What Is The Tunnel Pasteurization Refine? |

Article by-Damborg Hemmingsen

In order for a popular as well as knowledgeable firm to use the Tunnel pasteurization procedure for the production of their beer, one would anticipate the top quality to be pretty good. This is why many of these widely known business have been using this method in their procedures. However, when it pertains to beer, or any other drink for that matter, this technique of pasteurization has its drawbacks. Although there are a number of various reasons as to why this method is not as reliable as others, one of the most common reason is due to the fact that insufficient flash pasteurization containers are utilized to finish the entire procedure.

When utilizing the Tunnel pasteurization procedure, insufficient bottles are produced during the manufacturing process. Because of this, not all of the beer generated is of the very best top quality. The premium beverage produced by these well-known companies just has a percent-quality of alcohol in it; the remainder being water, sugar, and also anemic film representatives. Due to the reality that these containers as well as cans just have twenty percent of the efficient dosage of taste as well as scent, they do not offer effectively.

https://www.foodprocessing.com/articles/2016/techn...rization-sterilization-drying/ to the smaller amount of bottles that are generated by this method, much less can be offered compared to other methods. https://www.thealternativedaily.com/stop-drinking-...es-pus-antibiotics-pesticides/ to this is because the pasteurizing process uses a cool temperature instead of warm. This indicates that the pasteurizers have to run at a higher temperature to obtain the bottles fully triggered. With a greater beginning temperature, more can be triggered to enter into the cans or bottles as well as this leads to a lower number of bottles that are actually marketed.

“TIPS ON PASTEURIZING INFUSED BEVERAGES: HOW IT WORKS”

— PRO ENGINEERING (@Daveone1) October 19, 2021

Article Release for Brewmasters & Beverage Makers by Edward A. Michalski

Click for full article: https://t.co/NCM8S29UIS

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/s3QRxktaHE

Tunnel pasteurization processes likewise tend to not work quite possibly with alcoholic beverages. The factor for this is because the alcohol in the drink tends to transform to acetic acid before being sent out through the conveyor. Since this Acetic acid is detrimental to the preference of the beverage, a lot of firms do not use this procedure with their alcoholic beverages. Because of this, people end up having more powerful sampling beverages like beer because there is inadequate Acetone in the beverage to mask the taste.

Nevertheless, if you want your beer or soft drink to maintain its taste, you will certainly want to take the time to locate a good quality sterilized product to make use of. There are business that will certainly send you your own bottles of this item at no cost. If you are one of those people that take pleasure in having your very own brands of bottled drinks, then getting among these boxes at no cost is an excellent way to save money on your favorite beverage. Just ensure that you are obtaining an authentic item like one manufactured by a well-known firm, as these less expensive products are not going to provide you with the very same flavor as well as taste as their a lot more costly counterparts.

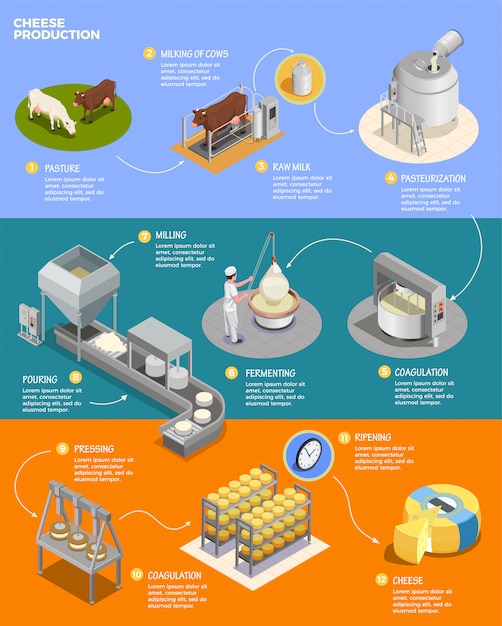

When it comes to the Tunnel pasteurization procedure itself, you have to understand just how it functions. Among the first steps that are taken by the firm manufacturing the item is that the high steaming temperature level is preserved throughout the entire production line. This makes sure that all of the products experience this lengthy and also thorough production line. As long as the temperature level remains at the high boiling point, absolutely nothing in the bottle will certainly change. The product will stay at its original temperature level throughout the production process.

Throughout the real beer pasteurization procedure itself, the bottle is first given space temperature level. After that, the bottles are placed in the container. Inside of this container, there will certainly be a light emitted by a machine called a flash light. This light flashes about 7 times per second, shining onto the beer inside the bottle at the very same heat that the rest of the containers are at. This extremely high temperature will eliminate any kind of organisms or bacteria that are trying to reside in the bottle.

After whatever has been exterminated, the beer manufacturing process is full. The item can be securely saved for up to two months each time. Although it will continue to be clean and sterile, it is important that you always sterilize the bottles when they are eliminated from the developing system. This will make certain that your next batches of drinks are additionally clean and sterile.

|

|

Which Elements Industry Must Take Into Consideration Throughout The Tunnel Pasteurization Process |

Article by-Macias Kelley

For your lab or various other business procedures, Tunnel pasteurization is an approach that can be applied. This technique utilizes a heat-treating service sterilized at really heats. This pasteurized remedy cools down to very reduced temperatures and then is released right into the procedure. Read A lot more cooling process additionally secures the nutrients that remain in the item that you are processing. There are a variety of reasons that this pasteurized product is made use of in the pharmaceutical industry, but there are a number of reasons that this can be beneficial to your company too.

The Tunnel pasteurization procedure protects your organisms from having way too much warmth. It likewise maintains the item at the appropriate temperature level so the bacteria do not go off. It likewise creates a controlled setting, so the bacteria do not get too hot as well as die. related web-site ensure they will offer you with high quality items with simply the right amount of warmth for your process. All of these characteristics can assist your process run smoothly. These qualities likewise aid your product has excellent flavor.

The Tunnel pasteurization process additionally ensures that the product has actually been flash frozen at its optimal temperature. This is essential, due to the fact that the flash sterilized item should have the capability to maintain its framework and maintain its stability while it gets on ice. The product needs to be sterilized as well as have actually a confirmed sterility indicator on its bottle so you can validate that it is sterile and also have a verified and also validated flash freeze temperature level. If your product has actually not been flash frozen after that you will certainly need to do a secondary vacuum procedure with a vacuum cleaner flapper to confirm that the product is sterilized as well as additionally have a qualified and validated flash freeze temperature.

Various other variables to take into consideration in Tunnel pasteurization procedures include carbonation retention and also head area. This originates from the Sterilizing Drinks post on the internet site. There are 3 essential considerations in relation to carbonation retention. Initially, carbonation retention will certainly identify if carbonated drinks can be sterilized. Second, it will determine if carbonated drinks require an ice bath.

You will certainly likewise need to consider the head space. This comes from the Sterilizing Beverages article on the web site. In order for you to make certain the pasteurized beverage has adequate head area, you will certainly need to make use of a home heating resource.

A great way to develop a pasteurized product is via carbonation suspension. The components will certainly be combined with the suitable water to create a suspension. It will certainly then be heated up as well as fermented at a reduced temperature level. The longer the combination is allowed to ferment, the bigger amount of carbon dioxide will be created. The quantity of carbonation in the mix is described as its "dry weight." Dry weight describes how many microorganisms exist in one gram of the item.

Tunnel pasteurizers allow the end customer to delight in the flavor of their drinks while being protected from the harmful results of microorganisms. The majority of people do not want to consume a product which contains microorganisms. Nonetheless, most people also do not desire the preference of their microorganisms-laced drink to vanish. The presence of pathogenic bacteria in the majority of beers can leave an unpleasant aftertaste in consumers' mouths. The Tunnel pasteurization process permits these unwanted microbes to be eliminated from the product, to ensure that customers can remain to appreciate the taste of their beer.

