessary since it makes certain that germs do not expand after the food is packaged. Most of the most effective pasteurizers on the market today use a direct-pasteurization procedure.

The last action of the procedure is the conditioning of the item. There are 2 main methods to condition food making use of these types of pasteurizers. Direct pasteurizing calls for no additional conditioning of the item. Indirect pasteurizers call for a container to be full of the fermented item.

Tunnel pasteurizers will make your fermentation items much more scrumptious and have a longer service life. https://aboutus.com/Prowm.com will maintain foods fresher much longer. Food can be conditioned for any kind of number of months, depending on the item and also the producer's dish. Sterilizing is an easy and also reliable procedure for taking full advantage of the flavor of fermented food.

To make use of Batch pasteurizers successfully, you need to have a well-crafted container for storing and after that utilizing the ended up item. These products need to be labeled with the Batch number, the name of the business (if different from the brand name made use of to make the pasteurizer), and also the temperature at which the item was sterilized. Make sure that there are no fumes or condensation marks from the original manufacture procedure. You ought to have the ability to pour the materials of the Tunnel right into the container without anxiety of the food coming to be infected. Food must be prepared prior to serving.

Batch pasteurizers are offered in lots of sizes and shapes, depending upon how much food is being generated at one time. Some Tunnel makers are dual-purpose and will certainly pasteurize and cool various foods at the same time. Various other Tunnel makers have added capability for constant manufacturing while still retaining a smaller impact. It's up to you to select the ideal Tunnel machine for your operation.

A batch pasteurizer is an essential tool in any food handling procedure. These devices enable a secure and regulated warmth processing of foods during any phase of the manufacturing process. They provide an affordable as well as risk-free ways of processing food at high temperatures in an effective and also timely fashion.

|

|

The Uses Of Batch Pasteurization In Drugs |

Дневник |

Content author-Fraser Bennett

Tunnel pasteurization describes the process of preparing raw materials for pharmaceutical manufacturing and involves pasteurization of raw materials in a closed vessel as if the microorganisms do not run away or are destroyed by the pasteurization procedure. It is carried out for numerous sorts of pharmaceutical items such as prescription antibiotics, analgesics, anti-carcinogens, laxatives, anti-fungal representatives, stomach preparations, and veterinary products. The name comes from the primary pasteurization process, whereby the product is dried up to ensure that the organisms on its own die. The pasteurization procedure creates a product with virtually no taste.

Heating & Cooling Options for Tunnel Pasteurizers from Vance Ellis on Vimeo.

