This Article Goes Over The Obligations Of A Pharmacist |

Staff Writer-Hill Hald

Having an occupation such as a pharmacist can be an extremely interesting and also fulfilling job. Nevertheless, before More Information and facts start your expert career you should understand all of the information concerning a job in this area. These consist of the credentials and education and learning demands, along with the obligations of a pharmacist.

Credentials

Whether you are thinking about a profession as a pharmacist or have actually currently decided, you need to ensure that you have the ideal qualifications. you could check here will certainly also require to comprehend the laws and also guidelines that govern your profession. There are several means to become certified to practice drug store.

The very first step is to gain a senior high school diploma or GED. You will certainly likewise require to register in a pharmacy institution. You might likewise obtain internal training from your company.

After finishing from a drug store school, you will require to take a licensing test. There are 3 sorts of licensing examinations available. These consist of the Multi-State Drug store Jurisprudence Examination, the Created as well as Practical Exam, as well as the North American Pharmacologist Licensure Exam. You will require to pass all of these tests prior to you can become a qualified pharmacist.

A pharmacist's career can be a rewarding one. They can operate in a variety of setups, consisting of healthcare facilities, retail pharmacies, and medication stores. They can also service weekend breaks and also nights.

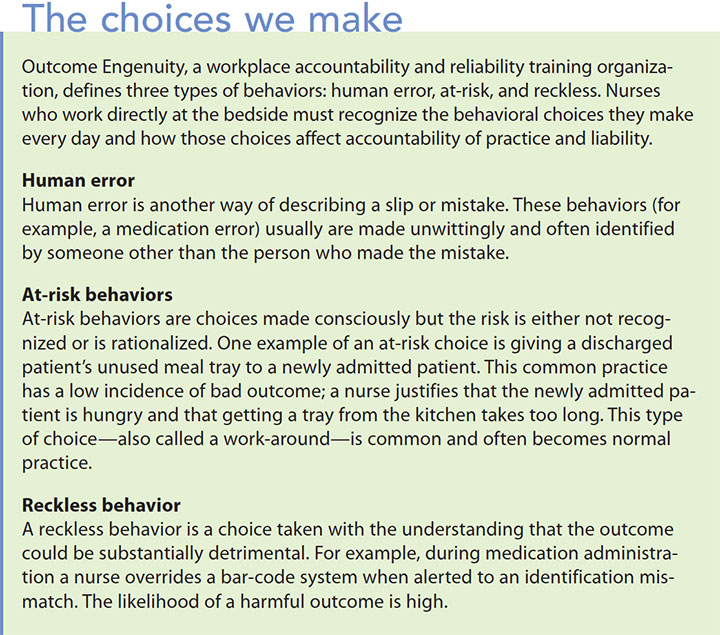

Obligations

Among the responsibilities of pharmacists is making sure the risk-free supply of medicines. The pharmacist is also responsible for the top quality of medications. On top of that, pharmacists may be associated with the formula of medications as well as dose forms. They can likewise be involved in the research study on pharmacotherapeutics as well as pharmacoepidemiology.

Pharmacists give pharmaceutical details to wellness specialists as well as the public. They additionally add to the development of appropriate info and education for wellness experts and also the general public. They can also participate in health and wellness promotion campaigns and also clinical trials.

Pharmacologists additionally have the role of counselling clients on the risk-free and also suitable use of medicines. They likewise offer health care advice to long-term individuals. Furthermore, pharmacologists can additionally take part in the education of regional neighborhood teams.

Pharmacists must additionally keep an effective system for inventory control. They must also know with the guidelines and policies that govern the technique of pharmaceutical science. They likewise need to maintain updated with the most up to date developments in the field of pharmaceutical scientific research.

Profession possibilities

Whether you are a pharmacist searching for a new role or a drug store pupil choosing your career course, there are a selection of job possibilities to consider. A PharmD will provide you the foundation you require to excel in the industry. In addition to discovering the different medicines and also their usages, you can additionally create your service acumen.

Some of the a lot more customized careers you can go after include r & d, regulative affairs, marketing, sales and also quality assurance. You can additionally seek scholastic opportunities, such as teaching aspiring pharmacologists. You can likewise operate in pharmaceutical communications, which is a field that deals with the advertising and marketing of brand-new medicines.

You can additionally function as a medical details analyst. This kind of placement includes assessing information and carrying out experiments in lab setups. You will certainly be accountable for creating accurate supplies and taking care of several jobs at once.

You can additionally work as a clinical pharmacologist, which includes assisting patients avoid errors in does as well as protect against medicine from being failed to remember. You may also be involved with joint drug treatment monitoring, which includes ordering lab examinations and also readjusting does to guarantee the most effective outcomes.

Education needs

Depending on the state, pharmacists might be required to complete continuing education and learning credit scores prior to they can exercise. Pharmacologists may additionally be required to complete added training if they want to specialize.

The Education Regulation was amended August 1, 2007, which eliminated an exception for newly certified pharmacologists throughout the very first triennial registration duration. Newly certified pharmacologists are not needed to finish proceeding education and learning for first certificate revival.

Pharmacists in New Jacket should finish an authorized internship prior to they can begin practicing. The teaching fellowship is 104 weeks long, and also need to be finished in a drug store that is permitted by the Board.

Throughout the triennial registration period, pharmacologists must finish at the very least 45 call hrs, consisting of 3 hrs of formal proceeding education. Most of the hours need to be online programs.

Pharmacists can likewise choose even more asynchronous choices for specialist growth. These training courses may supply even more adaptability, as on-demand learners might be much more pleased with the item.

Pharmacists are called for to finish three hrs of formal proceeding education and learning on approaches to minimize medicine errors. This may be completed through on the internet programs, webinars, or teleconferencing.

Just How To Use Modern Technology To Boost Medical Care Education And Learning? |

Article written by-Lindegaard Duelund

Informing individuals regarding health is a fundamental part of healthcare education and learning. Health and wellness education covers several areas, including physical, psychological, as well as sex-related health, in addition to reproductive and intellectual health. It includes health and wellness promo and also prevention programs that are designed to show people about their health and wellness.

North America is forecasted to have the greatest growth in the market

Presently, the healthcare education market is controlled by North America. The marketplace is expected to grow at a CAGR of 8.4% over the next 5 years. This growth is mostly driven by increased financial investments in medical care education. In addition to these efforts, technical improvements are likewise driving the marketplace.

The health care education and learning market is segmented into a number of sub-markets. The main market sectors are scientific monitoring systems (CMS), proceeding medical education and learning (CME), and also others. The marketplace is also separated into regions. Asia-Pacific, Europe, and The United States And Canada are the most famous regions. Furthermore, the market is identified by little local gamers and also multinational firms.

The worldwide health care system is undergoing substantial changes, mostly, because of technological innovations and raised focus on preventative treatment and also primary care. These growths have actually additionally made it essential to constantly upgrade cross-functional abilities.

Virtual mentor models

Utilizing modern technology to improve healthcare education and learning is not without its difficulties. Various techniques have been established to bridge the gap. These methods include telehealth, on the internet knowing, and simulation innovation. Nevertheless, these techniques have limitations and research study shows that students choose cognitive as well as affective understanding outcomes.

In order to establish a robust program, it is important to select a version that gives feedback to the teacher. https://fortune.com/education/articles/theyre-maki...how-to-earn-139000-as-a-nurse/ comments version can be made use of to build an integrated curriculum. https://www.healthaffairs.org/do/10.1377/forefront.20220125.695159/ is also crucial to consider just how a version will be used in a combined or hybrid program.