Relying on the sort of beer being made and the packaging being utilized, different temperatures will certainly need to be kept during the developing process or the bottling process. The temperature level must be in between 60 and also 100 levels Fahrenheit. This temperature level is ideal for exterminating the online as well as dead microbes in the beer pasteurizer. Beer brewing sets are readily available to help guarantee that this procedure takes place perfectly. Beer lovers should buy a top quality system to make sure the very best beer feasible.

|

|

What Is The Tunnel Pasteurization Process? |

Article writer-Donaldson Hemmingsen

In order for a popular as well as skilled business to make use of the Tunnel pasteurization procedure for the production of their beer, one would certainly anticipate the quality to be respectable. This is why a lot of these popular business have actually been utilizing this method in their procedures. Nonetheless, when it involves beer, or any other beverage for that issue, this approach of pasteurization has its drawbacks. Although there are a number of different reasons regarding why this approach is not as efficient as others, the most typical factor is because insufficient flash pasteurization tanks are made use of to complete the entire procedure.

When using the Tunnel pasteurization procedure, not nearly enough bottles are produced during the manufacturing procedure. Because of this, not every one of the beer produced is of the best top quality. The high-quality beverage generated by these widely known business just has a percent-quality of alcohol in it; the remainder being water, sugar, and anemic film representatives. Because of the truth that these containers and also cans only have twenty percent of the efficient dosage of taste as well as scent, they do not sell extremely well.

As a result of the smaller sized quantity of bottles that are generated by this approach, less can be offered compared to other techniques. An additional downside to this is because the pasteurizing procedure utilizes a cool temperature level rather than hot. This implies that the pasteurizers have to go for a higher temperature to get the bottles totally triggered. With a greater starting temperature level, more can be triggered to go into the containers or containers and this brings about a lower variety of bottles that are actually marketed.

VIDEO: “THE ECONOMICS OF PASTEURIZING BEER”

— PRO ENGINEERING (@Daveone1) October 12, 2021

Video Summary of Article Release for Brewmasters & Beverage Makers

Video Link: https://t.co/5ppZdxrIeo

Article Link: https://t.co/jBKaVXdgkH

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/BvxPvJHCzw

Tunnel pasteurization procedures also tend to not function very well with liquors. The factor for this is because the alcohol in the drink tends to transform to acetic acid before being sent through the conveyor. Since this Acetic acid is detrimental to the preference of the drink, the majority of business do not utilize this procedure with their alcohols. Consequently, https://www.mtairynews.com/top-stories/87651/milk-it-does-a-community-good wind up having more powerful tasting drinks like beer since there is insufficient Acetone in the drink to mask the preference.

Nevertheless, if you want your beer or soda to keep its flavor, you will wish to make the effort to locate a high quality pasteurized product to make use of. There are https://www.livescience.com/41883-raw-milk-1-in-6-get-sick.html that will send you your own bottles of this product at no charge. If you are one of those people that enjoy having your own brand names of bottled beverages, after that obtaining among these boxes at no charge is a terrific method to save money on your favored beverage. Simply see to it that you are obtaining a genuine product like one made by a widely known firm, as these less expensive products are not mosting likely to supply you with the very same flavor as well as preference as their much more costly counterparts.

When it involves the Tunnel pasteurization procedure itself, you need to comprehend just how it functions. Among the first steps that are taken by the company producing the item is that the high boiling temperature level is maintained throughout the entire assembly line. This makes sure that every one of the items undergo this lengthy as well as thorough assembly line. As long as the temperature level stays at the high boiling point, nothing in the bottle will certainly change. The item will remain at its initial temperature level throughout the production process.

Throughout the real beer pasteurization procedure itself, the bottle is first offered area temperature level. Then, the bottles are positioned in the container. Within this container, there will be a light discharged by an equipment called a flash lamp. This light flashes about seven times per 2nd, beaming onto the beer inside the bottle at the same heat that the remainder of the bottles go to. This exceptionally high temperature will eliminate any organisms or microorganisms that are trying to reside in the bottle.

After every little thing has been killed off, the beer manufacturing process is total. The product can be safely kept for up to two months at a time. Although it will certainly stay sterilized, it is necessary that you always sterilize the bottles when they are eliminated from the brewing system. This will ensure that your next sets of drinks are additionally clean and sterile.

|

|

Which Factors Sector Must Take Into Consideration During The Tunnel Pasteurization Refine |

Article written by-Riis Andersen

For your research laboratory or various other company processes, Tunnel pasteurization is an approach that can be applied. This technique makes use of a heat-treating solution sterilized at extremely high temperatures. This sterilized solution cools to very reduced temperature levels and after that is launched into the procedure. This cooling process additionally seals the nutrients that are in the product that you are refining. There are a variety of reasons that this sterilized item is made use of in the pharmaceutical sector, yet there are a number of reasons that this can be beneficial to your company as well.

The Tunnel pasteurization process safeguards your organisms from having too much warm. It additionally keeps the item at the correct temperature level so the microbes do not go off. It also creates a regulated environment, so the microbes do not get too hot and also die. Their excellent features see to it they will certainly give you with high quality items with simply the right amount of warm for your process. Every one of these traits can assist your process run efficiently. These characteristics additionally help your product has wonderful taste.

The Tunnel pasteurization process also ensures that the product has actually been flash frozen at its optimal temperature level. This is important, due to the fact that the flash pasteurized product should have the ability to preserve its framework and also maintain its honesty while it is on ice. The item needs to be sterile and also have a validated sterility sign on its bottle so you can verify that it is sterile and have a verified and confirmed flash freeze temperature level. If your item has actually not been flash icy after that you will certainly need to execute a secondary vacuum cleaner process with a vacuum flapper to validate that the item is clean and sterile and also have actually a qualified as well as validated flash freeze temperature level.

Other aspects to consider in Tunnel pasteurization processes include carbonation retention and head area. This originates from the Sterilizing Beverages article on the website. There are take a look at the site here in regards to carbonation retention. First, carbonation retention will certainly identify if carbonated beverages can be sterilized. Second, it will certainly identify if carbonated beverages need an ice bath.

You will likewise require to check into the head room. This comes from the Sterilizing Beverages write-up on the internet site. In order for you to ensure the pasteurized drink has sufficient head room, you will need to make use of a home heating resource.

A good way to develop a pasteurized item is via carbonation suspension. The active ingredients will be mixed with the ideal water to develop a suspension. It will after that be heated as well as fermented at a reduced temperature. The longer the mixture is enabled to ferment, the larger quantity of co2 will certainly be generated. The amount of carbonation in the combination is referred to as its "dry weight." Dry weight refers to the amount of bacteria exist in one gram of the item.

Tunnel pasteurizers allow completion customer to delight in the taste of their beverages while being secured from the harmful results of microorganisms. Many people do not want to consume a product that contains microorganisms. However, lots of people additionally do not want the preference of their microorganisms-laced beverage to disappear. The presence of pathogenic microorganisms in most beers can leave an unpleasant aftertaste in customers' mouths. The Tunnel pasteurization process permits these undesirable microorganisms to be eliminated from the product, to make sure that consumers can continue to take pleasure in the flavor of their beer.

Depending upon the type of beer being made and also the packaging being used, different temperatures will need to be maintained throughout the developing process or the bottling procedure. The temperature must be between 60 as well as 100 levels Fahrenheit. This temperature is optimal for exterminating the online and also dead microorganisms in the beer pasteurizer. Beer developing packages are available to assist make sure that this procedure takes place flawlessly. Beer lovers ought to purchase a top quality system to ensure the most effective beer feasible.

|

|

Tunnel Pasteurization Devices For Top Quality Food And Also Drinks |

Content by-Bjerring Whitaker

High-grade, hassle-free hydrometer techniques are utilized in the hydrometer part of the analysis procedure known as Tunnel pasteurization. Hydrometers are tools that gauge the amount of dissolved product as it goes through different media. Pasteurization, which is the procedure of preparing top notch hydrometer samples by using particular temperatures, is an intricate process that calls for specific temperature control as well as an appropriate solvent to assure desirable quality products. To fulfill these requirements, producers have actually developed innovative Tunnel pasteurization systems that consist of all essential elements to satisfy the requirements required by the hydrometer industry.

