Device Functions: Quality in Manufacturing from India |

Introduction

In today's swiftly progressing world, production plays an important role in driving financial development and development. With innovations in modern technology and a raising demand for top quality items, it is important for suppliers to stay in advance of the competitors. One country that has actually become a global manufacturing center is India. With its rich industrial heritage, knowledgeable workforce, and dedication to quality, India has ended up being a preferred location for companies looking for dependable and economical manufacturing solutions.

Machine Functions: Excellence at its Core

India Hand Machine: Grasping the Art of PrecisionIndia is renowned for its workmanship and attention to detail. When it involves hand makers, Indian producers excel in providing precision-engineered tools that satisfy the finest criteria. From elaborate woodwork to fragile fashion jewelry making, the India Hand Machine is a testimony to the country's rich artisanal heritage.

India Machine Components: Building Blocks of SuccessBehind every effective device exists a complicated network of elements collaborating effortlessly. Indian suppliers concentrate on creating top quality maker parts that are sturdy, efficient, and tailored to fulfill details requirements. From gears and bearings to screws and screws, India Machine Components are trusted by industries worldwide.

India CNC Machines: Where Precision Meets InnovationComputer Numerical Control (CNC) equipments have changed the manufacturing market with their capacity to produce complex styles with unequaled accuracy. India has actually become a worldwide leader in CNC device production, providing advanced modern technology and innovative options throughout various sectors. From auto parts to aerospace components, India CNC Machines are synonymous with excellence.

India Mill Equipment: Redefining EfficiencyThe milling procedure is important in shaping basic materials into finished items. Indian producers have refined the art of mill machines, delivering efficient options that maximize productivity while guaranteeing accuracy and precision. With advanced features and robust building, India Mill Machines are trusted by industries worldwide.

India Electronic Device: Powering the FutureAs technology remains to advance at a fast speed, the demand for electronic equipments has actually increased. Indian manufacturers have actually climbed to the occasion, creating state-of-the-art electronic machines that satisfy varied industries. From consumer electronics to industrial automation, India Electronic Machines are at the forefront of innovation.

India Machine Press: Transforming Raw MaterialsPress equipments are necessary in shaping and forming numerous products into preferred sizes and shapes. Indian manufacturers concentrate on generating trustworthy and efficient equipment presses that deliver consistent outcomes. With their durable building and advanced attributes, India Device Presses deal unrivaled performance.

India Equipment Maker: Driving EfficiencyGears play a crucial function in transferring power and motion within makers. Indian makers have understood the art of equipment production, providing high-quality https://controlc.com/b84a1146 equipment machines that guarantee smooth operation and ideal effectiveness. From automobile transmissions to industrial equipment, India Gear Machines are trusted by industries worldwide.

India Power Machine: Empowering IndustriesThe power sector calls for trusted and effective machines to generate power and satisfy expanding power demands. Indian producers have actually created advanced power makers that harness renewable energy sources while guaranteeing marginal ecological impact. With their innovative technology and sustainable solutions, India Power Equipments are driving the change towards a greener future.

India Machine Device: A Symphony of PrecisionWhen it pertains to making complicated items, accuracy is vital. Indian makers master creating machine makers that incorporate numerous features into a single system, enhancing space and raising efficiency. From automated production line to specialized manufacturing systems, India Equipment Equipments are changing production processes.

India Hydraulic Machine: The Power of FluidsHydraulic systems play an essential duty in numerous industries, enabling precise control and powerful force transmission. Indian producers specialize in creating premium hydraulic makers that satisfy rigorous performance criteria. With their sophisticated innovation and durable building, India Hydraulic Equipments are trusted by markets worldwide.

India CNC Maker: Redefining ManufacturingComputer Numerical Control (CNC) equipments have transformed the production landscape, making it possible for unmatched precision and efficiency. Indian suppliers have welcomed this modern technology, generating innovative CNC makers that cater to diverse markets. From aerospace parts to clinical gadgets, India CNC Machines are at the leading edge of innovation.

India Device Devices: Enabling Precision EngineeringMachine tools are essential in shaping and developing different materials right into preferred sizes and shapes. Indian manufacturers concentrate on generating high-quality equipment devices that deliver precision engineering solutions. With their sophisticated features and durable building and construction, India Machine Tools are relied on by sectors worldwide.

