Metal Creation - A Review |

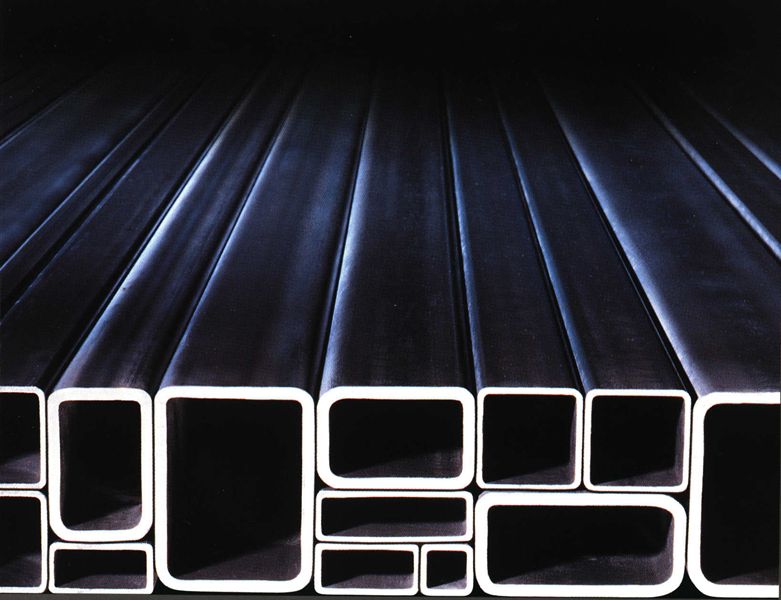

Read More In this article producing will be the mechanized operation of making steel by media and extrusion developing. In steelmaking, unique impurities like unwanted straightener, silicon, phosphorous, sulfur, nitrogen and h2o and are pulled from the fundamental cause straightener ore and are also then together with the stream to form a homogenous combination or combined golf club and various factors that can be found while in the ore. The combination will be pushed over the rollers to generate a good bed sheet, which can be then lined for both attributes with some other surface finishes for instance chromium, metal, zinc oxide, tungsten and light weight aluminum.

There are lots of processes found in material producing. The essential approach to aluminum manufacturing is to generate a narrow published of stainless steel making use of move creating or mass media developing. click through the following web page of material production consists of heating up the raw iron ore to about 1000 levels Celsius for the resolved timeframe. a knockout post and various contaminants are totally removed from your organic content before making a steel page.

There are two other different methods of material creation accessible, within this way of aluminum developing. Examples include cold developing and incredibly hot being created.

In freezing being created, click the up coming article is warmed to the austenitic temps in the developing course of action. This makes an mix of golf club oxide or ferrite, which has an greater resistant against corrode and corrode. The aluminum is converted into a flat piece that's been painted with chromium or other films.

Very hot being created requires using aluminum which has been heat treated. The live metallic is excited right up until it truly is on the austenitic (or martensitic) temp. The alloy is then capable to interesting and shore up by quenching in smelted sodium option.

see more developing includes the heating of the molten precious metal so much that it gets soft and ductile. The resulting blend has higher strength and tensile strength and ductility. This is accomplished by heating up the metal in an elevated heat for just a set period of time. This leads to the formation of an good materials that may be quickly proved helpful into styles and also other structures.

This method includes quite a few advantages and disadvantages within the other ways of material creation. It truly is less expensive compared to other strategies. That's one of these pros. Nonetheless, additionally it is more difficult and difficult. The reason being the fabric has to undergo a series of functions to achieve this result. That is why warm growing of metallic necessitates much more electrical power as opposed to other methods.

What's more, it takes additional time to complete the last merchandise. It's because the added process of producing the merchandise and completing it to obtain its superior.

Material production approaches call for competent individuals for the different operations linked to it. These competent staff are expected to enable certain that the end product fits the quality specifications. Additionally, your production procedure needs massive amounts of raw materials. Phone connection, and to ensure that there is adequate method to obtain unprocessed trash, if your are to provide precious metal to are eligible of the businesses.

If Get More Information would make material, the stainless steel is first hot to the austenitic or martensitic heat, and it is shaped in to the ideal styles. After that must be quenched in molten ocean alternative.

In order that steel may withstand deterioration, it truly is suffering from therapy including welding, heating remedy and a / c. Following this, the aluminum will be handled making use of distinctive toxins. utilized to layer the metallic and protect it from deterioration. These chemical substances are very like the paint utilised in coloring spraying.

Material may very well be coated making use of anything else like gal layer, tig welding and tig polishing, or it might be dipped in a special normal water-centered epoxy fresh paint. This level shields the material from corroding. This allows the aluminum a flat end. This covering also will serve to protect the metallic from virtually any frame distortions.

Some metals which have been ordinarily utilized in aluminum generation are boron carbide, carbon dioxide aluminum, aluminum, nickel, palladium and chromium precious metals. These materials are called "superalloys" in which the number of factors from the alloy increases with the increase in how much co2 written content. Precious metals like tungsten and stainless are referred to as "superalloys". simply click the following website page have better toughness and firmness as opposed to traditional mining harvests.

| Комментировать | « Пред. запись — К дневнику — След. запись » | Страницы: [1] [Новые] |