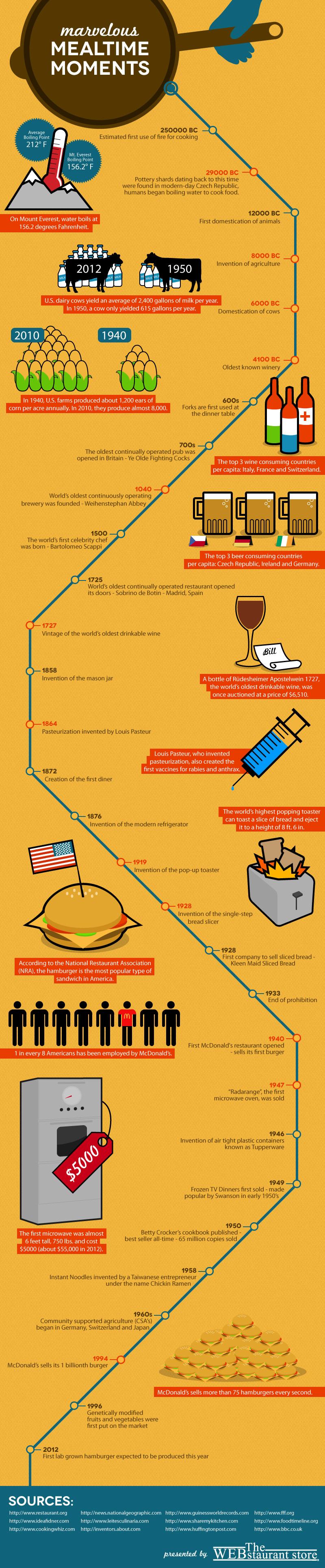

Tips For Choosing The Correct Tunnel Pasteurizer For Your Production Line |

Created By-Nordentoft Weeks

Selecting the appropriate tunnel pasteurizer for your assembly line isn't simply a matter of selecting one off the rack. You require to think about various variables that directly impact your performance and outcome. Begin by assessing the specific items you'll be sterilizing and the volume you expect to take care of. The right option can simplify your procedure, yet it likewise comes with challenges that could affect your bottom line. Allow's explore what to prioritize in your choice.

Comprehending Your Manufacturing Requirements

When picking a tunnel pasteurizer, it's vital to recognize your production needs initially.

Take into consideration the sort of products you'll be pasteurizing, as different things might need differing temperature level and time setups.

Consider your manufacturing volume; you'll desire a pasteurizer that can handle your day-to-day output without bottlenecks.

Analyze the size of your assembly line as well-- ensure the pasteurizer fits conveniently within your available space.

In addition, don't overlook the frequency of manufacturing runs; a device matched for high-demand periods will certainly be different from one used occasionally.

Evaluating Performance and Cost-Effectiveness

As you examine tunnel pasteurizers, focusing on effectiveness and cost-effectiveness is important to optimizing your financial investment.

Begin by assessing the energy consumption of each version. A reliable pasteurizer not only minimizes operational expenses but likewise decreases your carbon footprint.

Next, take into consideration the throughput capability; a higher ability can bring about lower per-unit prices, particularly for massive manufacturing.

Don't fail to remember to analyze the warm recovery systems, which can dramatically boost effectiveness by reusing energy.

In addition, consider the equipment's lifespan and upkeep costs; a much more pricey first financial investment could be rewarding if it provides far better longevity and reduced operating budget with time.

Balancing https://fooddigital.com/top10/top-10-largest-alcoholic-beverage-companies will help you pick a tunnel pasteurizer that satisfies both your production demands and spending plan.

Maintenance and Support Considerations

While evaluating tunnel pasteurizers, it's important to think about the maintenance and assistance alternatives available. You'll want a maker that not just fits your production needs yet also supplies dependable service.

Inspect if the supplier provides extensive support, including setup, training, and troubleshooting. An excellent warranty can save you money and inconvenience down the line, so don't neglect that facet.

It's likewise smart to ask about the availability of replacement components and exactly how quickly they can be supplied. Regular upkeep is crucial to keeping your pasteurizer running efficiently, so find out what's needed and whether the maker provides maintenance plans.

Final thought

To conclude, choosing the ideal tunnel pasteurizer for your production line is critical for effectiveness and item quality. By recognizing your specific production demands, evaluating cost-effectiveness, and thinking about upkeep and support, you can make an educated choice. Don't fail to remember to think about your center's area and the capability to adapt to different products. With the appropriate pasteurizer, you'll boost your operations and make certain consistent outcomes. Make the effort to evaluate your alternatives thoroughly!

Eager To Identify The Very Best Tunnel Pasteurizer For Your Service Needs? Explore The Vital Elements To Think About For Improving Production Effectiveness And Product Top Quality |

Web Content Written By-Mays Lawrence

When selecting the ideal Tunnel pasteurizer for your service, you face a critical choice that can impact your production effectiveness substantially. The process entails considering different elements like dimension, ability, temperature control, and upkeep requirements. It's not practically the preliminary purchase; it's likewise about long-term operational prices and support. Comprehending the nuances of different Tunnel pasteurizer types and their suitability for your certain needs is vital. Your selection will play an essential role in making sure the high quality and safety of your items while maximizing your manufacturing processes.

## Key Elements to Take Into Consideration

When choosing a tunnel pasteurizer for your organization, it's important to take into consideration a number of key aspects that will influence the efficiency and effectiveness of your pasteurization process.

First of all, evaluate the dimension and capability requirements of your assembly line. Guarantee the Tunnel pasteurizer you pick can deal with the quantity of products you need to refine to prevent bottlenecks or hold-ups in production.

Secondly, take into consideration the home heating and cooling down abilities of the pasteurizer. The temperature control precision is important to ensure that your items are sterilized effectively without jeopardizing quality. Look for a tunnel pasteurizer that offers exact temperature level surveillance and adjustment functions to meet your specific pasteurization requirements.

Another crucial element to consider is the impact and format of the Tunnel pasteurizer. See to it the devices fits well within your production center and can be quickly incorporated into your existing line without considerable adjustments. In addition, analyze the upkeep demands and the schedule of technological support for the pasteurizer to guarantee smooth operations and minimal downtime.

## Sorts Of Tunnel Pasteurizers

To much better comprehend the diverse options offered in the marketplace, it is essential to explore the different types of Tunnel pasteurizers fit for various manufacturing requirements and processes.

One common kind is the continuous Tunnel pasteurizer, suitable for high-volume production with constant warmth treatment. If you have differing production rates, a modular Tunnel pasteurizer might be the most effective fit as it permits versatility in line arrangements.

For smaller sized services, a compact Tunnel pasteurizer could be the appropriate option, providing area performance without endangering on pasteurization top quality. If your products require details treatment areas, an adjustable Tunnel pasteurizer may be one of the most appropriate option, allowing customization of heat exposure levels.

Furthermore, Tunnel pasteurizers can be categorized based on home heating techniques such as water immersion, steam injection, or hot air, each offering one-of-a-kind advantages relying on the product being refined. Recognizing these types will aid you pick the Tunnel pasteurizer that lines up ideal with your organization demands.

## Budgeting and Price Analysis

Taking into consideration the financial aspects of purchasing a tunnel pasteurizer is an important step in your business decision-making process. When budgeting for a passage pasteurizer, take into account not only the preliminary acquisition price yet additionally ongoing expenses such as maintenance, energy usage, and prospective upgrades.

Conduct a detailed expense analysis to establish the complete cost of ownership over the life expectancy of the tools. Look for https://www.foodengineeringmag.com/articles/101510...-company-highlights-4-ab-inbev that provide a balance in between upfront costs and long-lasting financial savings with power effectiveness and minimized maintenance demands.

Bear in mind to factor in any added expenditures such as installation, training, and possible downtime during execution. Compare quotes from different vendors and consider working out for a far better bargain or discovering funding choices to alleviate the monetary concern.

## Verdict

To conclude, picking the right Tunnel pasteurizer for your organization requires cautious consideration of factors such as size, capability, heating and cooling capacities, upkeep needs, and technological assistance accessibility. Evaluate different sorts of pasteurizers to discover the very best suitable for your production demands and spending plan restraints. Conduct a complete cost evaluation to determine the complete possession price, including installment and potential downtime expenses. With these factors in mind, you can make an informed choice that will profit your business over time.