India Design Machines: Structure a Much Better FutureEngineering is at the heart of technology and progression. Indian makers have developed a variety of design devices that accommodate varied sectors and applications. From building and construction tools to commercial automation, India Engineering Machines are driving development and development.

India Device Oil: Lubricating SuccessLubrication is important for preserving the efficiency and long life of makers. Indian makers produce top quality machine oils that ensure smooth operation, lower friction, and protect against deterioration. With their exceptional lubricating residential properties, India Equipment Oils are relied on by industries worldwide.

India Press Machines: Shaping the FuturePress equipments play an essential role fit numerous products into desired forms. Indian manufacturers excel in producing reliable and reliable press devices that provide constant results. With their sophisticated innovation and accuracy design, India Press Machines are forming the future of manufacturing.

India Steel Devices: Forging ExcellenceMetalworking is a basic process in manufacturing numerous products. Indian manufacturers specialize in creating high-grade metal makers that make it possible for reliable metalworking procedures. From sheet metal construction to building processes, India Metal Machines are synonymous with excellence.

Conclusion

India's production prowess has actually earned it a just track record for quality. Whether it's hand makers or CNC makers, maker elements or press devices, Indian makers consistently supply superior high quality products that meet worldwide standards. With their commitment to innovation, precision design, and consumer satisfaction, Maker Functions from India are driving development and revolutionizing the production market. Trust in the expertise and experience of Indian producers to take your company to new heights.

|

|

Processing Makers: Advancements Driving Growth in India's Manufacturing |

Original text too long. Text can have up to 4,000 https://www.trademama.com/machine-shaft/india/suppliers.html words.

|

|

Making Certain Smooth Procedures: The Importance of India's Machine Service Providers |

Introduction: In today's hectic planet, the effective function of machines is actually important for services to keep very competitive. India's machine company participate in an essential role in making sure that these machines operate perfectly and properly. Coming From India Paper Machines to India Glass Machines, these specialist deliver a wide variety of services to keep numerous markets running properly. In this particular short article, our team are going to check out the relevance of India's machine company and how they contribute to guaranteeing hassle-free functions for organizations across the country.

The Duty of India's Machine Service Providers

India Machine Storage India Machine Storage carriers play a crucial part in making sure that machines are actually kept safely as well as safely when not being used. Suitable storing helps protect against damages to the machines and ensures that http://lorenzonrln503.timeforchangecounselling.com...ility-of-cnc-machines-in-india they await make use of when needed.

India Machine Table India Machine Table suppliers give durable as well as reliable desks on which machines could be placed for optimum performance. These tables are developed to hold up against hefty loads and provide a secure surface for the machines to operate on.

India Glass Machine India Glass Machines are necessary for businesses in the glass field. These machines are used for reducing, forming, and also buffing glass items along with preciseness and also performance. Normal servicing and repairing through machine service providers are actually important to ensure the hassle-free function of these machines.

Types of Machines Serviced in India

India Machine Type India Machine Provider satisfy a large variety of machine styles, featuring industrial machinery, agricultural tools, publishing pushes, as well as much more. They possess the skills as well as knowledge to handle a variety of forms of machines and also ensure their appropriate functioning.