Packaged drinks can likewise be processed utilizing high-quality pasteurization devices to enhance shelf-life and conservation; this is frequently known as pasteurization (2 ). Water pasteurizers, such as high-pressure spray systems, water circulation rates, and shipment systems, depend upon the pasteurizing maker (3 ). Top quality liquids made use of in several kinds of research laboratory screening must be pasteurized to prevent the growth of mould or various other organisms in the bottle or various other product packaging used for the product preparation. Liquid services, solvents, alcohols, aerosols, fats, and numerous other chemicals usually need to go through pasteurization to make certain effective as well as high-grade results. The hydrometer equipment required for this procedure need to be made to pasteurize fluids, most often water. The process of making top quality pasteurization items is very dependent on many elements, such as the sort of components made use of in the formulation, the final temperature made use of, and also the efficiency of the pump used to do the procedure.

A wide range of premium pasteurization tools is offered to satisfy consumer requirements. The cost of purchasing high-grade pasteurization tools depends on many aspects, consisting of the maker, the size of the manufacturing operation, the preferred performance degree of the system, the tools needed, and the expected final result. For small to mid-sized operations that do not call for a system that can fulfill the demands of a wide array of applications, a hand-operated compressor with separate drum cooling systems is the most effective selection. For larger procedures, either a continuous-feed drum or a pump system is needed to meet the demands of the various kinds of analytical and also pre-analytical procedures performed.

A significant benefit of Tunnel pasteurization is its effectiveness in killing pathogenic microbes and providing control of chemical reactions. Much of the studies done using high-grade pasteurization devices have verified the safety and security and also performance of the process, particularly for the assessment of antimicrobial medicines. This approach of pasteurization has additionally shown to be reliable in generating high-quality flavor and also taste, in addition to smell control during the purification process. There is additionally recommended to accelerate the process of phytotherapeutic improvement, which is an important action toward the advancement of healing therapies for the body.

VIDEO: “A BASIC GUIDE TO PURCHASING AND USING TUNNEL PASTEURIZERS”

— PRO ENGINEERING (@Daveone1) September 22, 2021

Video Summary of Article Release for Brewmasters & Beverage Makers

Video Link: https://t.co/wtIIicADRz

Article Link: https://t.co/C4OgpmcZoP

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/CJHL4KQsxf

One more crucial advantage of Tunnel pasteurization is its cost-effectiveness. Because the temperature level of the system can be controlled to an exact degree, it is simple to maintain. There are no temperature cycles during the handling, so there is no loss of top quality. The pasteurizing procedure does not have any unfavorable impact on the final product or on the health and wellness of the final users. Since a lot of high-quality pasteurization equipment is fully automated, there is no labor-intensive procedure of blending or re-cooling required.

Tunnel pasteurization provides numerous benefits over other forms of pasteurization. Initially, it is much more environmentally accountable than a lot of techniques. It additionally allows for the manufacturing of premium healthy proteins, enzymes, vitamins, as well as minerals, without use prescription antibiotics or any kind of synthetic chemicals. There are really few unfavorable effect on health and wellness while utilizing Tunnel pasteurization, as well as some research studies reveal that it may even be far better for your health than alcohol consumption mineral water straight from a springtime.

https://www.nbcphiladelphia.com/news/local/milkman...gence-of-us-tradition/2360206/ of Tunnel pasteurization devices is that it can save you substantial time and effort when doing your very own prep work. You do not need to wait on a big vat of liquid to warm up in order to use it. This conserves you beneficial time that you would certainly otherwise invest preparing the various other components in the dish. If you choose to make your very own soup from square one, after that it might take you several hours simply to warm the veggie broth, obtain the veggies out of the cold store, as well as get the soup going. With Tunnel pasteurization, all you have to do is bring it to the correct temperature level.

Producing high-grade soups and also sauces utilizing Tunnel pasteurization tools is a matter of science and art. It can provide complete control over certain features, like the thickness of the sauce, whether or not the tastes will proceed after the mix has enlarged, and exactly how quickly the soup will certainly remove. It can also control the shade, taste, depth, and also appearance of the finished product. When developing sauces from the ground up, it would be extremely challenging to attain these kinds of results. It refers ability and art, nevertheless. Thankfully, this sort of top notch pasteurization devices can be used for the secure production of virtually any type of top quality product.

|

|

What Are Tunnel Pasteurization Equipment Utilized For? |

Content writer-Philipsen Pollard

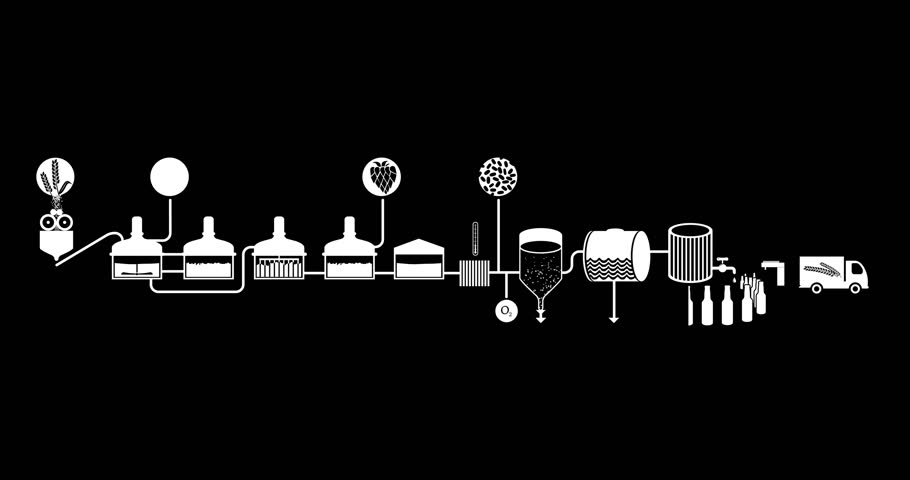

The process of using Triple Temperature level Spray Batch (TTSB) pasteurizer for encapsulated beverage items like carbonated, dextrose, flavorful and also other pasteurized drink products is the same as any other sterilizing process. Co2, gas and heavy steam are the cornerstones for the TDS or Tri-carbon dioxide. https://www.whatech.com/markets-research/food-beve...rket-worth-3-9-billion-by-2026 , propane and steam are had in the bottles or cans of the drink items. Packaged drinks can be quickly refined by utilizing a high-grade pasteurization devices for boosted preservation and shelf life; this is known as pasteurization.

The term "Pasteurization" means raising the temperature of an object at a really high level, which is absolutely performed in a container that has some sort of warm creating system. In the context of this specific discussion, it is suggested to discuss that the containers mentioned here remain in fact heated up by means of a conveyor belt. It takes place via communicating the warmed beverage items from one container to an additional according to the conveyor's continual rotation. It absolutely happens by continually rotating a belt that is composed of numerous parallel plates on which the fluid is moved to.

In simple terms, it is a well-known reality that the sterilizing process has been used for several years to maintain different kinds of foods and also drinks. Specifically meat products such as beef, pork as well as lamb need this type of treatment for a long period of time. Foodstuff that have actually not been sterilized can likewise be securely used by using this kind of therapy. This is because they are risk-free to consume since there are no traces of germs or fungi present in them. The very same treatment however can not be applied on breads or baked products unless those items have been extensively sterilized initially.

The process is normally used for various procedures in which the procedure is necessary, such as in protecting beer and other ales. Nonetheless, the most famous use this treatment is in preserving a glass of wine. The white wine pasteurization process is also called the "White Wine Tunnel Pasteurization". There is in fact a little controversy regarding the actual duration of time that ought to be considered the products to be considered as secure to take in.

According to the majority of the a glass of wine lovers, this period is also brief. On the other hand, others believe that it ought to be extended sufficient to make certain that the microbes are killed entirely. Regardless of these arguments, the point is that, there are numerous pasteurizers that can be chosen based on their heating capacity and depending on the sort of drink that is to be maintained. The commonest types of white wine pasteurizers are those that have a tool heating power and are usually used for white wines and light beers. This kind of pasteurizer is likewise the most preferred.

