Everything You Required To Learn About Tunnel Pasteurizers: Functionality And Importance |

Personnel Author-Ochoa Hendriksen

Tunnel pasteurizers assist lengthen beer rack stability and maintain flavors standing out without the aid of chemicals. They do this while eliminating virus and inactivating yeast and molds.

https://bisouv.com/uncategorized/1785572/non-therm...growth-after-covid19-pandemic/ bottled item, either bottles or containers, goes into the Tunnel and goes through a preheating section where it obtains sprayed with hot water. From there, it's gradually offered the desired pasteurization temperature and then cooled.

How They Function

Tunnel pasteurizers utilize a conveyor system to move items through a temperature-controlled Tunnel. As the beer canisters and containers relocate with the Tunnel, they are continually sprayed with warm water, which progressively raises their temperature levels until they reach the wanted pasteurization level. Then, https://www.packagingdigest.com/packaging-design/s...velopments-foods-and-beverages are held at that temperature level for a collection amount of time and then cooled once again.

After the pasteurization procedure is full, the beer canisters and bottles are transferred to a cooling Tunnel where their temperatures are reduced incrementally until they reach area temperature once again. This is done to avoid the drinks from experiencing an abrupt cool shock, which might change their flavor accounts.

While Tunnel pasteurizers can be utilized by both big and small breweries, it is essential that the right one is picked for your brewery. It's best to select a system designed and developed by relied on, experienced sector specialists. This will guarantee that your system can take care of the details temperature levels and timing needed for carbonated beverages while additionally pairing up with your assembly line's flow.

Why They're Necessary

Tunnel pasteurizers provide a reliable remedy to expanding life span without endangering item quality. While flash pasteurizers can just target the liquid inside the bundle, Tunnel machines heat both the container and the components - implying they can extend a beer's shelf security without influencing its complex jump notes.

Additionally, tunnels are terrific for soft drinks too - no require to fret about the heat ruining those fizzy bubbles. Specifically for craft breweries, Tunnel pasteurization is an indispensable tool to guarantee their products' resilient shelf stability-- all without endangering the mouth watering taste that consumers like.

Besides being effective, Tunnel pasteurizers are additionally adaptable and customizable. Temperatures in the different zones can be maximized to reduce energy usage and keep optimal pasteurization degrees. This is attained by readjusting the heating & cooling temperatures to match the requirements of the details drink being dealt with (2 ). In addition, the spraying nozzles can also be personalized to fit the bottle size and arrangement.

What You Required to Know

Simply put, Tunnel pasteurizers are a valuable device for breweries and other beverage manufacturers seeking to extend their beverages' service life. They can be used to exterminate any kind of virus or bacteria in the liquid and its product packaging. This will assist to prevent the drinks from spoiling or deteriorating before they get to consumers.

A tunnel pasteurizer is a machine that takes the already-bottled product and passes it through several temperature level zones with increasing warmth, until it gets to the desired pasteurization temperature level. Then it is cooled down.

The heating and cooling of the containers in a tunnel pasteurizer is accomplished making use of a series of spray nozzles. The specific positioning of these nozzles optimizes the effect and lessens the mixing of water in between different zones. They are additionally optimized to lower energy usage. In addition, they're safe for carbonated beverages - so they can safeguard your carbonated beers from over-carbonation and guarantee their durability. This is particularly essential for craft breweries and other beverage manufacturers that wish to maintain their consumers satisfied.

The Final Words

Tunnel pasteurizers are a large piece of machinery which contains an encased conveyor belt system where the bottles or containers move through zones that each have a details temperature and dwell time. As soon as the items are sprayed or immersed in hot water and held at that temperature level for the ideal quantity of time, they're after that promptly cooled and permitted to make their escape of the machine.

Tunnel pasteurization is a fantastic means to extend the life span of your beer and help avoid hazardous pollutants from spoiling your beverage. Nevertheless, due to the fact that it warms up the liquid as long, a lot of the features that give your beers their tasty flavor and scent can also obtain damaged while doing so.

One option to Tunnel pasteurization is flash pasteurization, which warms the beer for a shorter period of time and aids protect those specialized active ingredients you worked so tough to source for your beers. While flash pasteurization does cost even more in advance, it can save you money in the long run by avoiding pricey food and beverage recalls.

Every Little Thing You Require To Understand About Tunnel Pasteurizers: Their Capability And The Reasons Why They Are Important |

Article Author-Foster Myers

Tunnel pasteurizers help lengthen beer shelf stability and maintain flavors popping without the help of chemicals. They do this while killing pathogens and suspending yeast and molds.

The bottled item, either containers or containers, enters the Tunnel and undergoes a pre-heating area where it obtains sprayed with hot water. From there, it's slowly given the desired pasteurization temperature level and then cooled.

Exactly how They Work

Tunnel pasteurizers utilize a conveyor system to move items via a temperature-controlled Tunnel. As the beer canisters and bottles relocate via the Tunnel, they are continually sprayed with hot water, which slowly increases their temperature levels up until they reach the desired pasteurization level. Then, the containers are held at that temperature level for a collection quantity of time and after that cooled down again.

After the pasteurization process is complete, the beer canisters and containers are relocated to an air conditioning Tunnel where their temperature levels are lowered incrementally till they get to space temperature level again. This is done to prevent the drinks from experiencing a sudden cool shock, which can modify their flavor profiles.

While Tunnel pasteurizers can be used by both huge and tiny breweries, it is essential that the best one is picked for your brewery. It's ideal to pick a system designed and developed by relied on, experienced sector specialists. This will guarantee that your system can take care of the certain temperature degrees and timing needed for carbonated beverages while additionally matching up with your production line's circulation.

Why They're Essential

Tunnel pasteurizers provide an efficient remedy to extending life span without endangering product quality. While flash pasteurizers can only target the liquid inside the package, Tunnel devices heat both the container and the components - indicating they can expand a beer's shelf security without affecting its intricate hop notes.

In addition, tunnels are excellent for soft drinks as well - no need to fret about the high temperature ruining those fizzy bubbles. Specifically for craft breweries, Tunnel pasteurization is an essential tool to guarantee their products' resilient shelf stability-- all without threatening the mouth watering taste that customers enjoy.

Besides being https://www.dairyreporter.com/Article/2017/06/07/T...tes-on-pasteurized-milk-flavor , Tunnel pasteurizers are also adaptable and customizable. Temperatures in the different zones can be maximized to minimize power usage and maintain optimum pasteurization levels. This is achieved by changing the heating and cooling temperatures to match the requirements of the certain drink being treated (2 ). In addition, the spraying nozzles can likewise be tailored to fit the bottle dimension and setup.

What You Need to Know

Simply put, Tunnel pasteurizers are a valuable tool for breweries and various other beverage manufacturers aiming to extend their beverages' shelf life. They can be made use of to kill off any type of virus or microbes in the liquid and its packaging. This will certainly help to avoid the drinks from ruining or deteriorating prior to they reach consumers.

A tunnel pasteurizer is a maker that takes the already-bottled product and passes it via numerous temperature level areas with raising warmth, till it gets to the preferred pasteurization temperature level. Then it is cooled.

The heating & cooling of the containers in a passage pasteurizer is executed making use of a collection of spray nozzles. The accurate positioning of these nozzles maximizes the effect and minimizes the mixing of water in between various areas. mouse click the up coming website are likewise enhanced to minimize power consumption. In addition, they're safe for carbonated beverages - so they can shield your carbonated beers from over-carbonation and ensure their long life. This is particularly vital for craft breweries and various other drink manufacturers that want to keep their consumers happy.

The Final Words

Tunnel pasteurizers are a large piece of machinery that contains an encased conveyor belt system where the bottles or containers move via zones that each have a certain temperature and dwell time. Once the products are splashed or immersed in hot water and held at that temperature for the appropriate quantity of time, they're then promptly cooled down and permitted to make their way out of the machine.