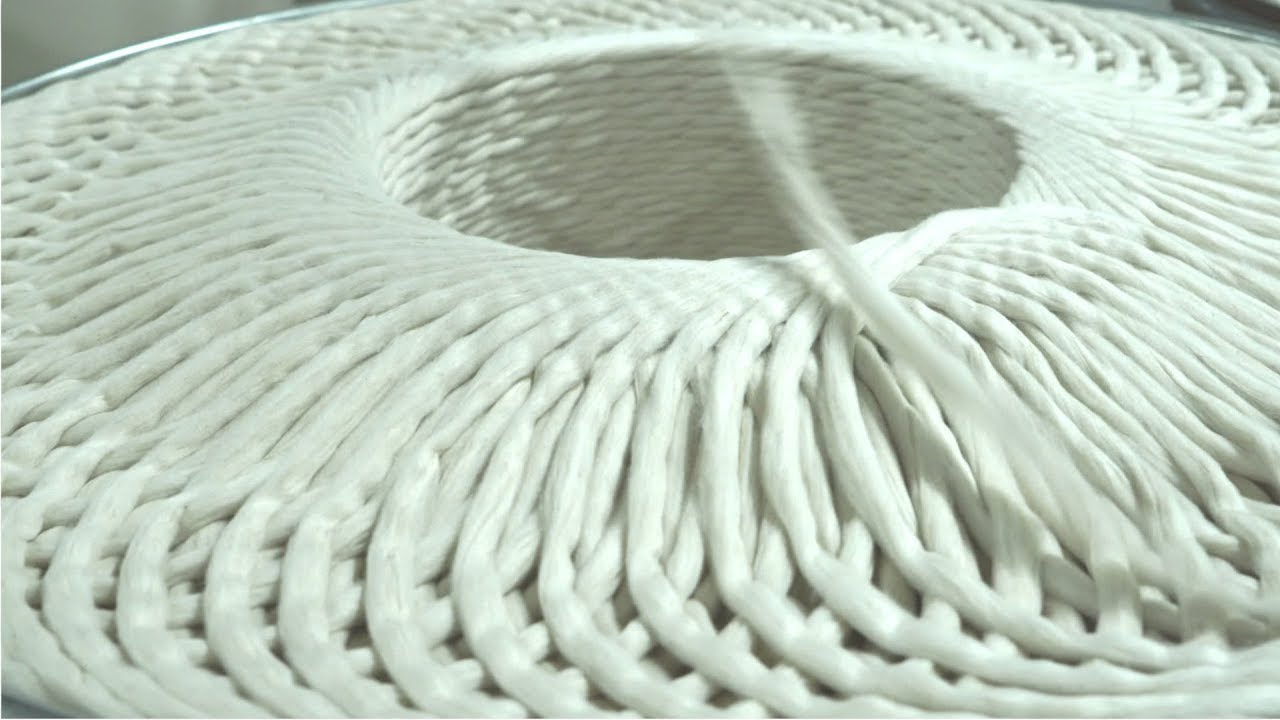

India Fabric Machine Textile industries rely intensely on India Textile Machines for manufacturing textiles and also garments. These machines need frequent upkeep and also servicing to stop break downs and also make certain nonstop production.

India Cap Machine India Cap Machines are utilized in the packaging industry for closing bottles and compartments with caps. Company specializing in cap machines deliver servicing, repair work, as well as substitute companies to maintain these machines running smoothly.

Ensuring Top quality Solution from India's Machine Providers

India Machine Lift Machine training is actually a vital component of machine maintenance, as it involves moving hefty machinery safely as well as successfully. India Machine Lift carriers have the required equipment and also experienced specialists to take care of machine lifting duties with precision.

India Quality Machine Top quality is actually critical when it involves machine repairing. India Quality Machine provider abide by meticulous high quality criteria to supply trustworthy companies that meet the demands of their customers. By delivering excellent companies, they assist companies maintain functional efficiency and also productivity.

FAQs regarding India's Machine Company Providers

- What companies perform India's machine specialist offer?

- India's machine company offer a wide variety of services, including routine maintenance, repairs, installment, gradation, upgrades, as well as more.

- How frequently should I set up routine maintenance for my machines?

- It is advised to plan frequent upkeep look for your machines at least once every 6 months to make certain ideal performance.

- Can India's machine provider service all sorts of machines?

- Yes, many service providers in India have experience servicing different types of machines all over different industries.

- What ought to I look for when deciding on a machine specialist in India?

- When choosing a machine company, take into consideration elements like expertise, know-how, stability, credibility, pricing, and also consumer reviews.

- Do India's machine company use unexpected emergency repair work services?

- Some provider might provide unexpected emergency repair service services for important issues that demand immediate attention.

- How may I prolong the life-span of my machines with routine servicing?

- Regular repairing aids pinpoint potential issues early, avoiding pricey detailed lists and also expanding the life expectancy of your machines.

Conclusion: To conclude, India's machine company play a critical part in making sure soft procedures for companies across various business. Coming from repair and maintenance to installations and also upgrades, these company give detailed options to keep machines managing efficiently. Through partnering along with trusted and also professional service providers, companies can enrich their operational performance, lessen downtime, as well as boost general productivity. It is actually necessary for organizations to prioritize regular repairing of their machines to avoid analyses and also sustain ideal functionality amounts. With the support of India's specialized machine service providers, services may obtain seamless procedures and also remain ahead of time in today's open market landscape.