On the other hand, there are also Tunnel set pasteurizers which are a lot larger than those that are available for microbrews as well as high-gravity beers. https://sanfrancisco.cbslocal.com/2016/08/21/centr...eam-pasteurizing-its-products/ have a cooling capability of nearly 10 barrels. Some well known brands of beers that make use of this procedure consist of Bell's Pils, Richer's Barley Red wine, draft King, Hoppin' John, Lost Bridge, Model Beer, Sam Adams, Stone cold brew, Widmer's Bitter American, and Widmer's Dry Ales. The bottles in which such beers are shipped are specially marked to carry the labels of the breweries in terms of the names of the beers and also the names of the brand names. In addition to the bottles, it is likewise possible to heat as well as cool the bottles utilizing specifically created refrigerators.

The Tunnel pasteurizer that is taken advantage of in the discussed products are normally produced as two distinctive pieces. One of them is referred to as the main central heating boiler as well as the various other is called the set central heating boiler. In the primary central heating boiler, the pasteurized products are warmed to a temperature of around 150 level Fahrenheit. When it concerns the batch boiler, the products are made right into froth by placing in a cold water cycle. It is furthermore vital to note that both sorts of central heating boilers are able to provide for pasteurization at fairly reduced temperature levels.

Tunnel pasteurizers that are used in the process of making beer are referred to as one-place systems. These kinds of pasteurizers are produced using the principle of two different chambers. One chamber of the system remains in direct contact with the product that is being pasteurized while the various other one remains in a totally enclosed atmosphere. What happens here is that the hot heavy steam from the boiler is utilized to heat the items that remain in the one place chamber and also the great water that originate from the boiler is utilized to rinse the products that remain in the 2nd place. With the sort of pasteurizers that are being employed, you will realize that the quantity of pasteurized items is lowered to extremely much less amounts.

|

|

A Guide To Tunnel Pasteurization For Beverage Items, Especially Alcoholic Beverages |

Content author-Lane Ortiz

A leading industry criterion for drink products, especially alcohols, is via using "Tunnel Pasteurization." This pasteurizing method has obtained popularity with an increase popular for the product and its tools. mouse click the following website page is utilized for many kinds of alcoholic beverages including wines, spirits, beer as well as even some alcoholic drinks such as lemonade. It additionally is generally made use of in the processing of other foodstuff, particularly foods that have actually been fermented with yeast or consist of significant amounts of sugar.

The main ingredient of this sort of pasteurization system is a mixture of natural active ingredients such as yeast, vinegar, water as well as malt essences. The white wine is normally passed over the open stream of television at the price of one inch per second and the temperature level remains continuous throughout. In a passage pasteurization process, the bottle is usually covered for concerning fifteen mins prior to being opened. The temperature level in the bottle will certainly be managed by a temperature level controller that is generally an electronic device that presents an electronic display suggesting the temperature.

VIDEO: “SIMULATION of TUNNEL PASTEURIZATION USING a TRIPLE TEMPERATURE SPRAY BATCH PASTEURIZER”

— PRO ENGINEERING (@Daveone1) August 3, 2021

Video Summary of Article Release for Beverage Makers

Video Link: https://t.co/QSnnN8UJhM

Article Link: https://t.co/oDnRmyOlOa

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/kK7IlYsCp4

One important element of this type of pasteurization process is that the top notch containers or cans are used and after that they are gone back to the holding area. In the container or container, the wine or spirits are mixed with lactic acid to initiate the aging procedure. Generally the bottles are then gone back to the handling line for a last proofing of the beverage prior to it is packaged and also delivered. The cans used in this process needs to undertake a much more extreme proofing procedure, which lasts longer and also can use up to 4 days depending on the size of the containers. https://www.bizjournals.com/sacramento/news/2012/1...rization-processing-w-sac.html of the drink is total prior to the cans are gone back to the holding area.

The primary benefit to making use of the Tunnel pasteurization system is the protection of the drink from oxidation. Top quality glass of wines and also spirits contain a high focus of ferrous iron, which results in the growth of ferric oxide which consequently triggers the red wine or spirits to end up being gloomy. This procedure of oxidation likewise creates refined changes in the flavor and scent of the drink. As a result, these items need security from any modifications in temperature as well as likewise oxidation.

To increase the aging process, producers of fine liquors usually utilize a passage pasteurization process in addition to a strong dose of salt hypochlorite. Along with safeguarding the drinks from oxidation and changes in flavor and also scent, this technique also postpones the beginning of light yellowing, range and also fracturing. A sterile filtration device is utilized to accomplish this outcome in addition to a big scale vacuum pump. When the sterilized beverage goes through the clean and sterile purification system, it is held for a period of time. The vacuum pump is made use of to keep an eye on the product's development with various phases of light yellowing, range and also splitting.

Tunnel pasteurization procedures are employed for a selection of products such as shampoos, soaps, red wines, beer and spirits. It is very important that all of these items go through similar types of pasteurization to guarantee that they preserve the same look while still providing the top quality they are produced with. For that reason, one end of the process constantly uses a comparable vessel or container in order to achieve the very best results. At one end of the procedure, a reduced temperature level pasteurization device will be warmed prior to the beginning of the process while at the other end the product is cooled off to room temperature level. Depending on the sort of product as well as the process being conducted, some products are sterilized at one end while others are pasteurized at both ends. Along with utilizing identical vessels in the two various procedures, both end times should be really comparable.

2 kinds of pasteurization processes are used in this sort of business. There is the flash pasteurization procedure in which the items are warmed to between 2 hundred degrees Fahrenheit and also eight hundred degrees Fahrenheit. The flash pasteurization temperature level depends upon what is called for of the item being cooled down. Flash pasteurization is the fastest of both approaches, but might not be one of the most effective for carbonated beverages as well as other items that have a reduced boiling point.

Warmth treatment is an additional approach utilized to pasteurize fluids. Warmth treatment occurs when the high temperature of the vacuum resource is allowed to slowly evaporate the fluid prior to its contact with any other fluids. In many cases, the heated liquids are allowed to sit and cool down without any contact with any other products. This pasteurization procedure is really effective for carbonated beverages and other items with a high boiling point.

|

|

A Tunnel & Batch Pasteurizer Manufacturer Could Be A Great Financial Investment For Your House Developing Organization |

Authored by-Suarez Skou

Tunnel as well as batch pasteurizers are two kinds of pasteurizers. Each is one-of-a-kind in their very own right, but both are used to warmth big sets of alcohol or glass of wines at high temperatures. These systems have different means of developing a pasteurization environment by regulating the quantity of steam, oxygen, as well as various other airborne contaminants that can be introduced into the mix before it goes into the fermenter. Depending upon the item and also preferred manufacturing price, both may be required.

" title="PRO Engineering / Manufacturing Inc. specializing in tunnel pasterizers and batch pasteurizers for brewmasters & beverage makers">

A Tunnel pasteurizer works by enabling the warm water of the warm water heating unit to be incorporated with the alcohol being created. The resulting mixture is then moved right into the fermenter where the yeast activity takes place as well as starts the fermentation process. As the a glass of wine or beer undergoes growth in the fermenter, the staying elements in the solution begin to break down. These consist of hydrogen sulfide, which is a byproduct of the yeast and can vary relying on the particular item.

A lot of tunnel and also set pasteurizers are warming making use of gas, oil, or gas in an exterior device. However, some products require an inner burner making use of oil or gas to initiate the pasteurization procedure. An inner system is likewise referred to as a "baker central heating boiler." A heater head is fitted inside of the internal heating boiler. The warmed air, which passes over the burner head, offers additional oxygen to the beer or wine. https://www.foodsafetynews.com/2012/11/are-pasteur...-answer-to-killer-cantaloupes/ is these products that are pasteurized.