Tunnel pasteurization is a great method to expand the shelf life of your beer and aid protect against hazardous pollutants from ruining your drink. Nevertheless, due to the fact that it warms up the fluid as long, most of the qualities that offer your beers their delicious taste and aroma can additionally obtain damaged at the same time.

One choice to Tunnel pasteurization is flash pasteurization, which warms the beer for a much shorter time period and helps preserve those specialty active ingredients you functioned so hard to resource for your beers. While flash pasteurization does set you back even more ahead of time, it can save you money over time by protecting against expensive food and beverage recalls.

Every Little Thing You Required To Find Out About Tunnel Pasteurizers: Functionality And Importance |

Uploaded By-Davidson Myers

Tunnel pasteurizers assist lengthen beer shelf stability and maintain flavors standing out without the help of chemicals. They do this while killing pathogens and suspending yeast and molds.

The bottled item, either bottles or cans, gets in the Tunnel and goes through a preheating area where it gets splashed with hot water. From there, it's gradually given the desired pasteurization temperature and then cooled down.

Just how They Function

Tunnel pasteurizers utilize a conveyor system to move products via a temperature-controlled Tunnel. As the beer canisters and containers relocate via the Tunnel, they are continually splashed with warm water, which slowly raises their temperature levels until they reach the wanted pasteurization level. After that, the containers are held at that temperature level for a set amount of time and after that cooled off once again.

After the pasteurization process is full, the beer containers and bottles are transferred to a cooling Tunnel where their temperature levels are reduced incrementally till they get to room temperature level once again. This is done to prevent the drinks from experiencing a sudden cool shock, which could alter their taste profiles.

While Tunnel pasteurizers can be made use of by both large and tiny breweries, it is essential that the best one is chosen for your brewery. It's ideal to choose a system created and developed by trusted, experienced industry specialists. This will make certain that your system can manage the details temperature degrees and timing needed for carbonated beverages while additionally comparing with your assembly line's flow.

Why They're Necessary

Tunnel pasteurizers supply an effective service to prolonging shelf life without compromising product top quality. While flash pasteurizers can only target the liquid inside the package, Tunnel equipments heat both the container and the materials - implying they can expand a beer's shelf stability without affecting its complicated jump notes.

Moreover, tunnels are great for carbonated drinks also - no require to stress over the heat damaging those fizzy bubbles. Especially for craft breweries, Tunnel pasteurization is a crucial device to ensure their items' durable shelf stability-- all without threatening the mouth watering preference that customers enjoy.

Besides being effective, Tunnel pasteurizers are likewise flexible and personalized. Temperature levels in the various areas can be enhanced to lower energy intake and keep optimum pasteurization levels. This is attained by readjusting the heating & cooling temperatures to match the needs of the certain beverage being treated (2 ). Additionally, the spraying nozzles can also be customized to fit the bottle size and setup.

What You Required to Know

Simply put, Tunnel pasteurizers are a beneficial device for breweries and various other beverage producers seeking to expand their drinks' life span. They can be utilized to kill off any type of pathogens or microbes in the fluid and its product packaging. This will certainly help to prevent the drinks from spoiling or deteriorating prior to they get to consumers.

A passage pasteurizer is an equipment that takes the already-bottled product and passes it with several temperature zones with raising heat, up until it reaches the wanted pasteurization temperature. Then it is cooled down.

The cooling and heating of the containers in a passage pasteurizer is performed utilizing a collection of spray nozzles. https://www.newfoodmagazine.com/article/100417/mil...ping-into-our-breakfast-bowls/ of these nozzles optimizes the impact and lessens the blending of water in between different zones. They are likewise enhanced to lower energy usage. In addition, they're safe for carbonated beverages - so they can shield your carbonated beers from over-carbonation and guarantee their durability. This is particularly crucial for craft breweries and other drink producers that intend to maintain their clients pleased.

The Final Words

Tunnel pasteurizers are a large piece of machinery that contains an enclosed conveyor belt system where the bottles or cans relocate through areas that each have a details temperature level and dwell time. Once the products are sprayed or submersed in hot water and held at that temperature level for the proper amount of time, they're after that swiftly cooled and permitted to make their escape of the equipment.

Tunnel pasteurization is a fantastic means to expand the life span of your beer and aid stop unsafe pollutants from spoiling your drink. Nonetheless, because it warms up the fluid as long, a lot of the characteristics that offer your beers their scrumptious flavor and fragrance can also get destroyed while doing so.

One option to Tunnel pasteurization is flash pasteurization, which heats up the beer for a much shorter amount of time and assists maintain those specialized components you functioned so hard to source for your beers. While flash pasteurization does cost more upfront, it can save you money in the future by avoiding costly food and drink recalls.

Boosting Efficiency: Maximizing Your Assembly Line With Tunnel Pasteurizers |

Web Content Writer-Greer Vick

Tunnel pasteurizers are large industrial-scale makers that heat and trendy beverages in order to eliminate microbes and expand their service life. Their performance depends on accuracy control.

Numerous beverage firms have retrofitted their existing Tunnel pasteurizers with new eco-friendly innovations to attain significant ecological benefits. These consist of decreased power usage, lower water usage and decreased greenhouse gas exhausts.

1. Boosted Performance

When you run a brewery, your goal isn't simply to get rid of dangerous pathogens, however additionally to provide uniformity in your products. A well-executed pasteurization procedure not just extends beer's service life, however it makes sure that every container of your beer will certainly taste the same, from your very first set to your last. This is specifically important for craft breweries wanting to bring in health-conscious clients that desire the carbonated goodness of carbonated drinks.

Tunnel pasteurizers function by bringing containers and canisters up to their preferred temperature level in phases, holding them there for enough time to exterminate the microorganisms that cause perishing. They after that bring them down once more in step-by-step steps up until they get to area temperature level, protecting taste profiles. By doing mouse click the up coming article , they not only stop bacteria from multiplying in the product, yet they also decrease energy usage by eliminating warm loss. These are the type of performance gains that can build up promptly.

2. Lowered Waste

As even more emphasis is positioned on environment-friendly manufacturing methods, beverage producers are searching for means to lower their waste production. Tunnel pasteurizers do an excellent work of this, especially when they are developed and built by skilled experts.

Tunnel pasteurizers make use of a series of sprays to heat up the bottles or containers as they move via the machine. This gets rid of the need for a large vapor tank that consumes energy and wastes water. Additionally, Tunnel pasteurizers utilize a water savings system to reuse the warm water utilized in the heating procedure, which minimizes water and sewer use.

Another advantage of Tunnel pasteurization is its compatibility with soft drinks, which is a large selling point for craft makers that wish to expand their products' service life and guarantee uniformity between batches. Unlike flash pasteurizers, which often fight with high levels of carbonation, Tunnel units can handle these effervescent mixtures without breaking a sweat (or a container).

3. Better Product High Quality

When your drinks are correctly treated in Tunnel pasteurizers, they're shielded from unsafe germs while protecting their flavor accounts. This indicates your mixtures, sodas, acid maintains (like fruits or acids), and health and wellness shots can expand their shelf life without losing their trademark preference.

In order to achieve this, passages include precise temperature control and even circulation throughout their numerous stages. In addition, conveyor belt speeds assist ensure equivalent treatment times for each container going into the maker. All this assists you guarantee high quality outcomes every single time.

Ultimately, tunnels are compatible with carbonated beverages, a growing pattern amongst health-conscious customers looking for carbonated alternatives to sweet soft drinks. Unlike https://www.qualityassurancemag.com/article/new-ne...pasteurizes-nuts-seeds-grains/ , which can struggle with high-carbonation degrees, Tunnel machines are made to handle them.

In addition, retrofitting tunnels with energy recovery systems reduces water use too. By using the retrieved water for air conditioning, you'll dramatically cut your power consumption and greenhouse gas emissions.