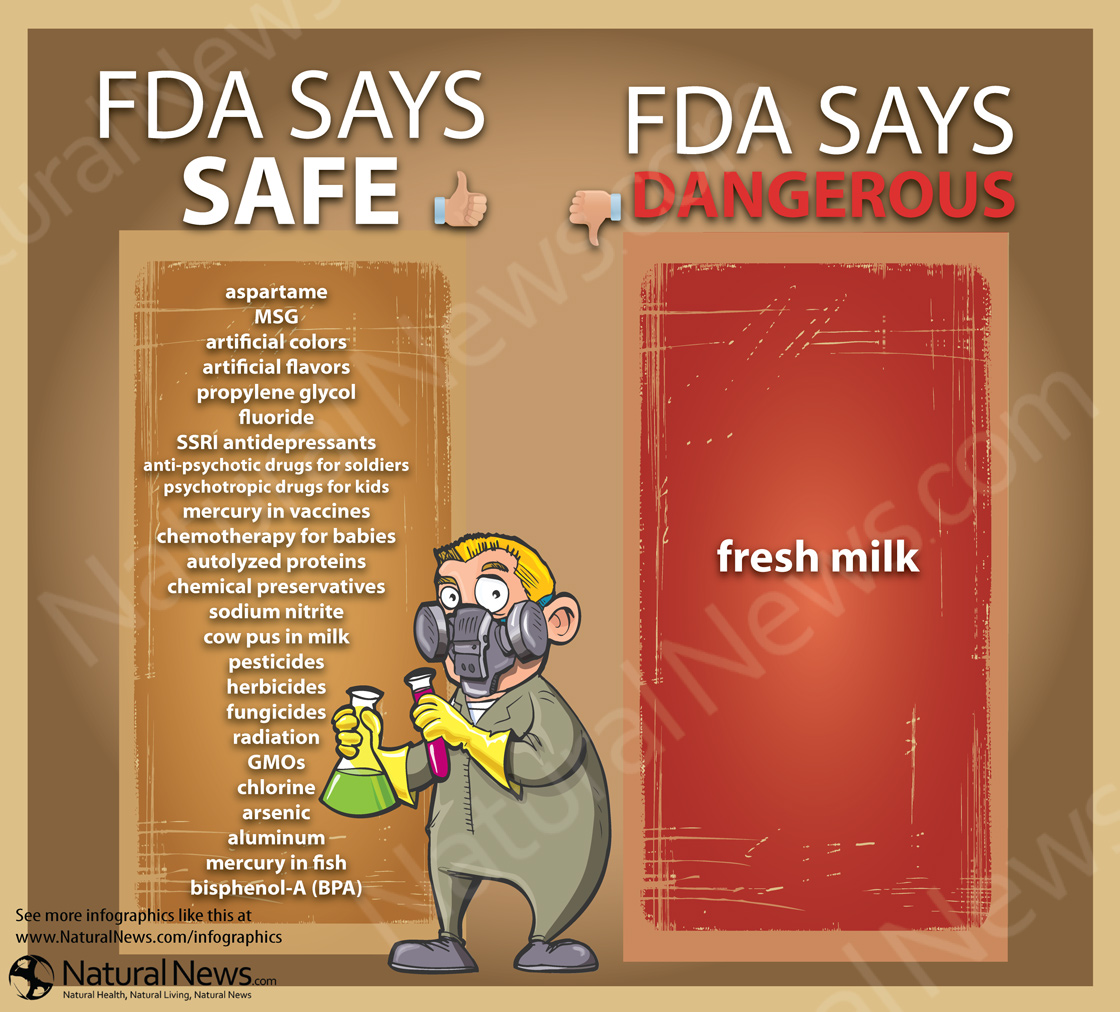

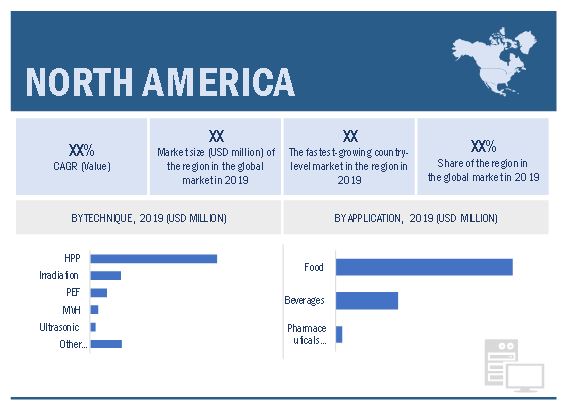

In order to satisfy the criteria set by the food and drug administration (FDA) for foods and medications, producers have to apply pasteurization processes as a part of the manufacturing procedure. The FDA defines a 'pasteurized product' as one that undertakes any kind of one of the four fundamental pasteurization processes: cool pasteurization, hot pasteurization, dry warm pasteurization, or caustic pasteurization. Actually, all pharmaceutical items might be pasteurized. There is considerable discussion over which of the 4 is most efficient.