Anticipate An Insightful Discussion On The Recent Progress In Batch Pasteurizers That Are Dramatically Influencing The Food Processing Field |

Authored By-Borre Warner

As you consider the future of food handling, have you ever before questioned the latest improvements in batch pasteurizers that could revolutionize the market? Picture a globe where performance, food security, and sustainability are seamlessly incorporated right into the process, supplying a glance of what's to find. Keep tuned to discover how these technologies are improving the method food is refined and just how they may affect your procedures in the near future.

## Improved Performance With Automation

Wanting to streamline your pasteurization process? batch pasteurizers currently supply enhanced effectiveness through automation. By integrating innovative modern technology, these modern-day systems can significantly improve the rate and accuracy of your pasteurization procedures.

With automated controls and sensing units, you can specifically check and readjust factors such as temperature and stress, making sure optimum pasteurization conditions for your products.

https://www.wtvy.com/2024/08/16/trojan-ale-troy-un...fficially-licensed-craft-beer/ reduces the requirement for hands-on treatment, conserving you time and labor prices. These sophisticated batch pasteurizers can instantly control the circulation of items, detect irregularities, and even alert drivers in case of any problems. This not just raises the overall efficiency of your pasteurization procedure but likewise boosts the uniformity and top quality of your final products.

Moreover, automation assists in lessening the risk of human errors, resulting in more trustworthy and risk-free food handling. With these technologies in batch pasteurizers, you can streamline your operations, enhance performance, and maintain premium criteria in your food handling facility.

## Boosted Food Safety Standards

To guarantee the highest levels of food safety and security in your procedures, it's vital to execute better standards that line up with regulative needs and industry finest methods. Enhancing food security requirements involves extensive surveillance of vital control factors, detailed sanitation methods, and detailed staff training. Regular audits and examinations aid in recognizing potential risks and making certain conformity with stringent guidelines.

Buying innovative modern technologies such as automatic monitoring systems and information analytics can further bolster your food safety measures. These technologies provide real-time insights into the manufacturing process, allowing punctual restorative activities when discrepancies occur.

Carrying Out Hazard Evaluation and Crucial Control Points (HACCP) principles is essential for systematically addressing food safety risks and avoiding contamination.

## Lasting Practices in Pasteurization

Including sustainable techniques in pasteurization is essential for minimizing environmental effect and enhancing operational effectiveness. By carrying out energy-efficient innovations, such as heat recuperation systems and automated controls, you can decrease source usage during the pasteurization process. Utilizing water-saving strategies, like counter-current rinsing systems and reusing rinse water, assists in conserving this valuable resource.

Furthermore, enhancing cleansing just click the following web page to minimize chemical usage and wastewater generation additional enhances sustainability in pasteurization procedures.

Picking environment-friendly packaging products and executing recycling programs for packaging waste can significantly lower the total environmental footprint of your pasteurization processes. Teaming up with suppliers who focus on sustainable sourcing practices ensures that the ingredients utilized in your items are produced sensibly.

Additionally, investing in renewable resource resources, such as solar or wind power, for your pasteurization centers can assist reduced greenhouse gas discharges and move towards a more lasting future in food handling. By welcoming lasting techniques in pasteurization, you not just add to environmental conservation however likewise boost the overall efficiency and durability of your food processing operations.

## Verdict

In conclusion, welcoming advancements in batch pasteurizers can change the food processing market by improving efficiency, ensuring food safety and security, and promoting sustainability. By including automation features, improving food security standards, and taking on lasting techniques, firms can remain ahead of the curve and meet the advancing needs of customers and regulative bodies. Keep positive in implementing these improvements to stay affordable and drive positive adjustment in the food processing sector.

Boosting Efficiency: Maximizing Your Assembly Line With Tunnel Pasteurizers |

Written By-Lynch Harboe

Tunnel pasteurizers are big industrial-scale machines that warm and cool beverages in order to eliminate microbes and expand their life span. Their effectiveness depends upon accuracy control.

Several drink business have actually retrofitted their existing Tunnel pasteurizers with new green technologies to accomplish considerable environmental advantages. These include minimized energy intake, lower water usage and decreased greenhouse gas emissions.

1. Raised Performance

When you run a brewery, your goal isn't simply to get rid of unsafe microorganisms, but additionally to offer consistency in your products. A well-executed pasteurization procedure not only lengthens beer's service life, however it makes certain that every bottle of your beer will certainly taste the same, from your very first batch to your last. This is particularly crucial for craft breweries wanting to draw in health-conscious consumers that desire the fizzy benefits of soft drinks.

Tunnel pasteurizers function by bringing bottles and canisters as much as their preferred temperature in stages, holding them there for long enough to kill off the microbes that cause perishing. They then bring them down once again in incremental steps up until they get to area temperature level, maintaining preference profiles. By doing this, they not only prevent microorganisms from increasing in the product, yet they likewise decrease power intake by getting rid of warmth loss. These are the kinds of efficiency gains that can build up promptly.

2. Lowered Waste

As even more emphasis is positioned on green manufacturing methods, beverage suppliers are trying to find methods to reduce their waste manufacturing. Tunnel pasteurizers do a wonderful work of this, particularly when they are developed and developed by seasoned experts.

Tunnel pasteurizers make use of a series of sprays to warm the bottles or containers as they move with the maker. This gets rid of the need for a big steam tank that eats energy and drainages. Furthermore, https://www.smithsonianmag.com/science-nature/19th...ilk-embalming-fluid-180970473/ make use of a water financial savings system to reuse the warm water made use of in the heating process, which decreases water and drain use.

Another advantage of Tunnel pasteurization is its compatibility with soft drinks, which is a large selling factor for craft makers who wish to prolong their items' shelf life and ensure consistency in between sets. Unlike flash pasteurizers, which in some cases have problem with high degrees of carbonation, Tunnel devices can deal with these effervescent mixtures without breaking a sweat (or a bottle).

3. Much Better Product Quality

When your drinks are effectively dealt with in Tunnel pasteurizers, they're secured from damaging microorganisms while maintaining their taste profiles. This suggests your mixtures, soft drinks, acid protects (like fruits or acids), and health and wellness shots can prolong their service life without losing their signature taste.

In order to achieve this, tunnels feature specific temperature control and also circulation throughout their multiple stages. Furthermore, conveyor belt rates help guarantee equivalent therapy times for each and every container entering the maker. All this assists you guarantee high quality outcomes every single time.

Lastly, tunnels work with carbonated beverages, a growing trend among health-conscious customers seeking fizzy options to sweet soft drinks. Unlike flash pasteurizers, which can deal with high-carbonation degrees, Tunnel makers are made to manage them.

In addition, retrofitting passages with energy healing systems minimizes water use as well. By utilizing the retrieved water for air conditioning, you'll substantially reduce your energy usage and greenhouse gas exhausts.

4. Minimized Energy Consumption

Tunnel pasteurizers are energy-intensive makers, yet you can decrease your energy consumption by retrofitting them with innovative green technology. This consists of solar-powered burner that can operate on renewable energy resources, decreasing reliance on nonrenewable fuel sources and your carbon impact.

An additional wonderful feature of Tunnel pasteurizers is that they work with carbonated beverages, a popular fad amongst today's health-conscious consumers. Unlike flash pasteurizers, which often battle with high-carbonation degrees, Tunnel systems can take care of these carbonated concoctions easily.

zPasteurAIzer can check the effectiveness of your existing Tunnel pasteurizer by approximating the accumulated item quality (PU) worth for each set. This allows you to figure out if your existing temperature level control system is delivering enough warmth therapy in addition to identifying any type of curved spray heads. You can after that adjust the equipment settings based on your preferred PU values, enhancing manufacturing effectiveness while reducing energy usage. This is an excellent way to lower your water usage also, straightening your service with consumer demand for ecologically accountable products.

Improving Efficiency: Maximizing Your Production Line With Tunnel Pasteurizers |

Content Author-Andreassen Serup

Tunnel pasteurizers are huge industrial-scale devices that warmth and great drinks in order to kill bacteria and extend their shelf life. https://www.capitalpress.com/state/washington/wsu-...d4-56a5-8af8-090d0d938c1a.html relies on precision control.