4. Reduced Energy Intake

Tunnel pasteurizers are energy-intensive machines, however you can minimize your energy usage by retrofitting them with cutting-edge green innovation. This includes solar-powered heating elements that can work on renewable energy resources, minimizing dependence on nonrenewable fuel sources and your carbon footprint.

Another wonderful function of Tunnel pasteurizers is that they are compatible with carbonated beverages, a popular trend among today's health-conscious customers. Unlike flash pasteurizers, which often fight with high-carbonation levels, Tunnel systems can manage these carbonated concoctions easily.

"BREWING UP THE PERFECT HOLIDAY: TOP BEER GIFTS FOR THE SEASON"

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) December 5, 2023

Article Release for Brewmasters and Beverage Makers, sponsored by PRO Engineering / Manufacturing Inc.

Click for the full article: https://t.co/Z3vUL8dCpU

PRO Engineering / Manufacturing Inc.

414-362-1500

zPasteurAIzer can monitor the effectiveness of your current Tunnel pasteurizer by approximating the accumulated item high quality (PU) value for every set. This allows you to figure out if your existing temperature control system is supplying enough warm treatment along with identifying any kind of curved spray heads. You can then adjust the maker settings based upon your favored PU values, increasing manufacturing effectiveness while decreasing power usage. This is a wonderful method to cut down your water consumption too, aligning your service with consumer demand for ecologically liable products.

Vital Details For Buying Skid Steer Tools: A Comprehensive Guide |

Author-McFadden Noer

Are you tired of looking for the excellent skid steer devices? Look no further!

In 'The Ultimate Skid Steer Tools Buying Guide: What You Need to Know,' we have actually put together all the important details you need to make an educated acquisition. Whether you're an experienced specialist or just beginning, this guide will walk you via the process detailed.

Discover the different types of skid guide add-ons available and learn about the elements to consider when it pertains to dimension and ability. With our specialist tips, you can confidently make the ideal choice for your demands.

Bid farewell to uncertainty and hey there to a successful purchase with this comprehensive overview.

## Types of Skid Steer Attachments

When considering purchasing skid steer equipment, it's important for you to comprehend the various kinds of accessories readily available.

With a large range of accessories created to deal with different jobs, knowing which ones appropriate for your demands is vital.

One preferred accessory is the pail, which is ideal for moving products like dust, crushed rock, and sand.

If you need to clear snow, a snow blade or snow blower attachment would be excellent.

For building jobs, a trencher add-on can help you dig trenches promptly and successfully.

If you're working on demolition or land clearing, a grapple accessory serves for getting and moving debris.

Various other usual accessories include augers, pallet forks, and brush cutters.

Comprehending these various alternatives will aid you make an educated choice when choosing skid guide tools.

## Factors to Take Into Consideration for Dimension and Capability

When getting skid steer devices, there are several factors that you need to take into consideration for size and capacity. Initially, consider the dimensions of the equipment and exactly how it will certainly match your work area. Take into consideration the elevation, width, and length of the skid guide devices to ensure it can navigate quickly in tight areas or through slim entrances.

Next off, take into consideration the capacity of the skid steer equipment. Think of the weight that the equipment will certainly need to raise or bring. It is very important to pick a skid steer with the ideal training capability for your certain needs. Remember that a larger capability generally implies a larger and a lot more effective maker.

## Tips for Making the Right Purchase Decision

To make the best purchase choice for your skid guide equipment, consider the certain requirements and spending plan you want. Here are some pointers to help you make the most effective selection:

- Research various brand names and designs: Look for respectable makers with a performance history of creating dependable tools. Compare features, requirements, and customer evaluations to locate the most effective fit for your needs.

- Consider simply click the next site : Think about the jobs you need the skid steer to carry out. Will you be using it for light-duty or durable job? Ensure the tools you pick can manage the demands of your work.

- Examine your budget: Identify just how much you want to spend and discover equipment that drops within your cost array. Bear in mind to consider long-term costs like repair and maintenance.

## Final thought

So there you have it, the supreme skid guide devices buying guide. Now that you understand all the types of add-ons, aspects to consider, and ideas for making the right purchase choice, you can confidently navigate the marketplace.

Just bear in mind, although skid guide tools is supposed to make your life simpler, the irony is that selecting the ideal one can be rather the obstacle. But with this guide, you're one action better to locating the best fit.

Satisfied buying!

|

Метки: Skid Steer Skid Steer Attachments Skid Steer Tree Puller Skid Steer Tree Spade Loader Attachments Tractor Attachments |

Avoid These 5 Common Errors When It Involves Maintaining Skid Guide Equipment |

Material Created By-Raun Holmgaard

So, you've obtained a dependable skid guide devices, huh? Well, let me tell you, my friend, it's not all fun and video games. If you desire that bad boy to maintain running efficiently, you much better avoid these five typical upkeep errors.

To begin with, do not also think about neglecting regular examinations. I suggest, that requires to look for potential issues when everything seems great, ideal? Wrong!

And do not even obtain me started on forgeting fluid maintenance. Your skid guide may simply choose to take an early retirement if you don't provide it the proper liquids it needs.

Oh, and proper lubrication? Yeah, that's not optional either.

So, distort up and get Highly recommended Webpage to learn more about these upkeep blunders you better stay away from.

Neglecting Normal Examinations

Do not neglect routine assessments of your skid steer devices. It might appear like an unnecessary problem, yet routine evaluations are crucial for the appropriate performance and durability of your equipment.

By conducting regular assessments, you can catch any type of prospective issues beforehand and prevent expensive repair services or break downs in the future. During these assessments, make certain to inspect the hydraulic system, engine, tires, and other vital parts. Seek any kind of signs of wear, leakages, or damage.

It's additionally important to inspect the safety attributes and ensure they remain in good working condition. By taking the time to examine your skid steer devices routinely, you can avoid unanticipated downtime and maintain your equipment running efficiently for years to find.

Overlooking Fluid Maintenance

Frequently check and keep the fluids in your skid steer tools to make certain optimal efficiency and avoid costly damages. Fluids play an essential duty in the smooth procedure of your devices, and disregarding their maintenance can result in serious effects.

Most importantly, consistently inspect the hydraulic fluid levels to ensure they're within the advised range. Reduced hydraulic fluid levels can result in poor efficiency and damages to the hydraulic system.

Additionally, do not forget to examine the engine oil consistently. Dirty or low engine oil can cause extreme damage on the engine, bring about minimized performance and potential break downs.

Finally, do not ignore the value of inspecting the coolant degrees and top quality. Proper coolant levels and quality are essential for protecting against getting too hot and keeping the general health of your skid guide tools.

Disregarding Appropriate Lubrication

To make certain optimum efficiency and stop expensive damage, it is essential to continually lubricate your skid guide tools.

Ignoring appropriate lubrication can result in raised wear and tear on vital parts, reduced performance, and even tools failure.

Without regular lubrication, the relocating parts of your skid steer equipment can become dry and start to grind against each other, triggering friction and heat build-up. This can result in increased wear and prospective failures.

By overlooking to oil your devices, you take the chance of expensive repairs and downtime.

To avoid these concerns, see to it to comply with the producer's suggestions for lubrication intervals and utilize the appropriate lubricants for every element.

Constant lubrication will extend the life expectancy of your skid guide equipment and maintain it running smoothly for many years ahead.

Ignoring Filter Replacement

Change the filters regularly to ensure optimum performance and avoid expensive damage to your skid steer devices. Ignoring filter substitute can cause clogged filters, which can limit the circulation of air, gas, and hydraulic fluid. This can lead to reduced engine power, poor fuel effectiveness, and also engine failure.

Clogged filters can likewise cause contaminants to bypass the filter and go into the system, leading to early wear and damages to vital elements. It is essential to comply with the producer's suggestions for filter replacement periods and utilize high-grade filters that are created for your particular devices.