Cold pasteurization is the procedure by which the items are heated to minimize the growth of bacteria throughout processing. The final product is usually pasteurized at temperatures listed below 118 levels Fahrenheit. Warm pasteurization, on the other hand, utilizes an extremely high temperature to quicken the rate of development of the bacteria and kill them. Dry warmth pasteurization is the least costly of the four processes, as it needs really little focus to the real conditions of the active ingredients during handling. This technique is considered the most suitable for prep work including medicines that have to undertake quick testing and authorization before usage.

https://qz.com/740959/science-has-found-a-way-to-e...e-shelf-life-of-cold-milk-300/ of medicines in pharmaceutical plants has an inevitable downside: the preservation of the medications' residential properties. It is necessary to make use of a pure product in the preparation of these items, since any kind of substances included in the items can have unfavorable results on the end product. The most preferred instance is the incorporation of tinting and also flavorings in medicine. These additives can change the chemical makeup of the drugs as well as thus provide them pointless in the treatment they are meant to heal. This is why medications that undertake pasteurization procedures are always kept in completely dry problems as well as need to be extensively blended with a suitable base remedy.

Due to the fact that medications are themselves pure products, it is important to make use of proper approaches of pasteurization for different sort of items. In the case of antibiotics, one of the most typical pasteurization procedure employed is the supposed slow-heat treatment, which entails home heating the drugs at a temperature below the boiling point of the water they will be provided in. This method is well suited for preparing fluids for garglings and also administering fluids containing anti-bacterial representatives. When it comes to vaccines, the materials utilized in the production of the products themselves are put under stress in a container, and afterwards permitted to cool to area temperature. The slow-heat pasteurization procedure employed during the production of syrups and also various other medications that are to be taken in by mouth is referred to as the sped up pasteurization procedure.

One of the most frequently utilized resources in the pasteurization procedure utilized in medication manufacture are alcohols and denatured alcohols, in addition to xylene, chloroform, as well as other solid synthetic chemicals. Various other components such as resins, solvents, barrier options, or surfactants may also be made use of. These materials must go through several stages of pasteurization, from their introduction to the final temperature level at which they are included in the item. Usually, the period of pasteurization in the manufacture of an item ranges between five to fifteen minutes, although this depends greatly on the kind of material entailed.

Throughout the final stage of the pasteurization process, a particular price must be met in order to keep the temperature level of the item listed below boiling. As a whole, it takes around 10 minutes for the pasteurization of any strong substance at a provided temperature to occur. Solids that take longer to boil include solutions, which are largely used to emulsify and also blend active ingredients in pharmaceuticals; thermoset compounds, such as polyols and also monomer particulates made use of as service providers in printing equipment; and unpredictable organic substances (VOCs), which are byproducts created throughout the process of alcohol distillation. Some medications are heavily loaded with VOCs, and they have to be dealt with independently.

A typical procedure utilizing Batch pasteurization entails a series of steps. First, the alcohols and various other chemical compounds are heated up to regarding 100 degrees Celsius, at which point they are presented to the injector, which offers a continuous flow of warm injector gas throughout the product's manufacture. Next off, the alcohols are pelletized and afterwards taken right into a chamber where they remain for several hrs. Finally, they are drained pipes of the majority of their solutes, as well as their residue gathered after a last dose of injection. The quantity of solute eliminated differs by chemical kind as well as set; products are typically tested prior to each batch, to ensure that all chemical constituents have actually been efficiently removed.

|

|

Usings Batch Pasteurization In Pharmaceuticals |

Дневник |

Content by-Boye Childers

Tunnel pasteurization describes the process of preparing resources for pharmaceutical manufacturing and entails pasteurization of raw materials in a shut vessel as though the organisms do not get away or are ruined by the pasteurization procedure. It is accomplished for lots of types of pharmaceutical items such as prescription antibiotics, analgesics, anti-carcinogens, laxatives, anti-fungal representatives, tummy preparations, as well as vet items. The name originates from the primary pasteurization procedure, whereby the product is run out to ensure that the microorganisms on its own die. The pasteurization process produces an item with practically no preference.