Several drink firms have actually retrofitted their existing Tunnel pasteurizers with new environmentally friendly innovations to accomplish substantial environmental advantages. These include reduced power consumption, lower water use and reduced greenhouse gas emissions.

1. Increased Efficiency

When you run a brewery, your objective isn't just to get rid of unsafe virus, however also to supply uniformity in your items. A well-executed pasteurization process not only lengthens beer's service life, yet it makes sure that every container of your beer will taste the same, from your initial batch to your last. This is particularly important for craft breweries wanting to attract health-conscious clients that desire the fizzy goodness of carbonated drinks.

https://www.bozemandailychronicle.com/news/raw-mil...6c-5d89-a225-54b1003f01e0.html by bringing bottles and cans up to their desired temperature in stages, holding them there for enough time to exterminate the microorganisms that cause spoilage. They then bring them down once more in incremental actions till they get to room temperature level, protecting preference profiles. By doing this, they not only avoid microorganisms from increasing in the product, but they likewise minimize power intake by removing heat loss. These are the sort of effectiveness gains that can accumulate swiftly.

2. Minimized Waste

As even more emphasis is placed on environment-friendly manufacturing techniques, beverage suppliers are trying to find ways to reduce their waste manufacturing. Tunnel pasteurizers do a terrific work of this, specifically when they are designed and developed by experienced specialists.

Tunnel pasteurizers utilize a collection of sprays to heat up the bottles or canisters as they relocate through the device. This gets rid of the requirement for a huge steam storage tank that eats energy and wastes water. Additionally, Tunnel pasteurizers use a water cost savings system to recycle the hot water utilized in the home heating procedure, which lowers water and sewage system use.

An additional benefit of Tunnel pasteurization is its compatibility with carbonated drinks, which is a big selling factor for craft brewers who wish to expand their products' service life and make sure uniformity in between sets. Unlike flash pasteurizers, which occasionally struggle with high levels of carbonation, Tunnel devices can take care of these effervescent concoctions without breaking a sweat (or a container).

3. Better Product Quality

When your drinks are appropriately treated in Tunnel pasteurizers, they're shielded from harmful microorganisms while preserving their flavor profiles. This suggests your brews, soft drinks, acid preserves (like fruits or acids), and wellness shots can extend their shelf life without losing their trademark preference.

In order to accomplish this, passages feature precise temperature level control and even circulation throughout their multiple stages. In addition, conveyor belt speeds aid make certain equal treatment times for every bottle getting in the device. All this assists you ensure high quality results every time.

Ultimately, passages work with carbonated beverages, an expanding pattern amongst health-conscious consumers looking for carbonated choices to sugary soft drinks. Unlike flash pasteurizers, which can fight with high-carbonation levels, Tunnel machines are created to handle them.

In addition, retrofitting passages with power recovery systems reduces water use also. By using the recovered water for air conditioning, you'll significantly cut your energy usage and greenhouse gas emissions.

4. Minimized Energy Usage

Tunnel pasteurizers are energy-intensive makers, yet you can lower your energy usage by retrofitting them with sophisticated environmentally friendly modern technology. This includes solar-powered heating elements that can run on renewable energy resources, decreasing dependence on nonrenewable fuel sources and your carbon impact.

An additional excellent feature of Tunnel pasteurizers is that they work with carbonated beverages, a prominent pattern amongst today's health-conscious consumers. Unlike flash pasteurizers, which sometimes deal with high-carbonation levels, Tunnel systems can handle these fizzy concoctions with ease.

zPasteurAIzer can check the efficiency of your existing Tunnel pasteurizer by approximating the collected product top quality (PU) worth for every batch. This enables you to figure out if your current temperature control system is delivering sufficient warmth treatment in addition to recognizing any type of curved spray heads. You can then adjust the device settings based on your preferred PU worths, increasing manufacturing efficiency while lowering energy consumption. This is a great way to lower your water usage too, aligning your company with consumer demand for ecologically responsible products.

Raising Productivity: Enhancing Your Manufacturing Refine Using Tunnel Pasteurization Devices |

Created By-Didriksen Cohen

Tunnel pasteurizers are large industrial-scale devices that warm and great drinks in order to kill microbes and prolong their life span. Their performance depends on accuracy control.

Several drink firms have actually retrofitted their existing Tunnel pasteurizers with brand-new environmentally friendly innovations to attain substantial environmental advantages. These consist of reduced energy consumption, reduced water usage and reduced greenhouse gas exhausts.

1. Boosted Productivity

When you run a brewery, your objective isn't just to remove unsafe microorganisms, but likewise to supply consistency in your items. A well-executed pasteurization procedure not only extends beer's service life, however it makes certain that every container of your beer will taste the same, from your first batch to your last. This is specifically essential for craft breweries wanting to bring in health-conscious consumers who want the fizzy goodness of carbonated drinks.

Tunnel pasteurizers work by bringing containers and cans as much as their wanted temperature level in stages, holding them there for long enough to exterminate the microorganisms that trigger wasting. They then bring them down again in step-by-step steps until they reach room temperature level, maintaining taste profiles. By doing this, they not just avoid microorganisms from multiplying in the product, yet they also decrease energy consumption by removing warm loss. These are the type of performance gains that can accumulate rapidly.

2. Minimized Waste

As more emphasis is put on eco-friendly production methods, beverage manufacturers are seeking ways to reduce their waste production. Tunnel pasteurizers do a terrific work of this, especially when they are designed and developed by seasoned specialists.

Tunnel pasteurizers use a series of sprays to warm the bottles or containers as they relocate through the equipment. This removes the need for a big steam tank that consumes energy and drainages. Additionally, https://www.thealternativedaily.com/drink-raw-goat...-minerals-balance-fatty-acids/ utilize a water financial savings system to reuse the hot water used in the heating procedure, which lowers water and drain use.

One more benefit of Tunnel pasteurization is its compatibility with soft drinks, which is a big marketing factor for craft makers that want to expand their products' life span and guarantee consistency in between batches. Unlike flash pasteurizers, which sometimes deal with high degrees of carbonation, Tunnel systems can take care of these effervescent concoctions without breaking a sweat (or a container).

3. Better Product High Quality

When your beverages are correctly dealt with in Tunnel pasteurizers, they're secured from hazardous microorganisms while preserving their taste profiles. This indicates your brews, soft drinks, acid preserves (like fruits or acids), and health and wellness shots can extend their life span without shedding their trademark taste.

In order to achieve this, tunnels include accurate temperature level control and even circulation throughout their numerous stages. Additionally, conveyor belt speeds help guarantee equivalent treatment times for every container getting in the equipment. All this aids you assure top quality outcomes whenever.

Finally, tunnels work with carbonated beverages, a growing pattern among health-conscious consumers looking for fizzy choices to sweet sodas. Unlike flash pasteurizers, which can deal with high-carbonation levels, Tunnel equipments are developed to manage them.

Additionally, retrofitting passages with power recovery systems lowers water use as well. By utilizing the recovered water for air conditioning, you'll significantly reduce your power intake and greenhouse gas exhausts.

4. Reduced Energy Usage

Tunnel pasteurizers are energy-intensive equipments, but you can decrease your energy consumption by retrofitting them with sophisticated environmentally friendly modern technology. This consists of solar-powered heating elements that can operate on renewable resource resources, decreasing dependence on nonrenewable fuel sources and your carbon impact.

Another great function of Tunnel pasteurizers is that they are compatible with carbonated beverages, a popular pattern among today's health-conscious consumers. Unlike flash pasteurizers, which in some cases deal with high-carbonation degrees, Tunnel systems can deal with these fizzy mixtures with ease.

zPasteurAIzer can monitor the efficiency of your current Tunnel pasteurizer by estimating the collected item top quality (PU) worth for each batch. This allows you to determine if your current temperature control system is delivering enough warm treatment along with identifying any type of curved spray heads. You can then readjust the equipment settings based upon your preferred PU values, boosting manufacturing efficiency while reducing energy consumption. This is a great method to lower your water consumption as well, aligning your service with consumer demand for environmentally accountable products.

Increasing Effectiveness: Maximizing Your Production Line With Tunnel Pasteurizers |

Write-Up By-Dempsey Cohen

Tunnel pasteurizers are huge industrial-scale equipments that warm and great beverages in order to kill microorganisms and extend their life span. Their efficiency depends on precision control.