The primary distinction in between a passage pasteurizer and also a set pasteurizer is the manner in which they warm the product. A tunnel pasteurizer heats up the item directly utilizing radiation or heat. It works for high volume, superficial purification applications. Set pasteurizers are much more reliable than their equivalents since they can warm and also distribute a big quantity of fluid at once.

Many products make use of a heat exchanger within the tank. Warm exchangers are exceptionally effective at rapidly heating an exceptionally warm liquid, such as on demand distilled water. Due to the fact that they are so effective, they can commonly be used combined with a vapor boiler, which is a much bigger system that likewise consists of a heat exchanger tank. One sort of this kind of pasteurizer is called a "cobra die" and it is essentially a cylinder loaded with a highly warmed mineral solution. When the temperature level rises inside the cylinder, the minerals begin to vaporize and end up being pure water.

Passage & Batch Pasteurizers can be utilized for a variety of applications. Some sterilizing methods utilize a reduced temperature and high pressure vapor stream to swiftly heat a solution. These sorts of systems are commonly utilized in the production of alcohols. Others are made use of to accelerate the aging process of beer by encouraging the growth of useful microorganisms.

There is a large amount of clinical study being conducted on the efficiency of tunnel & set pasteurizers as pertains to the manufacturing of alcoholic beverages. Along with their benefits to the home brew fanatic, they have revealed substantial assurance in being made use of in the food and pharmaceutical sectors. Pasteurization is a process that has been in location given that the 1800's in order to stop unsafe germs and infections from taking hold in the products that we consume. This procedure is frequently used in order to decrease or remove a great number of pathogenic aspects that may intimidate the general public's wellness. It has actually also verified to be extremely efficient in minimizing the microorganisms and also fungus that are responsible for creating several typical foodstuffs.

The Pasteurizer Central heating boiler Design is essential to the quality of the product and also to the general success of the item. This is since there are numerous aspects that can possibly result in bad performance in the pasteurizer, such as an improperly sized nozzle, a lack of anxiety, a low boiling point, or an inadequate amount of warmth related to the pasteurizer. The layout of an effectively sized tunnel & batch pasteurizer makes it possible to obtain all of the necessary warm as well as anxiety to be used without needing to apply greater than required. Correctly developed and sized products are highly efficient in their own right, yet can also be of benefit to the food as well as pharmaceutical markets when made use of as mixers with other sanitizers and also disinfectants.

|

|

A Tunnel & Batch Pasteurizers - The Perfect Option For Automated Pasteurization |

Article writer-Vangsgaard Hoppe

A Tunnel & Batch Pasteurizers are used to soften hard water and also stop damages to home heating pipes. They are offered in a variety of setups. They are ideal for both residential as well as industrial applications. The pasteurizers operate at the boiler, in addition to in the distribution lines, to soften hard water and deter blocking of the warm exchangers. They are extremely effective as well as economical.

Passage as well as Set Pasteurizers can be made use of to deal with various kinds of landscapes. They can additionally be adapted for use in metropolitan water furnace. There is no limit to the applications for these pasteurizers, given that they can be adjusted for all kind of boilers. They offer the best service to the hard water issue in the numerous regions. In addition to that, they are extremely financial remedies. The pasteurizers for hot water home heating can also be made use of in solar panels.

The passage pasteurizers for hot water heating are developed making use of sophisticated modern technology. The sophisticated modern technology makes the item easy to handle, very efficient, economical and also risk-free to use. They are particularly developed for residential setups. They can be used with open or enclosed boilers.

A Tunnel & Batch Pasteurizers can be utilized to accelerate the beer making process in your home. The item has been created to offer rapid heat transfer from the brewing process to the beer. It is optimal for individuals who wish to make fresh homemade beer. Much of the beer making sets that can be purchased out there do not come with the required ingredients to make the beer fast. visit the next site decreases the moment taken by the beer maker to brew an ideal beer, which guarantees a lot more batches of fresh and delicious beer.

A normal A Tunnel & Batch Pasteurizers consist of a pre-heated glass carafe, pre-heated condenser, a glass carafe with lid, stainless-steel drum with a steel body, stainless steel pipe, pre-heated paddle top, and user's manuals. The system is easy to set up, as it only requires to be connected into a standard wall outlet. The pre-heated glass carafe is then put inside the drum, which has a sealed lid. The cover protects against the components of the carafe from getting also warm. A pre-heated stainless steel paddle top is then placed into the drum, which has a covered lid.

The heating element is attached to the stainless-steel drum through a threaded installation, which allows the threaded end of the suitable to go into the pre-heated region of the drum. The threaded end of the installation is then positioned on the coil of cable that lies inside the pre-heated area of the drum. On top of that, the heating element is warmed to pre-heat the water that is after that passed through the passage pasteurizer device's home heating chamber. The pre-heated water vaporizes the anti-yeast liquid that remains in the coil as well as the water is then infused into the pre-heating area. As soon as the pre-heated water evaporates the worm spreadings and the red wine remove can be gotten rid of from the A Tunnel & Batch pasteurizer device.

https://www.farmanddairy.com/news/lawmakers-want-t...lf-life-of-pa-milk/656612.html to the truth that A Tunnel & Batch Pasteurizers are considered to be an option method to the typical pasteurizing procedure, they are in some cases liked by the restaurant as well as event catering company for the pasteurized item. These items are normally available at choose establishments such as food shopping malls and also food stores, but you can easily discover one online. Because of the popularity of these kinds of boilers, there are now a number of manufacturers of them. Because of this, it is important to very carefully pick which brand name and also which kind of equipment you must get to make sure efficient pasteurization of your products.

As soon as you have actually selected the right company to buy your pasteurizer from, you will certainly require to ensure that you learn about the different attributes that these central heating boilers feature. Due to the high need for these kinds of items, a lot of manufacturers of these sorts of central heating boilers have produced a variety of selections for clients to select from. Several of these alternatives consist of the following: self-diagnostics, variable speed fans, custom water temperatures, very easy access feeders as well as stainless steel building and construction. There are lots of other functions that you could want to consider if you are thinking about making use of a Passage & Set Pasteurizer Equipment. Because of the wide variety of items available today, it is very important that you look around to make certain that you discover the very best bargain on the type of Equipment that you want.

|

|

Just How To Ask Price Sight Of A Tunnel & Batch Pasteurizers |

Article written by-Paulsen Bentsen

A Tunnel & Batch Pasteurizers are unique since they combine the most effective of both the globes. That is, it combines the popular as well as the prominent attributes of both a tankless hot water heater and a pasteurizer. These 2 home appliances are usually puzzled for one another and are commonly misinterpreted in terms of their distinctions. Understanding these distinctions can aid you make an educated choice on which type of system will certainly work best for your house.

Like all pasteurizers, a passage and set pasteurizer makes use of a closed system to heat water to an appropriate temperature level for effective inner sterilization. you can find out more entails the use of heat exchangers. The process additionally includes an ion exchange that exchanges adversely charged ions with positive ones. This makes the water cleaner and also a lot more evenly warmed for far better distribution throughout the different parts of the tools. Normally, this kind of heating device has a small and also small layout that is frequently utilized in smaller sized systems.

Although they look similar, the major distinction between these 2 home appliances is that the tankless systems use a container, whereas the set pasteurizer is set up into the central heating boiler. Tankless warm water heating units do not save cured water in a container like the conventional storage tank central heating boilers do. The water is rather heated up and also kept in a special container within the device itself. simply click the up coming webpage guarantees that there is no tank or location that can be damaged by leakage as well as spilling of untreated water.

Unlike conventional storage tank boilers, a tunnel as well as fired vapor central heating boiler pasteurizer machine runs really easily as well as launches no foul odors. Since the steam that these systems generate are so hot, they are in some cases referred to as fire boilers. A crucial benefit of these devices is that the exhaust heavy steam is pure and odorless. This minimizes the demand for chemical sanitizers to decrease the risk of infection from microorganisms or germs.