On a regular basis checking and changing filters will aid keep the effectiveness and durability of your skid guide tools, saving you money and time over time.

Failing to Address Deterioration

Addressing deterioration on your skid steer devices is important to keeping its efficiency and staying clear of pricey repairs. Overlooking to deal with deterioration can lead to increased downtime and lowered performance.

It's important to routinely evaluate your equipment for indicators of wear, such as worn tires, harmed hydraulic hoses, or damaged bucket teeth. These concerns may seem minor initially, however if left unaddressed, they can quickly rise right into major problems that call for expensive repair work.

By resolving deterioration immediately, you can extend the lifespan of your tools and make sure that it remains to operate at its finest. Normal upkeep, including lubricating moving parts and changing worn-out components, is essential to keep your skid guide tools running smoothly and efficiently.

Don't neglect the indications of damage-- act to avoid costly fixings and keep your skid guide tools in optimum problem.

Conclusion

Don't let these usual maintenance blunders hinder your skid guide equipment!

Overlooking normal evaluations, fluid maintenance, proper lubrication, filter replacement, and resolving deterioration can bring about pricey repair work and downtime.

By putting in the time to properly preserve your tools, you can ensure its durability and optimize its performance.

So, do not wait up until it's far too late, make upkeep a priority and keep your skid steer equipment running efficiently.

|

Метки: Skid Steer Skid Steer Attachments Skid Steer Tree Puller Skid Steer Tree Spade Loader Attachments Tractor Attachments |

This Post Discusses The Tunnel Pasteurizers For Beer And Beverage Makers |

please click the following internet site created by-Andersson Caspersen

If you're a beer or drink maker, carrying out Tunnel pasteurization into your assembly line could be one of the very best means to make sure product safety. Nonetheless, it is very important to obtain the procedure done right.

Tunnel pasteurizers take bottled or canned products as well as spray them with warm water as they take a trip through the Tunnel. They after that hold the container at particular temperature level degrees to kill microorganisms.

Batch Pasteurizers

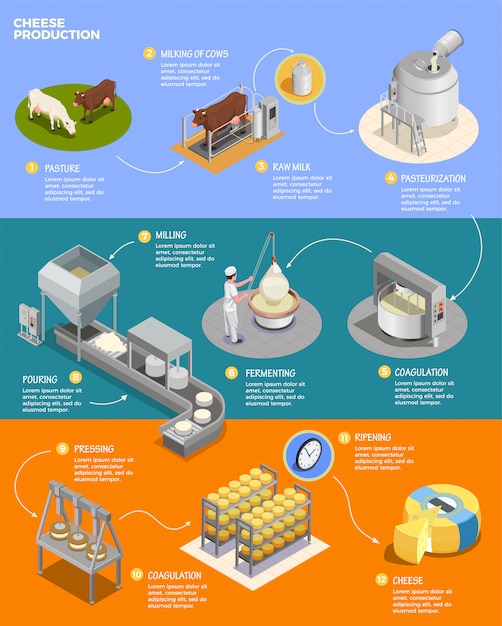

Pasteurization is a process for home heating and also holding drinks at temperatures of 140 levels Fahrenheit or less. It assists protect the product versus damaging microbes and extends the shelf-life of beverages and also other items.

Generally, non-dairy beverages are warm dealt with by running them through a tunnel and splashing warm water on them. They are after that cooled off once again after they've ended up the procedure.

Beer as well as drink manufacturers use this approach to heat their products, but it can also be utilized for a variety of other types of beverages and also food. It's coming to be a popular option for beer and various other non-dairy beverage manufacturers because it can rapidly and also efficiently warm and also cool down the drink.

The most effective means to get one of the most out of a passage pasteurizer is to make sure you have lots of water available for it. Recommended Studying implies transforming the water out regularly so that it doesn't have time to rest in between uses and also be a breeding ground for microbes.

Constant Pasteurizers

Direct heavy steam injection (DSI) pasteurizers are utilized for a variety of food and also beverage products, including dairy products, meat, egg, fruit juice, dietary beverages, infant formula, condiments, as well as salad dressings. These systems can be made use of together with a clean-in-place (CIP) system to guarantee hygienic processing conditions.

These systems make use of sanitary plate warm exchangers to raise the temperature of items. This heating phase is adhered to by a quick cooling stage.

DSI systems likewise have high regrowth effectiveness, which conserves energy and also helps reduce production prices. They are a good option for beer and beverage manufacturers that call for huge ability production.

When installing any devices or pipelines in the HTST pasteurizer system, it is important to completely analyze their effect on the total processing procedure as well as the security of the product. On top of that, a circulation schematic needs to be kept as well as upgraded whenever any kind of adjustments are made.

Compact Pasteurizers

When you're making beer and beverage products that need to be packaged, pasteurizing them is necessary. This prevents preference destruction as well as expands service life.

There are several means to pasteurize your beer as well as drink. Several of one of the most typical are vat pasteurization and HTST (heat short time) or flash pasteurization.

GEA offers various technical options to satisfy your pasteurization requires. These array from HTST, straight side indirect home heating and ultra heat procedure.

The PRO Huge Collection Tunnel Pasteurizers are a wonderful alternative for tiny to mid-tier craft brewers and also various other drinks that require an economical as well as straightforward huge pasteurizer. These machines supply a variety of features, including an HMI touch screen interface with PLC

Modular Pasteurizers

Whether you're a small or big beer and drink manufacturer, our modular pasteurizers can fit your space and also budget plan. They can be constructed with ability based upon the product, packaging, and temperature called for.

During the pasteurization procedure, a liquid is warmed and also held in the thermal procedure for a specific amount of time to shut off microbes that can affect the taste, aroma, and quality of packaged beverages. This is especially crucial for beer and other soft drinks, as they can come to be infected by microorganisms throughout storage space or shipping.

HTST pasteurization is one of the most typical approach, raising a liquid to at the very least 161deg F for no less than 15 secs and after that rapidly cooling it down. HHST resembles HTST, however it uses a little different equipment and also elevates a liquid to greater temperatures for a much shorter period of time. The procedure can be used for milk, cheese, juices, as well as other food and also beverage items, in addition to specialized different foods as well as marijuana infused edibles.

Tunnel Pasteurizers Are Used To Securely Pasteurize Beverages To Boost Their Shelf Life |

Article created by-Axelsen Purcell

Tunnel Pasteurizers are used to securely as well as efficiently process liquids and also various other products for pasteurization. Tunnel Pasteurizers are constructed from stainless-steel and also have several areas for pasteurization. Each area has its own set of spray nozzles and drip pans to uniformly warm and cool the item being pasteurized.

Tunnel Pasteurizers are comprised of different sections with their own flow pump, collection sump, screen/filter box, as well as water spray system. If any one of these elements fails, the process may be jeopardized and also can result in problems with safety, procedure dependability, bundle quality, and total cost of possession.

Tunnel Pasteurizers have several benefits over flash pasteurization. For one, they are much less difficult than flash pasteurization as well as do not require different processes for different kinds of beverages. Tunnel Pasteurizers are normally utilized in the beer sector, however can likewise be made use of to pasteurize vegetables and fruit products.

Tunnel Pasteurizers are very efficient machines that get rid of microorganisms from food and beverage items. They are available in a range of sizes, and also are used in the food and drink industry to eliminate microbes, stop fermentation, as well as enhance shelf stability. A number of factors contribute to the fragility of these equipments, including significant temperature changes, caustic cleaning chemicals, and enormous mechanical anxieties. Damaging bottles, for instance, can seriously harm the tool. Fortunately, there are https://charlatan.ca/2018/09/science-blog-the-scoop-on-raw-versus-pasteurized-milk/ who comprehend the need to maintain their products as well as can supply reputable service.