Remember: Guaranteeing Smooth Procedures: The Importance of India's Machine Service Providers is crucial to success!

|

|

Layer Machines: Shaping India's Metalworking Market |

Introduction

The metalworking industry in India has actually seen significant growth in recent times, many thanks to the innovations in plate devices. These machines, additionally called press devices, have revolutionized the production process by giving efficient and specific shaping of metals. With their wide variety of applications and capacities, plate machines have actually ended up being an important component of the metalworking sector in India.

In this short article, we will certainly explore the different types of plate devices made use of in India, their parts, and the impact they have actually carried the country's metalworking sector. We will look into the advancements made in innovation and just how these equipments have actually transformed the production landscape. So let us dive deep into the world of plate makers and comprehend just how they are shaping India's metalworking industry.

Plate Equipments: The Foundation of Metalworking

Plate makers play a critical role in the metalworking market as they allow producers to shape metals with accuracy and accuracy. These machines are utilized for a range of applications such as flexing, cutting, boxing, and shearing metals. They are capable of handling various sorts of products including steel, light weight aluminum, brass, and copper.

India Hand Device: A Pioneer in MetalworkingOne of the popular players in the Indian market is India Hand Machine (IHMC). The business concentrates on producing high-grade plate machines that accommodate numerous sectors such as auto, aerospace, building and construction, and extra. IHMC's plate makers are recognized for their toughness, reliability, and progressed features.

India Equipment Elements: Essential for EfficiencyTo make sure optimal efficiency of plate equipments, high-quality device parts are vital. India Machine Components (IMC) is a distinguished supplier that concentrates on generating precision-engineered elements for plate makers. IMC's components add to the efficiency and long life of these machines.

India CNC Machines: Precision at its BestComputer Numerical Control (CNC) equipments have revolutionized the metalworking sector by supplying unparalleled precision and precision. India CNC Machines (ICM) is a leading supplier of CNC plate devices in India. With their sophisticated modern technology and state-of-the-art functions, ICM's CNC devices are extremely demanded by manufacturers.

India Mill Machine: A Flexible WorkhorseWhen it concerns crushing metals, India Mill Machine (IMM) is a name that stands apart. IMM provides a vast array of mill equipments that can deal with various sizes and shapes of steel parts. These devices are recognized for their flexibility, longevity, and effectiveness in the metalworking industry.

India Digital Device: Advancing AutomationAutomation has ended up being an essential component of the manufacturing process, and India Electronic Machine (IEM) goes to the leading edge of this change. IEM specializes in making digital plate machines that can executing intricate jobs with minimal human intervention. These machines have dramatically improved productivity and efficiency in the metalworking industry.

Plate Equipments: Innovations in Technology

The metalworking sector has actually seen considerable developments in technology, and plate machines have actually played a crucial function in driving this progression. Let us take a more detailed consider several of the technical advancements that have shaped India's metalworking industry.

India Maker Press: Powering PrecisionIndia Device Press (RASCAL) has contributed in improving the precision and effectiveness of plate equipments. Brat's hydraulic press equipments supply high pressure capacities, allowing manufacturers to form metals with utmost precision. These makers are commonly utilized in markets such as vehicle, aerospace, and construction.

India Gear Device: Smooth OperationsGears play a crucial duty in plate makers as they make it possible for smooth and specific movements. India Gear Machine (IGM) specializes in making high-quality equipments that are utilized in various types of plate makers. IGM's equipments https://www.trademama.com/hand-machine/india/suppliers.html make certain smooth procedures and add to the total effectiveness of these machines.

India Power Device: Empowering ManufacturingPower is a vital element of plate makers, and India Power Machine (IPM) has gone to the forefront of offering reputable and reliable power solutions. IPM's power devices are developed to fulfill the details requirements of plate machines, making certain continuous procedures and boosted productivity.

India Machine Tools: The Backbone of ManufacturingMachine devices are crucial for the appropriate functioning of plate machines. India Machine Tools (IMT) is a leading manufacturer of device devices that are utilized in numerous types of plate makers. IMT's devices are recognized for their toughness, precision, and dependability, making them an essential part of the metalworking industry.

FAQs

What are plate machines? Plate equipments, likewise referred to as press equipments, are made use of to form metals with precision and precision. They are capable of carrying out jobs such as bending, cutting, punching, and shearing metals.

