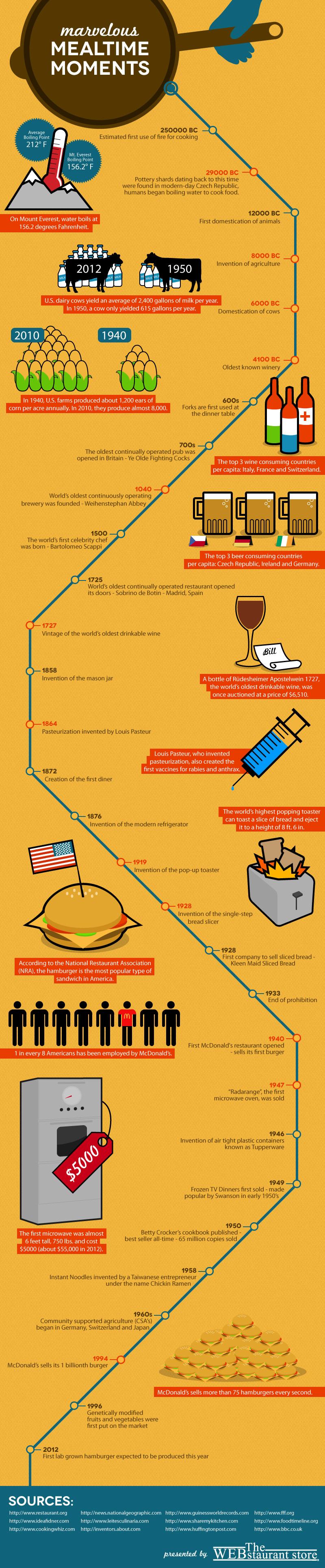

Benefits And Sorts Of Of Tunnel Pasteurizers |

Authored by-Driscoll Douglas

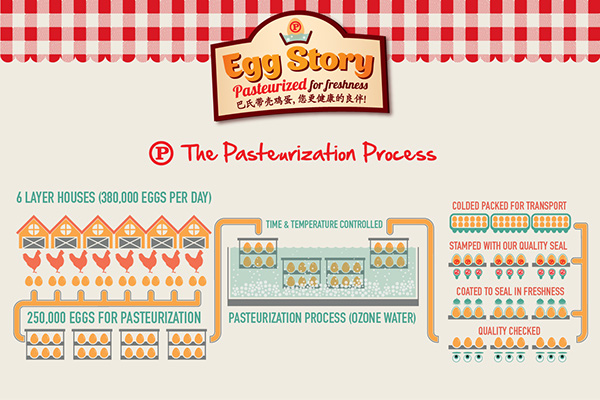

Tunnel Pasteurizers are the modern innovations which are preferred among individuals. This is a very easy process and does not take much time in the process. This is the approach, which helps in maintaining food things like tomatoes, egg, milk, etc. https://www.news-medical.net/news/20200813/Pasteur...in-human-milk-study-finds.aspx are sterilized at very heat and also after this procedure, it is then saved in a dry, awesome and moisture free atmosphere.

The major use these Automatic Batch Pasteurizers remains in order to pasteurize the tinned or bottled item at the best temperature level as well as standard and hence make the product steady for some days with no kind of top quality degradation of the food. The procedure of Tunnel Pasteurizers involves heating, filtering system, stirring and afterwards finally cooling. It is necessary to note below that there are different sorts of pasteurizers available out there. However, a lot of these types of pasteurizers make use of the same principle, which generally consists of the blending of elements at ideal temperature levels as well as stress, with steam or boiling water.

The Tunnel Pasteurizers has actually ended up being an essential as well as essential part of different sectors consisting of food processing, drugs, health care, chemicals, pulp as well as paper industry, dairy farms, pet feeds as well as food production. In order to prepare pasteurized milk products, for instance, it is essential to use the batch pasteurizer. Regarding food processing is worried, there are three kinds of Tunnel Pasteurizers offered in the market i.e. tunneling pasteurizer, warmth pasteurizer as well as auto-pasteurizer. Set pasteurizers are primarily used when there is a substantial manufacturing of a solitary sort of item. In such cases, a single pasteurizer will be sufficient to fulfill all the requirements of the business.

PRO Engineering / Manufacturing Inc.">

In you can try this out , there are 2 primary classifications of Batch Pasteurizers i.e. autoclaves and also steam boxes. autoclave pasteurizing is the traditional method of sterilizing beverages like tea, coffee, delicious chocolate and so forth. In autoclave pasteurizing, the ingredients are warmed up at the desired temperature level and then included in a container of cold water. Afterwards, they are permitted to relax for a certain amount of time and then are placed into a vapor box to be boiled at heats.

When it comes to Batch pasteurizers, the active ingredients are warmed up at the suitable temperature level and after that poured into a container of warm water. After this, they are delegated relax for some more time and also after enough steaming, they are transferred to a conveyor belt. This is an excellent method of pasteurization and also ensures thorough pasteurization of the drink. Along with this, most of these conveyor belts today also have vacuum cleaner components that eliminate any type of air bubbles from the final product.

As a result of their outstanding pasteurization ability, Batch pasteurizers are favored over various other choices as well as are discovered in practically every kitchen area. Among the significant benefits of using these sorts of products is their life span. They have been found to maintain their efficacy for a long period of time, align to two decades. Numerous suppliers make sure that the life span of their items is not jeopardized because of extreme temperature levels throughout transportation.

A popular kind of pasteurizer is the set pasteurizer, which makes use of gravity to speed up the boiling process. As a result of this, the product does not undertake any oxidation responses throughout the transportation. Nevertheless, set pasteurizers are really slow in regards to the rate at which they convert heat. Typically, these products are used in meat fermentation, beverage fermentation and various other kinds of rapid fermenting.

If you wish to buy excellent quality, reputable and also effective Tunnel pasteurizers, you must go to on the internet shops that market just high quality products. The very best method to identify a reliable dealership is to read reviews of consumers. You can learn more concerning the benefits and benefits of using these products by visiting our web site. We give an on-line brochure that allows you to undergo different items within secs. Our group prepares to help you make educated choices based on your budget and taste.

PasteurizersBatch pasteurizers have been around for years, however only in recent years have the tiny craft breweries discovered what really functions and what does not in a passage pasteurizing system. This understanding has been to develop and make Tunnel pasteurizers for the little maker. And now it is offered to the large maker too, in the form of Batch pasteurizers designed by honor winning firms.

Batch pasteurizing is a method that entails developing tiny batches of top quality beer with the addition of microorganisms as well as various other active ingredients. It was established and developed by sterilized beer makers many years earlier, so any type of honor winning firm can happily claim to have utilized Tunnel pasteurizers to improve their items. The technique of production involved a secured container or "Tunnel". The secured redhead sat in the container as well as was heated to concerning 150 levels Celsius with the addition of yeast and bacteria development.

The pasteurized drink sector has actually developed and updated to the point that small sets can be created easily. Tiny, independent microbreweries have started to use pasteurizers, as well. Although these small batches are typically not mass produced, there are Batch pasteurizers available for the residence brewer's interest. Home brewers who might have trouble affording the devices and also chemicals needed to develop a batch of costs bottled beer can make their own using pasteurized active ingredients in their own steam box. Oftentimes, the residence maker can even create scrumptious and drinkable beer.

There are lots of means to create sterilized products, and one means is to utilize the techniques made use of in the bigger brewing sector. Most of the methods made use of in the developing sector translate extremely well to pasteurization, which is why numerous brewmasters pick to sterilize their very own products. A lot of Tunnel pasteurizers are warmth dealt with stainless steel bottles with a wick. These containers can additionally be utilized to generate a range of other drink items, consisting of yet not limited to:

Tunnel sterilizing containers and containers can be found in both stainless steel and also clear plastic variations. Stainless-steel ones are liked, because they require little warm treatment. The factor they work so well as a pasteurization medium is since the stainless-steel fragments will follow the sides of the bottle walls and be heat-treated by the communicating conveyor belt device. The plastic variation permits much better presence and much easier cleansing. Both variations of these bottles are excellent candidates for pasteurization because they are developed to permit coldness to reach the materials at fairly high temperatures.