A tunnel pasteurizer is an exceptional alternative for those who are looking for a quick, reliable, and also inexpensive choice to blink pasteurization and also sterilized filtration. Tunnel Pasteurizers can be tailored to fit the needs of different business, and are often furnished with automated stop systems to stop overpasteurization. They can likewise be created to fit certain dimension requirements.

Powder Coating - Protect Your Steel Things From Deterioration |

Content by-Guldbrandsen Buus

Whether you want a layer of paint or you want to make a face-lift for your office or home, there are several sort of finishings readily available. Powder Coating is one type of Coating that you might wish to think about. Unlike standard fluid paint, powder Coating can be applied as a free-flowing completely dry powder as well as cured with heat or ultraviolet light.

Electrostatic spray deposition method

Utilizing electrostatic spray deposition to use a powder Coating to a non-metallic part can be a reliable method to secure the underlying material from corrosion. Utilizing the best procedure will allow for an even application as well as a smooth surface.

https://writeablog.net/jong1854shanelle/powder-coa...ly-multi-color-powder-coatings involves a chemical reaction which produces lengthy molecular chains. The molecular chains are very durable and withstand malfunction. The chain reaction additionally creates a smooth finish.

There are two common ways to apply powder Coating. First of all, making use of an electrostatic spray gun. This technique is frequently referred to as dipping.

The other approach is using a fluidised bed. Using this approach includes dipping the part into a fluidized powder. The powder is after that sprayed using a high-powered electrostatic spray gun.

Both approaches are relatively economical as well as offer an even, tough coating. They are likewise much more durable than fluid applications. This is due to the fact that the spray gun utilizes high-voltage to force the powder into the part.

Fluidized bed powder Coating technique

Essentially, the fluidized bed powder Coating method is a procedure in which a part is preheated and then dipped into a fluidized bed of put on hold powder. The powder complies with the part by electrostatic pressures. This procedure is usually used for layers with high leaks in the structure products.

Typical application methods include the dry powder Coating method and also electrostatic spray deposition. These approaches supply numerous advantages over liquid finishes. They are economical and create a thicker Coating. The thickness of the Coating depends on the powder chemistry and also the dwell time.

The powder Coating process utilizes finely ground pigment or polymeric resin to apply a coat. It also utilizes a recovered powder to improve powder Coating transfer performance. It can be applied to a variety of objects.

It can be utilized for Coating steel superstructures. It likewise functions well for Coating small items. It is also useful for Coating components that are vulnerable to deterioration.

Concealing items are applied

Various masking products are made use of in the powder Coating procedure. These products are made to safeguard parts from the application procedure. In addition, these products can be used to mask areas that are not needed to get powder Coating. These locations can be mating surfaces or electric conductivity.

The most typical masking item made use of is high temperature polyester tape. simply click the following article are made to be utilized in the powder Coating procedure as well as are resistant to severe treatment temperatures. These tapes are available in a selection of sizes and shapes. They can be acquired on a roll or pre-cut.

Another usual powder Coating masking product is silicone. This kind of masking product is immune to high temperatures and can be utilized in applications that require hostile chemicals. Additionally, it has an adhesive that is resistant to high temperatures and can be quickly eliminated after high warm processes.

Various other masking items include cork and also paper. Cork can be utilized in reduced temperature completing procedures. However, these products are not as adaptable as silicone or neoprene tapered plugs.

Longevity

Making use of powder Coating on your steel objects allows them to be resistant to corrosion, weather, and chemicals. It also helps them last much longer. Commonly, these finishings will certainly last as much as twenty years.

The resilience of powder Coating is figured out by the kind of material utilized and the application technique. On top of that, the high quality of the surface is likewise a factor. It is very important to ensure that the products are tidy and are in compliance with regional codes.

Powder coated items are normally more immune to rust, chips, as well as scratches. They also resist damage far better than various other treatments.

Powder Coating is a cost effective option for lots of projects. It is available in a variety of colors and appearances. It is also eco-friendly. Compared to fluid paint finishing, powder Coating makes use of much less hazardous waste as well as launches minimal VOCs right into the environment.

Powder Coating is also used to coat many typical household items, including appliances, family pipes, and kitchen area surface areas. It is likewise used on a variety of structure projects. It additionally offers a sturdy finish that can last as much as a decade in good conditions.

|

Метки: Powder Coating Powder Coating Company Powder Coating Services Industrial Powder Coating Powder Coating Metals Commercial Powder Coating Silk Screening |

Below Is A More Detailed Look At What Is Powder Coating? |

Content by-Johannessen Gustafsson

Usually, the term powder Coating refers to a type of Coating that is applied as free-flowing dry powder, after that treated with warm or ultraviolet light. This kind of Coating is various from traditional liquid paint, which is supplied using vaporizing solvents.

Preparation of powder Coating parts

Getting your powder covered parts ready is a procedure. It entails a collection of steps that can vary from easy to clarify. If you intend to see to it that your finished item is ideal, you have to be sure to comply with the appropriate steps.

https://squareblogs.net/velda1980arden/the-advanta...so-downsides-of-powder-coating is to get rid of any type of dust, dust and various other surface pollutants. You can make use of a stress washing machine or just soak the components in clean water.

The next step is to sandblast the surface to get rid of any kind of flaws and provide structure. This is additionally important to guarantee that the powder layer adheres correctly. Sandblasting can be done with a range of abrasive media. Selecting a tidy sandblasting media is essential to guarantee an effective powder coat.

The powder layer procedure entails the application of a polymer mixed with pigments. This is then cured in a treating oven. The process is relatively simple and economical. Relying on the component size, the treating time will certainly vary. The temperature level ought to be established according to the producer's requirements.

One of the most crucial action is the pre-treatment. This is the very best method to ensure that your powder layer is used effectively. It involves getting rid of oil from metal pores, eliminating any type of paint that might be lingering on the surface, and cleansing the surface of dust and grime.

Environmentally friendly option to solvent-laden paints

Utilizing an environmentally friendly alternative to solvent-laden paints is currently a sensible alternative. For a tiny financial investment, you can change harmful paints with eco-friendly ones that are without damaging chemicals.

These paints are not just healthier for the setting, however they can also save you money in the future. They can save you 5 to $11 per cars and truck. They likewise assist you minimize discharges, which implies much less co2 in the air.

One of the very best environmentally friendly alternatives to solvent-laden paints is latex paint. They have a lower VOC content and do not send out a scent like various other paints. They can also be an excellent option for LEED debts.

An additional eco-friendly paint is one that uses steels as pigments. Paints that utilize metals in the pigment can be more secure than chemical pigments.

A number of companies have actually teamed up to make products that are both reduced in VOCs and also high in safety. Among these companies is ECOS Paints. They market a selection of paints, varnishes, and spots. They are made from natural ingredients and also are free of harmful chemicals. They are packaged with naturally degradable product packaging and 100% recycled plastic.

They are likewise certified by the Green Seal program, which restricts the harmful chemicals in their products. An additional alternative is Colorhouse. They have a beautiful choice of shades as well as emphasize sustainability as well as recycling. They also make use of metals as well as unsafe components as minimally as possible. https://www.motorcyclenews.com/new-rider/choosing-...esium-wheels-be-powdercoated-/ are likewise LEED Compliant as well as MPI Extreme Green accredited.

Can be recovered and also recycled

Using powder layers can decrease the ecological effects of using solvents. Powder Coating systems also decrease expenses related to the risk-free disposal of volatile organic substances. Powder layers are utilized in numerous sectors. They are durable and resistant to deterioration and fading. They are additionally available in a wide range of colors, gloss levels, as well as structures.

The powder Coating procedure allows components to be shipped right away after treating. This minimizes the quantity of time that parts invest in stock. It additionally assists to decrease waste.

