Which Elements Sector Must Think About During The Tunnel Pasteurization Process |

Article by-Ashley Andersen

For your laboratory or other service procedures, Tunnel pasteurization is a method that can be used. This technique utilizes a heat-treating option sterilized at extremely heats. This pasteurized solution cools to really low temperature levels and after that is launched into the procedure. This cooling process additionally seals the nutrients that are in the item that you are refining. There are a number of factors that this pasteurized product is used in the pharmaceutical market, yet there are a number of reasons that this can be beneficial to your organization too.

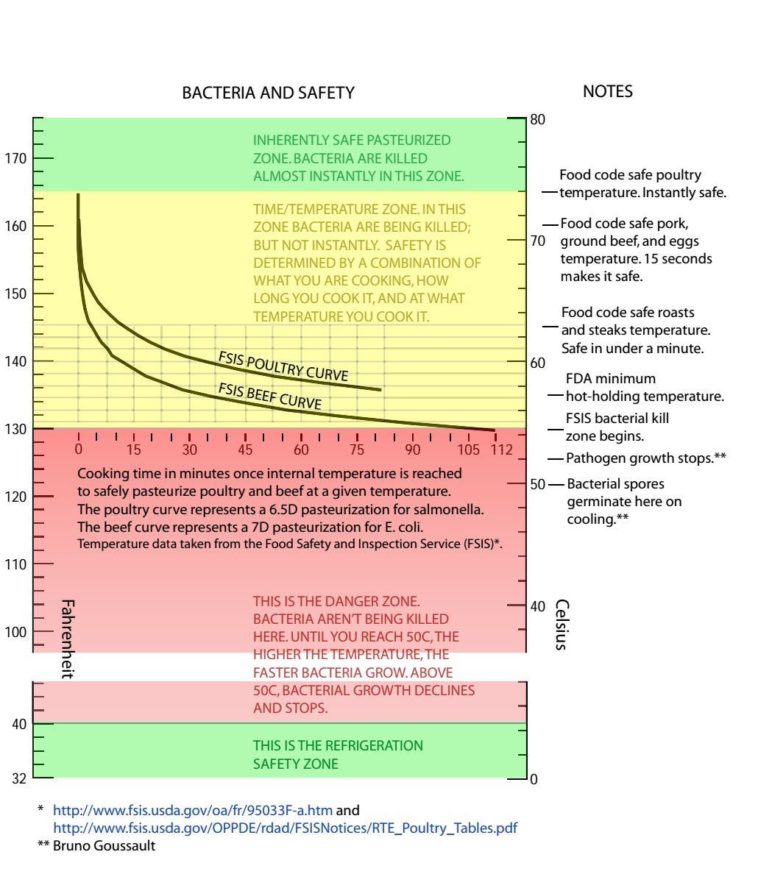

The Tunnel pasteurization procedure shields your microorganisms from having way too much heat. It likewise maintains the product at the proper temperature level so the bacteria do not go off. It additionally creates a controlled atmosphere, so the bacteria do not overheat and also die. Their outstanding attributes ensure they will offer you with premium quality items with just the correct amount of heat for your procedure. All of these characteristics can aid your procedure run smoothly. These traits additionally aid your product has excellent taste.

The Tunnel pasteurization process also ensures that the product has actually been flash frozen at its maximum temperature. https://www.anchoragepress.com/weed/hashade-partia...a7-11e9-b532-7f9b3b973953.html is very important, because the flash sterilized product needs to have the capability to maintain its framework and keep its integrity while it gets on ice. The item needs to be sterilized and have a confirmed sterility indication on its container so you can verify that it is clean and sterile and have a confirmed and also validated flash freeze temperature. If your item has not been flash frozen after that you will certainly need to execute a second vacuum cleaner process with a vacuum cleaner flapper to confirm that the item is sterile as well as additionally have a qualified and confirmed flash freeze temperature level.

simply click the up coming article to consider in Tunnel pasteurization processes include carbonation retention and head room. This originates from the Sterilizing Beverages short article on the site. There are 3 essential factors to consider in regards to carbonation retention. First, carbonation retention will determine if carbonated drinks can be pasteurized. Second, it will certainly identify if carbonated beverages need an ice bath.

You will certainly also need to consider the head area. This comes from the Sterilizing Drinks short article on the website. In order for you to guarantee the pasteurized beverage has enough head area, you will have to utilize a home heating source.

A good way to create a sterilized item is with carbonation suspension. The components will be combined with the ideal water to develop a suspension. It will then be heated up and also fermented at a low temperature level. The longer the combination is allowed to ferment, the larger quantity of carbon dioxide will certainly be produced. The quantity of carbonation in the mix is referred to as its "completely dry weight." Dry weight refers to how many microbes exist in one gram of the item.

Tunnel pasteurizers allow the end customer to take pleasure in the flavor of their beverages while being shielded from the unsafe impacts of microorganisms. Most people do not wish to consume an item that contains microbes. However, the majority of people additionally do not desire the preference of their microorganisms-laced drink to go away. The existence of pathogenic microorganisms in the majority of beers can leave an unpleasant aftertaste in customers' mouths. The Tunnel pasteurization procedure enables these unwanted microbes to be eliminated from the product, so that consumers can continue to enjoy the flavor of their beer.

Depending upon the sort of beer being made and also the product packaging being made use of, different temperature levels will have to be maintained during the developing procedure or the bottling process. The temperature level must be in between 60 and also 100 levels Fahrenheit. This temperature level is optimum for killing off the live and dead microbes in the beer pasteurizer. Beer brewing sets are readily available to aid ensure that this process occurs perfectly. Beer fanatics should invest in a top quality system to make sure the best beer feasible.

| Комментировать | « Пред. запись — К дневнику — След. запись » | Страницы: [1] [Новые] |