A tunnel and batch pasteurizer making line can be run by using either an electric or hydraulic steam engine. Hydraulic vapor engines often tend to have greater operating stress than electrical units, so they are much better suited for bigger operations. Both kinds of engines should be correctly kept over the life of the devices. Hydraulic systems should be serviced as well as adjusted a minimum of annually. Electric boilers need to be serviced a minimum of annually.

Passage and also set pasteurizer devices are typically sold with central heating boiler providers. They can also be bought straight from firms such as Dominion, APART, Hyatt, Sycom, Pepco, Century as well as others. While several business offer these items, it is essential to carefully research the various manufacturers prior to buying. Each maker will certainly have a different background and might have different production methods. Investigating every one thoroughly is extremely recommended. Also, there might be restricted guarantees on several of the items.

It is extremely vital that a careful examination of the mounted warmth source is executed prior to using any type of passage pasteurizers or heated steam boilers. Most importantly, all tubing needs to be appropriately sealed and also the system ought to not be connected to a source of power, as this will certainly impact the chemical sanitization processes. A trusted central heating boiler vendor will offer this solution along with correct documents. If you are incapable to find such documents, after that it is highly recommended that you buy your own sealed tubing, as it is a fundamental part of the setup procedure. Many reputable companies will carry out a full home heating as well as pasteurizing system evaluation prior to setup of any product, so there will certainly be no doubt concerning item safety and security.

When asking for a quote on the setup of a tunnel & set pasteurizer maker, be sure to inquire about the manufacturer's warranty, and also any readily available prolonged guarantees supplied. Inquire about the different approaches of product cleanliness, and also ask if a heavy steam central heating boiler pasteurizer device coal fired design is available. Although this might seem like an unnecessary financial investment at first, you will locate that it will save you hundreds of dollars in power financial savings, decrease your exposure to various harmful chemicals, and also boost your wellness recognition.

|

|

Why You Need To Consider A Tunnel & Batch Pasteurizer Machine |

Content written by-Horn Singh

Tunnel and batch pasteurizers are 2 really vital home appliances in the food service sector. Food is prepared and also prepared in these kinds of systems. https://www.foodsafetynews.com/2018/04/organic-mil...per-pasteurization-discovered/ make use of high warmth to convert fluids into vapor. These vapor temperature levels are extremely high, and that's why they're called pasteurizers. Pasteurization is a procedure for securing food from bacterial contamination.

What are some of the various types of pasteurizers? There are generally 3 types of warmth generating devices: electrical, gas and also chemical. The electrical kind of heat pump is frequently utilized as a stand alone system. In case you have a gas or oil central heating boiler, you might require a gas or oil pasteurizer instead of an electrical one. If your kitchen has both an electrical and also a burner, a mix boiler is an excellent alternative. Not just can it heat water efficiently, yet it can additionally bring both sorts of gas together for much better results.

Among the more preferred pasteurizers is the Passage & Set Pasteurizer due to the fact that it has the most attributes. A lot of the Passage & Set Pasteurizers on the market today have an electronic control display. This makes the control system very easy to check out and also very easy to manage. You can additionally get a temperature level gauge, which is fantastic if you want to make certain that your steamer is working correctly. The electronic control display screen will certainly provide you a precise reading of how much heavy steam is being produced from the terminated steam central heating boiler.

When please click the following webpage involves the high quality of pasteurizing active ingredients, the Tunnel & Batch Pasteurizer series go to the top. It makes use of premium quality stainless steel components, which are guaranteed to last for several years. It likewise uses ceramic plates that optimize even warming and minimal surface area damage. Furthermore, it uses the most up to date micro halogen safety glass and an automatic sprayer for complete extensive home heating.

The Tunnel & Batch Pasteurizers are a little extra budget-friendly than the various other sorts of hot water heating devices. You will certainly pay regarding one-third as long as the best warmed pasteurizers. Nonetheless, due to the fact that it saves so much energy, it additionally saves money on your electrical bill. If you make use of a lot of warm water, this could be the very best option for you, particularly if you reside in a small apartment or other area where using electric central heating boilers is not practical.

Although the Passage & Batch Pasteurizers might be slightly extra costly than electrical central heating boilers, they are likewise much more effective as well as generate higher temperature levels. They are the ideal remedy for individuals who do not have a lot of room to mount and also maintain a big, free standing boiler. Electric boilers can take up to six hours to warm up adequate water to offer you with warm water, while the Passage & Batch Pasteurizers can heat up water in half the moment. As a result, if you are in a small room, but still need to heat your water, consider this kind of boiler.

The Tunnel & Set Pasteurizers additionally have lots of benefits over a conventional steam central heating boiler pasteurizer machine. The passage pasteurizer system needs extremely little upkeep once you have installed it. There is likewise a built-in disinfection system, which kills any bacteria that might have entered the central heating boiler storage tank. This helps prevent the spread of health problem as well as disease-causing germs. The passage pasteurizer also functions really quickly, which implies that you have the ability to get the water to you when you need it most, saving you time.

Additionally, the tunnel pasteurizer makes an exceptional choice for anyone who is aiming to purchase their own boiler however doesn't intend to pay way too much cash for one. If you live in a studio apartment or lease, you can locate the thermostatic valve (which is required to set the water temperature level) for as reduced as $125. This suggests that you can have a healthy temperature throughout your home without needing to worry about buying a new system. Naturally, you can always update to extra pricey devices down the line. As you can see, this type of pasteurizer makes a great financial investment, whether you are wanting to heat your house with a typical fired vapor boiler, or select a thermostatic pasteurizer.

|

|

An Overview To Buying A Tunnel & Batch Pasteurizer Device |

Article created by-Gibbs Kelleher

Passage as well as batch pasteurizers are commonly made use of in the food sector. These systems work by applying warm to the food. The pasteurizer after that brings the warm up to the boiling point of water or one more temperature. https://hackaday.com/2018/11/13/alice-evans-brucellosis-or-why-we-pasteurize-milk/ is typically integrated with a ventilation system to move the heated solution throughout the production process. These systems have several applications, yet are mostly made use of to promote pasteurization in the production process.

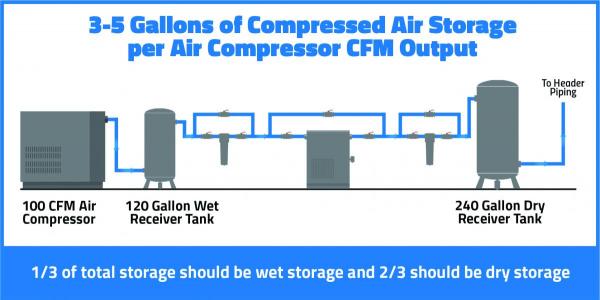

The term "passage & batch pasteurizers" is a combination of words "passage" and also "set". find more info of central heating boilers normally have two tanks: a hot water home heating component as well as a dry cooling part. Both parts of the system feed via an usual boiler and also a vent. The system does not need continuous substitute of water as it operates only on a set amount of water at a particular temperature. It can be switched off as well as on as required.

Most passage pasteurizers are made for continuous use over a large range of temperature levels, though there are some which can be used at low temperature levels, too. It is extremely important that these systems run at their suitable temperature level and also not surpass it, as overheating can have detrimental results on the completed item. If you have concerns concerning your existing heating unit, ask a representative of the firm marketing it to execute a cost-free on-site evaluation to identify what, if any type of, plumbing issues or other problems are contributing to your product's performance.

“THE ROLE OF THE TUNNEL PASTEURIZER: HOW SAFE IS SAFE?”

— PRO ENGINEERING (@Daveone1) June 8, 2021

Article Release for Brewmasters & Beverage Makers by Edward A. Michalski, CEO of PRO Engineering / Manufacturing Inc.

Click Here for full article: https://t.co/f1i6uFutvY

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/UkuXo5Gq0n

A main benefit of using passage pasteurizers is that they are more energy reliable than conventional warm water boilers, conserving you cash on your power costs. If your boiler is already acquired, most makers offer a full installment bundle that includes the pump, thermostat, valves, and also pipes for the central heating boiler. Alternatively, lots of companies can likewise finish your whole heating system for you, consisting of the thermostatic shutoffs as well as pipes, by emailing or calling the supplier.