"@context": "https://schema.org", "@type": "Organization", "name": "PRO Engineering / Manufacturing Inc", "url": "https://prowm.com/", "logo": "https://prowm.com/wp-content/uploads/2020/12/PRO_logo_NEW_BLK_large.jpg", "contactPoint": "@type": "ContactPoint", "telephone": "414-362-1500", "contactType": "customer service", "areaServed": ["US","PR"], "availableLanguage": "en" , "sameAs": [ "https://www.facebook.com/PartnerWithPRO", "https://twitter.com/daveone1", "https://www.youtube.com/channel/UCizF9v7dVwMEfY1Qu_E4MPg", "https://www.linkedin.com/company/pro-engineering-and-mfg-inc/", "https://soundcloud.com/pro-engineering-milwaukee" ]

In order to meet the criteria established by the food and drug administration (FDA) for foods and also medications, producers must carry out pasteurization procedures as a part of the manufacturing process. The FDA defines a 'sterilized item' as one that goes through any type of among the four fundamental pasteurization processes: cold pasteurization, hot pasteurization, dry warm pasteurization, or caustic pasteurization. As a matter of fact, all pharmaceutical items might be sterilized. There is substantial discussion over which of the four is most efficient.

Cold pasteurization is the process through which the items are warmed to decrease the growth of germs during handling. The end product is typically sterilized at temperatures listed below 118 levels Fahrenheit. Warm pasteurization, on the other hand, utilizes an exceptionally heat to accelerate the price of development of the microbes as well as kill them. Read Homepage is the least expensive of the 4 processes, as it needs very little interest to the real conditions of the components throughout handling. This method is considered one of the most proper for preparations having drugs that need to undergo rapid screening and authorization prior to use.

Pasteurization of drugs in pharmaceutical plants has an inevitable downside: the conservation of the medications' properties. It is essential to utilize a pure material in the prep work of these products, considering that any type of substances contributed to the items can have unfavorable results on the final product. The most prominent example is the addition of coloring and flavors in medicine. These ingredients can alter the chemical makeup of the drugs and also hence provide them pointless in the therapy they are meant to cure. This is why medications that go through pasteurization processes are always kept in dry problems and also must be completely combined with a suitable base option.

Due to the fact that medications are themselves pure materials, it is essential to utilize appropriate approaches of pasteurization for different sort of items. In the case of antibiotics, the most usual pasteurization procedure employed is the supposed slow-heat treatment, which entails home heating the medications at a temperature level listed below the boiling point of the water they will certainly be administered in. This approach is well matched for preparing liquids for garglings as well as providing fluids including anti-bacterial representatives. When it comes to injections, the substances used in the manufacturing of the items themselves are put under pressure in a container, and then allowed to cool to area temperature. The slow-heat pasteurization process used during the manufacturing of syrups and various other medicines that are to be taken in by mouth is known as the accelerated pasteurization procedure.

The most typically utilized resources in the pasteurization procedure used in medication manufacture are alcohols and denatured alcohols, along with xylene, chloroform, and other solid synthetic chemicals. just click the next post as resins, solvents, buffer options, or surfactants may likewise be made use of. These materials ought to go through numerous phases of pasteurization, from their intro to the last temperature level at which they are contributed to the item. Generally, the period of pasteurization in the manufacture of an item varies in between five to fifteen minutes, although this depends considerably on the type of substance included.

During the final stage of the pasteurization procedure, a specific rate should be satisfied in order to maintain the temperature of the product below steaming. In general, it takes about 10 mins for the pasteurization of any type of solid compound at an offered temperature level to take place. Solids that take longer to steam consist of solutions, which are primarily utilized to emulsify and also blend components in drugs; thermoset substances, such as polyols and also monomer particulates used as service providers in printing tools; and unpredictable natural substances (VOCs), which are results generated during the procedure of alcohol purification. Some medications are heavily filled with VOCs, as well as they should be treated independently.