In order to review the efficiency of the online teaching version, scientists performed a study of pupils signed up in a range masters level program. Students completed a questionnaire that asked to take into consideration the toughness as well as weaknesses of the training version. The outcomes revealed that students done better in online teaching than standard training approaches.

On-line platforms

Whether you are a doctor, an allied wellness professional, or a management aide, there are on-line platforms readily available for you. These systems help you keep up to date on your area. They are also beneficial for your individuals.

The medical care sector is an extremely dynamic setting. This means that it calls for constant upgrades as well as adjustments. It's also an area where safety is a significant concern. To avoid mishaps, health care organizations need to continually educate their employees.

On-line understanding uses health care professionals a means to improve their abilities and also stay updated on the current licensing as well as accreditation programs. It can likewise help you develop very personalized educational program. This sort of education has been effective in other fields, as well.

The EDUCARE platform from Boston Scientific Company provides doctors and also allied health professionals a purpose, centralized resource for medical education. It's built on a foundation of quality material as well as thought leadership. The platform supplies access to a library of clinical information summaries, live instance recordings, recorded webinars, as well as a lot more. It additionally includes a directory of local training facilities, and a schedule of upcoming events.

Value-based healthcare

Enlightening country healthcare providers about value-based health care is a vital priority for Boise State College. The College's Value-Based Healthcare Certification program is a 17-week program that covers a variety of subjects from the health care setting to regulative adjustments to alternative delivery designs. The training course is used to pupils, physicians, and also registered nurses. The program includes situation conversations of successful high-value treatment versions, and also trainees will learn exactly how to make services based on person demands as well as perspectives.

The College's program is aimed at trainees, medical professionals, as well as public health policymakers. It has been made to attend to the challenges encountering the medical care sector, including executing value-based settlement versions. It is additionally developed to assist students and medical professionals add worth to their clients.

The University's training course is developed to give an understanding of value-based medical care, including its background, metrics, and payment versions. It additionally includes practical tips for carrying out value-based care.

mHealth

mHealth is the use of wireless innovation to boost medical as well as wellness info dissemination and also prevention of condition. It can be utilized by healthcare specialists, patients, and also relative. It can likewise assist enhance human resource administration and also emergency response systems. It can additionally supply information to medical personnel in remote places.

Over the last few years, using mobile modern technologies has actually increased significantly in many nations. This consists of technologies that permit the collection of medically pertinent information, such as smartphone-based thermometers and pulse oximeters. This technology is especially beneficial for remote monitoring of chronic illness. The expanding availability of cellphones has opened brand-new chances for mHealth tasks.

As a health care teacher, it is necessary to understand the potential of mHealth to enhance the individual experience. This consists of early detection of illness. It can additionally minimize the requirement for costly interventions.

This Post Goes Over The Certifications For Pharmacy Technicians |

Content author-Friedman Daley

Performing pharmacy-related features, drug store technicians team up with a licensed pharmacist. This is carried out in order to guarantee that individuals get the most effective medications. Furthermore, technicians additionally help to arrange as well as store prescriptions.

Qualifications

Whether you are searching for a brand-new career or an existing profession, there are numerous types of qualifications for pharmacy service technicians. These qualifications are necessary since they can help you boost your job opportunity.

Certifications for drug store service technicians are available in every state. They can be acquired with a formal education and learning program, such as an area college, or with an employer. Nevertheless, several states have details laws and also requirements for drug store specialists.

Depending upon your state, you may need to get accredited before you can obtain hired. This might include obtaining a GED, passing an examination, or doing a teaching fellowship.

The National Organization of Boards of Pharmacy checklists all states that call for qualification. While visit the site can be worked with without qualification, most employers prefer candidates with an official education and learning.

Suggested Site can work in a number of settings, consisting of independent drug stores, medical facility drug stores, as well as food store. You may also have the chance to work with a pharmacist of your own choosing.

Responsibilities

Generally, the duties of drug store service technicians include finishing prescription orders, inspecting labels, confirming individual info, as well as keeping inventory. The job of a drug store technician includes a lot of manual labor and also can call for long hours. They may work in a hospital, a retail drug store, or a home infusion center.

Drug store professionals are accountable for preserving high degrees of accuracy and also safety in the pharmacy. They must have the ability to handle the stress of a hectic drug store and pay attention to the information. They may also be called upon to carry out various other obligations. These tasks are mostly depending on the drug store's demands and also the state's regulations.

Drug store technicians are likewise required to pass an examination. They might additionally be called for to complete a formal education program. The program instructs them regarding the medicine classifications as well as uses, as well as the lawful elements of pharmacy.

Drug store professionals work under the guidance of pharmacologists. They may be accountable for a variety of tasks, from filling prescriptions to handling insurance conflicts.

Profession innovation chances

Those working in the drug store market have plenty of profession development possibilities offered. These tasks vary from bringing medicines to individuals in clinical centers to managing drug store devices.

Relying on your unique rate of interests, you may wish to seek among the many specializations readily available in the field. This will certainly raise your worth to employers as well as can cause greater pay and also better task safety. Specializeds consist of automated drug giving, HIV therapy, cancer cells treatment, radiation treatment, as well as injections.

There are additionally numerous organizations that provide a selection of occupation advancement opportunities for specialists. These include the Accreditation Council for Drug Store Education, which supplies a live on the internet event as well as extra readings.

An additional fantastic way to advance your job is to become a certified professional. In fact, 63% of companies state they pay their certified workers greater than their non-certified equivalents. This results from the reality that technicians are more sought after than ever before.

Field of expertise likewise gives pharmacy service technicians the possibility to progress into higher settings and gain higher pay. For instance, a nuclear pharmacy professional is trained to safely manage radioactive drugs.

Requirements

Depending upon the state you live in, there are different needs for drug store professionals. A few states do not require training or certification, while others have demands that vary from a senior high school diploma to an university level.

Drug store professionals are in charge of giving medicines and for keeping the high quality of prescriptions. They collaborate with pharmacists in retail and health center setups. They likewise monitor various other drug store technicians. They ensure that all medications are filled precisely and in a secure way.

Lots of employers want pharmacy technicians who have finished a formal education program. These programs consist of education as well as training in drug store regulation, pharmaceutical ethics, and recordkeeping. They likewise consist of continuing education hours. Some programs include hands-on knowing as well as internships.

Drug store specialists might additionally wish to gain national certification. This is done with the Drug Store Specialist Accreditation Board or the National Wellness Profession Association. Depending upon the company, certification may be called for at the time of employment or before the first revival of a certificate.

Here Are The Various Welding Strategies Offered For Industrial, Business And Residential Projects |

Content by-Schulz Gammelgaard

Whether you are working on a commercial, industrial, or domestic job, welding is a crucial skill. There are a variety of welding techniques that are readily available. A few of the methods include Shielded steel arc welding, MIG welding, as well as Oxy-acetylene lantern welding

Oxy-acetylene lantern welding

Making use of oxy-acetylene torch welding is an effective and also dependable means to reduce metal. It needs a great deal of prep work. It can be made use of in a variety of tasks. It additionally needs a great deal of safety and security considerations.

Oxy-acetylene lantern welding resembles plasma cutting in that both techniques incorporate power and also gas in an encased room. Oxy-acetylene torch welding calls for an acetylene gas container and also oxygen cylinders. https://nicolasa62deidre.werite.net/post/2022/11/1...-Relevance-Of-Welding-Training is typically environment-friendly, while the fuel gas hose pipe is red.

Oxy-acetylene welding can be used to weld slim steels, such as moderate steel as well as copper, yet it's not suggested for welding thick metals. To weld steel, you require to heat the sides of the steel to red before you bond. This protects against the steel from ruining.