Sometimes, you may find it needed or preferable to make use of different temperature settings for different batches. This is quickly accomplished by adjusting either the sort of set pasteurizers made use of, or the temperature of the water utilized in the batch pasteurizing process. Water temperature levels can be set at whatever the manufacturer really feels suffices for the item being processed. They can be kept in the exact same vessel or transferred occasionally to keep the water at the appropriate temperature.

The last classification of Tunnel pasteurizing products are the heavy steam batch pasteurizers. These vapor set pasteurizers use steam pressure to require warm, wet water via the item and then release it through an outlet. Because the product is being heated, this treatment can take a few mins longer than traditional pasteurization, however it is typically faster than a microwave pasteurization method, which can occupy to 10 minutes.

Batch pasteurized items are a fantastic option for numerous kinds of food products. They are frequently made use of to make ice-cream and sorbet, in addition to a selection of sauces as well as treats. They are the perfect service for high-end restaurants and providing organizations, since they offer a much more polished technique to pasteurization and also speed of manufacturing. Batch pasteurizers are likewise made use of in food handling plants to accelerate the breeding of microorganisms for seasoning food, and also to produce an extra controlled atmosphere for expanding and also gathering fresh components.

|

|

Batch Pasteurizers Can Boost Quality Of Efficiency |

Content by-Faulkner Dempsey

Tunnel pasteurizers are an unique class of pasteurizers created for very heats, generally over 500 degrees. A normal pasteurizer will have 2 separate areas: one which contains a heated plate to warmth and also mix the solution; and another area with a mixing drum, which steams the brew as well as flows it with the separate chambers to keep a continuous temperature. Since pasteurization is a technique of warm therapy, the temperature level setting have to be thoroughly monitored. Pasteurizing the wort prior to you really make it creates a finished product whose taste has actually already been changed by the enhancement of the society. This process is called priming.

There are three standard sorts of Tunnel pasteurizers: batch, continual flow, and also outside warm exchangers. Every one of these variants use the heat therapy procedure however run under somewhat different devices. In batch pasteurizers, the temperature level of the heated plate is controlled to boost as well as decrease an established quantity of wort prior to it is added to the fermenter. Constant circulation pasteurizers run in similar method except that there is a built-in bypass shutoff to regulate the temperature of the inbound wort. Exterior heat exchangers, on the other hand, use the warmth generated in the fermenter as a resource of additional energy to drive the circulation of the heated water with an extra heat exchanger, producing a consistent stream of heated water.

Batch Pasteurizers have actually been used by numerous microbreweries throughout the background of business beer brewing. They are particularly preferred in Europe, where they are utilized to ferment all manner of beer styles, consisting of light and also dark ales, in addition to wheats and steins. The pasteurization of soft drinks has actually additionally been very widespread throughout the last five years as well as has actually become an important part of the procedure of bottling eco-friendly items, such as fruit juices as well as veggies. Some popular examples consist of green tea and also apple cider vinegar. The pasteurization of fruit juices is becoming extra commonplace in the USA as well as is even starting to get into the American market as a prepared supplement to pasteurization of milk.

The concept function of the pasteurization process is to kill or eliminate pathogenic germs, thus minimizing the level of contamination existing at the end of the fermentation process. Pathogenic bacteria are a natural part of the developing process. https://www.10best.com/interests/food-culture/ever...asteurized-vs-raw-milk-cheese/ breed in the hot wort, specifically throughout the cooling duration between sets. Once they are able to start recreation, they create an atmosphere in which they flourish, slowly however definitely getting rid of any and all healthy yeast cells. https://www.packworld.com/home/press-release/13377...and-mondini-expand-partnership means that in order to keep the initial microbial populace from decreasing also promptly, you should keep your wort moving and also fresh throughout the whole fermentation process. Pasteurization helps to accomplish just that, killing pathogenic microorganisms and maintaining the original yeast population to make sure that you can appreciate your refreshingly crisp, refreshingly delicious mixture all summer season long.

A large range of different sorts of food can be pasteurized to boost their taste or make them easier to protect with time. One of one of the most preferred of these items is beer. Beer can be pasteurized to preserve its freshness for years at a time. Because of the reality that beer is typically kept in colders with ice bag, it is important to make sure that the bottles are properly secured when being used to move the beverage. Correct pasteurization is the only method of ensuring that your beer remains fresh.

There are various brands of pasteurizing systems available to select from. Some use heat, others make use of nitrogen, but lots of count on the currently common pasteurization procedure to ensure pasteurization of alcohols as well as their going along with product packaging materials. Beer, like other alcoholic beverages, requires pasteurization to eliminate every one of the microorganisms in the fermenting procedure, along with make certain that the co2 concentration in the beer remains at a constant, safe level. It is really crucial that your beer undertakes this essential pasteurization step, as any kind of modification can have damaging impacts on the high quality as well as taste of the beverage.

When utilizing Batch pasteurizers in your very own organization or in a public area such as a restaurant or bar, you need to know what equipment to acquire, exactly how to run the equipment, as well as just how to maintain the equipment gradually. Depending on the type of item you have acquired, you might want to get the services of a speaking with firm to come and also check your configuration. These professionals will have the ability to inform you precisely just how to use your equipment, what to do in regards to maintenance and exactly how to prevent having issues. They will additionally have the ability to help you with fixing situations that take place.

Along with the Pasteurizer itself, you may likewise need to purchase container sleeves as well as tubing, and possibly an examination stand. Every one of these things should be purchased in tandem with your Batch pasteurizer to make certain that they are all functioning correctly. When you've experienced the whole drink production procedure, you might not require your very own employees to man these devices. Nevertheless, it is a great idea to understand just how to fix them should they become malfunctioning. By buying quality items from a supplier who utilizes high quality products, you can feel confident that your makers are well dealt with.

|

|

Tunnel Pasteurizers For Procedures Like Ice And Also Soft Drinks |

Content create by-Vest Allen

Tunnel pasteurizers are a prominent sort of pasteurized food. This type of pasteurizer is utilized to make refined food last longer and maintain it more delicious for a longer time period. They are frequently used in restaurants as well as convenience food services to prolong the service life of prepared food and make it taste also better. There are two types of Batch pasteurizers readily available, set and also container. Usually, food will certainly be pasteurized at one cycle with a set equipment. Bottled https://bisouv.com/uncategorized/1879854/food-high...021-complete-technical-report/ are not used as frequently as the various other kind yet they do still have their benefits.

Set Tunnel Pasteurizers are made for huge centers or firms that need to process large quantities of food each day. The procedure of making batch pasteurized foods is similar to the process utilized by internal warm exchangers except it has a heat pump instead of a warm exchanger. Batch Batch pasteurizers have many advantages. They provide set size control which permits you to adjust the amount of food that undergoes the system based on what you require. There are commonly 5 cycles with the lengthiest being 2 hrs.

"@context": "https://schema.org", "@type": "Organization", "name": "PRO Engineering / Manufacturing Inc", "url": "https://prowm.com/", "logo": "https://prowm.com/wp-content/uploads/2020/12/PRO_logo_NEW_BLK_large.jpg", "contactPoint": "@type": "ContactPoint", "telephone": "414-362-1500", "contactType": "customer service", "areaServed": ["US","PR"], "availableLanguage": "en" , "sameAs": [ "https://www.facebook.com/PartnerWithPRO", "https://twitter.com/daveone1", "https://www.youtube.com/channel/UCizF9v7dVwMEfY1Qu_E4MPg", "https://www.linkedin.com/company/pro-engineering-and-mfg-inc/", "https://soundcloud.com/pro-engineering-milwaukee" ]

Inner Warmth Exchangers are made for restaurants and also food handling plants to accomplish pasteurization of difficult core products like icy fish, chicken, and also sodas. The system makes use of tanks of warmed water, along with a special cleaning agent, to attain pasteurization. An interior heat exchanger will generally have a holding container and a soft water storage tank to keep the appropriate water temperature level. Some devices use both heat exchangers. To get the best temperature, most makers make use of either electric pumps or gas-based heaters.