What markets make use of plate machines? Plate equipments locate applications in different industries consisting of automotive, aerospace, construction, manufacturing, and more.

What products can be refined with plate machines? Plate machines can manage different kinds of products including steel, light weight aluminum, brass, copper, and more.

What is the role of CNC in metalworking? CNC (Computer Numerical Control) technology has actually transformed the metalworking sector by offering unequaled precision and accuracy fit metals.

How have plate machines added to the metalworking sector in India? Plate machines have actually transformed the metalworking sector in India by enhancing effectiveness, performance, and total top quality of manufactured products.

What improvements have been made in plate device technology? Plate maker modern technology has actually seen developments such as hydraulic press systems, electronic automation, progressed equipments, and power options that have actually improved accuracy and efficiency.

Conclusion

Plate machines have actually ended up being an important part of India's metalworking industry as a result of their capability to form metals with precision and accuracy. These machines have actually changed the manufacturing procedure and have added to raised effectiveness, performance, and high quality in numerous industries. With advancements in modern technology and continuous advancement, plate devices are expected to play a a lot more considerable duty fit India's metalworking industry in the future.

|

|

Cold and Determined: The Impact of India's Cold Machines |

Introduction

In today's hectic world, making use of machines has actually come to be an integral component of numerous industries. India, recognized for its technology and technical improvements, has actually gone to the forefront of establishing cool machines that are revolutionizing the production field. From India Bar Machine to India Control Machine, these sophisticated technologies are transforming the means organizations run and lead the way for increased performance and productivity.

Cold Machines: A Game-Changer in the Manufacturing Industry

Cold machines have come to be a game-changer in the production market, offering accuracy, rate, and reliability like never ever previously. With developments in modern technology, India has become an international leader in creating top notch chilly machines that cater to a wide variety of industries. Whether it is India Auto Machine or India Precision Machine, these innovative technologies are transforming the way products are manufactured and establishing brand-new standards for high quality and efficiency.

The Development of Cold Machines in IndiaOver the years, the advancement of cold machines in India has been amazing. From standard machinery to modern modern technologies like India Laser Machine and India Concrete Machine, producers have actually embraced development to stay in advance of the competition. These cold machines not just improve manufacturing processes but also decrease costs and lessen errors, making them an important property for organizations aiming to enhance their operations.

The Benefits of Using Cold Machines- Increased Productivity: Cold machines such as India Heavy Machines and India Machine Saw can substantially increase efficiency by automating jobs that were formerly done manually. Improved Precision: With sophisticated attributes like India Machine Box and India Flow Machine, manufacturers can achieve exceptional accuracy in their manufacturing processes. Cost-Efficiency: Buying cold machines like India Power Machines can help companies conserve money in the future by decreasing waste and maximizing resources. Enhanced Quality: Cold machines such as India Sheet Machine and India Service Machine guarantee constant top quality outcome, conference industry requirements and customer expectations.

FAQs concerning Cold Machines in India

- What types of markets take advantage of making use of chilly machines in India?

- Various sectors such as auto, aerospace, electronic devices, and medical care gain from making use of cool machines for manufacturing processes.

- How do cold machines improve effectiveness in manufacturing lines?

- Cold machines automate recurring tasks, lower human mistake, and ensure constant top quality result, thereby boosting efficiency in production lines.

- Are cool machines cost-efficient for small businesses in India?

- Yes, cold machines can be found in a variety of sizes and price points, making them obtainable to small companies looking to enhance their manufacturing capabilities.

- What duty do cool machines play in lasting production practices?

- Cold machines help in reducing waste by maximizing resources and lessening errors, making them crucial for sustainable production practices.

- How does maintenance benefit chilly machines in India?

- Regular upkeep is essential to making certain optimum efficiency of cold machines; suppliers often offer maintenance services to keep these machines running smoothly.

- Can cool machines be customized to satisfy details producing requirements?

- Yes, lots of suppliers provide modification choices for chilly machines to tailor them to certain manufacturing demands and processes.