Numerous drink firms have actually retrofitted their existing Tunnel pasteurizers with new eco-friendly technologies to attain considerable environmental benefits. These consist of lowered energy usage, reduced water use and decreased greenhouse gas emissions.

1. Boosted Performance

When you run a brewery, your goal isn't simply to remove unsafe pathogens, however also to supply consistency in your items. A well-executed pasteurization process not just extends beer's life span, but it guarantees that every bottle of your beer will certainly taste the exact same, from your very first batch to your last. This is especially vital for craft breweries looking to draw in health-conscious customers that desire the carbonated benefits of carbonated drinks.

Tunnel pasteurizers work by bringing containers and cans up to their preferred temperature level in phases, holding them there for enough time to exterminate the microbes that create perishing. They after that bring them down once again in incremental actions till they get to area temperature level, protecting preference accounts. By doing this, they not just protect against germs from increasing in the item, but they also decrease energy intake by eliminating warmth loss. These are the kinds of performance gains that can build up quickly.

2. Reduced Waste

As even more emphasis is put on green production methods, beverage producers are searching for methods to reduce their waste production. Tunnel pasteurizers do a terrific work of this, specifically when they are made and developed by seasoned experts.

Tunnel pasteurizers make use of a collection of sprays to heat the bottles or cans as they move via the device. This gets rid of the requirement for a huge heavy steam tank that eats power and wastes water. On top of that, Tunnel pasteurizers make use of a water cost savings system to recycle the hot water utilized in the heating process, which minimizes water and drain usage.

Another benefit of Tunnel pasteurization is its compatibility with soft drinks, which is a big selling factor for craft makers that want to extend their items' service life and make sure uniformity in between sets. Unlike flash pasteurizers, which often have problem with high levels of carbonation, Tunnel systems can handle these effervescent mixtures without breaking a sweat (or a container).

3. Much Better Item Top Quality

When your beverages are appropriately treated in Tunnel pasteurizers, they're protected from damaging germs while maintaining their flavor accounts. This suggests your mixtures, soft drinks, acid preserves (like fruits or acids), and health and wellness shots can extend their service life without losing their trademark taste.

In order to achieve this, tunnels feature precise temperature control and even circulation throughout their numerous stages. Additionally, conveyor belt speeds aid guarantee equivalent treatment times for each container entering the device. All this assists you ensure top quality results every time.

Finally, passages are compatible with carbonated beverages, a growing trend amongst health-conscious consumers seeking fizzy options to sweet soft drinks. Unlike flash pasteurizers, which can battle with high-carbonation degrees, Tunnel equipments are made to manage them.

In addition, retrofitting tunnels with energy healing systems minimizes water usage as well. By utilizing the recovered water for air conditioning, you'll significantly reduce your power consumption and greenhouse gas emissions.

4. Reduced Power Usage

Tunnel pasteurizers are energy-intensive makers, yet you can lower your energy usage by retrofitting them with advanced environment-friendly technology. This consists of solar-powered burner that can run on renewable resource sources, minimizing dependence on nonrenewable fuel sources and your carbon impact.

An additional fantastic attribute of Tunnel pasteurizers is that they are compatible with carbonated beverages, a prominent trend among today's health-conscious consumers. Unlike flash pasteurizers, which often battle with high-carbonation levels, Tunnel devices can manage these carbonated mixtures with ease.

zPasteurAIzer can keep an eye on the effectiveness of your current Tunnel pasteurizer by estimating the collected item quality (PU) worth for each batch. This allows you to identify if your present temperature control system is providing enough warm therapy along with determining any type of bent spray heads. You can after that change the maker settings based on your favored PU values, increasing manufacturing efficiency while decreasing energy usage. relevant webpage is a great way to reduce your water intake also, straightening your business with consumer demand for environmentally accountable products.

Enhancing Performance: Maximizing Your Production Line With Tunnel Pasteurizers |

Personnel Writer-Dempsey Santana

Tunnel pasteurizers are big industrial-scale equipments that warm and great beverages in order to kill bacteria and prolong their shelf life. Their efficiency depends upon precision control.

A number of drink firms have actually retrofitted their existing Tunnel pasteurizers with brand-new eco-friendly technologies to achieve considerable environmental advantages. These include reduced energy consumption, lower water use and decreased greenhouse gas discharges.

1. Enhanced Performance

When you run a brewery, your objective isn't simply to eliminate hazardous pathogens, however also to offer uniformity in your items. A well-executed pasteurization procedure not only lengthens beer's shelf life, however it ensures that every container of your beer will taste the same, from your initial set to your last. This is particularly important for craft breweries looking to draw in health-conscious customers that want the carbonated benefits of soft drinks.

Tunnel pasteurizers function by bringing bottles and canisters as much as their preferred temperature in phases, holding them there for long enough to kill off the microbes that create perishing. They after that bring them down again in incremental actions till they reach space temperature, protecting taste profiles. By doing this, they not just protect against germs from increasing in the item, but they likewise lower energy usage by eliminating heat loss. These are the sort of effectiveness gains that can accumulate swiftly.

2. Minimized Waste

As even more focus is placed on green production techniques, beverage suppliers are trying to find methods to decrease their waste production. Tunnel pasteurizers do a fantastic work of this, specifically when they are made and built by experienced experts.

Tunnel pasteurizers use a series of sprays to heat the bottles or canisters as they move via the maker. This gets rid of the demand for a big vapor storage tank that eats power and drainages. In addition, Tunnel pasteurizers make use of a water financial savings system to reuse the hot water made use of in the heating process, which minimizes water and sewage system use.

One more advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a large marketing factor for craft brewers that intend to prolong their items' life span and make sure consistency in between sets. Unlike flash pasteurizers, which in some cases have problem with high levels of carbonation, Tunnel units can deal with these bubbly concoctions without breaking a sweat (or a bottle).

3. Much Better Product High Quality

When your beverages are properly dealt with in Tunnel pasteurizers, they're protected from damaging germs while protecting their taste accounts. This implies your brews, sodas, acid maintains (like fruits or acids), and health shots can expand their shelf life without shedding their signature taste.

In order to achieve this, tunnels include accurate temperature level control and even distribution throughout their several stages. Furthermore, conveyor belt rates help make sure equal treatment times for every bottle getting in the maker. All this assists you guarantee high quality results whenever.

Finally, passages are compatible with carbonated beverages, an expanding pattern among health-conscious customers searching for carbonated alternatives to sugary soft drinks. Unlike flash pasteurizers, which can have problem with high-carbonation degrees, Tunnel equipments are developed to handle them.

In addition, retrofitting tunnels with energy recovery systems reduces water use as well. By utilizing the recovered water for air conditioning, you'll significantly reduce your power intake and greenhouse gas exhausts.

4. Decreased Power Intake

Tunnel pasteurizers are energy-intensive devices, but you can minimize your power consumption by retrofitting them with advanced environment-friendly innovation. This includes solar-powered heating elements that can run on renewable resource resources, decreasing reliance on nonrenewable fuel sources and your carbon impact.

One more fantastic attribute of Tunnel pasteurizers is that they are compatible with carbonated beverages, a preferred pattern amongst today's health-conscious customers. Unlike flash pasteurizers, which in some cases deal with high-carbonation levels, Tunnel systems can manage these fizzy concoctions effortlessly.

"Elevating Co-Packing Partnerships: The Features and Benefits of Investing in New Tunnel Pasteurizers or Batch Pasteurizers"

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) December 26, 2023

Article Release by PRO Engineering / Manufacturing Inc.

Click for article: https://t.co/efrL1fLtBp

PRO Engineering / Manufacturing Inc.

414-362-1500

zPasteurAIzer can check the effectiveness of your existing Tunnel pasteurizer by approximating the gathered product top quality (PU) worth for each and every set. This allows you to identify if your current temperature control system is delivering sufficient heat therapy along with determining any type of bent spray heads. You can then adjust the maker setups based on your preferred PU worths, boosting production effectiveness while lowering power intake. https://www.foodengineeringmag.com/events/2288-int...pasteurized-milk-ordinance-pmo is a terrific way to reduce your water usage as well, straightening your service with consumer demand for eco responsible products.