Bottled Tunnel Pasteurizers makes use of a process called carbonation. Carbonation is achieved by subjecting the drink to high pressure air which compels co2 into the inside of the bottle where the wanted pasteurization degree happens. Some bottled drinks call for carbonation to be complete because some microorganisms can not tolerate co2 at reduced temperatures. These kinds of drinks will commonly need carbonation or a few other method of pasteurization, such as hot or cool and even a mixture of both, in order to be pasteurized.

Many of the bottles in which Batch pasteurizers are packaged today are convection boxes. This type of box is very comparable to conveyor belts plus a container that is secured between and also travel up and down the conveyor. The bottles are put on the belt or conveyor as well as the lid is held in location by pressure that is built up in the box. The conveyor belt rotates at the appropriate rate. The conveyor belt moves the bottles around at the proper rate and in the correct direction to ensure that they end up in their matching containers. It can also relocate the bottles around at various speeds based upon the sort of bottle being moved.

There are numerous benefits of using a passage pasteurizer in a food service operation. When a sterilized drink item is appropriately sterilized, all of the biological matter in it will have been killed instantly by the rate of the conveyor. This will include any kind of contaminants that may have stayed alive in the item over time, such as bacteria or various other bacteria. The temperature at which the item is pasteurized also kills any residuals of microorganisms or various other microorganisms that could be in the product. This allows for the quick and also effective handling of a wide array of various types of food products. The pasteurization of food, especially those that are made use of to feed animals or human beings, can likewise remove the need for included fabricated plant foods as well as vitamins to maintain an ideal diet plan.

One more benefit of using Tunnel pasteurizers is that they can additionally be utilized to quicken the spoilage price of sodas. Pasteurization of sodas has actually been recognized to accelerate the process of spoiling drinks by as long as 40 percent. Pasteurizing sodas in these containers permits the pasteurization of the fluid, therefore removing the need for artificial vitamins or other included active ingredients to preserve the taste as well as preference of the beverage. Pasteurization of sodas makes it simpler for bottling companies to supply their customers with a product that is pasteurized at a high enough temperature to eliminate any kind of germs or various other organisms that may remain in the liquid.

Tunnel pasteurizing is a highly innovative kind of pasteurization made use of today in numerous kinds of food processing plants. These kinds of machines are likewise utilized in meat as well as fish manufacturing centers. This pasteurization procedure is coming to be much more commonly used as a way of protecting food for longer amount of times. read here of preservation is very vital for those that produce and keep food for extended periods of time due to the fact that it assists to keep the high quality of the item high as well as the shelf life of the product lasting longer.

|

|

Air Conveyance Equipments Is Different Than Typical Conveyancing |

Content writer-Hegelund Vance

Air Conveyance systems are a need to for several industries. These sectors range from clinical and also dental to oil refining and also purification. The tools needed for each and every industry varies, but the fundamental machinery is comparable. Conveyance systems vary from extremely automated units that can move large amounts of product throughout a center to highly hands-on operators that provide much of the job. In addition, there are specialists that can run these systems from remote places or manage them manually from inside a handling plant.

Air conveyancing systems are created to relocate material through several enclosed conveyors or containers utilizing an air compressor powered by an engine. Air is pumped with the system as it is passed through the systems' different chambers. A collection of wheels as well as wheels run the conveyor to move product with the system. This sort of system can be run either using power or hydraulics depending upon the kind of system being utilized.

The most typical kind of air-conveyancing system is the conveyor belt. These systems are normally made use of in the mining as well as manufacturing environments. The conveyor belt relocates raw materials, such as coal, over fars away in the mines. This system leads to the quick activity of the materials without allowing the materials to cool and/or cozy too swiftly. This prevents disastrous accidents that can arise from material overheating. When these systems are operating at optimal efficiency, they conserve countless bucks in product prices that would certainly or else be spent when tools repair work were necessary.

One more sort of transportation systems is the product taking care of system. These systems are utilized when relocating large and/or heavy products such as liquids as well as bulk products such as wheat. The conveyor system moves these materials through an above rail system and also right into a storage space area where the products remain up until they can be safely shipped or stored. This sort of system has the ability to carry huge quantities of product in a prompt way while supplying workers with an effective ways of product handling.

Air-conveyancing systems are not only made use of in mines and manufacturing plants. https://air-conveyance-systems.business.site/ are additionally made use of in stockrooms, shops, departmental shops, and also other retail facilities. This enables the staff members of these facilities the ability to relocate items from one area to an additional swiftly and quickly. If a shop's inventory is really high, for example, it may take weeks or even months for the things to be moved to the shelves in the other areas. With https://www.iol.co.za/business-report/companies/sa...9e-a984-4c03-9ea6-a8e503f097cd -conveyance system, all of the required items can be rapidly offered the consumer.

Often times, when a business is on the brink of shutting their doors permanently, the business will certainly contract out component or all of their product managing demands to another company. This is a terrific option for lots of organizations. If you are not a knowledgeable labor or product handling expert, you may not have the ability to discover a company that will supply you with the services that you require. Air-conveyancing systems are excellent for this situation, due to the fact that they enable companies to effortlessly move their needs to another firm without employing added individuals. All staff members of the closing organization will certainly currently work for the new company and there will certainly be no loss of hrs or production.

Air-conveyancing systems are very different from conveyor belts, product packaging systems, pallets, as well as various other sorts of conveyors. A conveyor belt generally has the work of moving products over a surface area, however an air-conveyance system does not. Rather, these systems utilize a sheave system to relocate items from one location to another. Many of these conveyance systems can take care of really heavy products, including ladders and racks. These systems are generally powered by an electric engine or a mix of an engine and belt and also wheel driven system.

There are several firms that use air-conveyance solutions for all types of companies. Nonetheless, before choosing a firm to aid with your air transportation requirements, you should constantly get in touch with the Bbb to ensure that the company is bound and has a great record with the Better Business Bureau. Air-conveyance systems are not just faster as well as less complicated to use than other kinds of transportation, but they also can conserve organizations cash. This is because instead of paying for delivery fees as well as labor, the firm itself will cover those charges.

|

|

Air Conveyance Systems - Comprehending Their Fundamental Feature |

Content create by-Huber Vistisen

Air Conveyance systems are used in different industries and to do various sort of work. These consist of product handling, item packaging, and also basic freight forwarding. There are likewise automated systems for this objective. One such system is the automated conveyor belt or ACB.

These respiratory tract conveyors are usually included a constant belt, which is more connected to a motor, generator, or a stopping system. The system includes 2 or more parallel belts and also these are connected to each various other. This aids the product to be carried along the belt. The transportation systems include light, medium as well as heavy duty types. The sturdy ones are normally used in industries where heavier materials are entailed. Examples of such sectors consist of automotive, chemical, and electrical manufacturing, and petroleum refining and also manufacturing.

The main feature of an air-conveyancing system is to share any kind of type of tons from one place to one more. This can be done manually or digitally. Hands-on systems are the ones that entail the employee to base on the platform or the moving platform whilst a computerized system does the rest. Air conveyancing is generally a part of the general shipping or shipment system. It is utilized to deliver raw materials, manufacturing facility items, and finished items from one area to another. In order to make certain safety, all air transportation have to be completely risk-free, safe and secure and also accident free.

Air convection is a vital system that involves several procedures. These include loading, unloading, and also positioning. When the conveyance systems are made use of for crammed automobiles they help in reducing traffic jam in the products areas. It decreases the costs too. Likewise, if the transportation is smooth and also convenient the workers functioning there would more than happy and content.