The most efficient means to recycle powder overspray is by recovering it. Recuperation systems can recover up to 98 percent of the overspray. This is a wonderful way to minimize waste and conserve money.

A powder healing system is comprised of a recovery booth, an enthusiast, as well as filters. The collector will certainly collect overspray from the recuperation booth. It will certainly then be transferred to a feed hopper. Some feed receptacles will vibrate to assist stop powder clumping.

Healing systems will not always return the exact same ratio of base to impact as virgin powder. On top of that, some powder may be shed in the collection filters. Using a cartridge-style filtration system will minimize the quantity of destruction of the powder.

The recovery process can also boost procedural efficiency. For instance, it can enable components to be stacked more detailed with each other on a conveyor. This can also enable even more components to travel through the production line in much less time.

|

Метки: Powder Coating Powder Coating Company Powder Coating Services Industrial Powder Coating Powder Coating Metals Commercial Powder Coating Silk Screening |

Let'S Talks About The Benefits Of Powder Coating In This Article |

Content written by-Funder Ballard

Unlike liquid paint, powder Coating is used as free-flowing completely dry powder and then cured with heat or ultraviolet light. The powder is commonly applied electrostatically.

Pretreatments

Having a pretreatment on an item prior to applying a powder layer is important for several reasons. Other than avoiding rust, it will likewise enhance the long life of the Coating. Getting it right will additionally assist you stay clear of any feasible personal dangers.

The pretreatment procedure starts with cleansing the surface area. Usually, powder coated rims santa clarita is done with a cleansing option splashed onto the substrate. This gets rid of the surface area soils and also dust, consequently enabling the powder layer to stick better.

Other than cleaning, the pretreatment process also consists of preparing the surface area for the powder layer. This consists of adding a phosphate layer, a chemically bound material that helps to reinforce the Coating. The phosphate layer aids avoid oxidation externally. It is additionally a good idea to layer the item with a clear movie to protect it from UV rays.

An additional technique of pretreatment is chemical etching. Unlike the traditional procedure, this process does not call for manual work. It is likewise an affordable approach. The procedure uses chemicals to get rid of surface dust, grease as well as other pollutants.

Sorts of powder Coating cubicles

Whether you're looking for a powder spray paint booth for a big or tiny application, there are numerous various types to pick from. Each type of powder spray booth has advantages and disadvantages.

When determining which sort of powder spray paint cubicle is right for you, you must think about the size and also quantity of parts that you're Coating. This will certainly determine the air circulation needed for your powder containment. Powder spray booths are available in numerous sizes as well as can be either open-faced or closed-faced.

For large devices ending up applications, powder Coating booths are a great remedy. They offer efficient air flow as well as allow for color modifications throughout the process. They likewise offer a clean area for powder Coating, keeping the rest of your shop tidy.

One more benefit of powder spray cubicles is that they have a built-in filtration system. The purification can be built into the floor or walls, relying on your requirements. HEPA filters are usually utilized to record fragments. They also enable exhaust to be routed back right into your shop.

Approaches of application

Depending upon the kind of material that you are Coating, there are various methods of application. These include electrostatic spray deposition, fluidized bed dipping as well as "warm flocking" (electrostatic spray on preheated surfaces).

Electrostatic spray deposition is the most common approach of applying powder Coating to metal. An unique electrostatic gun is made use of to spray the powder onto a based steel surface area. Depending upon the kind of Coating that you are using, you might additionally require a power system as well as a powder spray booth.

Contrasted to conventional paint, powder Coating is much more long lasting and eco-friendly. It is also cost-efficient. It can be used on a selection of surfaces including metal, wood, and plastic.

Fluidized bed powder Coating was patented in 1953 by Edwin Gemmer. It utilizes the exact same fluidising principles as a conventional fluidized bed, but without the need for preheating. It was created to use slim films with uniform fragment dimension.

The powder Coating process additionally supplies advantages to coaters. These consist of expense financial savings as well as marginal driver training. The powder is splashed onto a substratum, which is after that healed. The completed product can have a matte or glossy finish. Relying on the size as well as thickness of the component, a movie can be used in density from 8 to 125 millimeters.

Drawbacks

Whether you're aiming to safeguard your wheels from damages or simply keep them looking new, powder Coating can be a wonderful choice. It's not just inexpensive and also very easy to apply, yet it likewise has a variety of benefits.

look at this site has excellent mechanical homes and a sturdy surface coating. It is likewise highly immune to cracking, damaging, and also fading. click for more info can last as long as 20 years on steels, and also up to one decade on timber.

Powder Coating can be utilized to safeguard several metals and surface areas. It's an economical alternative to repaint, and also it's also less flammable than solvent-based liquid coverings. Nevertheless, powder Coating has its own set of drawbacks.

Powder Coating has issues with shade matching as well as progressing. It can also be hard to retouch locations that have been missed. It's also hard to attain a slim film construct. It additionally has difficulties removing stains.

Powder coated aluminum is less expensive than conventional paint services. It's likewise more resistant to chemicals, UV direct exposure, and dampness.

|

Метки: Powder Coating Powder Coating Company Powder Coating Services Industrial Powder Coating Powder Coating Metals Commercial Powder Coating Silk Screening |

Let'S Discusses The Benefits Of Powder Coating In This Write-Up |

Created by-Yusuf Dugan

Unlike fluid paint, powder Coating is used as free-flowing dry powder and afterwards cured with heat or ultraviolet light. The powder is generally applied electrostatically.

Pretreatments

Having a pretreatment on an item before applying a powder layer is necessary for several reasons. In addition to protecting against corrosion, it will also enhance the durability of the Coating. Getting it right will certainly additionally help you stay clear of any possible individual hazards.

The pretreatment procedure begins with cleaning the surface area. Generally, this is made with a cleansing service splashed onto the substratum. https://karrie5sharie.werite.net/post/2022/11/28/R...e-Advantages-Of-Powder-Coating removes the surface soils and also dust, consequently making it possible for the powder layer to stick better.

In addition to cleaning, the pretreatment process likewise includes preparing the surface for the powder coat. This consists of including a phosphate layer, a chemically adhered compound that helps to reinforce the Coating. The phosphate layer helps stop oxidation on the surface. It is additionally an excellent idea to layer the product with a clear movie to secure it from UV rays.

An additional method of pretreatment is chemical etching. Unlike the standard procedure, this process does not call for manual labor. It is likewise a budget-friendly technique. The process utilizes chemicals to remove surface dust, oil and also various other impurities.

Sorts of powder Coating cubicles

Whether you're searching for a powder spray paint cubicle for a large or tiny application, there are numerous various types to choose from. Each type of powder spray booth has advantages and also downsides.

When deciding which kind of powder spray paint cubicle is right for you, you should take into consideration the dimension and amount of parts that you're Coating. https://www.coatingsworld.com/contents/view_breaki...uction-capacities-for-acematt/ will figure out the air circulation needed for your powder containment. Powder spray booths are offered in various dimensions as well as can be either open-faced or closed-faced.

For huge equipment completing applications, powder Coating cubicles are a fantastic service. They supply efficient air circulation and enable shade adjustments throughout the process. They additionally offer a tidy area for powder Coating, keeping the rest of your store tidy.

An additional benefit of powder spray cubicles is that they have an integrated filtration system. The filtering can be built right into the flooring or wall surfaces, relying on your demands. HEPA filters are typically used to capture bits. They also allow for exhaust to be routed back into your store.

Approaches of application

Depending on the sort of material that you are Coating, there are numerous approaches of application. These include electrostatic spray deposition, fluidized bed dipping as well as "hot flocking" (electrostatic spray on preheated surface areas).

Electrostatic spray deposition is the most usual approach of applying powder Coating to steel. A special electrostatic gun is utilized to spray the powder onto a based steel surface area. Relying on the sort of Coating that you are using, you may additionally need a power device and a powder spray cubicle.