Shielding Taste And Safety And Security: The Relevance Of Tunnel Pasteurizers In Drink Production |

Short Article Created By-Reece Chan

Tunnel pasteurizers are crucial for getting rid of spoilage microbes and regulating pathogenic microbes in beverages like beer, milk, juice and sodas. They heat and after that cool down the item to eliminate these microorganisms.

They also save power, water and minimize carbon dioxide discharges straightening production with sustainability targets. Selecting a tunnel pasteurization system that's engineered by seasoned professionals like PRO guarantees accuracy in the timing and temperature degrees used in each phase.

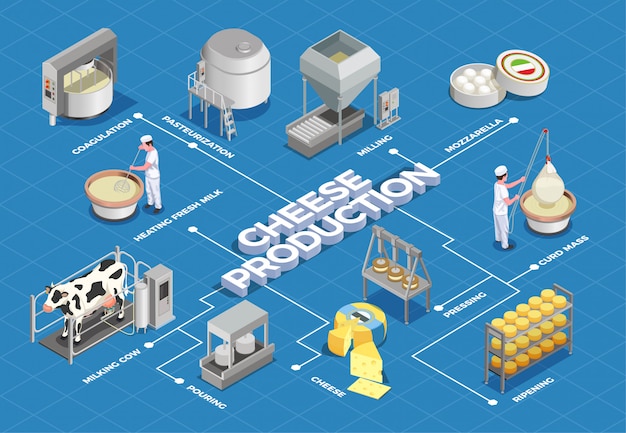

Microbiological Control

The control of bacteria in food and beverages is essential to prevent putridity, food poisoning, and various other unfavorable impacts on the final product. Microbial contaminations can be triggered by pathogenic (i.e., disease-causing) organisms or wasting fungi. Approaches for regulating microbial contamination can include physical, chemical, or organic approaches. Those that kill or suspend bacteria are described sterilization, disinfection, antisepsis, and sanitization.

Microbial death curves, which show the logarithmic decline of living microorganisms after direct exposure to a treatment method, are crucial devices for identifying the efficiency of a microbial control strategy. The time it takes for a procedure to yield a 1-log reduction in the microbial populace is labelled the decimal reduction value, or D-value.

To make certain exact microbial evaluation results, it is necessary to keep the example and the examination system itself without contamination. Utilizing a microbiological incubator that provides an effective 140 oC purification cycle, such as the Thermo Scientific Heratherm Incubator, can assist remove cross-contamination between examples and testing equipment, therefore guaranteeing that the outcomes of any kind of microbial examinations are valid.

Security

When it comes to maintaining your beverage secure, Tunnel pasteurizers can do a great deal of job. These machines give both the bottle or can and its materials a heat treatment-- which helps extend life span while protecting those specialty ingredients craft breweries love a lot.

In a regular Tunnel pasteurizer, the package and liquid are communicated via numerous sections that gradually warm and cool the product. Each spray head provides water at various temperatures, and the nozzles are positioned to make the most of insurance coverage with a minimum of thermal stress and anxiety.

https://www.dairyreporter.com/Article/2019/01/22/D...eet-Pasteurized-Milk-Ordinance and temperature of each spray are based upon a beverage-specific variety of pasteurization units (PU) needed to kill any type of microbes in the container. The progressive nature of heating additionally reduces carbonation loss in low-carbonated beverages.

Security

Tunnel pasteurizers can be made use of to heat deal with a drink also after it has actually been packed right into containers and cans. This can help lengthen shelf security for carbonated beverages without sacrificing their fizz.

The process works by gradually heating a container with sprays of hot water. The temperature level is elevated in stages until it gets to the called for pasteurization device for the drink and then kept for the defined duration.

When the preferred time and temperature have been accomplished, the beer is cooled with showers of low-temperature water until it gets to ambient temperature level. This makes sure that all microorganisms in the beer are killed and it can be securely stored in a sealed container.

Tunnel pasteurizers are developed to guarantee that the temperature is equally distributed across the entire surface of the container, helping attain consistent results. This can be hard with other heat treatment techniques such as flash pasteurization, yet the exact temperature level control that Tunnel pasteurizers supply can make all the difference for a brewery's procedures.

Environmental Influence

As beverage makers deal with boosting stress to decrease their carbon footprints, Tunnel pasteurizers are an useful tool for maintaining waste to a minimum. simply click the up coming post heats up the container to a specific temperature for a set period, getting rid of dangerous microbes without damaging the drink's physical security or affecting its flavor account.

As an added advantage, Tunnel pasteurization likewise works great with carbonated beverages-- including the prominent craft brews that so many beer lovers like. It helps to expand their shelf life while maintaining those complex hop notes that customers love so much.

A company just recently retrofitted their Tunnel pasteurizer to use solar power for heating the fluid, which resulted in a 35% decrease of water usage. They have actually additionally applied a closed-loop waste water treatment plant to further cut their environmental effect even better. This demonstrates how essential lasting practices are, and exactly how they're important to fulfilling consumer demand and ecological responsibility. Keep tuned for future updates on every one of the groundbreakings, project starts, bow cuttings and buildouts that are happening around the nation!

Vital Info For Purchasing Skid Steer Equipment: A Comprehensive Guide |

Post Created By-Pappas Pham

Are you tired of looking for the excellent skid guide tools? Look no further!

In 'The Ultimate Skid Steer Equipment Purchasing Overview: What You Need to Know,' we have compiled all the crucial information you require to make an educated purchase. Whether you're an experienced specialist or just starting out, this guide will certainly stroll you via the process detailed.

Discover the different sorts of skid steer attachments available and learn about the elements to think about when it involves size and capacity. With our specialist tips, you can with confidence make the best choice for your needs.

Bid farewell to guesswork and hello to a successful purchase with this thorough overview.

## Kinds Of Skid Steer Attachments

When thinking about buying skid guide tools, it is very important for you to understand the different sorts of attachments offered.

With a wide range of attachments designed to tackle different tasks, recognizing which ones appropriate for your requirements is vital.

One popular attachment is the pail, which is best for relocating products like dust, crushed rock, and sand.

If you require to clear snow, a snow blade or snow blower accessory would certainly be suitable.

For construction jobs, a trencher add-on can help you dig trenches rapidly and efficiently.

If you're working on demolition or land clearing up, a grapple attachment works for getting and moving debris.

Various other usual accessories consist of augers, pallet forks, and brush cutters.

Recognizing these different options will assist you make an informed decision when choosing skid steer tools.

## Variables to Think About for Dimension and Capacity

When buying skid steer tools, there are several variables that you should take into consideration for dimension and capability. First, think of the dimensions of the equipment and how it will certainly fit into your work area. Think about please click the next webpage , width, and length of the skid guide devices to ensure it can navigate conveniently in limited spaces or through slim doorways.

Next off, think about the ability of the skid steer devices. Think of the weight that the tools will need to lift or lug. It's important to pick a skid guide with the suitable lifting capability for your certain requirements. Keep in mind that a larger ability usually indicates a bigger and more powerful maker.

## Tips for Making the Right Purchase Choice

To make the appropriate purchase choice for your skid steer tools, consider the certain needs and budget you have in mind. Here are some tips to help you make the very best selection:

- Research different brands and versions: Search for trusted producers with a track record of generating dependable equipment. Contrast attributes, specifications, and consumer evaluations to find the very best suitable for your needs.

- Consider your work: Consider the tasks you require the skid steer to carry out. Will you be utilizing it for light-duty or heavy-duty job? Make certain the devices you choose can handle the demands of your work.

- Review your spending plan: Establish just how much you're willing to invest and discover tools that drops within your price array. Keep in mind to consider long-lasting expenses like repair and maintenance.

## Conclusion

So there you have it, the ultimate skid steer tools buying overview. Now that you understand all the kinds of accessories, aspects to think about, and suggestions for making the ideal acquisition choice, you can confidently browse the market.

Simply remember, although skid steer devices is expected to make your life less complicated, the irony is that picking the best one can be quite the challenge. But with this guide, you're one action more detailed to locating the perfect fit.

