Excessive Sodium Hydroxide Specification Recommendations |

Flexible connections and fittings will cut back vibration stress on fittings, gaskets, and the tank because of pumps and related piping. Poured concrete diking could be an efficient means of secondary containment for bulk NaOH storage. Most supplies aren't fully inert or immune caustic soda liquid to chemical leaching, even when the results are minor. Paints or other forms of sealing liners could be applied to concrete settings which will increase concrete’s resistance to caustic soda.

Carbon steel is acknowledged as typically protected for the dealing with and storing of NaOH, however will chemically assault this gentle metal at elevated temperatures. Caustic soda ought to be saved in containers which might be proof against the chemical’s corrosive nature. Solid alkali can even specific its corrosive nature if there is water, corresponding to water vapor.

Conversely, by making https://en.wikipedia.org/wiki/Sodium_hydroxide of heat power into a dilute sodium hydroxide resolution the water will evaporate so that the solution becomes more concentrated and thus stores the equipped heat as latent chemical vitality. As with other alkaline solutions, it feels slippery with skin contact because of the process of saponification that occurs between NaOH and natural pores and skin oils. If you need help caustic soda pearls 99 msds or would like extra data concerning sodium hydroxide polyethylene tanks or secondary containment options, Protank welcomes you to contact us. We work immediately with the top sodium hydroxide producers within the United States and can work instantly with you for a solution to all of your chemical storage wants. In the meals industry, NaOH is reportedly utilized to chemically wash and peel sure vegetables and fruits.

Common names for sodium hydroxide embody caustic soda, lye, and its chemical formulation NaOH. More out of date and historical names are soda lye, white caustic, and sodium hydrate.

Sodium hydroxide

Storage temperatures for caustic tanks should be beneath a hundred°F for polyethylene tanks and beneath one hundred twenty°F for carbon metal tanks. If these elevated temperatures are required, tank annealing and / or NaOH-resistant corrosion barrier coatings must be thought of to counteract potential tank injury. Sodium hydroxide doesn't naturally form hazardous decomposition products, contribute to hazardous polymerization, nor categorical sensitivity to UV, and is considered a steady chemical.

These reactions are sped by the warmth generated when sodium hydroxide and the opposite chemical elements of the cleaner dissolve in water. Such alkaline drain cleaners and their acidic variations are extremely corrosive and ought to be dealt with with great warning.

- Sodium hydroxide options can freeze at temperatures beneath 60°F (15.5°C), relying upon NaOH focus, which may trigger release and buildup of strong NaOH.

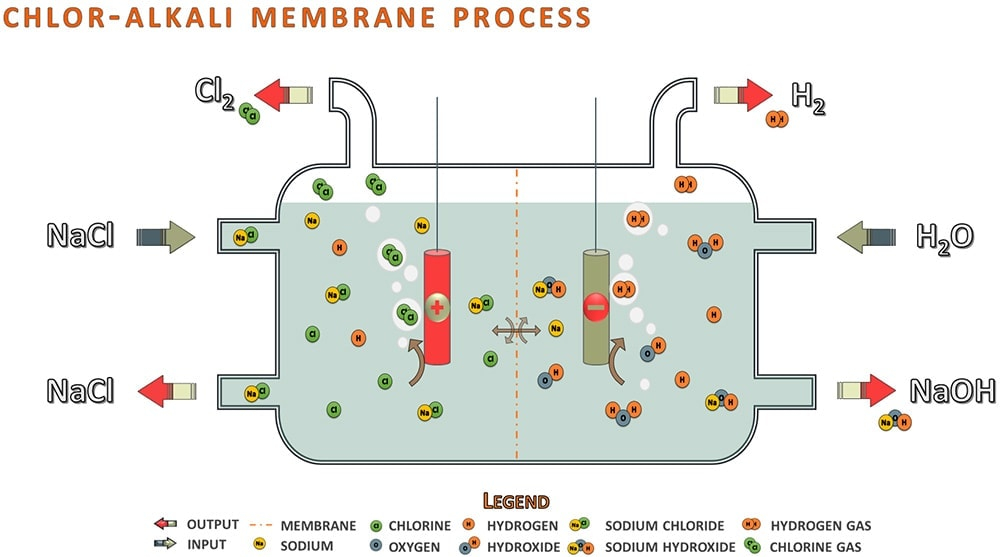

Certain metals must be averted when storing or transporting NaOH. These metals embody aluminum, lead, tin, zinc, and the alloys of zinc such as brass and bronze. Galvanized steel should also be averted because of the presence of zinc in the protecting coating. Sodium hydroxide will chemically attack these metals, releasing them into the solution where the excessive pH and presence of water results in the era of flammable and explosive hydrogen gas.

In bulk, it's most frequently handled as an aqueous resolution, since solutions are cheaper and easier to handle. Historically, sodium hydroxide was produced by treating sodium carbonate with calcium hydroxide in a metathesis response. (Sodium hydroxide is soluble while calcium carbonate just isn't.) This course of was known as causticizing. In 2004, world manufacturing was estimated at 60 million dry tonnes of sodium hydroxide, and demand was estimated at 51 million tonnes. North America and Asia each contributed round 14 million tonnes, whereas Europe produced around 10 million tonnes.

You Can Use Our Caustic Soda in Countless Ways

/ishtarcompany.com/caustic-soda-flakes/">sodium hydro xide specification"/>

/ishtarcompany.com/caustic-soda-flakes/">sodium hydro xide specification"/>As the solution temperatures fall and close to the freezing point, NaOH can start to crystallize (precipitate) out of resolution, which can trigger buildup of the solid within storage containers, pumps, or piping. Precipitation occurs when a chemical factor dissolved in resolution comes out of resolution caustic soda suppliers in UAE to its strong state. This is due to conducive environmental circumstances such as temperature, strain, answer concentration, and other chemical substances present within the solution.

| Комментировать | « Пред. запись — К дневнику — След. запись » | Страницы: [1] [Новые] |