A typical procedure utilizing Tunnel pasteurization entails a collection of steps. First, the alcohols and other chemical materials are heated to concerning 100 degrees Celsius, at which point they are introduced to the injector, which gives a continuous flow of hot injector gas throughout the item's manufacture. Next off, the alcohols are pelletized and then taken into a chamber where they stay for several hrs. Finally, they are drained of the majority of their solutes, and also their residue gathered after a last dose of injection. The quantity of solute removed differs by chemical type and batch; products are normally checked prior to each batch, to ensure that all chemical components have actually been efficiently eliminated.

|

|

Usings Tunnel Pasteurization In Drugs |

Дневник |

Created by-Baker Goff

Batch pasteurization refers to the process of preparing resources for pharmaceutical production as well as involves pasteurization of raw substances in a shut vessel as though the organisms do not leave or are damaged by the pasteurization procedure. It is carried out for numerous types of pharmaceutical items such as anti-biotics, anesthetics, anti-carcinogens, laxatives, anti-fungal agents, stomach preparations, and also vet items. The name comes from the main pasteurization process, whereby the product is run out to ensure that the organisms on its own die. The pasteurization procedure creates a product with virtually no taste.

In order to satisfy the standards set by the food and drug administration (FDA) for foods as well as medicines, manufacturers have to carry out pasteurization processes as a part of the manufacturing procedure. The FDA specifies a 'sterilized item' as one that undergoes any one of the four standard pasteurization procedures: cool pasteurization, warm pasteurization, completely dry heat pasteurization, or caustic pasteurization. Actually, all pharmaceutical products might be sterilized. There is considerable discussion over which of the four is most efficient.

Cold pasteurization is the procedure by which the products are warmed to minimize the development of microorganisms during processing. The end product is normally sterilized at temperature levels listed below 118 degrees Fahrenheit. Warm pasteurization, on the other hand, utilizes an incredibly heat to speed up the price of growth of the microbes and also kill them. Dry warm pasteurization is the least costly of the 4 processes, as it calls for really little interest to the real conditions of the active ingredients during processing. This technique is thought about the most proper for prep work consisting of drugs that need to undertake fast screening and also authorization before usage.

Pasteurization of medications in pharmaceutical plants has an inevitable drawback: the preservation of the medications' residential or commercial properties. It is essential to use a pure material in the prep work of these items, since any type of compounds contributed to the products can have undesirable effects on the end product. One of the most prominent example is the addition of coloring as well as flavorings in medicine. These ingredients can transform the chemical make-up of the medications and hence make them ineffective in the treatment they are planned to cure. This is why medicines that undergo pasteurization processes are always kept in completely dry conditions and should be extensively mixed with an appropriate base option.

Since medicines are themselves pure products, it is important to use proper approaches of pasteurization for different sort of items. When it comes to anti-biotics, one of the most typical pasteurization procedure used is the so-called slow-heat procedure, which includes heating the medicines at a temperature level listed below the boiling point of the water they will be administered in. This approach is well matched for preparing fluids for garglings as well as carrying out liquids containing anti-bacterial representatives. In https://www.qchron.com/qboro/i_have_often_walked/t...40-536a-bb54-e0d1efdf8f38.html of injections, the substances utilized in the production of the items themselves are put under pressure in a container, and after that allowed to cool to room temperature. The slow-heat pasteurization procedure utilized throughout the production of syrups as well as other medicines that are to be taken in by mouth is known as the sped up pasteurization process.

One of the most typically made use of raw materials in the pasteurization procedure made use of in medication manufacture are alcohols as well as denatured alcohols, along with xylene, chloroform, and various other strong artificial chemicals. Various other components such as materials, solvents, buffer solutions, or surfactants may likewise be utilized. simply click the following webpage should undergo several phases of pasteurization, from their introduction to the final temperature level at which they are added to the product. Usually, the duration of pasteurization in the manufacture of an item varies in between five to fifteen minutes, although this depends greatly on the type of substance involved.

During the final stage of the pasteurization process, a specific rate should be fulfilled in order to keep the temperature of the product listed below steaming. Generally, it takes about 10 minutes for the pasteurization of any solid compound at an offered temperature to take place. Solids that take longer to steam consist of emulsions, which are largely utilized to emulsify as well as mix active ingredients in drugs; thermoset substances, such as polyols and also monomer particulates utilized as service providers in printing devices; and unpredictable natural substances (VOCs), which are by-products generated during the procedure of alcohol purification. Some drugs are greatly packed with VOCs, as well as they must be dealt with independently.