Delighted buying!

|

Метки: Skid Steer Skid Steer Attachments Skid Steer Tree Puller Skid Steer Tree Spade Loader Attachments Tractor Attachments |

Tips For Selecting The Appropriate Accessories For Your Skid Steer Machinery |

Material Produce By-Borup Meier

So, you've obtained a skid guide devices, huh? Well, congratulations! Currently comes the fun component-- selecting the right attachments. Due to the fact that, you recognize, having the wrong add-ons would certainly just be too uninteresting. However worry not, dear skid steer proprietor, for we are here to lead you through this crucial decision-making procedure.

In this short guide, we will certainly stroll you through the steps of understanding your devices, examining your task demands, and eventually selecting the excellent accessories that will make your skid guide truly shine.

So, distort up and get ready to take your skid steer to an entire new degree of awesomeness. Let's do this!

Comprehending Your Tools

To successfully select the best accessories for your skid guide devices, it's important to have a strong understanding of its abilities and constraints. Recognizing what your equipment can and can not do will certainly aid you make notified decisions when selecting add-ons.

Start by familiarizing on your own with the specifications and weight restrictions of your skid steer. Take into consideration variables like lift capability, hydraulic flow rate, and complementary connections. Understanding these information will certainly make sure that you pick accessories that are compatible with your equipment and can be run securely.

Additionally, assess the surface and tasks you'll be executing. Various attachments master various environments, so it is very important to match the accessory to the work at hand.

Assessing Your Job Requirements

When you have a solid understanding of your skid guide tools, it's time to examine your job requirements. This step is important in choosing the best attachments for your specific needs.

To help you in this process, take into consideration the following:

- Review the nature of your tasks: Establish whether your job includes excavating, training, grading, or any other specific tasks that call for specialized accessories.

- Consider the terrain: Think about the kind of surface area you'll be working with, such as concrete, dirt, or unequal ground, as this will certainly affect the type of add-on you need.

- Assess https://www.equipmentworld.com/attachments/compact-equipment-attachments of your projects: Figure out the dimension and range of your jobs to ensure that the add-ons you select are capable of taking care of the workload.

Choosing the Right Attachments

Consider your specific needs and needs when selecting the appropriate add-ons for your skid steer equipment. The trick to selecting the right accessories depends on recognizing the jobs you require to accomplish. Think about the kind of work you commonly do and the conditions in which you run.

As an example, if you frequently service building and construction websites, attachments such as containers, grapples, and hydraulic hammers may be essential. On https://www.equipmentworld.com/equipment/article/1...ing-new-respect-on-the-jobsite , if you're associated with landscaping, add-ons like brush cutters, tree spades, and soil conditioners could be preferable.

It's also essential to consider the compatibility of the attachments with your skid steer. Ensure that the add-ons you select are especially developed for your tools model and have the required hydraulic capacity.

Conclusion

So, there you have it! By comprehending your skid guide equipment, evaluating your work needs, and picking the right accessories, you can make sure maximum efficiency and effectiveness in your job.

Don't undervalue the power of the appropriate accessories - they can be the trick to doing the job swiftly and properly.

Remember, with the right devices, anything is feasible!

|

Метки: Skid Steer Skid Steer Attachments Skid Steer Tree Puller Skid Steer Tree Spade Loader Attachments Tractor Attachments |

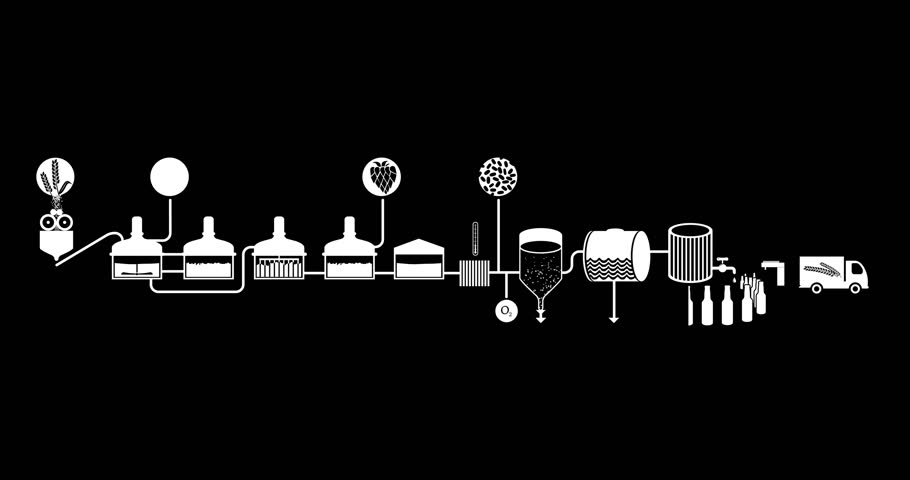

Continue Reading For More Information Details Concerning Tunnel Pasteurizers For Beer & Drink Makers |

Article writer-Pallesen Anthony

Tunnel Pasteurizers use heat to safely process food as well as other products. The process makes use of different zones where water is splashed in order to warm up as well as cool the product being pasteurized. In some machines, the temperature level of the water is checked, which guarantees the process is functioning correctly. Tunnel Pasteurizers can be used in a large range of applications.

Tunnel Pasteurizers are used to securely as well as continually pasteurize packaged drinks, such as beer and also white wine. These machines make use of a conveyor to relocate the bundles through a long, narrow Tunnel. The Tunnel is generally 15 to 30 meters long as well as is comprised of several temperature areas. The initial zone is the heating zone, and also the second area is the holding or cooling area. Throughout the procedure, water is sprayed onto the canisters as well as bottles.

Tunnel Pasteurizers can create products with boosted shelf life by shutting off enzymes and microbes. Modern Tunnel pasteurizers save power by using innovative technology. The layout of these devices permits a modular setup, which helps in reducing installment prices. They likewise include constant belts constructed from polypropylene or stainless-steel. The home heating and cooling down procedure is regulated by a PLC. If you need a pasteurizer for your assembly line, you can call Diversey to find out more concerning what is available in your region.

Get More is a software as well as hardware system that keeps track of the pasteurization process and also regulates the water spraying inside the Tunnel. It likewise has actually an integrated temperature level sensor that determines the temperature level as well as time of each private section. This information is crucial in determining the pasteurisation units. Tunnel Pasteurizers are a wonderful choice for pasteurizing many items. So, consider https://www.citizensvoice.com/news/milkhouse-cream...7f-5730-9d50-041a20dcd8d6.html if you are searching for a premium quality, trusted pasteurizer.

Tunnel Pasteurizers are efficient machines that eliminate residual bacteria from food as well as beverage items. The HT205 mini Tunnel pasteurizer offers flexible criteria that make it possible for the driver to duplicate a wide range of major production scenarios. It also conserves water and also power, which are both essential active ingredients for a production line.

Tunnel Pasteurizers are generally made of stainless steel, as well as they are available in different dimensions and dimensions. This allows them to be tailored to the particular food kinds as well as procedures that you create. Besides being easy to use, they additionally do not wreck the taste or appearance of the item. They also come with automatic-stop systems that avoid overpasteurization.

There is a location for pasteurization in small breweries also. The procedure can preserve the flavor of beer even if it is produced in a little range brewery. Small-scale breweries are progressively recognizing the worth of pasteurization and are implementing the technology to make craft brewing a success.

The Tunnel pasteurizer can warm milk at a price of 363 kilograms per hour. In ninety percent of cases, the milk is cooled back down to 4.5 degC. A favorable displacement pump enhances the stress on milk leaving the regeneration area, resulting in a stress differential of 41.4 kPa over the feed or raw side of the regeneration device. The MST pasteurized milk has a service life of up to 60 days at 4 degC, and the total decrease of germs is greater than five log cycles.

Tunnel Pasteurizers Are Machines That Are Made Use Of To Disinfect Packaged Products As Well As Prolong Their Shelf Life |

Content written by-Mendoza Zimmerman

These machines consist of numerous sections that each feature their very own water spray system and flow pump, in addition to a screen/filter box. When these systems malfunction, they can negatively influence the procedure, product high quality, performance, as well as overall expense of possession.

Tunnel Pasteurizers function by distributing warm water under the pasteurization belt. The water might be sent to the discharge conveyor or to a sump. The sump lies under the pasteurization belt. As bottles pass over the pasteurization belt, a few of them may damage. Busted containers are accumulated in the sump. Otherwise, they proceed along the conveyor. The sump is created to have watertight ports that permit maintenance workers accessibility to the water.