Conclusion

In final thought, the impact of India's cold machines on the production market can not be downplayed. From boosting productivity to improving precision and quality, these sophisticated technologies are driving advancement and setting brand-new benchmarks for excellence. As even more services accept chilly machines like India Line Machine and https://tempaste.com/ahr2I8nb65h India Dryer Machine, we can anticipate to see ongoing development and advancement in the production market. With their indisputable benefits and unequaled capacities, it is clear that cool machines are below to stay as a keystone of modern-day industrial practices.

|

|

Optimizing Manufacturing with India Filling Machines |

Are you seeking to improve your manufacturing performance with high-grade filling up machines from India? Look no more! In this extensive guide, we will check out exactly how India filling machines can change your manufacturing process, rise output, and enhance total quality. From hydraulic machines to CNC machines, we will cover whatever you need to know about optimizing production with India filling machines. Allow's dive in!

Introduction

Optimizing manufacturing with India filling machines is critical for organizations wanting to enhance their procedures and boost productivity. By investing in premium machinery from India, companies can accomplish faster turn-around times, reduce waste, and ultimately boost profitability. Whether you remain in the food sector, drugs, or cosmetics, selecting the best filling up machine from India can make all the difference.

Why Choose India Filling Up Machines?

India has developed itself as a global leader in producing a vast array of commercial machinery. From hydraulic machines to CNC machines, India supplies cutting-edge technology at affordable costs. When it pertains to filling up machines, Indian suppliers focus on advancement, precision, and dependability. By going with India filling machines, services can gain from premium performance and durability.

Types of Filling up Machines Offered in India

1. Hydraulic MachinesIndia Hydraulic Machines are recognized for their durable building and construction and high effectiveness. These machines make use of fluid power to execute different tasks such as filling up, securing, and labeling.

2. CNC MachinesIndia CNC Machines utilize computer system mathematical control to https://jsbin.com/deyuvekifu automate the manufacturing process. These machines offer unequaled precision and repeatability.

3. Machine ToolsIndia Machine Devices encompass a vast array of devices utilized for cutting, forming, and ending up components. These devices are important for precise and efficient manufacturing.

4. Design MachinesIndia Engineering Machines are designed for durable applications in industries such as auto, aerospace, and construction.

5. Machine OilIndia Machine Oil is particularly formulated to lubricate and safeguard commercial machinery, guaranteeing smooth procedure and longevity.

Advantages of Using India Filling Up Machines

- Precision: India filling machines are crafted to provide specific dimensions and regular results. Efficiency: With sophisticated automation features, India filling machines can significantly raise production efficiency. Reliability: Indian makers are understood for their commitment to high quality and reliability. Cost-Effective: In spite of their innovative functions, India filling machines are competitively priced compared to other global brands. Customization: Many Indian makers use customizable remedies to meet particular production requirements. After-Sales Support: Indian companies provide exceptional after-sales sustain and maintenance services.

Frequently Asked Questions (FAQs)

1. Are India filling machines ideal for small-scale productions?Yes! There are numerous alternatives readily available out there that satisfy small manufacturings without compromising on high quality or efficiency.

2. How can I make certain the durability of my India filling up machine?Regular upkeep and appropriate use guidelines offered by the maker can aid lengthen the lifespan of your machine.

3. Can I incorporate multiple procedures right into one machine with India filling up machines?Yes! Numerous innovative versions supply multi-functional capabilities to streamline production processes.

4. Are India filling machines easy to operate?Most modern-day India filling machines featured straightforward user interfaces and intuitive controls for convenience of operation.

5. Do Indian manufacturers supply training for running their loading machines?Yes! Numerous producers give thorough training programs for drivers to guarantee ideal performance.

6. Can I update my existing loading machine with brand-new attributes from an Indian manufacturer?Yes! Indian suppliers typically offer upgrade bundles to enhance the functionality of existing machines.

Conclusion

In verdict, enhancing manufacturing with India Filling Machines is a strategic financial investment that can generate significant advantages for businesses across various industries. With a wide variety of options available-- from hydraulic machines to CNC machines-- Indian makers continue to set the criterion for quality, innovation, and integrity in the global market. By picking India filling machines, business can enhance their functional efficiency, enhance product top quality, and eventually drive service development in an affordable environment.

So why wait? Check out the limitless possibilities of optimizing manufacturing with India Filling Machines today!

|

|

Discovering the Background and Impact of Hair Metal Music |

Introduction: In this comprehensive short article, we will dig deep right into the interesting world of hair metal music. From its origins to its influence on popular culture, we will certainly explore the history and impact of this famous style.