Discover More -acetylene tools consists of adaptable pipes and also a blowpipe that links to the acetylene storage tank. The gas pressure in the hose pipe is controlled by a regulatory authority. https://stewart-ardell46kelley.technetbloggers.de/...elder-through-welding-training and fuel gases to the welding torch. Oxy-acetylene welding generates a hot fire that can reach 3,200 levels Fahrenheit.

Oxy-acetylene torches are typically made use of to replace mills. However, they can be hazardous. It's finest to utilize a spark-lighter to fire up the gas.

Oxy-acetylene torch welding can be utilized for various kinds of tasks, including cutting and brazing. It is also made use of to produce custom pieces.

Shielded steel arc welding

SMAW or Protected steel arc welding is an electrical arc welding process that uses a flux-coated electrode to sign up with metals. This welding process can be used to weld a wide array of steels. Regular steels made use of in SMAW are carbon steel, stainless steel, and tool steel. It can also be made use of for covered steels as well as heat-resisting steels.

Protected steel arc welding is a straightforward and cost-effective welding procedure. However, it does have some restrictions. Among these constraints is spatter. This spatter can affect the top quality of the weld. To eliminate spatter, welders should follow a couple of easy guidelines.

The very first policy of shielded metal arc welding is to maintain the electrode in contact with the surface area. This is very important because it stops the electrode from staying with the base metal. An additional guideline is to maintain the best range in between the electrode as well as the surface. If the electrode is too near the surface, the weld might damage.

To begin the welding process, a welder will require a welding power source, an electrode owner, and also an electrode. He will certainly additionally need to make use of a ground clamp to hold the electrode in place.

After the electrode has been placed right into the holder, he will need to attach the electrode to the welding power source. An electric arc will certainly after that be developed.

MIG welding

Among the various welding techniques, MIG welding is just one of the simplest and also most efficient to learn. Despite its simplicity, MIG welding can likewise threaten if you don't follow appropriate safety preventative measures.

MIG welding makes use of electric present to generate a strong, durable weld. The welding procedure is a semi-automatic process. In this kind of welding, the electrode cable is continuously fed. The electrode wire takes a trip through the welding gun, creating an arc that thaws both the electrode and the base metal.

The arc is created by a mix of high voltage and securing gas. Shielding gas protects the weld swimming pool from impurities in the air. The securing gas includes 15% co2.

MIG welding is a tidy procedure, allowing the welder to create excellent quality welds. Nevertheless, it is essential to remember that the best products and also tools will create the most effective results.

There are 4 different transfer kinds available for MIG welding. These consist of the short circuit transfer, the globular transfer, the metal transfer, and also the wire in MIG transfer.

The cord in MIG transfer is achieved by utilizing a combination of high voltage as well as shielding gas. The cord in MIG transfer makes a popping audio as well as makes a mist-like appearance on the joint.

The cord in MIG transfer also makes a snap audio. This results from the mix of high voltage and argon shielding gas.

|

Метки: Welding Programs Welding Training Pipe Welding Structure Welding Welding School Welding Career Welding Trade School Underwater Welding Welding Technician |

Exactly How To Use Welding Tips To Boost Your Welds |

Posted by-Kure Storm

Using welding ideas can make a substantial distinction when it involves your welding process. They assist you to stay clear of damages to the materials that you are collaborating with, as well as additionally help to improve the high quality of the final product.

Contact suggestion size

Selecting the best call suggestion size for welding is vital to getting an excellent weld. top 10 welding schools in the us can aid you maintain your tip temperature levels reduced, lower existing transfer and extend the life of your call tip. The size of your contact tip depends upon the sort of welding you are executing as well as the sort of cable you are utilizing. Picking the wrong dimension can trigger your weld to be misaligned and also result in micro-arcing, bad electric pick-up, and a careless arc.

The American Welding Culture's code 5.18 states that the best get in touch with tip is the one with a +- 0.002-inch diameter helix, yet that doesn't indicate you ought to make use of a helix that's over one inch. The most effective get in touch with pointer dimension is the one that enables one of the most smooth and also precise wire feeding.

Call suggestion recess

Selecting the correct call suggestion recess can boost weld quality, decrease spatter and reduce puddle porosity. It likewise lowers the risk of burn-through as well as warping of thinner materials. A call pointer with the right recess can additionally save you money by lessening downtime and also prolonging its life time.

A get in touch with idea recess is the placement inside the nozzle where the get in touch with suggestion is located. The placement of the get in touch with pointer has a straight influence on cable stickout, the quantity of induction heat generated by the arc, and also the amount of shielding gas insurance coverage.

Safety and security precautions

Throughout welding, there are several safety preventative measures that need to be followed. These consist of the secure use of electric equipment, use of safety helmets and also eye protection, use of fire extinguishers, and also use fireproof guards. Maintaining the welding location tidy as well as organized is additionally essential.

Besides being https://www.click4r.com/posts/g/7086463/this-short...ost-effective-welding-programs , welding can also release hazardous fumes. These gases can affect the breathing system, create frustrations, vomiting, and weakness. To prevent these health hazards, workers must follow the proper Interior Labor Regulations and be trained to utilize a first-aid set.

Apart from using a helmet, workers need to likewise use fire immune gloves as well as galoshes. These will help avoid burns caused by the sprinkles of hot steel.

Fillets

Producing fillet welds for welding includes a selection of variables. https://canvas.instructure.com/eportfolios/1000988...pic_Regarding_Welding_Programs include the loved one strength of the steel being joined, in addition to the toughness of the parent metal.

The toughness of fillet welds is normally in the variety of 0.8-0.9. There are various other variables that can influence this stamina, such as the base metal's stamina, ductility, as well as family member strength of the weld steel. The strength of the fillet weld is likewise dependent on the throat size of the weld.

If the weld metal is thinner than the base metal, it is feasible that the base metal will warp if it undergoes a constant run. This can trigger a weld to damage in its profile.

Tightening up the call suggestion

Utilizing the right get in touch with tip when welding can aid you achieve far better welds, while minimizing your downtime. There are several crucial things to keep in mind when selecting a new suggestion, consisting of the material it's made from, the dimension of the pointer, and also the holder it's mounted in. Picking the ideal tip can be a challenging task, as well as if done incorrectly it can end up creating troubles.

A contact suggestion can be a terrific addition to your welding equipment, however it is necessary to pick a high-grade pointer that will certainly offer you with a lengthy life span. This will assist you avoid the expensive repercussions of early pointer failing, that include downtime and minimized performance.

Striking the electrical arc

Producing an electrical arc in between the electrode and also the job item is the initial step in the welding procedure. This electric arc, or plasma, develops a bead of molten steel that is made use of to cover the base metal and also load the area between the items being signed up with. It also releases a vapor that shields the weld from impurities.

Producing an arc is very easy if you have a steady hand as well as a good welding setup. This consists of an electrode, a neutral clamp, and a racer. Once the electrode is established, the welding equipment can be activated.

Securing gas

Picking the best protecting gas for welding can make all the difference. It can assist you create tidy, attractive welds. Yet if you select the incorrect one, it can cause unequal infiltration, splits, or improper grain shapes.

Common components of protecting gases include helium, oxygen, nitrogen, and co2. The shielding gas that you pick depends on the type of steel you are welding and also the kind of cord that you are utilizing. The composition of the filler cord is also crucial. It ought to work with the weld joint characteristics you are attempting to produce.

|

Метки: Welding Programs Welding Training Pipe Welding Structure Welding Welding School Welding Career Welding Trade School Underwater Welding Welding Technician |

Allow Us Talk About The Types Of Welding In This Post |

Article by-McAllister Dodd

Whether you are a specialist or a person just discovering just how to weld, there are a couple of points you ought to recognize. Some of these points prevail feeling, however others might be extra complicated. You need to likewise understand that there are several different sorts of welding These include: TIG, arc welding, and gas steel arc welding

Atomic hydrogen welding

Created by Irving Langmuir, atomic hydrogen welding uses an electrical arc to weld. This welding process is perfect for welding stainless steel as well as other alloys. It is also made use of for repairing dies and also other devices. It creates spick-and-span and also top quality welds.