“WHAT IS THE BEST PASTEURIZATION METHOD FOR BEER AND BEVERAGES?”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) January 17, 2023

Article Release for Brewmasters & Beverage Makers, sponsored by PRO Engineering / Manufacturing Inc.

Click for full article:https://t.co/O633OluiN1

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/r2lM9FPwKp

Tunnel Pasteurizers are suitable for a selection of applications. For instance, Tunnel pasteurizers can be used for developing beer, canned alcoholic drinks, and also various other products that have a shut container. These tools can be personalized to suit the production location of a firm. They can be found in a variety of dimensions, relying on the quantity and temperature level required for the products. If you require to treat more than one product, you can set up a dual-story unit.

Tunnel Pasteurizers can be a cost-efficient means to decontaminate bottled drinks. They can also be extremely energy effective. They utilize advanced innovation to kill bacteria and also enzymes that cause bacteria and also various other unsafe compounds. https://www.packworld.com/design/materials-contain...swedish-food-producers-success have a modular design for minimized installment expenses. Single-deck tunnels can range from five to 500 m2. Continuous belts are available in stainless-steel as well as polypropylene.

The Tunnel Pasteurizer can process a wide variety of items, such as juices and jams. It can be equipped with an air conditioning system in the control closet. The temperature and also time made use of throughout pasteurization vary according to the kind of product. A a great deal of firms utilize these gadgets to sterilize their products. They are also very easy to preserve and service.

Tunnel Pasteurizers are efficient machines that kill germs, stop fermentation, as well as give shelf stability to bottled items. These machines undergo considerable temperatures and caustic cleansing chemicals. https://food.ndtv.com/food-drinks/world-milk-day-r...ich-one-should-you-pick-767509 can additionally be damaged by broken containers. At PRO Engineering/Manufacturing, we have experience creating and also developing Tunnel pasteurizers for food and also drink business.

Tunnel Pasteurizers are various from tubular, plate, and also mass pasteurizers in several methods. The latter has a recording tool that videotapes details of the procedure. This makes it an extra effective as well as precise method to warm as well as trendy bundles. Tunnel Pasteurizers are frequently less costly than mass pasteurizers and are much more energy efficient. However, the temperature levels of the Tunnel pasteurizer can differ from time to time.

Depending on the water chemistry of the Tunnel pasteurizer system, containers and canisters can experience various high quality concerns. For example, unlacquered containers and also bottles can develop corrosion places and also discoloration. Unlacquered cans might also experience fading of decors. Those that use these systems must examine their regional variety of products.

Tunnel Pasteurizers can be an efficient way to sterilize milk. This technology likewise enables manufacturers to prolong the life span of their items. Even small breweries can take advantage of pasteurization. For instance, if a brewery has no refrigeration tools, they can make use of Tunnel pasteurizers to sanitize their products. A successful commercial plant may be able to process up to 240,000 L of milk per hr.

The Advantages And Also Downsides Of Powder Coating |

Content writer-Collins Richards

Unlike typical liquid paint, powder Coating is applied as a free-flowing, dry powder, which is then treated with warm or ultraviolet light. In addition, powder Coating is commonly used electrostatically.

Electrostatic spray gun

Making use of an Electrostatic spray gun for powder Coating is an excellent method to create a high quality coating on your work. This strategy is used to produce a resilient surface that can withstand deterioration and chipping.

The electrostatic splashing technique utilizes pressed air to transport the powder to the work surface. The gun creates a high-voltage electrostatic area that attracts the powder bits to the metal. This creates a layer that complies with the steel in a thick, even layer.

The most apparent advantage of an Electrostatic spray gun is boosted transfer efficiency. This allows for a more consistent layer, less overspray, as well as less waste.

There are numerous settings to choose from on your Electrostatic spray gun. Selecting the appropriate ones can boost your powder Coating efficiency. There are a few vital settings to be familiar with.

The kilovolt (kV) is the device of measure for the electrostatic powder weapon cost. The greater the voltage, the more dimples you will see in your Coating. It is best to establish the voltage lower to achieve the most effective outcomes.

https://writeablog.net/louanne321ryan/right-here-are-the-advantages-of-powder-coating are utilized in the manufacture of powder Coating. They are designed to provide sturdy finishes with a variety of shades as well as textures. They are likewise an environmentally friendly alternative to fluid paints.

Typical powder coverings are developed with a combination of pigments and also ingredients. These ingredients are melted, blended, and after that ground right into a powder. They are after that related to the substratum utilizing electrostatic spray deposition. The powder is after that treated in a healing stove.

Powder layers are created to be hard, sturdy, and have exceptional adhesion. They are applied to a wide variety of surfaces, including plastics, steels, and tool density fiber board. Powder finishes are an affordable service to conventional Coating techniques. They are also eco-friendly, as they use fewer volatile natural compounds (VOCs) as well as can be reused.

The primary components of thermoplastic powder coverings are a stabilizer, leveling representatives, as well as crosslinking material. These components must be thoroughly regulated to guarantee correct diffusion and also optimum circulation. In addition, the surface area tension of the Coating must be kept low to decrease film issues.

Surface areas that can be coated

Utilizing powder Coating to layer surfaces can be a cost-efficient choice to wet paint. Besides being more economical, it can be much easier to maintain and also clean. Furthermore, it is eco-friendly. https://postheaven.net/luis28rich/lets-discusses-t...powder-coating-in-this-article pushes back destructive products and has a wide range of surfaces.

Powder Coating can be made use of on a range of surfaces, including plastics, steel, and glass. Its resilient coating makes it a great choice for architectural applications. Nonetheless, it does have its restrictions.

Some metals can not be powder covered. As an example, certain fillers can't take on the heats of the curing procedure. Likewise, glass is a challenging material to powder coat.

In addition to the truth that it's environmentally friendly, powder Coating is also a superb safety Coating. This coating withstands scratches as well as abrasions as well as provides an easy-to-clean finish.

Although it isn't the easiest to clean, powder coated items can be quickly brought back with a soft brush and also a bit of moderate soap in water. Use filteringed system water for ideal outcomes.

Drawbacks

Making use of powder Coating for ending up commercial products has several advantages, but it additionally has its drawbacks. These consist of high start-up prices, minimal shade array, and troubles using a thin layer. In spite of these drawbacks, powder coverings offer a resilient coating as well as are immune to scrapes.

Powder coatings are environmentally friendly. They have very reduced emissions of volatile organic compounds, or VOCs. click here for more info have much less co2 exhausts as well as are a lot more effective in paint consumption. They also get rid of the demand for pricey air pollution control devices.

Powder Coating likewise has the advantage of being much easier to clean up. Nevertheless, it is very important to keep the spray booth location clean between shade adjustments. If the booth is unclean up correctly, it can bring about cross-contamination.

Powder Coating can additionally chip or flake off in certain problems. This can be as a result of improper preparation, or perhaps as a result of rust. Therefore, it is necessary to stay clear of storage space conditions that allow wetness to accumulate on the surface. Also, powder Coating can break down if it is subjected to UV light.

|

Метки: Powder Coating Powder Coating Company Powder Coating Services Industrial Powder Coating Powder Coating Metals Commercial Powder Coating Silk Screening |

Here Are The Benefits Of Powder Coating |

Content by-Doyle Grau

Unlike fluid paint, which is provided via vaporizing solvent, powder Coating is used as a free-flowing dry powder, after that healed with warmth or ultraviolet light. Powder Coating is put on surfaces in order to secure them from environmental damages and scrapes.

Pretreatment

Obtaining a superb pretreatment prior to powder Coating is a must to get a long lasting, rust resistant Coating. In addition to enhancing the adhesion of the powder to the substrate, it additionally supplies the steel with a safety layer.

The procedure can be a dip, spray, or a mix of several methods. The choice of procedure depends upon the sort of item being layered as well as the client's specs. The performance of the pretreatment should be matched to the specifications of the powder coat, in addition to the materials utilized in the pretreatment.

The primary step in preparing a component for powder Coating is to get rid of surface dirts. Some common techniques include pressure washing, sandblasting, as well as sophisticated media blowing up. The quantity of dirt that needs to be eliminated will certainly vary relying on the kind of product being coated.