The Birth of Hair Metal

Hair metal, additionally called glam metal, arised in the late 1970s and reached the height of its appeal in the 1980s. Bands like Motley Crue, Toxin, and Bon Jovi were at the forefront of this flamboyant and energetic genre.

Metal ConsoleMetal consoles are a preferred selection for displaying decorative things or storing digital tools. With their streamlined style and toughness, they add a touch of style to any type of room.

Metal Outdoor BarstoolsMetal outside barstools are excellent for including a fashionable touch to your patio or yard. With their strong building and weather-resistant products, they are ideal for outside entertaining.

Metal Clothing RackA metal clothes rack is a practical solution for arranging your wardrobe. With its adjustable elevation and durable style, it can hold a lot of garments without using up too much space.

The Increase to Fame

Hair metal bands swiftly rose to fame with their catchy hooks, fancy attire, and over-the-top phase efficiencies. Their video came to be MTV staples, propelling them right into superstardom.

Watch MetalWatch metal is a term made use of to describe the fancy precious jewelry used by hair metal musicians. From extra-large watches to diamond-encrusted arm bands, these accessories were an essential part of the hair metal look.

Metal RodsMetal poles are typically utilized in construction and manufacturing markets. With their high tensile stamina and resistance to corrosion, they are necessary elements in different applications.

The Influence on Fashion

Hair metal had a considerable influence on fashion trends during its heyday. Leather pants, spandex shirts, and teased hair became signature appearances associated with the genre.

Hair MetalThe term "hair metal" refers to the distinctive hairdo sported by artists in this genre. Huge hair was achieved through teasing, hairspray, and often even hair extensions.

Metal Coffee PotA metal coffee pot is a long lasting and elegant option for developing your early morning cup of joe. With its heat-retaining homes and traditional layout, it adds a touch of elegance to your kitchen.

The Soundtrack of a Generation

Hair metal songs worked as the soundtrack for a generation that welcomed excess and rebellion. Its anthemic carolers and guitar solos captured the spirit of youthful defiance.

Metal ClampsMetal clamps are functional devices used for holding items with each other firmly. Whether you're working on woodworking projects or vehicle repairs, these handy devices come in numerous sizes and designs.

Metal Footwear RackA metal shoe rack is a reliable storage space option for maintaining your footwear organized. With several tiers and sturdy building and construction, it trademama metal suppliers can accommodate several sets of footwear while saving space.

The Legacy Lives On

metal suppliersAlthough the heyday of hair metal has passed, its tradition remains to influence contemporary rock-and-roll. Many modern bands point out hair metal as a major inspiration for their audio and style.

Outdoor Metal ChairsOutdoor metal chairs are sturdy alternatives for providing your outdoor patio or garden. With their weather-resistant products and sleek style, they provide both convenience and design for outdoor seats areas.

Metal StudsMetal studs are attractive elements used in apparel, devices, and home style items. With their edgy appeal and adaptability, they include a touch of rock 'n' roll mindset to any kind of design.

Conclusion:

In conclusion, exploring the background and influence of hair metal music exposes its enduring effect on popular culture. From fashion fads to musical designs, this genre continues to inspire artists across various categories. As we review its legacy, we can value the imagination and development that defined a period controlled by loud guitars and bigger-than-life personalities.

FAQs:- What defines hair metal music?

- Hair metal music is defined by its appealing melodies, flamboyant stage existence, and focus on image.

- Who were some renowned hair metal bands?

- Iconic hair metal bands include Motley Crue, Poisonous Substance, Bon Jovi, Def Leppard.

- How did hair metal influence fashion trends?

- Hair metal influenced fashion fads with natural leather trousers, spandex t-shirts, teased hair.

- Is hair metal still relevant today?

- While not as noticeable as in the past, components of hair metal can still be located in contemporary rock music.

- What are some vital accessories related to hair metal?

- Essential accessories include watch metals (showy precious jewelry), spiked bracelets.

- What duty did MTV play in promoting hair metal music?

- MTV played a substantial role in advertising hair metal with music videos that showcased elegant visuals.

|

|

The Rise of CNC Machines in the Indian Manufacturing Landscape |

Introduction

CNC (Computer System Numerical Control) machines have actually reinvented the production market worldwide, and India is no exemption. With developments in innovation and raised automation, CNC equipments have ended up being an essential part of the Indian manufacturing landscape. This short article looks into the various aspects of CNC makers in India, their effect on the industry, and the future leads they hold.