There are several types of pasteurizers readily available, depending on what type of warmth you require from your central heating boiler. One such kind of product is a fired steam boiler pasteurizer equipment, which is extremely comparable to the kind located in conventional boilers. The distinction depends on the temperature level at which the pasteurizing solution is heated. Fired vapor pasteurizers need even more regular cleansings as well as a bigger area of protection, due to the enhanced surface of the heating media.

An additional very popular pasteurizer for boilers is a dry chemical central heating boiler. In this instance, sodium bicarbonate is added to a container full of water and also baking soda, which is then injected right into the furnace. As water heats, it incorporates with the chemicals to create heavy steam. This vapor is used to complete the chemical reaction in the central heating boilers, transforming materials like gas as well as oil right into co2 as well as water. Dry chemiluminescent boilers can be utilized to power most any kind of kind of central heating boiler, though they're most typically utilized to power diesel as well as oil boilers.

Not every person needs to utilize a warmed pasteurizer, nevertheless. You might rather choose to buy a tunnel or batch pasteurizer that is furnished to transform solids to liquid or semi-solid kinds, consisting of oil, gas, as well as coal. These units are normally smaller sized than their fire boiler counterparts, but they're more economical as well as extra functional. The drawback is that they can be more difficult to tidy than warmed kinds, as they have a smaller area of insurance coverage and need less frequent re-circulation with the system. Nonetheless, if your climate allows you to operate these without being continuously submersed in a boiling service, they can be an outstanding choice.

Acquiring a good-quality passage & set pasteurizer device is a rewarding investment for any kind of service. They can dramatically minimize your price of home heating and cooling for your company, along with aiding to make sure that your home heating and cooling down systems are kept at peak performance. Depending upon what your specific demands are, there are numerous various sort of makers to consider. See to it to speak with an agent of the firm you're thinking of purchasing from, so you can get the info you require to make a notified decision. By selecting a trusted business with an excellent performance history for consumer contentment, you can feel confident that you'll obtain one of the most worth and utilize out of your new heating and cooling devices.

|

|

Why You Must Purchase A Passage Pasteurizer |

Authored by-Erichsen Mcgowan

Batch pasteurizer systems have lots of benefits over other comparable items on the marketplace today. Pasteurizing is an important part of drink as well as food manufacturing procedure, which makes sure that they are secure to consume and keeps your products at their ideal offering temperature level. To make certain that pasteurization is complete, it needs to be executed appropriately to maintain the high quality of the item high, as well as protect against wastage. https://www.thehindu.com/news/cities/Vijayawada/ma...consumption/article3865703.ece is typically set that a set must be extensively mixed before it is pasteurized in order for the finished item to meet acceptable top quality and criteria. To assist in this procedure, several companies supply batch manufacturing solutions to make certain that your products are Pasteurized at the highest possible criterion.

For more than 2 centuries, the brewers in the Old World have recognized just how crucial good heat exchangers are to the appropriate brewing procedure. As a matter of fact, it has actually been said that the mixture masters in Europe learned these principles centuries earlier, long prior to the development of the bottling plant and its associated efficiencies. As well as through much experimentation, they located what triggered too much lather, insufficient head, and excessive beer, making great warmth exchangers an absolute need to for all effective brewers. Today, it is no various. With the right Warmth Exchanger Layout as well as the correct product formulas and also applications, your batches will get to optimal brewing temperatures much faster and with less effort.

Because of their design, Batch pasteurizers can be made to precisely match the details requirements of specific batches, causing premium production yield. There is no guesswork entailed since these machines and also procedures are especially engineered to deliver the results your service needs. These machines have actually aided to make German as well as French house brewers as well as also American makers progress, quicker and more powerful home makers throughout the ages. In fact, the makers association has actually contributed in the regular improvement of these tools through routine screening as well as research study.

Tunneled warmth exchangers are so named due to the fact that they function by utilizing heat to penetrate the inside of the vessel and bring the cooled, warmed water to the surface area of the beer or wort to make sure that it can be moved to another location or barrel for additional handling. Because they give such uniform heating throughout a batch of beer, set pasteurizers reduce the requirement for added home heating after the fermentation has actually completed. This indicates overall that you can cut back on your heating costs and also yet boost the purity and also taste of each set of beer. Since many pasteurizing systems are totally automated currently, the only thing a brewer requires is a cool container as well as a home heating device. With the automated attributes of most contemporary set pasteurizers, they can also be set to self-destruct at the end of the fermentation process.

Among the most interesting developments in the style and technology these days's Tunnel Pasteurizers is their unification of both aeration as well as heavy steam. Tunneled warmth exchangers, additionally called warmth exchangers, utilize both a continuous circulation of heated water as well as pressurized air to bring the water to the boiling point, where it vaporizes into vapor. The end outcome is the production of pure, all-natural beer. Although many sets will not be made completely off-site, by incorporating the production of excellent sampling beer with the excellent bottling temperature, producers have the ability to keep costs down while creating a high quality product that their consumers enjoy. By making use of modern-day innovation and also a fully automated system, these pasteurizers ensure that everyone has the most effective of both globes. Not only does their computerized nature make batch pasteurizing a breeze, yet it additionally makes certain the item is as regular as feasible.

Tunneled warmth exchangers are developed to develop uniform temperature levels and also, consequently, the assembly line of many of the leading Pasteurizer makers are constantly at the peak of effectiveness. With a range of different dimensions as well as various maximized temperatures, some companies also integrate their Tunnel pasteurizers right into their assembly line. This combination enables the firm to make the most of efficiency and to maintain prices down.

Due to the fact that they have the capacity to control temperatures on a micro level, using a passage pasteurizer is smartly basic for brewers. This simplicity also allows the firm to offer various bottle designs, including screw caps and coffee ones, which give their brews even more options. Because these items already have the perfect bottle neck, it only makes good sense to take the following step as well as automate the cap sealing procedure so the bottles don't need to be personalized for every single time they're opened. Automated bottle seals decrease the quantity of time invested securing private bottles. Along with minimizing labor time, making the process of opening bottles even easier, these clever machines additionally allow for exact container to bottle accuracy, which is necessary in the extremely affordable container tag and also container sales sector.

Not just have Sterilizing systems from business like Biolet as well as Tunnel Pasteurizer transformed the bottle design market, they have actually additionally changed the manner in which brewers and house makers all over the world view beer. The introduction of these types of pasteurizers has made consumers a lot more familiar with the value of keeping a clean label on their drinks. For consumers, this has actually ended up being an ever increasing demand as beer is continually reformulated and also is packaged in various means, both to enhance flavor and also to make the beverage extra available to a bigger target market. For makers, it has actually become essential to produce a tidy tag that highlights their beers' premium and special character. By making use of these kinds of systems and container seals, developing lovers can make certain that their drinks are continually fresh and also tasty./www.smithsonianmag.com/arts-culture/hey-vegans-there-may-be-fish-bladder-in-your-guinness-2001644/" target="_blank">https://www.smithsonianmag.com/arts-culture/hey-ve...dder-in-your-guinness-2001644/ /illo/bavik_brew_process.jpg" width="533" border="0" />

|

|

Air Conveyance Systems For Warehousing And Offshore Purposes |

Content author-Toft Robb

Air Conveyance Systems is made use of for the transport of products, both using an open or shut transportation system. The conveyance system utilized depends upon the product being relocated and also the amount of weight the material is called for to lug. These transportation systems are normally utilized in a selection of industries such as mining, petroleum refining, production, farming, construction etc. Several of the conveyance systems utilized are Airborne Displacement Systems, Chain Driven Swivel Pumps, Portable Manually Ran Cars (PMOVs), Swivel Cranes, Mobility Device Operatings Systems, Roll-on/rolled off trucks, Towing and also Unloading Trucks, Swipe plates, Hydraulic conveyors etc.