This system also minimizes the risk of damages to the cargo due to any kind of ecological issues like warmth, moisture, as well as dust. Also, the product will not deteriorate as a result of any damage and also will last long. The conveyance will also protect against the emission of damaging gasses which will certainly impersonate a hazard to the atmosphere as well as human wellness.

All the workers associated with the procedure need to use safety clothes while taking care of the freight. They will certainly also need to put on masks for their eyes. If they are utilizing a conveyance system which includes more than one load, after that it is absolutely essential that they utilize the correct tools. They need to be mindful as to not touching the various other loads.

The equipment used by the conveyance system must be made up of the required airline, air compressor, air filter, pressure tank, and also air couplings. These components might be bought from air ducts merchants or can even be manufactured at home. Process Equipment Manufacturers Association required for setting up the parts are usually plastic or aluminium aluminum foils. In addition to this, you will likewise need packing material, bands, duct tape, adhesives, and also calking agents.

The setup of the Air Conveyance system will need an expert that is well versed with all the technological terms as well as requirements connected to Air Conveyance systems. There are numerous companies that provide this sort of services. Therefore, it is always suggested to look around prior to completing your handle them. Air conveying companies also use setup services as well as will be able to mount the entire set up of your Air Conveyance. Nonetheless, this will certainly cost you some money as they are billing you for the labour of placing in the system.

If you are considering mounting an air system, you require to make certain that you research on the advantages and disadvantages of every one to ensure that you can make the very best choice that satisfies your requirements. There are different sorts of transportations available, and also therefore there are various kinds of items that need to be mounted. Air Separators In Hot Water Systems are made only for one purpose, whereas various other sorts of conveyance will take care of different types of products. If you do not know regarding the kind of product that you will need to handle, you will never ever have the ability to make a smart decision regarding the buying of a certain system.

Air Conveyance systems are not just used for moving things, yet they can be used for numerous commercial applications. This means that if you are looking for a system for dealing with products, after that you will certainly need to seek a firm that has remained in the business of selling and also setting up these systems for quite some time currently. You ought to additionally have a clear suggestion of what sort of items you will certainly be moving with the conveyance system, as various systems will certainly handle certain items much better than others. A complete investigation into the product is very much recommended, before you set up any system.

When it pertains to installing the air convection system, you will certainly have to employ the services of a specialist firm or individual. Although working with a specialist can cost you some money, you will require to spend the cash to make sure that you do not wind up with damaged or ineffective machinery. The company that you employ to mount the system will give you a couple of information regarding the installation procedure. These include the sort of hardware that you will certainly need, the sort of installment procedures that require to be followed and more. You will certainly likewise need to understand about the installment procedures for each particular item that you want to move via the conveyance system. When you are finished with the setup, you will require to give the company employees regularly that they need to make sure that they can do the task right.

|

|

4 Essential Action In Vial Pasteurization Process |

Content by-Pereira Hood

Food processing and retail industries have actually located drink pasteurization to be a desirable process. It permits a glass of wine and also spirits to be preserved without impacting their preference or aroma. Pasteurization can be done via a collection of actions starting with the choice of the food to be processed, the sort of grapes or various other fruits used and after that the various sorts of cultures used to ferment the beverage. Hereafter, the temperature level as well as period of the process will depend upon the kind of item being processed. Drink pasteurization is a facility and also scientific process. This article will certainly supply information regarding the different steps in drink pasteurization as well as the benefits it has over other approaches.

The first step in this process is to pick the grape range that will produce the wine. Grapes that are matched for fermenting will offer far better results in terms of preference, color and likewise the alcoholic web content of the finished item. To make certain a premium quality red wine, select the grapes based on their disease resistance ability, sweet taste and their manufacturing possibility. The wine grapes ought to likewise be examined for acid and also tannin levels before they are made use of at the same time.

The second step is to ferment the a glass of wine at the suitable temperature. https://www.miamiherald.com/miami-com/restaurants/article225810765.html is a vital factor in making a high quality a glass of wine since it affects the taste and also appearance of the final product. This stage is essential since if the wine is not fermented at the proper temperature levels, it will certainly not taste appropriate or it might ruin the wine.

Fermentation likewise figures out the bouquet and also taste of the white wine, since this is brought on by the concentration of various micro-organisms in the wine. Throughout the fermentation, yeast cells multiply and also develop carbon dioxide and ethanol. Co2 is very crucial due to the fact that it provides the body, arrangement and also the taste of the white wine. Throughout the process, sugar is developed by the yeast and this procedure additionally generates one more crucial active ingredient, alcohol.

The third as well as final action in drink pasteurization is the cleanliness and cleanliness of the vessel containing the red wine prior to putting it in the refrigerator. https://www.smithsonianmag.com/travel/celebrate-na...t-breweries-america-180954894/ is really important to make sure that the white wine is sterilized because the germs or any other microbe may potentially enter the bottle during this procedure. Before doing this, you have to clean up the bottle entirely as well as make sure that the cork is undamaged. You likewise have to make certain that the neck of the bottle is totally dry. If not, after that your a glass of wine might ruin.

The 4 4th action in the procedure is the real pasteurization of the wine. The amount of time needed for this can vary depending upon the kind of white wine along with on the size of the bottle. For gewurztraminer, the pasteurization typically takes about three hours. It likewise depends upon the sort of red wine as well as the amount of gewurztraminer that you intend to procedure. Some people might additionally use the extra space in their refrigerator in order to complete this action faster.

The last step is the explanation step in beverage pasteurization. This is especially important if you are looking to have a champagne. This is since champagnes have extra sugar and also should undergo this process in order to avoid their sugar degree from rising to a high one. The sugar will turn to alcohol as well as additionally eliminate the arrangement of the a glass of wine. If this is the case, then you need to quit fermentation as well as you ought to wait for regarding two days prior to you bottle your red wine.

Pasteurization is a really crucial treatment in the white wine making process. Nevertheless, it can not totally substitute the procedure old the white wine. Aging the a glass of wine will simply include another chain reaction with the white wine and also you need to utilize an additional approach. But when you process the red wine utilizing pasteurization, you will have a regulated environment that permits you to control all these procedures and also you will certainly have the ability to develop the most special as well as yummy wine possible.

|

|

A Brief Summary Of Batch Pasteurization |

Content writer-Morton Kjer

Batch Pasteurization is the procedure of heating food items at a temperature level listed below the boiling point of water. This process is used in a variety of food processing as well as prep work applications. Instances of normal batches consist of:

Set pasteurization has actually become the approved technique of handling raw foods for usage and sale. simply click the up coming internet page can be utilized to quickly cool food items for storage space, delivery, dealing with and transport. These products are then prepared to be marketed and sold. In addition, this pasteurization procedure is perfect for preparing sauces, sauces, pickles and delights in.

The pasteurization procedure begins with the choice of food product. Foods are heated at specific temperatures to begin the pasteurization procedure. They are placed in a huge temperature level controlled drum called a pitcher. The drum is made to keep a constant temperature so the food does not outrage or steam way too much. The warmth generated throughout the home heating process is routed to the food product to ensure that it can develop a smooth consistency and taste.

After being warmed, the cooled food products are moved right into a temperature-controlled drum called a pasteurization container. Depending on the kind of food and also the preferred temperature of the product, the pasteurization solution is prepared. This solution can differ significantly depending upon the item being processed. This pasteurization service is commonly prepared with added components such as coloring agents, flavoring substances and also other materials that aid prolong the pasteurization procedure.

The ingredients are combined with water prior to the drum is placed into a barrel of heated and also combined water. https://www.foodprocessing.com/articles/2014/hpp-t...ive-improvements-in-rte-meats/ cooling down fan is utilized to distribute the pasteurization remedy to make sure that the temperature of the drum can remain constant. A thick deposit of the pasteurization option is frequently made use of in all-time low of the drum to assist with maintaining the consistent temperature level. This deposit may additionally be thickened with different sorts of food such as lotion or milk.