The main benefit of this procedure is that it does not call for flux or protecting gas. Learn Even more is additionally appropriate for tiny diameter alloys. Nevertheless, it is not a good selection for big metals or transferring metals. It additionally has a high expense.

The arc generated in atomic hydrogen welding has a temperature level of over 4000 degC. Furthermore, it has the capability to dissociate right into molecular hydrogen and atomic hydrogen.

It has actually additionally been discovered that the process can melt tungsten, a metal that is challenging to weld. It additionally has the ability to weld thin sheets of metal.

Globular transfer welding

Making use of a high warm, globular transfer welding develops a blob of filler steel. It resembles short circuit welding, yet is limited by the uneven geometry of the resulting weld. Welding operators must comprehend the advantages as well as drawbacks of each welding procedure. Understanding which one is right for your welding application is crucial.

Globular transfer welding is a low cost procedure that can be made use of to weld 1/8 inch base materials. The cable feed speed as well as voltage needed for globular transfer welding are generally higher than those required for short circuit welding The procedure also calls for a greater quantity of securing gas circulation. This is due to the bigger dimension of the beads created by globular transfer welding.

The bead of filler steel produced by globular transfer welding is larger than the diameter of the welding cord. This makes the process tough to control.

Gas metal arc welding

GMAW is a welding technique that uses an electric arc to weld steels. It was established around the turn of the century. Gas metal arc welding (GMAW) can be done manually or instantly. It is among one of the most preferred welding approaches for welding corrosion-resistant alloys. In the early days of GMAW, carbon electrodes were utilized.

The surface area tension of the weld pool is very important for a high-quality weld. It reduces spatter as well as offers an outstanding weld quality. get more info helps to make the arc show up continuous to the human eye.

The fundamental tools required for gas steel arc welding include an electrode wire, a welding gun, a cable feed system, and also a shielding gas supply. For welding steels, a 70 percent argon, 28 percent carbon dioxide, as well as 2 percent oxygen mix is becoming popular.

TIG welding

Regardless of its simpleness, TIG welding is an extreme procedure that calls for careful control of welding parameters. TIG welding creates a weld with a smooth finish, making it suitable for a wide range of applications.

The TIG welding procedure includes a tungsten electrode and also an electrical arc. The electrode has a melting point of 6,192 degrees Fahrenheit, which allows it to hold up against the hot temperature level of the welding arc. TIG welding is made use of to weld non-ferrous steels as well as metals that are immune to corrosion.

https://writeablog.net/onie5leandra/just-how-to-get-the-right-welding-training of TIG welding can be performed manually or autogenously. The welder holds the lantern in one hand while feeding the filler rods with the other. Prior to starting the welding process, the welder has to readjust the maker setups to match the needs of the project.

Rubbing welding

Contrasted to other kinds of welding, Rubbing Welding is a fairly inexpensive process, especially for smaller sized parts. Additionally, it produces a high strength user interface with a low stress weld. It likewise has the advantage of enabling the signing up with of different materials without the need for expensive tooling. Additionally, it is well-established in the engineering globe.

The standard concept behind friction welding is that kinetic energy is transferred into the easily revolving part when the wanted rotational speed is gotten to. Sometimes, the product remains in a strong state during this process.

Friction welding utilizes a combination of turning as well as pressurized components. The stress increases swiftly when the rotation quits, which develops frictional warm. A high-speed spindle is made use of for the weld process.

|

Метки: Welding Programs Welding Training Pipe Welding Structure Welding Welding School Welding Career Welding Trade School Underwater Welding Welding Technician |

This Write-Up Will Offer Details On Common Welding Processes, Protective Equipment, As Well As Joining Methods For Plastics. |

Article created by-Patton Kilgore

Whether you're building a residence or fixing a car, welding is a skill you require to recognize.

Safety gear

No matter how experienced or seasoned you are, you must constantly use protective equipment for welding. You require to secure your hands as well as eyes from the heats and also triggers associated with welding. Putting on the ideal gear can reduce the threat of burns, eye injuries, and also skin infections.

Putting on the best protective gear can make the difference in between a quick fix and a catastrophe. The very best protective equipment for welding will be able to secure your hands from high temperatures, secure your feet from flying triggers, as well as keep you cool.

One of the most vital safety equipment for welding is the ideal pair of gloves. The most typical type of gloves are natural leather gloves. These gloves will safeguard your hands from warm and likewise prevent splinters.

In addition to shielding your hands, your face and also eyes need to also be shielded. Eye defense will likely be a welding helmet with eye guards. It is additionally a great concept to have a welding beanie to protect your face.

Common welding procedures

Numerous welding processes are employed for a selection of applications. https://www.click4r.com/posts/g/7083250/this-artic...ic-concerning-welding-programs are made use of for signing up with different products such as metals, wood, as well as thermoplastics. These procedures are also helpful in numerous industrial setups. However, there are some distinctions between them. It is necessary to recognize the differences between welding procedures before deciding on the best procedure for a specific application.

Flux-cored welding is one more sort of steel welding. This procedure is commonly used for thicker metals. Nevertheless, it can be done on slim metals too. It can be performed inside your home or outdoors.

Steel Inert Gas welding is another prominent welding procedure. It is used to join various kinds of metals and also alloys. It can be used in numerous applications consisting of automotive repair, building, pipes, and also robotics. It also prevents contamination by dampness and also airborne impurities. It maintains the purity of the liquified metal pool.

Resistance welding is a process of using pressure to a steel. The process entails the development of a pool of liquified metal that is melted by the application of an electric present. Numerous elements influence the top quality of the welded joints. They include the kind of metal, the temperature level, the filler material, the securing gas, and the process used.

Signing up with techniques for plastics

Different signing up with methods are readily available for plastics. Several of these approaches are mechanical fastening and also glue bonding. These approaches appropriate for signing up with polycarbonate polymers. They have various benefits as well as downsides. https://blogfreely.net/eleonora45edythe/how-to-get-the-right-welding-training are likewise not suitable for automated processes.

Mechanical fastening techniques are more efficient for joining polymer compounds. They are additionally simpler to examine as well as disassemble. Several of the benefits of mechanical fastening include the capacity to join big composite structures. The downsides consist of high stress and anxiety focus as well as long curing time.

Sticky bonding utilizes a chemical procedure to form a bond between 2 materials. It has some downsides, consisting of a limited variety of products and trouble bonding to plastics. Furthermore, the procedure takes time to heal as well as might be inefficient when signing up with dissimilar products.

Adhesive bonding is likewise the most costly and also labor extensive of all the signing up with approaches. It calls for a large amount of surface preparation prior to applying heat as well as pressure. This approach is also not as strong as mechanical attachment.

Usual weld changes

Commonly, welding strategies are used to join two different metals. Making use of these techniques has ended up being prevalent as they are able to produce solid, permanent links without corrosion. Nonetheless, some problems may emerge. These problems can take place because of metallurgical or craftsmanship problems. They may additionally be caused by equipment breakdowns.

For instance, a high-resolution thermal imaging system is essential for precise recognition of welding defects. This method supplies info on problem detection, stage shift monitoring, and also the thermal background of the liquified steel. It is additionally a technique for producing post-weld photos. In addition, it gives missing information for robotic systems.