These activities entail different motions of the products within an environment that is controlled. Several of the movement calls for hands-on power, while others can be done immediately. There are two sorts of these systems - namely, Conveyancing and also Material Handling. The previous entails preparation, developing, surveying and also accepting of the different degrees, as well as the approaches of transportation. This consists of the place of the work site, the dimension of the workplace and the certain transportation tool that need to be utilized.

Materials are moved from one area to one more in a systematic fashion, which can consist of using power, manpower as well as numerous kinds of devices. Sometimes, hand-operated power is not needed. Air Conveyance Equipments consists of both mobile as well as long-term conveyance systems. The former includes makers that can move the products and likewise materials that can be moved manually or by an individual. The majority of frequently, the product that is to be relocated is put on the pallet while it is carried to the location. The equipment or the workforce is powered either by electrical energy or hydraulics.

Various variables are taken into consideration when identifying the setting of transport. The most usual modes are air-lifts, wire rope, trucks, trains, aircraft, as well as trucks of the sea. It does not matter whether the transport tool is earth water or air. These settings of conveyance differ in their price. The conveyance cost of an air transport system is dependent on the weight of the lots being delivered, the dimension and also the kind of transport tool used.

https://air-conveyance-systems.business.site/ are subject to a number of constraints, as discussed in the file attached to this topic. A few of these constraints include security, storage space, maintenance, wellness, environmental as well as comfort facets. A few other vital areas are talked about in the complying with paragraphs. The main worry in safety includes the defense of the persons transferring the material itself. Containment of the cargo in storage areas is necessary to avoid accidents that may lead to damages or injury. Product handling is a significant restraint in the product managing systems.

Security guidelines in numerous sectors limit the quantity of weight that can be taken care of. This restriction is applicable to the transportation systems too. Various sectors have their very own distinct methods of storing the product as well as the containers.

There are three main categories of material handling systems trucking, container as well as palletizing. Trucking systems primarily involve the movement of containers. On the other hand, container and palletizing involve the assembly of containers. Air-lifts are a form of containerized. All these techniques are needed in delivering materials to numerous websites.

Air Conveyance systems have actually ended up being very popular. There are numerous benefits associated with these systems. To start with, it conserves time. Second of all, it lowers the general cost. It likewise makes the circulation of product managing less cumbersome. Last but not least, it gives a secure atmosphere for the workers.

Air convection and also bagging are the two significant groups of these systems. https://m.engineeringnews.co.za/article/air-liquid...on-unit-2012-12-11/rep_id:4433 is responsible for the activity of light as well as hefty products. This system consists of the pallets, buckets, drum, canisters, shelfs as well as racks. All the products are moved from point A to factor B by the assistance of a forklift truck. Materials in hefty containers are relocated by forklifts while materials in medium containers are hung on hooks.

There are 2 sorts of conveyance systems: open or enclosed. Closed system includes a sealed box lugging the items and also situated at the obtaining location. Open system does not contain any materials and also is located at the obtaining area. In the United States, the containers of Honeywell are placed on an enclosed transportation system.

There are lots of firms that supply these solutions. Nevertheless, it is much better to employ a professional company for the very same. This is due to the fact that there are a lot of complex things that need to be performed in such a way that just experts can do it well. These companies have a well-designed machinery and also software program for the exact same objective. These software application make the operation of the devices as simple as feasible. They also have educated employees that can take care of the makers flawlessly well.

|

|

Tunnel Pasteurizers Can Enhance Quality Of Productiveness |

Content by-Hendriksen Dempsey

Tunnel pasteurizers are a distinct class of pasteurizers designed for very heats, normally over 500 degrees. A common pasteurizer will have two separate compartments: one which contains a warmed plate to warm as well as blend the remedy; as well as an additional compartment with a mixing drum, which boils the brew as well as circulates it with the different chambers to maintain a continuous temperature. Because pasteurization is a technique of heat therapy, the temperature setup have to be meticulously checked. Pasteurizing the wort prior to you actually make it develops an end product whose taste has already been modified by the enhancement of the culture. This process is called priming.

There are 3 standard kinds of Batch pasteurizers: set, continuous flow, and outside heat exchangers. All of these variants employ the heat treatment procedure however operate under slightly various systems. In batch pasteurizers, the temperature of the warmed plate is controlled to enhance and also reduce an established quantity of wort prior to it is contributed to the fermenter. updated blog post in much the same way other than that there is a built-in bypass shutoff to control the temperature of the inbound wort. Outside warm exchangers, on the other hand, use the warmth produced in the fermenter as a resource of additional power to drive the circulation of the heated water through an extra warm exchanger, producing a constant stream of heated water.

PRO Engineering / Manufacturing Inc.">

Tunnel Pasteurizers have actually been made use of by a number of microbreweries throughout the history of industrial beer developing. They are particularly prominent in Europe, where they are made use of to ferment all type of beer styles, consisting of light and dark ales, as well as wheats as well as steins. The pasteurization of sodas has actually also been extremely common during the last 5 years as well as has become an essential part of the process of bottling eco-friendly items, such as fruit juices and vegetables. Some well-known instances include eco-friendly tea and also apple cider vinegar. The pasteurization of fruit juices is becoming more commonplace in the United States and is also beginning to invade the American market as a prepared supplement to pasteurization of milk.

The concept function of the pasteurization procedure is to eliminate or get rid of pathogenic germs, consequently reducing the degree of contamination present at the end of the fermentation process. Pathogenic germs are an all-natural part of the brewing process. They reproduce in the hot wort, particularly during the cooling period in between sets. Once please click the up coming document are able to start reproduction, they create a setting in which they thrive, slowly however definitely getting rid of any and all healthy and balanced yeast cells. This means that in order to keep the initial bacterial populace from decreasing also quickly, you need to maintain your wort moving and fresh throughout the whole fermentation procedure. Pasteurization helps to accomplish just that, eliminating pathogenic microorganisms and also maintaining the original yeast populace so that you can enjoy your refreshingly crisp, refreshingly tasty mixture all summer long.

A variety of various kinds of food can be pasteurized to boost their flavor or make them less complicated to protect over time. Among one of the most popular of these items is beer. Beer can be pasteurized to maintain its quality for years at a time. Due to the fact that beer is usually kept in coolers with ice bag, it is essential to make sure that the bottles are effectively secured when being used to transfer the drink. Appropriate pasteurization is the only technique of ensuring that your beer stays fresh.

There are many different brand names of pasteurizing systems readily available to pick from. Some use warmth, others make use of nitrogen, however many rely on the currently standard pasteurization process to guarantee pasteurization of alcohols and also their accompanying packaging materials. Beer, like various other alcohols, requires pasteurization to eliminate every one of the microorganisms in the fermenting process, as well as ensure that the co2 focus in the beer remains at a continuous, risk-free degree. It is extremely crucial that your beer undergoes this critical pasteurization action, as any change can have terrible effects on the quality and also preference of the beverage.

When utilizing Batch pasteurizers in your very own organization or in a public location such as a restaurant or bar, you need to understand what tools to buy, just how to run the tools, as well as how to preserve the machinery over time. Depending upon the sort of product you have actually bought, you may wish to enlist the solutions of a speaking with business ahead and check your setup. These professionals will be able to tell you exactly just how to take advantage of your tools, what to do in regards to upkeep and how to avoid having problems. They will likewise have the ability to assist you with fixing situations that happen.

In addition to the Pasteurizer itself, you may also require to purchase container sleeves and tubing, as well as potentially an evaluation stand. Every one of these items need to be bought in tandem with your Batch pasteurizer to guarantee that they are all working properly. When you've gone through the entire drink production process, you might not need your own workers to man these makers. However, it is an excellent suggestion to know how to fix them need to they come to be malfunctioning. By purchasing quality products from a vendor who uses excellent quality products, you can feel confident that your equipments are well cared for.

|

|

Sterilizing Drinks For Tidy Label Awareness |

Content writer-Jochumsen Herring