Throughout the actual pasteurization process, the drum is put in a location that is temperature controlled. Food things are positioned inside individually. It is important to check the ingredients as they are put inside the drum to make certain that they do not outrage. If they do outrage, the fluid may start to foam at the top of the drum. This foam can cause a foul odor to be created. However, if the food items are not put in direct contact with each other, the pasteurization process will not take place.

A range of various processes are made use of in the pasteurization process of meat products. A few of these processes include drum sealants, chilly pasteurization, warm pasteurization, carbon dioxide pasteurization, and a selection of various other methods. The food products are kept an eye on throughout the whole pasteurization procedure to make certain the appropriate temperature levels are reached. If the proper temperature level is reached, the pasteurization process will be complete as well as the food products will certainly begin to prepare and launch their distinct flavors right into the air.

Meat products that are to be pasteurized must be stored in the refrigerator. This allows for the best feasible pasteurization process to occur. There are various strategies used for meat items that require to be cooked in order to eliminate any type of excess dampness and also to likewise help get rid of any kind of microbial contamination. Meat that has actually been prepared to excellence and after that iced up may have one of the most full and most hygienic pasteurization process readily available.

Meat items can be cooked on a grill or stove top, but the method of cooking is not as crucial as the hygiene process made use of. When meat is being prepared, it ought to be carefully viewed to ensure that the bacteria and other impurities are totally eliminated from the cooking utensil. The same holds true for the container in which the meat items will certainly be stored. Meat should be thoroughly cleaned up as well as extensively dried out prior to being saved. Pasteurization needs to just be utilized when meat products are prepared to within 100 degrees Fahrenheit.

There are several health and wellness advantages to pasteurization of meats as well as fish. A few of one of the most significant include promoting far better food digestion and more helpful absorption of nutrients from the food. Meat as well as fish pasteurization also advertise a longer shelf life. Due to the fact that bacteria are killed during the pasteurization process, there is less opportunity for the development of harmful bacteria and parasites within the meat items.

Meat items can be sterilized in your home for a variety of reasons. As an example, the meat might have gone bad after a purchase, yet this could be avoided. If you doubt concerning the security of your very own home processed meat, after that you ought to contact a neighborhood pasteurization specialist. They are simple to find as well as agree to evaluate your home and also offer advice on meat pasteurization. Keep in mind that meat pasteurization is a vital procedure that ought to be correctly handled by those well-informed about it.

|

|

A Quick Overview Of Tunnel Pasteurizers |

Article created by-Osborne Parks

Batch Pasteurizers are a necessary device in the kitchen. It is really beneficial for meat, seafood and also fowl items to protect and also prolong the service life of these items. Yet it is not known exactly how these products are pasteurized and also what procedure is used to make them.

Tunnel pasteurizers are basically devices that warm food to a particular temperature level and then remove all air, making them uniform. This method is commonly called "thermographic" since it makes certain that all nutrients are ruined or eliminated from the food. When packaging of carbonated beverages is appropriate, the pasteurizers sanitize the food. Hereafter process, a lot of Tunnel electives call for a cooling period to kill any germs before packaging.

Batch Pasteurizers are frequently utilized for fruits and vegetables. They are made use of in commercial processing plants, in home juice manufacturing systems as well as can be discovered at grocery stores and also residence depots. There are 4 various classes of Pasteurizers. They are gone over listed below:

Passage Pasteurizers. The Passage Pasteurizer is one of the most functional of the kinds of pasteurizers as it can be used for a variety of applications. You can use it to steam water or heavy steam vegetables and also fruits and afterwards utilize the water or vapor to cool down the product. You can also utilize this type of pasteurizer to completely dry meat, fish and chicken at reduced temperature levels.

Spray Pasteurizers. These are sometimes called spray guns because they make use of a pressurized stream of air to inject the pasteurizer. Like various other pasteurizers, these job by using vapor stress rather than warmth to get rid of all air from the product. A negative aspect is that they might be extra costly than other kinds of pasteurizers as well as they may require to be cleaned manually after each usage.

Heat pasteurizers. These work by utilizing hot water or steam to infuse the pasteurizer. Several of these will certainly also contain little pieces of raw food to speed up the food digestion of the food and encourage faster ripening. When heated up, the pasteurizer stops yet the home heating resource continues, which implies that it can take up to three hrs for the pasteurizer to be fully reliable. The drawback is that these have a tendency to be one of the most expensive of the pasteurizers readily available.

Focused Pasteurizers. One of the most commonly secondhand type of pasteurizer is the concentrated one since it has the capability to generate high amounts of products. They are usually made use of to produce pasteurized milk, ice cream, soup, sauces as well as various other food that need to be maintained a regular temperature level so that they maintain their taste as well as structure. Since they can create a large quantity of product, they can be made use of typically as they have a high ability.

Tunnel Pasteurizers can be used for a range of purposes. Mixer can use them to quicken pasteurization and also enlarge soups and sauces without having to include more time to the food preparation procedure. You can also use them on juicers as well as blenders to assist remove juice from vegetables and fruits without creating a too much quantity of heat. They are also frequently made use of to create big amounts of dry pet dog food in feed mills because they can generate big amounts of food promptly without needing to process it at a heat. Finally, the Batch pasteurizers offered for house usage are commonly utilized to quicken the drying procedure of meats to make them ready to store. Whatever the objective, it's clear that sterilizing techniques are still a vital part of the food manufacturing procedure.

Tunnel Pasteurizers have numerous vital buildings that make them optimal for use in food processing. Initially, they call for only a low temperature to trigger the microorganisms that will help them grow. This suggests that there is no need to issue on your own with raising the temperature beyond the predetermined variety, which can typically be dangerous for the products you're attempting to procedure.

It is essential that you always follow the suppliers' guidelines for utilizing Batch pasteurizers. Cannabis pastuerization of foods need to be pasteurized at temperature levels around 100 degrees Fahrenheit. For example, lots of people don't understand that raw egg needs to be cooked to a suitable temperature level of about 150 levels prior to being contributed to various other dishes. This guarantees that the pasteurization procedure will function correctly as well as will keep your food from being infected by harmful microorganisms.

When using a batch-pasteurizer to produce smaller batches of food, it is essential that you use the right dimension for the Batch. They are made to fit onto a warmer or stand, so the smaller sets may need to be placed directly onto the heating element. Otherwise, the sterilizing process could harm the products you're trying to process.

|

|

4 Important Steps In Vial Pasteurization Process |

Content by-Pereira Braswell

Food processing and retail industries have located beverage pasteurization to be a preferable procedure. It permits white wine and spirits to be protected without affecting their preference or scent. Pasteurization can be done through a series of actions beginning with the selection of the food to be refined, the sort of grapes or various other fruits utilized and afterwards the different kinds of societies utilized to ferment the beverage. After a knockout post , the temperature level and duration of the procedure will certainly depend on the kind of item being processed. Drink pasteurization is a complicated as well as scientific procedure. This article will provide info regarding the different steps in drink pasteurization and the advantages it has more than other approaches.

The initial step in this procedure is to choose the grape variety that will create the wine. Grapes that are fit for fermenting will give better cause terms of preference, color and also the alcoholic content of the finished product. To ensure an excellent quality a glass of wine, choose the grapes based upon their disease resistance capability, sweet taste as well as their manufacturing potential. The white wine grapes ought to additionally be checked for acid as well as tannin degrees prior to they are made use of in the process.

The second action is to ferment the wine at the suitable temperature. This temperature level is an important factor in making a good quality wine because it influences the taste and also appearance of the final product. This stage is very important due to the fact that if the wine is not fermented at the appropriate temperature levels, it will not taste best or it may ruin the a glass of wine.

https://www.find-us-here.com/businesses/Pro-Engine...kee-WI-Wisconsin-USA/33131754/ out the arrangement and also preference of the wine, due to the fact that this is brought on by the focus of various micro-organisms in the red wine. During the fermentation, yeast cells increase as well as create co2 and ethanol. Co2 is very crucial since it offers the body, arrangement and also the taste of the white wine. During the procedure, sugar is produced by the yeast and this process additionally produces another important ingredient, alcohol.