The technique incorporates the benefits of temperature dimension with high-resolution imaging. The video is made up of a series of structures recorded in real time. It also gives a map of the thermal area in 2 spatial dimensions.

The thermal history of the liquified steel can be determined from its position, temperature, and also time. This information is specifically crucial for examining the thermal history of products. It can also assist to recognize freezing points.

|

Метки: Welding Programs Welding Training Pipe Welding Structure Welding Welding School Welding Career Welding Trade School Underwater Welding Welding Technician |

This Post Will Supply Information On Common Welding Procedures, Safety Gear, And Signing Up With Techniques For Plastics. |

https://squareblogs.net/kymberly71wes/the-list-bel...erview-of-the-most-usual-types by-Danielsen Johansson

Whether you're constructing a residence or repairing a car, welding is an ability you require to know.

Safety gear

Regardless of just how competent or knowledgeable you are, you should constantly use protective equipment for welding. You need to shield your hands and also eyes from the high temperatures and also stimulates connected with welding. Putting on the best equipment can lower the risk of burns, eye injuries, and skin infections.

Using the best safety gear can make the distinction in between a quick fix as well as a catastrophe. The most effective protective equipment for welding will be able to shield your hands from heats, safeguard your feet from flying triggers, as well as keep you cool.

https://www.wnc.edu/roads-program-removes-obstacle...dent-to-pursue-welding-career/ of the most essential protective equipment for welding is the ideal set of handwear covers. The most common type of gloves are natural leather gloves. These gloves will certainly safeguard your hands from heat and also prevent splinters.

Along with shielding your hands, your face and also eyes ought to also be safeguarded. Eye defense will likely be a welding safety helmet with eye shields. It is likewise a great concept to have a welding beanie to protect your face.

Common welding procedures

Several welding processes are used for a variety of applications. They are made use of for joining various materials such as steels, wood, and thermoplastics. These processes are likewise valuable in various commercial settings. Nonetheless, there are some differences in between them. It is very important to understand the differences in between welding procedures before choosing the best procedure for a specific application.

Flux-cored welding is one more kind of metal welding. This process is usually utilized for thicker steels. Nonetheless, it can be done on thin steels as well. https://canvas.instructure.com/eportfolios/1000948...A_Welder_With_Welding_Training can be performed inside your home or outdoors.

Steel Inert Gas welding is one more popular welding process. It is used to join different types of metals and alloys. It can be utilized in lots of applications consisting of automobile repair service, structure, pipes, and also robotics. It also prevents contamination by dampness and also airborne contaminants. It preserves the pureness of the molten metal pool.

Resistance welding is a process of using pressure to a steel. The procedure includes the development of a pool of liquified metal that is melted by the application of an electric current. A number of elements affect the quality of the welded joints. They consist of the kind of steel, the temperature, the filler material, the securing gas, and also the procedure made use of.

Signing up with approaches for plastics

Numerous signing up with methods are readily available for plastics. Some of these methods are mechanical attachment and also sticky bonding. These methods are suitable for joining thermoplastic polymers. They have different advantages as well as disadvantages. They are also not suitable for automated processes.

Mechanical attachment approaches are a lot more efficient for joining polymer composites. They are also easier to evaluate as well as take apart. Several of the advantages of mechanical attachment consist of the capability to sign up with large composite frameworks. The drawbacks include high tension focus and also lengthy treating time.

Sticky bonding uses a chemical procedure to develop a bond between two products. It has some disadvantages, including a limited series of materials and problem bonding to plastics. Furthermore, the procedure requires time to heal and also may be inadequate when signing up with different products.

Glue bonding is likewise the most pricey and labor intensive of all the joining approaches. It requires a great deal of surface area preparation prior to using warmth as well as stress. This technique is likewise not as strong as mechanical fastening.

Usual weld shifts

Typically, welding methods are utilized to join 2 dissimilar steels. The use of these techniques has ended up being extensive as they are able to create strong, long-term connections without corrosion. Nonetheless, some troubles may arise. These troubles can happen due to metallurgical or craftsmanship problems. They might likewise be triggered by devices breakdowns.

For instance, a high-resolution thermal imaging system is necessary for accurate identification of welding defects. This technique provides details on defect discovery, stage transition tracking, and also the thermal history of the molten steel. It is additionally a technique for creating post-weld pictures. Furthermore, it gives missing out on data for robotic systems.

The strategy combines the advantages of temperature level measurement with high-resolution imaging. The video clip is made up of a series of frameworks caught in real time. It also supplies a map of the thermal area in 2 spatial dimensions.

The thermal background of the molten steel can be established from its placement, temperature, and time. This details is specifically crucial for assessing the thermal background of materials. It can likewise assist to recognize freezing points.

|

Метки: Welding Programs Welding Training Pipe Welding Structure Welding Welding School Welding Career Welding Trade School Underwater Welding Welding Technician |

Here Are The Options For Welding Training Go Over In This Write-Up |

Author-West McGee

Whether you intend to find out welding by yourself or via an instruction, there are several alternatives available There are apprenticeships, on-the-job training, as well as accreditation programs, which are all readily available to aid you learn as well as earn while you are functioning.

Accreditations are available

Obtaining welding certification is an excellent way to boost your work prospects. It can result in higher earnings and more security. Yet it additionally needs time and prep work. You can start by signing up for classes.

The American Welding Society (AWS) is one of the most identified welding body in the United States. It sets standards for welding accreditation. Along with establishing the requirements for welding accreditation, it offers code qualification for welding used by the American Oil Institute (API).

AWS qualification can be earned in several different positions. https://www.bikeexif.com/motorcycle-welding is the Certified Welding Program (CWE). This is a much more generalized course, which is suitable for beginners. During this course, you'll find out the essentials of welding, consisting of metallurgy, pipe welding, pipeline positioning, as well as pipeline brazing.

One more sort of welding accreditation is the AWS Certification Program for Robotic Arc Welding (CROAW). This program uses training on welding procedures, welding codes, and robot arc welding makes use of. The program requires reexamination every 3 years.

On-the-job training enables us to advance in the field without participating in a vocational or trade institution

Obtaining a welder certification is a good way to breakthrough in the welding field. Lots of sector companies use qualifications, such as the American Petroleum Institute and the American Welding Culture. There are likewise certification programs that you can finish while you are working.

Profession schools, or occupation colleges, are a quick method to get involved in your dream career. They are likewise a great deal less expensive than a college. Usually, https://justine91darcel.werite.net/post/2022/11/20...ical-Sorts-Of-Welding-Training can earn your associate degree in less than 2 years. There are also numerous programs that are readily available online.

Trade schools are a fantastic method to learn more about your profession and gain real-world experience. They additionally provide you a possibility to prove your skills to employers. Generally, students who go to trade colleges are established to create their abilities in a specific area.

Professions generally need specific training and also accreditation. The American Oil Institute, the American Welding Society, and the American Culture of Mechanical Engineers all use accreditations.

Trades are usually self-employed, but you can additionally come to be a supervisor in your profession. A supervisor's task is to be knowledgeable in a particular trade.

Instructions permit you to "earn as well as learn" at the same time

Whether you are a high school pupil, university student, or working professional, instructions are an excellent means to make an excellent salary while discovering useful work abilities. Depending on the training program, students might learn on the job or in the classroom.

If you want to learn more about apprenticeships in welding, you can call a welding institution and also discover more regarding the program. They can likewise connect you with business wanting to hire welders You can likewise speak with your current employer about the possibility of looking for an instruction.