Compared to traditional paint, powder Coating is much more resilient and also eco-friendly. It is additionally affordable. It can be made use of on a variety of surface areas including steel, wood, and plastic.

Fluidized bed powder Coating was patented in 1953 by Edwin Gemmer. It makes use of the very same fluidising principles as a conventional fluidized bed, yet without the need for preheating. It was developed to use slim movies with consistent particle size.

The powder Coating process also offers advantages to coaters. These include price financial savings as well as marginal driver training. The powder is splashed onto a substrate, which is after that cured. The completed product can have a matte or shiny finish. Depending on the dimension and thickness of the part, a movie can be applied in density from 8 to 125 millimeters.

Drawbacks

Whether you're looking to secure your wheels from damage or simply maintain them looking brand-new, powder Coating can be an excellent choice. It's not only budget friendly and very easy to apply, however it also has a range of benefits.

Powder Coating has great mechanical homes and also a resilient surface coating. It is additionally very immune to cracking, scratching, as well as fading. Its coating can last as long as 20 years on steels, and also as much as one decade on timber.

Powder Coating can be made use of to shield many different steels as well as surfaces. It's a cost-efficient alternative to repaint, and also it's also less combustible than solvent-based fluid coatings. Nevertheless, powder Coating has its very own collection of drawbacks.

Powder Coating has problems with color matching and also progressing. It can also be tough to retouch areas that have actually been missed. It's likewise hard to achieve a slim film develop. It additionally has problems getting rid of spots.

Powder coated aluminum is less expensive than standard paint solutions. It's likewise extra resistant to chemicals, UV direct exposure, as well as wetness.

|

Метки: Powder Coating Powder Coating Company Powder Coating Services Industrial Powder Coating Powder Coating Metals Commercial Powder Coating Silk Screening |

Powder Coating - Shield Your Steel Things From Corrosion |

Staff Writer-Guldbrandsen Chandler

Whether you desire a layer of paint or you want to make a makeover for your office or home, there are various kinds of coatings available. Powder Coating is one type of Coating that you might want to think about. Unlike conventional liquid paint, powder Coating can be applied as a free-flowing dry powder and cured with warm or ultraviolet light.

Electrostatic spray deposition approach

Using electrostatic spray deposition to apply a powder Coating to a non-metallic component can be an effective way to protect the underlying product from rust. Making use of the appropriate process will certainly enable an also application and a smooth surface.

https://jenna01boris.bravejournal.net/post/2022/11...so-Downsides-Of-Powder-Coating entails a chain reaction which generates lengthy molecular chains. The molecular chains are really resilient and also withstand failure. The chemical reaction additionally creates a smooth coating.

There are 2 usual means to use powder Coating. First of all, using an electrostatic spray gun. This approach is commonly referred to as dipping.

The various other method is using a fluidised bed. Using this technique involves dipping the part right into a fluidized powder. The powder is after that sprayed using a high-powered electrostatic spray gun.

Both approaches are fairly affordable as well as provide an even, tough surface. They are likewise extra durable than liquid applications. This is because the spray gun uses high-voltage to require the powder into the component.

Fluidized bed powder Coating method

Generally, the fluidized bed powder Coating technique is a procedure in which a part is preheated and then dipped into a fluidized bed of suspended powder. The powder sticks to the part by electrostatic pressures. This process is usually utilized for coverings with high leaks in the structure materials.

Typical application methods consist of the dry powder Coating method as well as electrostatic spray deposition. These techniques supply a number of benefits over fluid finishings. http://merrilee506andres.jigsy.com/entries/general...e-Advantages-Of-Powder-Coating are economical and also produce a thicker Coating. The density of the Coating hinges on the powder chemistry and also the dwell time.

The powder Coating process utilizes carefully ground pigment or polymeric resin to apply a layer. It also uses a redeemed powder to enhance powder Coating transfer performance. It can be applied to a large range of things.

It can be made use of for Coating metal superstructures. It also functions well for Coating tiny items. It is also beneficial for Coating components that are prone to corrosion.

Masking items are used

Numerous masking products are used in the powder Coating process. These items are made to safeguard parts from the application procedure. Additionally, these products can be made use of to mask areas that are not required to obtain powder Coating. These areas can be mating surfaces or electric conductivity.

One of the most usual masking product made use of is high temperature polyester tape. These tapes are created to be made use of in the powder Coating procedure and also are immune to extreme treatment temperature levels. These tapes are offered in a variety of shapes and sizes. They can be bought on a roll or pre-cut.

An additional common powder Coating masking item is silicone. This type of masking material is immune to heats and can be utilized in applications that need aggressive chemicals. On top of that, it has a glue that is resistant to heats and can be easily removed after high warm procedures.

Other masking items consist of cork as well as paper. Cork can be made use of in reduced temperature ending up procedures. However, these materials are not as adaptable as silicone or neoprene tapered plugs.

Sturdiness

Making use of powder Coating on your steel items allows them to be resistant to rust, climate, and also chemicals. It additionally helps them last much longer. Typically, these coverings will certainly last as much as twenty years.

The toughness of powder Coating is established by the type of material made use of and also the application approach. Furthermore, the high quality of the finish is also a factor. It is very important to ensure that the materials are tidy and also remain in conformity with neighborhood codes.

Powder layered items are normally much more resistant to corrosion, chips, and also scratches. They also withstand wear and tear better than various other coverings.

Powder Coating is an economical choice for many jobs. It is available in a wide array of shades and also appearances. silkscreening on powdercoated aluminum is likewise eco-friendly. Contrasted to liquid paint ending up, powder Coating utilizes less hazardous waste and launches marginal VOCs into the ambience.

Powder Coating is likewise utilized to coat many common house things, including appliances, family pipelines, and kitchen surfaces. It is also made use of on a range of building projects. It also supplies a long lasting surface that can last as much as a decade in good conditions.

|

Метки: Powder Coating Powder Coating Company Powder Coating Services Industrial Powder Coating Powder Coating Metals Commercial Powder Coating Silk Screening |

Allow'S Discusses The Benefits Of Powder Coating In This Short Article |

Staff Writer-Husum Refsgaard

Unlike fluid paint, powder Coating is applied as free-flowing completely dry powder and afterwards healed with heat or ultraviolet light. The powder is commonly used electrostatically.

Pretreatments

Having a pretreatment on a product prior to applying a powder layer is necessary for many reasons. Aside from stopping rust, it will certainly likewise increase the long life of the Coating. Getting it right will certainly likewise assist you avoid any type of possible individual hazards.

The pretreatment procedure begins with cleaning up the surface. Generally, this is done with a cleaning option splashed onto the substratum. This gets rid of the surface soils and dust, thus enabling the powder layer to adhere better.

In addition to cleansing, the pretreatment procedure likewise consists of preparing the surface area for the powder layer. This includes including a phosphate layer, a chemically bonded substance that aids to strengthen the Coating. The phosphate layer aids protect against oxidation on the surface. It is likewise an excellent concept to layer the product with a clear film to protect it from UV rays.

One more technique of pretreatment is chemical etching. Unlike the conventional procedure, this procedure does not call for manual labor. It is additionally an economical technique. The process makes use of chemicals to get rid of surface dust, grease and various other pollutants.

Kinds of powder Coating booths

Whether you're seeking a powder spray paint cubicle for a big or little application, there are several various types to select from. Each sort of powder spray cubicle has advantages as well as drawbacks.

When determining which kind of powder spray paint booth is right for you, you have to consider the dimension as well as quantity of parts that you're Coating. This will figure out the air circulation needed for your powder containment. Powder spray booths are readily available in numerous dimensions as well as can be either open-faced or closed-faced.

For big equipment ending up applications, powder Coating booths are a wonderful solution. They offer reliable air flow as well as enable color adjustments throughout the process. They also provide a clean area for powder Coating, maintaining the rest of your store tidy.