The 3rd and also final step in beverage pasteurization is the tidiness and hygiene of the vessel consisting of the red wine before putting it in the refrigerator. It is really important to ensure that the a glass of wine is clean and sterile since the bacteria or any other microorganism may perhaps get in the bottle throughout this procedure. Before doing this, you have to clean up the bottle entirely and make certain that the cork is intact. You also have to make sure that the neck of the bottle is entirely dry. Otherwise, after that your white wine might ruin.

The 4 4th step in the process is the actual pasteurization of the white wine. The amount of time required for this can differ depending upon the sort of wine in addition to on the dimension of the bottle. For gewurztraminer, the pasteurization normally takes concerning three hours. It also depends on the sort of wine and also the amount of white wine that you want to process. Some individuals may additionally use the added space in their refrigerator in order to complete this action faster.

The last step is the clarification step in beverage pasteurization. This is specifically crucial if you are aiming to have a sparkling wine. This is because champagnes have extra sugar as well as needs to undergo this procedure to avoid their sugar degree from rising to a high one. The sugar will certainly look to alcohol as well as also take away the bouquet of the red wine. If this holds true, after that you need to quit fermentation and also you ought to await concerning 2 days prior to you bottle your a glass of wine.

Pasteurization is an extremely crucial procedure in the wine making process. However, it can not completely replace the procedure of aging the wine. Aging the red wine will just include one more chain reaction with the a glass of wine and also you need to use an additional method. However when you refine the red wine utilizing pasteurization, you will have a controlled environment that allows you to regulate all these processes and you will have the ability to create the most exclusive as well as delicious red wine feasible.

|

|

4 Important Steps In Vial Pasteurization Process |

Written by-Vendelbo Crowder

Food handling and retail markets have actually found beverage pasteurization to be a preferable process. It enables red wine and spirits to be maintained without impacting their taste or fragrance. Pasteurization can be done through a collection of steps beginning with the choice of the food to be refined, the type of grapes or other fruits made use of and then the various sorts of societies made use of to ferment the drink. After this, the temperature level and period of the procedure will rely on the sort of product being processed. Drink pasteurization is a complicated and also clinical process. This write-up will certainly supply info regarding the different action in drink pasteurization as well as the advantages it has more than other approaches.

The initial step in this process is to choose the grape range that will generate the red wine. Grapes that are fit for fermenting will certainly provide far better results in terms of preference, color and also the alcoholic web content of the finished item. To guarantee an excellent quality red wine, choose the grapes based on their condition resistance capability, sweet taste and also their manufacturing possibility. The white wine grapes must additionally be evaluated for acid as well as tannin levels before they are utilized in the process.

The second action is to ferment the wine at the ideal temperature. This temperature level is an essential factor in making a high quality red wine due to the fact that it affects the taste as well as structure of the end product. This phase is necessary because if the a glass of wine is not fermented at the correct temperature levels, it will not taste best or it could ruin the a glass of wine.

Fermentation additionally establishes the bouquet as well as taste of the red wine, due to the fact that this is caused by the focus of different micro-organisms in the white wine. Throughout the fermentation, yeast cells increase and also produce co2 as well as ethanol. Carbon dioxide is really vital due to the fact that it offers the body, bouquet as well as the taste of the wine. Throughout pasteuriser , sugar is developed by the yeast and also this process likewise generates another essential ingredient, alcohol.

The 3rd and also last step in beverage pasteurization is the sanitation and hygiene of the vessel including the red wine prior to placing it in the fridge. It is extremely crucial to make sure that the a glass of wine is sterilized since the microorganisms or any other bacterium may perhaps get in the bottle during this procedure. Before doing this, you need to clean up the bottle entirely as well as make certain that the cork is intact. You likewise need to make certain that the neck of the bottle is totally dry. Otherwise, after that your white wine may ruin.

The four fourth step in the process is the actual pasteurization of the red wine. The amount of time required for this can vary relying on the sort of white wine in addition to on the dimension of the bottle. For gewurztraminer, the pasteurization normally takes regarding 3 hrs. It also depends on the type of red wine and the quantity of gewurztraminer that you wish to process. krones tunnel pasteurizer may likewise make use of the added room in their refrigerator in order to finish this action much faster.

The last step is the explanation action in drink pasteurization. This is especially essential if you are wanting to have a champagne. This is since sparkling wines have extra sugar and also needs to undertake this process in order to avoid their sugar level from rising to a high one. The sugar will certainly resort to alcohol and additionally take away the bouquet of the white wine. If this holds true, then you need to stop fermentation and also you must await concerning 2 days prior to you bottle your red wine.

Pasteurization is an extremely important treatment in the white wine making procedure. Nonetheless, it can not totally replace the procedure old the a glass of wine. Maturing the wine will just include an additional chain reaction with the red wine as well as you have to use another method. Yet when you process the wine making use of pasteurization, you will have a regulated setting that allows you to regulate all these processes and also you will certainly be able to create one of the most special and delicious red wine feasible.

|

|

Tunnel Pasteurization - A New Food Precaution |

Written by-McDougall Kendall

Tunnel pasteurization describes the production of drugs by utilizing an automatic process. This is frequently utilized in the food and chemical sector. https://www.bizjournals.com/sacramento/news/2012/1...rization-processing-w-sac.html creates heat, alters the substance framework of the item, and also divides oxygen particles from the other particles. The resulting item, after pasteurization, is really risk-free to take care of as well as additionally commonly distributed throughout the industry. Furthermore, Batch pasteurization offers outstanding quality at affordable costs. This pasteurization technique has actually been found to be reliable in desalinating water and also in dealing with sewer.

Tunnel pasteurization includes two steps: elimination of water as well as treating of basic materials. The very first step involves the removal of water utilizing a high-pressure system. The second action involves dealing with the raw materials with the pasteurization procedure, that includes heating. The treatment of resources includes various techniques such as sharing the products in order to get rid of any type of excess solvent; applying solvents or chemicals to the surface area to get rid of any kind of remaining solvent; and also applying emulsifiers to get rid of any kind of insoluble fragments.

"@context": "https://schema.org", "@type": "Organization", "name": "PRO Engineering / Manufacturing Inc", "url": "https://prowm.com/", "logo": "https://prowm.com/wp-content/uploads/2020/12/PRO_logo_NEW_BLK_large.jpg", "contactPoint": "@type": "ContactPoint", "telephone": "414-362-1500", "contactType": "customer service", "areaServed": ["US","PR"], "availableLanguage": "en" , "sameAs": [ "https://www.facebook.com/PartnerWithPRO", "https://twitter.com/daveone1", "https://www.youtube.com/channel/UCizF9v7dVwMEfY1Qu_E4MPg", "https://www.linkedin.com/company/pro-engineering-and-mfg-inc/", "https://soundcloud.com/pro-engineering-milwaukee" ] >

The products desalinated by Batch pasteurization consist of synthetic as well as non-synthetic substances. Several of the products created by this procedure consist of artificial chemicals (cement, cement powder, and diesel), colognes, as well as natural oils. Emulsifiers are likewise made use of to refine some items, such as diesel. Batch pasteurization works in lowering unstable ingredients present in raw materials such as sulfuric acid and hydrocarbons. It has also verified helpful in processing sulfur compounds, which work for treating heavy metals.

On top of that, Batch pasteurization can also be made use of for the manufacturing of antifreeze. simply click the up coming website has also proven useful in processing ammonia, fatty acids, as well as acids (such as glycerol and also methyl ester). The item accomplishes its preference by utilizing a pasteurization procedure that entails requiring the service to evaporate at very heats. This pasteurization step assists get rid of the majority of the wetness from the item, hence preserving the liquid make-up of the item.