Apprenticeships are work-based understanding programs developed to help individuals gain a portable, nationally-recognized credential. Businesses also see apprenticeships as an useful ability advancement device.

Registered instruction programs are detailed as well as flexible. Relying on your state, apprenticeships can lead to a fulfilling job. You can likewise gain university credit ratings as part of the training program.

Registered https://writeablog.net/chante92yong/what-you-can-e...from-a-welding-training-course have actually remained in place worldwide for over 80 years. These programs are moneyed by the U.S. Department of Labor as well as are acknowledged by state as well as federal government companies. They integrate classroom research with comprehensive on-the-job training. They likewise satisfy nationwide criteria for registration with the united state Division of Labor.

Career potential customers for welders

Whether you're wanting to get in the labor force or are already operating in a proficient trade, it is necessary to recognize the occupation prospects for welding trainees. There are lots of advantages to having a profession in welding, including high incomes, high demand as well as plenty of possibilities.

A career in welding is a great alternative for youngsters, as it is an extremely available area. You can start with a certificate or level from a profession institution. You can also find beginning settings with simply a senior high school diploma.

The need for welding workers is growing, as the sector continues to be a key part of the production field. The American Welding Culture estimates that there is a 290,000 task shortage in the welding market by 2020.

There are numerous markets that make use of welding, including building, architectural metals making and also motor vehicle production. There is likewise an expanding demand for welding device operators, as business purchase even more robotic welding machinery.

|

Метки: Welding Programs Welding Training Pipe Welding Structure Welding Welding School Welding Career Welding Trade School Underwater Welding Welding Technician |

Continue Reading To Figure Out Even More Concerning The Tips For Successful Welding |

Content author-Waters Danielsen

Whether you are welding glass or metal, it is necessary to recognize just how to use the proper equipment and also comply with the right procedures. By following these tips, you will be able to finish your job more conveniently.

Steel

Making use of welding techniques, metals can be collaborated. There are various welding processes, each of which has its very own advantages and downsides. The complying with defines the various kinds of welding and their applications.

Steel Inert Gas (MIG) welding combines a molten filler steel with a change that shields the steel from atmospheric contamination. The molten filler product is fed with a welding weapon. The protecting gas is argon or co2. This gas stops the oxide inclusions from forming in the molten steel.

Metal Inert Gas (MIG) welding is typically made use of to join thin steels. The filler steel has a melting point listed below the base metal. The filler steel can be circular or oblong.

The argon gas made use of for the welding gun avoids porosity as well as additionally suppresses plasma development. The gas is also used to make certain that the laser light beam is transmitted accurately.

Glass

Traditionally, the weld procedure made use of a gas or oxy-gas lantern to join 2 pieces of glass. However, researchers at Heriot-Watt University have lately created a new welding approach utilizing an ultrafast laser. This innovative technology has the potential to transform the market.

The ultrafast laser creates a section of intense heat within a material, integrating it with the metal and finishing the weld. visit my homepage is a fantastic feat due to the fact that regular commercial lasers do not function well with glass.

The ultrafast laser system additionally uses high mathematical aperture optics as well as dynamic concentrating to accomplish a round thaw swimming pool. In theory, this procedure should generate high quality welds on any form part.

Different kinds of glass are generally bonded. Thermoplastics, such as polyvinyl chloride (PVC), polyethylene, and polypropylene, form long molecular chains and also do not have the long-range crystalline order discovered in many glass.

Plastic

Making use of plastics to weld is a wonderful method to create a stronger bond than using adhesives. In addition, they are much easier to reuse. Plastics can be bonded making use of a selection of strategies. Nonetheless, each technique has its very own benefits and drawbacks.

Thermoplastics, such as polycarbonate and polyethylene, can be bonded using the hot gas welding strategy. It is a kind of welding that goes across molecular chains to form a solitary item of plastic.

Warm gas welding is the most usual method. This technique entails making use of a plastic welding gun that has a heated chamber. A plastic filler pole assists to help with the welding procedure.

Additionally, plastic welding calls for that you understand the kind of plastic you are welding. Different qualities of plastics do not generally meshed. On top of that, the toughness of a weld can be affected by detergents.

Codes as well as specs

Primarily, welding codes and specs are standards that are made use of to analyze the top quality of welds. They also specify the needs for manufacture as well as evaluation of welds, as well as the materials that can be used in these procedures. These codes and also standards are developed by various organizations.

The American Welding Culture is probably the largest producer of welding codes in the United States. They have released greater than 350 various papers on welding, with a mission to advance welding modern technology and also applications. They also produce welding standards for a vast array of sectors.

The American Oil Institute is an additional major manufacturer of welding codes and also specs. They promote the gas and also chemical procedure industries, and they supply piping design standards for a variety of applications. https://writeablog.net/genaro4andres/what-you-requ...erstand-about-welding-training create welding codes for pipeline construction and assessment.

Securing

Utilizing the correct protecting when welding is essential. Shielding can secure the weld from contaminants and also impurities, consequently guaranteeing the high quality of the finished weld. It likewise establishes the mechanical residential or commercial properties of the final weld.

When welding steel, porosity can occur. aluminum welding school occurs when gas is caught in the weld during the solidification process. It is thought that this occurs because of air, yet in truth it can happen as a result of the surrounding setting.

Protecting can avoid air from obtaining trapped inside the weld puddle. It can additionally prevent hydrogen bubbles. Additionally, it can boost the weld pool travel speed and also stop oxidation of the metals. It also prevents the development of an undercut.

The protecting gas must be able to secure the weld from air as well as various other impurities. It needs to likewise make sure correct weld bead infiltration. Relying on the metal being welded, various shielding gas mixes can be utilized.

|

Метки: Welding Programs Welding Training Pipe Welding Structure Welding Welding School Welding Career Welding Trade School Underwater Welding Welding Technician |

What You Required To Learn About Welding Processes |

Content create by-Hendrix Dyer

Whether you have actually operated in welding prior to or not, there are several points to understand about the procedures involved in welding. Several of the basic processes consist of MIG, TIG, as well as GMAW In addition, you ought to learn about Protecting gas, Atomic hydrogen, as well as short-circuiting.

GMAW

GMAW welding is among one of the most popular welding processes today. It is suitable for welding many types of metals. This welding procedure is also understood for its flexibility and also speed. It is made use of for various applications in a vast array of sectors. GMAW can be made use of in a range of different sectors, from automobile repair service to the construction sector. It can likewise be used in little service center.

GMAW welding is also one of the fastest welding procedures available. This welding process is able to deposit a huge quantity of filler steel promptly. This welding process supplies a long-term bond that is much less most likely to damage.

TIG

Making use of electricity to form an electrical arc in between a tungsten electrode as well as a steel, TIG welding generates a premium quality weld. This process is used on a wide array of metals, alloys, as well as materials. TIG welding is made use of in many industrial applications, including fixing of devices and also passes away, fusion of two metals, as well as building of important seals in nuclear power markets.

TIG welding requires a constant filler steel in the weld swimming pool. This is normally the exact same steel as the component being bonded. This prevents the weld from splattering. It additionally avoids the oxidation of the weld area. The metal in the weld pool might be a filler metal, a steel cord, or a mixture of both.

MIG

Usually, MIG welding is much faster than stick welding for smaller parts. In addition to that, it's additionally more flexible, enabling even more variety in the products utilized. With MIG, you can bond different types of metals at the same time, depending upon the application.

You can likewise make use of MIG to weld steels in slim, thick, or delicate plates. Making use of MIG, you can even repair vehicle structures, prefab structure components, and also various other fragile steel tasks.

When utilizing MIG, you require to ensure that you're using the appropriate wire, shielding gas, as well as electrodes. browse around here feature charts that help you select the right electrode for your project.