An additional benefit of powder spray booths is that they have an integrated filtering system. The filtering can be built right into the flooring or wall surfaces, relying on your needs. HEPA filters are usually utilized to capture particles. They also enable exhaust to be routed back right into your shop.

Techniques of application

Depending upon the sort of product that you are Coating, there are various approaches of application. These include electrostatic spray deposition, fluidized bed dipping as well as "warm gathering" (electrostatic spray on preheated surface areas).

Electrostatic spray deposition is one of the most typical method of using powder Coating to steel. An unique electrostatic gun is made use of to spray the powder onto a based steel surface area. Relying on the sort of Coating that you are using, you might likewise need a power system and also a powder spray booth.

Compared to traditional paint, powder Coating is extra long lasting and environmentally friendly. It is also affordable. It can be utilized on a range of surfaces consisting of metal, timber, as well as plastic.

Fluidized bed powder Coating was patented in 1953 by Edwin Gemmer. It makes use of the same fluidising concepts as a standard fluidized bed, yet without the need for preheating. It was created to apply thin films with consistent particle dimension.

The powder Coating process also uses benefits to coaters. These consist of expense savings and also marginal operator training. The powder is splashed onto a substratum, which is after that healed. The completed item can have a matte or glossy finish. Depending on the dimension as well as thickness of the component, a film can be applied in density from 8 to 125 millimeters.

Drawbacks

Whether you're looking to secure your wheels from damage or simply maintain them looking brand-new, powder Coating can be an excellent alternative. It's not just inexpensive and also easy to use, yet it also has a variety of advantages.

Powder Coating has good mechanical residential or commercial properties as well as a sturdy surface area coating. It is also very immune to damaging, scraping, and also fading. Its coating can last as long as 20 years on metals, as well as up to 10 years on wood.

https://postheaven.net/donny2151andres/powder-coat...se-multi-color-powder-coatings can be utilized to protect several metals and surfaces. It's a cost-effective option to repaint, as well as it's also less flammable than solvent-based liquid coatings. However, powder Coating has its very own set of downsides.

Powder Coating has issues with shade matching and progressing. https://www.pfonline.com/articles/powder-coating-i...ications-what-you-need-to-know can likewise be hard to touch up areas that have actually been missed out on. It's additionally hard to achieve a slim movie develop. It additionally has problems getting rid of stains.

Powder covered light weight aluminum is less costly than conventional paint remedies. It's also more immune to chemicals, UV direct exposure, and moisture.

|

Метки: Powder Coating Powder Coating Company Powder Coating Services Industrial Powder Coating Powder Coating Metals Commercial Powder Coating Silk Screening |

Powder Coating - Just How To Apply Multi-Color Powder Coatings |

Posted by-Foged Copeland

Unlike standard fluid paint, powder Coating is a sort of Coating that is applied as free-flowing dry powder and after that treated by heat or ultraviolet light. It is usually applied electrostatically.

Pretreatment

Relying on your application and product, the pretreatment prior to powder Coating process can be intricate. The procedure will certainly depend on your efficiency objectives and also your end user's specs.

Pretreatment prior to powder Coating is not something that needs to be taken lightly. The process can generate high quality results if done effectively. The best pretreatment will certainly protect against rust and deterioration of your item's surface area.

The best pretreatment will certainly require appropriate training as well as a little knowledge. The best pretreatment will include a variety of procedures, every one of which are developed to enhance the performance of your product. This consists of eliminating impurities from the surface area as well as preparing it for powder application. The pretreatment process may also consist of conditioning, sealing and also washing.

A great pretreatment will permit you to attain a consistent finish coat. This is specifically essential for outdoor applications. The right pretreatment will certainly protect your product from UV rays and also protect against deterioration. Using the appropriate pretreatment will certainly likewise assist stop attachment failure, which can cause peeling off as well as splitting of the coating.

The most effective pretreatment will likewise be one of the most economical. This is specifically real if you are searching for a single task. For a larger-scale line, you may wish to consider a multi-stage procedure. The benefits include a consistent finish, less downtime and higher efficiency.

An excellent pretreatment might additionally confirm to be the best investment you make. The best pretreatment will certainly supply you with a smooth surface to bond with your powder layer.

Multi-color powder layers

Whether you are a beginner or a seasoned specialist, there are a variety of advantages to applying multi-color powder finishes. While the application process might appear complicated, it is in fact a rather easy procedure. Here are a couple of ideas to keep in mind.

One of the most typical powder Coating special effects is a textured finish. These can be achieved by mixing various colors. The resulting finish can be anything from a shiny roof covering to a speckled pattern. The structure of the finish hinges on the item you are Coating.

An additional usual powder Coating unique effect is the one-step effect. This is splashed on like standard powder. These unique effects are created by utilizing multiple colors and mixing them prior to treating. Common powder finishings have softening temperatures of around 80 degC.

Unlike fluid paint, powder Coating does not release harmful products right into the setting. Additionally, Read Alot more is far more durable and also resistant to scrapes and also fading. https://www.pfonline.com/articles/how-to-choose-the-right-coating-for-fasteners make powder finishes a great selection for commercial applications.

Unlike liquid paint, powder layers do not need a primer. This makes them suitable for applications where the surface requires to be applied in a selection of setups. Powder covered components can be related to a range of products consisting of glass, steel, as well as plastic.

Two-color powder layers need extra attention to information. The second shade requires to be sprayed in addition to the very first. This is typically done utilizing a high temperature tape. This will mask off the first coat and also soften the edges.

Overspray

During the last 3 decades, powder finishings have actually been verified to be a superior Coating technology. They offer a thicker film than liquid paint as well as have a reduced ecological impact. They are likewise more energy-efficient.

powder coating santa clarita, los angeles county

They can be used in lots of industrial applications. They are also utilized in aerospace applications. Among the advantages are reduced initial prices, less pollution, and also expanded life time.

Besides, powder finishes do not produce VOCs (volatile natural compounds), which are known to be dangerous. These substances can create liver and also central nerves damages. They can also trigger cancer.

To minimize the amount of waste created from powder Coating overspray, there are reclaim systems available. These systems recuperate the oversprayed powder as well as recycle it for a brand-new Coating.

These systems function making use of a cartridge-style filtering system. They also offer tidy air for recirculation back into the plant. The filtering system does not require an exhaust stack, minimizing the expense and maintenance of an exhaust system.

The powder Coating system can be used with minimal workforce. This results in reduced expenses for the maker.

This procedure is likewise energy-efficient because it reduces the amount of stove air that should be worn down. The powder Coating process additionally does not need venting. This additionally results in no hazardous waste to be gotten rid of.

|

Метки: Powder Coating Powder Coating Company Powder Coating Services Industrial Powder Coating Powder Coating Metals Commercial Powder Coating Silk Screening |

This Write-Up Discusses The Benefits Of Powder Coating |

Content writer-Giles Udsen

Using Powder Coating on a vehicle will certainly give the vehicle a gorgeous, glossy coating. This type of Coating is applied as a completely dry powder and is after that cured with warmth or ultraviolet light.

Electrostatic spray deposition technique

Whether you're seeking a high-performance Coating or a cost-efficient alternative to liquid paints, you can locate an electrostatic spray deposition approach that suits your demands. The strategy works by applying a layer of powder to a metal substrate. It can be made use of to coat pipes, for instance, for increased longevity.

Contrasted to liquid applications, electrostatic spray deposition is more resilient as well as more affordable. While conventional damp paint can leave you with an irregular surface, this technique leaves your parts smooth and also shiny.

powder coating santa clarita, los angeles county

This procedure requires the use of a specialized spray gun. It also takes advantage of compressed air to push the powder with the gun as well as out of the nozzle. This air relocates the powder along at a high rate and also atomizes the powder. It is also a terrific means to prevent clumping.