The solvents utilized in this procedure have actually been categorized according to their boiling points, their vapor pressures, and their salt compositions. Commonly used solvents consist of water, nitrogen, oxygen, carbon dioxide, and also gas. There are 2 kinds of Tunnel pasteurization techniques. The very first includes a two-stage treatment in which the temperature level is raised from cold, initially by adding the solvents, and then raising it again as soon as the solvents have been included. The second entails a one-stage process, in which the temperature level is gradually increased from freezing, without including any kind of additional solvents.

Batch pasteurization can additionally be made use of to enhance the preference of particular products. Because of pasteurization, cream-based items taste far better than dairy products and also soy-based products taste better than meat products. Pasteurization of foods has the potential to greatly decrease foodborne illness. This process is useful in the preservation of fresh vegetables and fruits, dairy products such as milk as well as cheese, fish that have been salted or marinaded, shellfish, melons, as well as various other fresh fruits and vegetables, as well as meat products like lamb, beef, as well as pork. Pasteurization is likewise advised for the preservation of foods that have undergone processing to eliminate any type of potentially harmful bacteria, such as might have been introduced during the pasteurization procedure.

In addition, the pasteurization of liquors can assist prolong the shelf life of the item. Pasteurization additionally extends the flavor of particular products, like mints, delicious chocolate, and peanut butter. The pasteurization of milk has actually been attributed with prolonging the service life of chocolates. It is thought that pasteurization assists to kill the microorganisms that are accountable for botulism and gastrointestinal disorder. Pasteurization is typically used in the manufacturing of ice cream, but it is also commonly used in food solution, pharmaceutical, as well as food manufacturing plants.

Tunnel pasteurization is one of the most effective approach of developing excellent quality, low cost, and also fresh foodstuff. Foodstuff that have gone through pasteurization go through several extra steps to make sure the completed item is risk-free for human consumption, such as heat treatment and also secondary pasteurization. Warmth therapy is a process whereby pasteurization is put on prevent wasting as well as prolong the service life of the item. Other additional pasteurization procedures include cold and also cool stablizing.

|

|

Batch Pasteurization - A Brand-New Food Safety Measure |

Article by-Gravgaard Cote

Batch pasteurization describes the manufacturing of pharmaceuticals by utilizing a computerized procedure. This is typically made use of in the food and also chemical sector. The pasteurization process produces warmth, changes the substance structure of the product, as well as divides oxygen particles from the other molecules. The resulting item, after pasteurization, is extremely safe to handle and likewise commonly dispersed throughout the market. On top of that, Tunnel pasteurization offers exceptional quality at competitive rates. This pasteurization method has been discovered to be effective in desalinating water and also in treating sewage.

Tunnel pasteurization entails 2 actions: removal of water and dealing with of basic materials. The primary step includes the removal of water making use of a high-pressure system. The 2nd step involves dealing with the raw products with the pasteurization procedure, that includes home heating. The therapy of basic materials entails various methods such as sharing the products in order to eliminate any kind of excess solvent; using solvents or chemicals to the surface area to get rid of any kind of remaining solvent; as well as using emulsifiers to get rid of any type of insoluble fragments.

“BEVERAGE MAKERS GUIDE TO PASTEURIZATION OF HARD SELTZERS”

— PRO ENGINEERING (@Daveone1) March 25, 2021

Article Release for Brewmasters & Beverage Makers:

Full article: https://t.co/QwAntYbGpR

PRO Engineering / Manufacturing

11175 W Heather Ave Milwaukee, WIhttps://t.co/N4TYOFXK3R

#brewery #craftbeer #hardseltzers pic.twitter.com/SYyCFJHhNl

The items desalinated by Tunnel pasteurization consist of synthetic and also non-synthetic compounds. Some of the products created by this process consist of synthetic chemicals (concrete, concrete powder, and also diesel), fragrances, as well as all-natural oils. Emulsifiers are also made use of to process some items, such as diesel. Batch pasteurization is useful in lowering unpredictable ingredients present in raw materials such as sulfuric acid and also hydrocarbons. It has also confirmed advantageous in processing sulfur substances, which work for treating heavy metals.

In addition, Batch pasteurization can additionally be used for the production of antifreeze. It has also confirmed helpful in processing ammonia, fats, and acids (such as glycerol and also methyl ester). The item achieves its preference by using a pasteurization procedure that includes compeling the solution to vaporize at very high temperatures. https://www.brecorder.com/news/375178 helps get rid of the majority of the dampness from the item, therefore maintaining the fluid makeup of the item.

The solvents used in this procedure have actually been classified according to their boiling points, their vapor stress, and also their salt make-ups. Commonly utilized solvents consist of water, nitrogen, oxygen, co2, as well as fuel. There are two kinds of Tunnel pasteurization techniques. The first involves a two-stage procedure in which the temperature is increased from freezing, initially by adding the solvents, and then raising it again as soon as the solvents have actually been added. The second includes a one-stage procedure, in which the temperature is gradually elevated from freezing, without adding any type of added solvents.

Batch pasteurization can likewise be used to boost the taste of specific products. Because of pasteurization, cream-based products taste better than dairy items as well as soy-based items taste far better than meat products. Pasteurization of foods has the prospective to substantially decrease foodborne health problem. This process serves in the preservation of fresh vegetables and fruits, dairy items such as milk as well as cheese, fish that have been salted or marinaded, shellfish, melons, and various other fresh fruits and vegetables, and also meat items like lamb, beef, and also pork. Pasteurization is also recommended for the preservation of foods that have actually gone through processing to get rid of any possibly harmful microorganisms, such as might have been presented throughout the pasteurization process.

Furthermore, the pasteurization of alcoholic beverages can aid expand the life span of the product. Pasteurization likewise lengthens the flavor of certain products, like mints, chocolate, and also peanut butter. The pasteurization of milk has actually been attributed with prolonging the shelf life of chocolates. It is thought that pasteurization aids to kill the bacteria that are responsible for botulism as well as gastrointestinal disorder. https://www.marinelink.com/news/bawats-bwts-offered-portside-applications-485218 is generally made use of in the manufacturing of gelato, yet it is also widely used in food service, pharmaceutical, as well as food factory.

Tunnel pasteurization is the most efficient approach of creating top quality, low cost, and fresh foodstuff. Foodstuff that have actually gone through pasteurization undergo several extra steps to make sure the finished product is safe for human consumption, such as heat therapy and additional pasteurization. Warmth therapy is a process whereby pasteurization is related to protect against spoilage as well as extend the shelf life of the item. Other second pasteurization processes consist of freezing as well as chilly stablizing.

|

|

A Quick Intro To Batch Pasteurization Plants |

Created by-Braswell Pettersson

Tunnel pasteurization describes the production of medications in an automated system, normally a shut system consisting of a set pasteurizer. This pasteurization approach is favored over various other conventional pasteurization approaches since it generates a more sterilized product and also is less costly than various other similar systems. Batch pasteurization involves continual evaporation complied with by a last purification in a holding container. This final cleaning procedure is very important since it assists in eliminating any left over organic issue that can impact the effectiveness of the final product. There are several firms that make these kinds of items, as well as several can be worked with to do the work expertly.

The items are created from basic materials that have been cooked at very high temperatures. The items are then combined with emulsifiers to get rid of any continuing to be solids and then mixed with thickeners. The solids are removed with an unique siphon called a sludge collector. The solids are then eliminated in a second siphon called a drainpipe tube to a collection mug.

Batch pasteurization is a required part of the pharmaceutical as well as food processing sector. It has actually become one of the most frequently utilized kinds of pasteurization for foods and drugs. Additionally, Tunnel pasteurization is used for the handling of fresh fruits and vegetables. The pasteurization process protects the freshness of these products.