The Surge of CNC Machines in India

India has seen a substantial increase in the adoption of CNC equipments across different markets. From small sectors to big factory, CNC devices have actually come to be crucial tools for accuracy engineering and mass production. The demand for top quality products, raised performance, and reduced labor prices has actually fueled the development of CNC makers in India.

India Hand Machine: Accepting AutomationThe traditional techniques of hand-operated machines are gradually being replaced by CNC makers in India. The accuracy and accuracy offered by CNC makers have actually made them much more reputable and reliable compared to hands-on procedures. With the surge of automation, India hand machine operators are transitioning to embrace this sophisticated innovation for enhanced productivity.

India Machine Components: Enhancing QualityCNC machines play an essential duty in manufacturing high-quality maker elements in India. The exact cutting, shaping, and drilling abilities of these devices make sure consistency and precision in creating detailed parts. This has led to an overall renovation in the top quality of equipment components produced in India.

India Cnc Makers: Streamlining ProductionCNC devices have streamlined manufacturing procedures in numerous industries across India. Whether it's automobile, aerospace, or consumer goods producing, these devices have substantially reduced manufacturing time while keeping constant top quality criteria. The capacity to program complex designs and automate repetitive jobs has resulted in boosted efficiency and cost-efficiency.

India Mill Device: Accuracy at Its BestThe surge of CNC milling machines in India has actually transformed milling procedures. These equipments offer precise control over reducing specifications, allowing the production of detailed shapes and shapes. India mill machines have actually ended up being the best option for markets requiring https://anotepad.com/notes/qmm42td7 high-precision milling, such as device and die making, mold production, and model development.

India Electronic Maker: Fulfilling Technical DemandsAs the need for electronic tools remains to rise in India, CNC machines have played a crucial role in meeting the technological demands. From motherboard manufacturing to electronic component fabrication, these equipments ensure precision and efficiency in generating electronic tools. The assimilation of CNC technology has thrust India's electronic devices market to new heights.

FAQs concerning CNC Equipments in India

- What are the benefits of utilizing CNC equipments in Indian manufacturing?

- CNC makers use greater accuracy and accuracy compared to standard methods. They simplify manufacturing processes, minimizing time and increasing productivity. These devices can handle complicated styles and automate repeated tasks. CNC machines improve the quality of manufactured elements and products.

- How are CNC equipments adding to the development of Indian industries?

- By enhancing performance and effectiveness, CNC makers are increasing the competitiveness of Indian industries. These equipments make it possible for producers to satisfy worldwide top quality requirements, broadening their reach in international markets. CNC equipments are driving advancement by helping with the production of facility and detailed designs.

- Are there any kind of challenges connected with embracing CNC devices in India?

- Initial investment prices can be high for small-scale manufacturers. Training drivers to use CNC equipments effectively calls for time and resources. Maintaining and servicing CNC makers require specialized skills.

- What is the future overview for CNC machines in the Indian manufacturing landscape?

- The demand for CNC machines is expected to expand additionally as more industries realize their benefits. Advancements in technology will result in much more innovative and effective CNC machines. The adoption of Sector 4.0 ideas, such as IoT assimilation and data analytics, will certainly additionally boost the capacities of CNC machines.

- How can CNC devices add to sustainable manufacturing practices in India?

- CNC devices enhance material usage, minimizing waste and decreasing ecological impact. The accuracy supplied by these makers makes sure effective use resources. By automating processes, CNC machines minimize the reliance on manual work, promoting a safer working environment.

- Are there any type of details government campaigns to advertise the use of CNC equipments in India?

- The Indian federal government has launched numerous systems and plans to support the fostering of CNC machines. Programs like "Make in India" and "Skill India" objective to improve producing abilities via innovation upgradation and ability development.

Conclusion

The surge of CNC equipments in the Indian manufacturing landscape marks a considerable change towards automation, accuracy, and efficiency. These sophisticated devices have actually transformed markets by improving production processes, boosting product high quality, and enhancing total performance. With continued developments in innovation and enhancing demand for top notch products, CNC equipments are positioned to play a crucial duty in shaping the future of production in India. Accepting this technical change will unquestionably drive India's setting as an international production hub.

|

|