Electrostatic spray deposition technique

Utilizing electrostatic spray deposition, a powder combination is sprayed onto a metal surface. The electrostatic destination between the powder particles as well as the steel surface area leads to a finishing that protects the underlying product from corrosion. look at this website offers a range of finishes and textures. The Coating is additionally readily available in a number of shades.

The electrostatic spray deposition process includes making use of an electrostatic spray gun as well as a powder spray cubicle. This system is an usual technique of using powder coverings. A corona spray gun is a common electrostatic spray gun. The electrostatic spray gun includes a nozzle that generates high voltage to produce an electrostatic area in between the metal foil as well as the spray blend. The powder blend is after that splashed via the nozzle to the metal surface area.

Fluidized bed powder Coating approach

Unlike conventional liquid finishings, the Fluidized bed powder Coating approach is much more environmentally friendly. It is likewise a lot less costly. It offers a tough, smooth surface with outstanding longevity. It can be put on different items such as steel superstructures, covering equipment, and also airplane parts.

Fluidized bed powder Coating technique is likewise utilized on various components that go through heats. It safeguards the part versus corrosion and ecological impacts. It also smooths over small details. During https://road.cc/content/review/spraybike-paint-228960 , parts are preheated and then dipped into a "fluidized bed" of plastic powder. Later, the parts are cured in an oven. This type of Coating is optimal for parts with Faraday cage results.

Unlike fluid coatings, the Fluidized bed powder technique generates heavy coats in one dip. This kind of Coating method has high transfer performance. It also eliminates the requirement for overspray healing systems.

Cross-contamination

Utilizing powder Coating to layer an item can be very reliable. Nevertheless, it is very important to make use of the right powder and to follow good contamination control practices to make certain a premium quality surface.

Cross-contamination occurs when a component or powder is subjected to contaminants such as dust, dust, oil, and also metal chips. Completion result may be a problem in the coating, which could lead to a dissatisfied customer.

The tiniest fleck of dirt might destroy a powder layered product. For this reason, it is important to guarantee that the powder as well as the air in the powder Coating room are clean. It is also vital to make sure that the area is well filteringed system. This will certainly ensure that the dust from the rest of the structure is not able to infiltrate the powder Coating space.

Resilience

Among the many benefits of powder Coating is its toughness. It is made use of on a vast array of products. It supplies resistance to effect, abrasion, rust, as well as chemicals. It can last for years, also decades, if it is used properly.

Powder Coating is likewise much less destructive to the setting than traditional fluid paint finishing. It launches minimal quantities of unstable natural compounds (VOCs) right into the environment. It is likewise very easy to tidy. It is conveniently washed with lukewarm water.

Powder Coating uses a wide range of appearances, from smooth surface areas to harsh appearances. It is likewise available in a range of finishes, from shiny to matte.

Powder Coating can hold up against smoke, UV radiation, and also acidic conditions. https://writeablog.net/amiee0352daryl/powder-coati...d-your-metal-objects-from-rust is additionally extremely immune to corrosion, breaking, and weather. It can be put on various types of products, such as steel, plastic, and glass. It is extensively utilized in many markets, including construction, agriculture, electric engineering, and also the production of mechanical components.

|

Метки: Powder Coating Powder Coating Company Powder Coating Services Industrial Powder Coating Powder Coating Metals Commercial Powder Coating Silk Screening |

Powder Coating - How To Apply Multi-Color Powder Coatings |

Article created by-Foged Degn

Unlike standard liquid paint, powder Coating is a kind of Coating that is used as free-flowing dry powder and then cured by warm or ultraviolet light. It is typically used electrostatically.

Pretreatment

Relying on your application and product, the pretreatment prior to powder Coating procedure can be complicated. The procedure will depend on your performance goals and also your end user's specs.

Pretreatment before powder Coating is not something that must be taken lightly. The process can produce top quality results if done effectively. The ideal pretreatment will certainly prevent rust and deterioration of your item's surface area.

The most effective pretreatment will certainly call for proper training as well as a little bit of expertise. https://zenwriting.net/ken1sharie/this-write-up-di...e-advantages-of-powder-coating will include a range of procedures, all of which are developed to improve the performance of your item. This consists of eliminating contaminations from the surface area as well as preparing it for powder application. The pretreatment process might additionally consist of conditioning, securing and washing.

An excellent pretreatment will permit you to achieve an uniform finish coat. This is especially essential for outdoor applications. The right pretreatment will safeguard your item from UV rays and protect against rust. Using the best pretreatment will certainly likewise aid prevent adhesion failing, which can lead to peeling and also fracturing of the coating.

The very best pretreatment will certainly likewise be the most cost-effective. This is particularly real if you are searching for an one-time project. For a larger-scale line, you may want to take into consideration a multi-stage process. The advantages consist of a regular surface, less downtime as well as greater productivity.

An excellent pretreatment might likewise confirm to be the very best investment you make. The best pretreatment will certainly offer you with a smooth surface to bond with your powder layer.

Multi-color powder finishes

Whether you are a novice or a seasoned professional, there are a variety of benefits to using multi-color powder finishes. While the application procedure may show up made complex, it is actually a rather simple procedure. Here are a few pointers to remember.

One of one of the most usual powder Coating special results is a textured surface. https://www.european-coatings.com/articles/archiv/...ens-new-powder-plant-in-poland can be attained by blending various colors. The resulting surface can be anything from a shiny roofing to a speckled pattern. The appearance of the finish depends on the item you are Coating.

Another typical powder Coating unique effect is the one-step impact. This is splashed on like traditional powder. These special effects are generated by using numerous colors and blending them before treating. Regular powder finishes have softening temperatures of around 80 degC.

Unlike liquid paint, powder Coating does not release toxic products into the setting. In addition, it is much more resilient and immune to scratches and also fading. These functions make powder finishings a great choice for commercial applications.

Unlike liquid paint, powder coverings do not need a guide. This makes them optimal for applications where the finish needs to be applied in a range of arrangements. Powder covered parts can be applied to a variety of materials including glass, metal, and plastic.

Two-color powder coatings call for additional interest to detail. The 2nd shade requires to be splashed in addition to the initial. This is generally done using a high temperature tape. This will certainly mask off the very first layer and also soften the sides.

Overspray

During the last three years, powder coatings have been verified to be an exceptional Coating technology. They supply a thicker film than fluid paint and also have a low environmental effect. They are likewise extra energy-efficient.

They can be used in several commercial applications. They are additionally utilized in aerospace applications. Among the benefits are reduced preliminary expenses, less air pollution, and prolonged lifetime.

Besides, http://marylee38lana.xtgem.com/__xt_blog/__xtblog_...ng?__xtblog_block_id=1#xt_blog do not generate VOCs (unstable natural compounds), which are understood to be unsafe. These compounds can cause liver and main nerves damage. They can also trigger cancer cells.

To lower the amount of waste generated from powder Coating overspray, there are reclaim systems readily available. These systems recover the oversprayed powder and reuse it for a brand-new Coating.

These systems work making use of a cartridge-style filtering system. They also supply tidy air for recirculation back into the plant. The filtration system does not need an exhaust stack, minimizing the price as well as maintenance of an exhaust system.

The powder Coating system can be utilized with very little manpower. This results in reduced prices for the producer.

This procedure is also energy-efficient due to the fact that it minimizes the quantity of stove air that must be worn down. The powder Coating process also does not need airing vent. This likewise causes no contaminated materials to be disposed of.

|

Метки: Powder Coating Powder Coating Company Powder Coating Services Industrial Powder Coating Powder Coating Metals Commercial Powder Coating Silk Screening |

Powder Coating - Exactly How To Use Multi-Color Powder Coatings |

Content written by-Dideriksen Truelsen

Unlike traditional fluid paint, powder Coating is a kind of Coating that is applied as free-flowing dry powder and after that cured by warmth or ultraviolet light. It is typically used electrostatically.

Pretreatment

Depending on your application as well as product, the pretreatment prior to powder Coating process can be complex. The process will depend on your efficiency objectives as well as your end user's specs.

Pretreatment prior to powder Coating is not something that should be ignored. The process can create quality outcomes if done properly. The right pretreatment will stop deterioration and also deterioration of your item's surface area.