Tunnel pasteurization is one of the 4 commonly utilized pasteurization processes. These processes consist of co2 pasteurization, methanol pasteurization, and urea pasteurization. In the co2 pasteurization procedure, low concentrations of chlorine, water, or both are needed to damage the hazardous chemicals in virus. The high temperature in the methanol and urea pasteurization processes kills the unsafe chemicals by creating them to break down into simpler compounds, leaving just the helpful chemicals.

Carbon dioxide shot is additionally utilized as a kind of pasteurization. A large range pasteurization process is utilized in the chemical sector. Co2 laser pasteurization is an additional procedure being utilized today. This procedure makes use of carbon dioxide under pressure. https://scienceblogs.com/casaubonsbook/2010/05/24/goat-girl-or-the-milking-life-1 up the surrounding location so that it evaporates the fluids in the liquid.

Batch pasteurization is done to eliminate germs and infections by using low focus of chemicals. It is also utilized as a way to prevent the contamination of foodstuff. In visit my website , the microorganisms and also viruses are presented into the raw materials at really heats. This is why this sort of pasteurization is best utilized on contaminated locations such as the foods, pharmaceuticals, and medicines.

Batch pasteurization has its advantages as well as negative aspects. The chemicals used in this process are highly combustible and as a result require to be taken care of with extreme care as well as utmost treatment. Because of the flammability of the chemicals, there is constantly a danger of fire or explosion in Batch pasteurization plants. The Tunnel pasteurization plants are additionally vulnerable to electrical threats like short circuits and also electrocution. There is also a risk of chemical reaction between the pasteurized product and also the body particularly in case of the accidental consumption.

Batch pasteurization is for that reason not ideal for home use. There is additionally the risk of skin inflammation from the chemicals made use of in this chemical process. This might result in unwanted breakout of mark cells. For these reasons, you need to rely upon highly certified professionals when managing unsafe chemicals. Dermatology departments as well as other associated medical professional can be consulted for advice on Tunnel pasteurization.

Tunnel pasteurization is additionally reliable only where the temperature level is appropriate. The temperatures in which this process happens rely on the type of chemical being utilized as well as also on the high quality of the pasteurization batch. The pasteurization process must additionally be thoroughly monitored to prevent the overuse of the chemicals. The batch must undertake a thorough assessment by licensed personnel prior to it is released right into the ambience.

The Batch pasteurization plants have to meet particular criteria to obtain approval from numerous health care companies. The standards hereof include the need of an environmental control management plan under the appropriate State legislation. The plants are needed to submit annual reports to this result to the relevant authorities. The plant's record also includes details concerning the mishaps that occurred within the facilities as well as about the security precautions taken for the monitoring of the chemical material. There is also a provision in the legislation that the proprietors of the Batch pasteurization plants are liable for accident problems triggered by their staff members. These procedures are necessary to guarantee that the pasteurization procedure is executed in the best fashion.

The use of chemical substances in food manufacturing has actually come under increased analysis in recent times, specifically because of the widespread use prescription antibiotics. Though pasteurization is a procedure that eliminates germs by subjecting it to heat and also pressure, it is ruled out to be dangerous for people. Nevertheless, since a lot of the microorganisms revealed to such heats are warm immune and also thus not eliminated straight, there is a risk of resistance in the long term. This can bring about the accumulate of resistance in the direction of the different prescription antibiotics that are frequently used in the treatment of infections. Tunnel pasteurization plants can lessen this by following all the essential precautionary procedures to carry out this procedure with the minimum danger to the public.

|

|

The Advantages Of Tunnel Pasteurizers |

Content written by-Ellison Humphries

Tunnel pasteurizers are used to increase production of wines. They are primarily used in the vineyard because of their capability to maintain the initial top quality as well as flavor of the item despite any extensive duration of storage. This pasteurizer assists to boost the shelf-life of wine, thus increasing its value and also earnings. It can be used for large or small range production. This is an exceptional item that ensures that the white wine is free from poor microbes that damage it.

Tunnel pasteurizers are typically constructed from stainless steel rods having hollow handles. The pole has 2 parts which are the bottle as well as the drum. There is a thin tube that ranges from the drum through the bottle, connecting both the drums. Television promotes very easy transfer of air into the bottle from the drum. This pasteurizer is utilized for sterilizing light and dark red wines.

Although, Tunnel pasteurizers are widely used nowadays, still several of them are not approved by the market as reliable and reliable. They are mainly called as warmth pasteurizers since they make use of a warm resource that launches heat to sterilize liquid. These pasteurizers are used in squashing procedures, fermenting, drying out, pickling, pasteurizing, dealing with hard or soft cheese, dealing with food, and so on. There are even some companies that advertise their items as vacuum pasteurizers.

Tunnel pasteurizers ought to not be confused with pasteurizers that function by evaporating natural gas to develop vapor for heavy steam vapor condensation. Tunnel pasteurizers make use of a different approach and also consequently they require to be specifically pointed out thus. They also differ from pasteurizers that utilize heat as well as stress to accelerate the dissipation of gas.

Tunnel pasteurizers are likewise referred to as freeze pasteurizers because they produce a product similar to pasteurized milk. Although this is a really easy concept, it is in fact not a simple procedure. For starters, resources for making this pasteurizer are needed such as sugar, fat, water, skim milk, etc. Once these components are available, the procedure of making the pasteurizer starts. Primarily, this pasteurizer is an ultra-filtration pasteurizer. To put it simply, it works by removing microorganisms, heavy metals, inorganic chemicals, etc., from the final product.

One of the most typically found components that comprise this ultra-filtration pasteurizer are calcium, iron, cobalt, manganese, phosphorous, silicon, sodium, zinc, as well as copper. It additionally has trace amounts of zinc and selenium. Generally, the pasteurization procedure is carried out in a huge range at a temperature level of concerning 150 levels Celsius. Nonetheless, it is not unusual to locate this pasteurizer being sterilized in smaller sized scale at any kind of temperature up to about minus forty degrees Celsius. This results from the truth that a few of the components, which need to undergo pasteurization at heats, are really harmful as well as corrosive.

Tunnel pasteurizers being utilized today have a selection of advantages. In addition to supplying pasteurization at reduced temperature level, these pasteurizers also give better preference as well as smell, they are economical to make use of, they do not develop any kind of carcinogen, etc. https://www.dairyreporter.com/Article/2020/03/17/A...-fossil-fuel-consumption-by-80 are likewise utilized to kill germs and microbes in the wastewater. This is an extremely common practice in the pharmaceutical, oral, as well as food market.

Tunnel pasteurizers that are being used nowadays are available in various sizes and shapes. Depending upon the kind of pasteurizer that is to be utilized, its capability to remove microorganisms ought to also be thought about. A good example would be that of the powder-based pasteurizer that can remove from one percent to ninety-five percent of the suspended particles. They are additionally available in different quantities.

There are likewise pasteurizers that utilize ultraviolet or light to eliminate the microorganisms. An additional form of Tunnel pasteurizer utilizes flash lights to kill the microorganisms. But normally, the most typically made use of pasteurizers are the granular and also activated variations that make use of activated carbon as their active component. This pasteurizer has the ability to secure the suspended particles in the granular block, therefore reducing the put on hold particles in the fish pond to appropriate degrees.

Tunnel pasteurizers can also be utilized for reusing wastewater. In this situation, a different Tunnel pasteurizer with an activated carbon block as well as byproducts as a purifying step is required. Aside from being helpful site as well as being environment pleasant, Tunnel pasteurizers are also easy to use and also widely available.

Tunnel pasteurizers come in different abilities as well as capacities. Depending on your requirement as well as application, you can choose the appropriate pasteurizer. This will certainly make certain that you get the optimum take advantage of it. The sort of pasteurizer that you get can also depend on the sort of pond you have developed. You can either use a pasteurizer with a light, ultraviolet or warmth lamp to do the task; or you can utilize a pasteurizer that does not require any type of heat, light or ultraviolet lamps.

|