Atomic hydrogen

Making use of hydrogen in welding is a procedure that produces extremely high levels of warm. It also works as a shielding gas, as well as shields the metal from pollutants. Nevertheless, it needs an extremely skilled worker.

The procedure uses 2 tungsten electrodes that are held in an owner. They are prepared in a V-shape, and also are divided by 1.5 mm. welding trade schools near me of regarding 2 mm is likewise maintained at the pointer of the electrodes.

The dimension of the arc is essential in the welding process. It can be changed to regulate the warmth created. A follower shape can additionally be modified by transforming the present level.

Short-circuiting

Throughout welding, short-circuiting transfers are utilized to deposit metal at a reduced existing and reduced warmth input than globular transfer. Nonetheless, this technique can be much less effective than other sorts of transfers as well as can take longer to bond. It might likewise result in distortion and spatter.

Short-circuiting transfers happen during the welding procedure as well as can be used on a wide array of products. best welding schools near me is normally made use of on slim products. It generates less spatter than other sorts of transfers. It also has a low power input, which implies much less distortion.

Short-circuiting transfers require smaller sized electrodes than various other transfer approaches. This is since the electrodes touch the job as well as produce a brief. The present after that boosts to develop a pinch force that thaws the suggestion of the cord. It also generates a slight explosive audio.

Securing gas

Choosing the ideal protecting gas for your welding is an essential consider the performance of your welding procedure. The gas ought to be selected based upon your welding application and also welding kind. It's an excellent suggestion to use a flow meter to check for leaks in your gas system. If you locate that you are utilizing extra gas than you need, you might want to discover various other welding options.

The primary role of protecting gas is to prevent the molten weld pool from being subjected to the air. If the molten steel is in contact with air, it can introduce impurities right into the weld swimming pool. These contaminations might trigger different problems.

|

Метки: Welding Programs Welding Training Pipe Welding Structure Welding Welding School Welding Career Welding Trade School Underwater Welding Welding Technician |

Below Is A More Detailed Look At Types Of Welding Processes |

Content by-Svendsen Bright

Whether you are a skilled pro or new to the welding scene, there are numerous various welding processes that you may be unfamiliar with. The kinds of welding that you will certainly be subjected to consist of Shielded Metal Arc Welding (SMAW), Stick Welding, Gas Welding, and also Solid-Phase Welding.

Solid-phase procedures

Whether you're welding a cars and truck component or a furniture piece, solid-phase welding processes can assist you satisfy your manufacturing objectives. They can likewise resolve issues with different products.

A solid-phase welding procedure is a procedure that counts on heat and also pressure to join two parts. This type of welding can generate steels with better mechanical residential properties. It's a process that's been around for centuries, however it's just recently that the technology has actually gotten to a point where it's practical to execute. It's additionally one that can be easily controlled using a computer.

There are three primary blocks in the complete welding procedure. The initial block, the fusion stage, relies upon melting to sign up with products. The second block, the metallurgical phase, includes intimate get in touch with between metals. click here to read , the diffusion stage, depends on the diffusion of atoms.

Gas welding

Selecting the appropriate welding gas for the work is a crucial step. The wrong selection can lead to a weak weld, spatter or incorrect transfer of steel. Several of the fundamental welding gases are oxygen, acetylene, lp and also fume.

Oxyacetylene welding is one of the most usual gas welding technique. This process needs a gas regulatory authority and also cyndrical tube valves. It is easy to use and also mobile. It is advised for steel plates 25 mm thick or smaller sized.

Acetylene has a high flame temperature level. It is not advised for welding refractory metals. It is also flammable. It has a two-stage response.

Acetylene is dangerous when utilized above 15 psi. To safeguard yourself from the warmth, put on security clothes and also safety glasses. It is also suggested to use a regulatory authority.

Stick welding

Unlike various other welding processes, stick welding is relatively inexpensive as well as mobile. It likewise has the potential to produce high-quality welds. It can be used for a variety of metals, consisting of steel, stainless steel, nickel, copper, as well as light weight aluminum.

Stick welding is likewise referred to as Shielded Metal Arc Welding, or SMAW. It is a patented treatment invented in 1889 by Charles L. Coffin.

Stick welding is a technique of joining steels utilizing an electrode that is covered with a change. This layer prevents contamination by atmospheric gases. It also sends out vapors, which create a shielding gas that protects the molten base metal.

Stick welding is suitable for a variety of products, including metals, steel, iron, copper, aluminum, brass, and also magnesium. please click the next page is also ideal for a variety of sectors. It is often used in the shipbuilding sector, the tractor and also ranch equipment markets, as well as the pressure vessel manufacture sector.

Atomic hydrogen welding

AHW welding is a type of welding process that uses atomic hydrogen to create intense heat. It is mostly made use of for high-grade work with stainless-steel, non-ferrous metals and also hard emerging.

AHW welding produces exceptional quality welds. It is especially valuable for steels with a slim scale. It likewise offers a smooth weld surface. It is an excellent welding process for industrial usage.

The welding process is also quicker than the other alternatives. It is a type of automatic welding that ensures an excellent quality bonded whenever. AHW welding offers a number of choices, consisting of the choice of an electrode holder to avoid tungsten from entering into contact with your hand.

Atomic hydrogen welding is likewise described as tungsten inert gas welding The process is made use of to weld thin sheets of steel as well as alloys such as stainless-steel. It is likewise used for quickly, accuracy welds as well as fixing of tools and also molds.

Shielded steel arc welding

During protected metal arc welding, a pole of steel is put in an electrode owner. The electrode holder is connected to a source of power and also the job is connected to a second power source. The power source develops an electric arc between the electrode and the work. The arc melts the steel pole inside the electrode. The molten steel swimming pools create a weld.

Secured https://www.cranestodaymagazine.com/features/visionary-thinking-10349509/ is made use of for steels such as steel, iron, and also nickel alloys. It is typically used for outdoor applications. It is additionally utilized in industrial manufacture.

Shielded metal arc welders generate premium quality welds. Nevertheless, this process is hard to control. It also creates fumes and also slag. This procedure can cause slag additions as well as problems.

Shielded steel arc welding is used to weld steel, iron, nickel alloys, as well as other steels. Normally, cast iron is utilized for this process. Aluminium may likewise be used. Nevertheless, light weight aluminum calls for a different welding procedure.

|

Метки: Welding Programs Welding Training Pipe Welding Structure Welding Welding School Welding Career Welding Trade School Underwater Welding Welding Technician |

What You Need To Understand About Welding Processes |

Author-Lang Dyer

Whether you have operated in welding before or otherwise, there are numerous things to learn about the processes associated with welding. Several of the fundamental processes include MIG, TIG, as well as GMAW Furthermore, you need to learn about Protecting gas, Atomic hydrogen, and also short-circuiting.

GMAW

GMAW welding is among the most popular welding procedures today. It appropriates for welding numerous kinds of steels. This welding procedure is also recognized for its flexibility and speed. It is utilized for different applications in a vast array of sectors. GMAW can be made use of in a selection of different sectors, from auto repair to the construction industry. It can additionally be used in small service center.

GMAW welding is also among the fastest welding procedures readily available. This welding procedure is able to deposit a huge quantity of filler steel quickly. This welding procedure gives a permanent bond that is much less most likely to break.

TIG

Using power to form an electric arc between a tungsten electrode and a steel, TIG welding generates a top quality weld. This process is made use of on a wide variety of steels, alloys, and also products. TIG welding is used in lots of commercial applications, including repair work of tools as well as dies, combination of two steels, and building of crucial seals in nuclear power industries.

https://writeablog.net/marcellus37antone/this-post...o-this-important-subject-about requires a continuous filler steel in the weld pool. This is generally the exact same metal as the component being bonded. This avoids the weld from splashing. It likewise avoids the oxidation of the weld location. The metal in the weld swimming pool might be a filler steel, a steel cord, or a mix of both.

MIG

Usually, MIG welding is quicker than stick welding for smaller sized parts. Along with that, it's likewise extra versatile, permitting more variety in the products utilized. With MIG, you can bond different sorts of steels at the same time, relying on the application.

You can likewise use MIG to weld steels in thin, thick, or delicate plates. Utilizing MIG, you can also fix vehicle structures, prefab structure parts, and various other delicate steel projects.

When utilizing MIG, you need to guarantee that you're utilizing the ideal wire, shielding gas, and also electrodes. Some MIG welders feature graphes that aid you pick the right electrode for your job.

Atomic hydrogen

Making use of hydrogen in welding is a process that generates extremely high levels of heat. It also acts as a protecting gas, as well as protects the metal from impurities. Nevertheless, it requires an extremely skilled worker.

The process uses two tungsten electrodes that are kept in a holder. They are organized in a V-shape, and are divided by 1.5 mm. A void of concerning 2 mm is additionally preserved at the tip of the electrodes.

The dimension of the arc is necessary in the welding procedure. It can be transformed to manage the heat produced. A follower form can likewise be changed by transforming the present degree.

Short-circuiting

During welding, short-circuiting transfers are made use of to down payment metal at a reduced existing and also reduced heat input than globular transfer. Nevertheless, this approach can be much less effective than various other kinds of transfers as well as can take longer to bond. It might additionally cause distortion and also spatter.

Short-circuiting transfers take place throughout the welding procedure and also can be used on a wide variety of materials. click the up coming site is generally used on thin materials. It generates less spatter than other sorts of transfers. read more has a low power input, which suggests less distortion.

Short-circuiting transfers require smaller sized electrodes than other transfer methods. This is due to the fact that the electrodes touch the job and also create a brief. The present after that increases to produce a pinch force that thaws the pointer of the cord. It also generates a small explosive sound.

Securing gas

Choosing the ideal securing gas for your welding is an essential factor in the performance of your welding procedure. The gas needs to be picked based on your welding application and also welding type. It's a good concept to make use of a flow meter to look for leakages in your gas system. If you find that you are utilizing extra gas than you need, you may want to explore other welding options.

The main duty of securing gas is to stop the liquified weld pool from being revealed to the air. If the molten steel touches with air, it can introduce contaminations into the weld pool. These contaminations might create various issues.

|

Метки: Welding Programs Welding Training Pipe Welding Structure Welding Welding School Welding Career Welding Trade School Underwater Welding Welding Technician |

This Write-Up Will Certainly Give Details On Usual Welding Processes, Protective Gear, And Also Signing Up With Approaches For Plastics. |

Suggested Browsing written by-Harrell Mortensen

Whether you're developing a house or repairing an automobile, welding is an ability you require to understand.

Protective equipment

No matter how proficient or skilled you are, you ought to always wear safety equipment for welding. You need to protect your hands as well as eyes from the high temperatures as well as stimulates associated with welding. Putting on the best equipment can minimize the danger of burns, eye injuries, and also skin infections.

Wearing the right safety gear can make the difference between a quick fix as well as a catastrophe. The most effective safety gear for welding will be able to safeguard your hands from heats, secure your feet from flying sparks, as well as maintain you cool.

Among the most important protective gear for welding is the ideal pair of gloves. The most common sort of gloves are leather handwear covers. do you need a highschool diploma for welding school will certainly protect your hands from heat as well as also protect against splinters.

In addition to protecting your hands, your face as well as eyes ought to likewise be safeguarded. Eye defense will likely be a welding helmet with eye guards. It is also a great idea to have a welding beanie to protect your face.

Typical welding procedures

Numerous welding procedures are employed for a range of applications. They are used for signing up with different products such as metals, timber, and also thermoplastics. These procedures are likewise beneficial in numerous industrial settings. However, there are some differences between them. It is necessary to understand the distinctions in between welding procedures before choosing the very best process for a certain application.

Flux-cored welding is one more sort of metal welding. top 10 underwater welding schools is normally made use of for thicker steels. Nevertheless, it can be done on thin metals as well. It can be performed inside or outdoors.

Steel Inert Gas welding is one more popular welding procedure. It is used to sign up with various types of metals as well as alloys. It can be utilized in numerous applications including auto repair, structure, pipes, and also robotics. It additionally stops contamination by dampness as well as airborne contaminants. It preserves the pureness of the molten metal puddle.

Resistance welding is a process of using stress to a metal. The procedure involves the production of a swimming pool of liquified steel that is thawed by the application of an electric current. Numerous elements influence the top quality of the bonded joints. They include the type of metal, the temperature, the filler product, the protecting gas, as well as the process utilized.

Joining techniques for plastics

Various signing up with methods are readily available for plastics. Several of these methods are mechanical attachment and glue bonding. These techniques are suitable for joining thermoplastic polymers. They have various benefits and also downsides. They are likewise not appropriate for automated processes.

Mechanical fastening approaches are a lot more effective for joining polymer compounds. They are additionally simpler to evaluate as well as disassemble. A few of the benefits of mechanical fastening include the ability to sign up with huge composite structures. The drawbacks consist of high tension focus as well as lengthy curing time.

Glue bonding utilizes a chemical process to form a bond in between two products. It has some downsides, consisting of a restricted variety of products and also trouble bonding to plastics. Additionally, the procedure takes time to heal as well as may be inadequate when joining different materials.

Adhesive bonding is also one of the most pricey and labor intensive of all the joining approaches. It requires a large amount of surface prep work prior to using heat and also pressure. This approach is likewise not as solid as mechanical fastening.

Common weld transitions

Commonly, welding techniques are made use of to join 2 dissimilar steels. The use of these techniques has ended up being widespread as they have the ability to create solid, irreversible links without deterioration. Nevertheless, some problems may emerge. These issues can happen as a result of metallurgical or workmanship defects. They may also be brought on by devices malfunctions.

As an example, a high-resolution thermal imaging system is needed for precise identification of welding issues. This technique gives info on issue discovery, stage change tracking, as well as the thermal history of the liquified steel. It is likewise an approach for producing post-weld photographs. Additionally, it supplies missing information for robotic systems.

The strategy incorporates the advantages of temperature level dimension with high-resolution imaging. The video clip is made up of a series of frameworks captured in real time. It likewise supplies a map of the thermal field in two spatial measurements.

The thermal history of the molten metal can be figured out from its setting, temperature level, and also time. This details is particularly vital for assessing the thermal background of materials. It can also help to identify freezing points.

|

Метки: Welding Programs Welding Training Pipe Welding Structure Welding Welding School Welding Career Welding Trade School Underwater Welding Welding Technician |

What You Required To Know About Welding Processes |

Content by-Munksgaard Reilly

Whether you have worked in welding prior to or otherwise, there are numerous things to know about the procedures associated with welding. A few of the standard procedures consist of MIG, TIG, and also GMAW Furthermore, you should know about Securing gas, Atomic hydrogen, and short-circuiting.

GMAW

GMAW welding is among the most prominent welding procedures today. It is suitable for welding many types of steels. https://postheaven.net/aurelia78norbert/right-here...ng-lets-have-a-look-at-some-of is additionally known for its versatility and rate. It is utilized for various applications in a wide range of markets. GMAW can be utilized in a range of various markets, from automotive repair service to the building market. It can additionally be utilized in small service center.